Method for preparing novel nano-material V10O24.12H2O

A technology of V10O24·12H2O and nanomaterials is applied in the field of vanadium oxide material preparation to achieve the effects of stable performance, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention and its beneficial effects are further described below through the embodiments and accompanying drawings.

[0031] A new type of nanomaterial V 10 o 24 12H 2 The preparation method of O comprises the following steps,

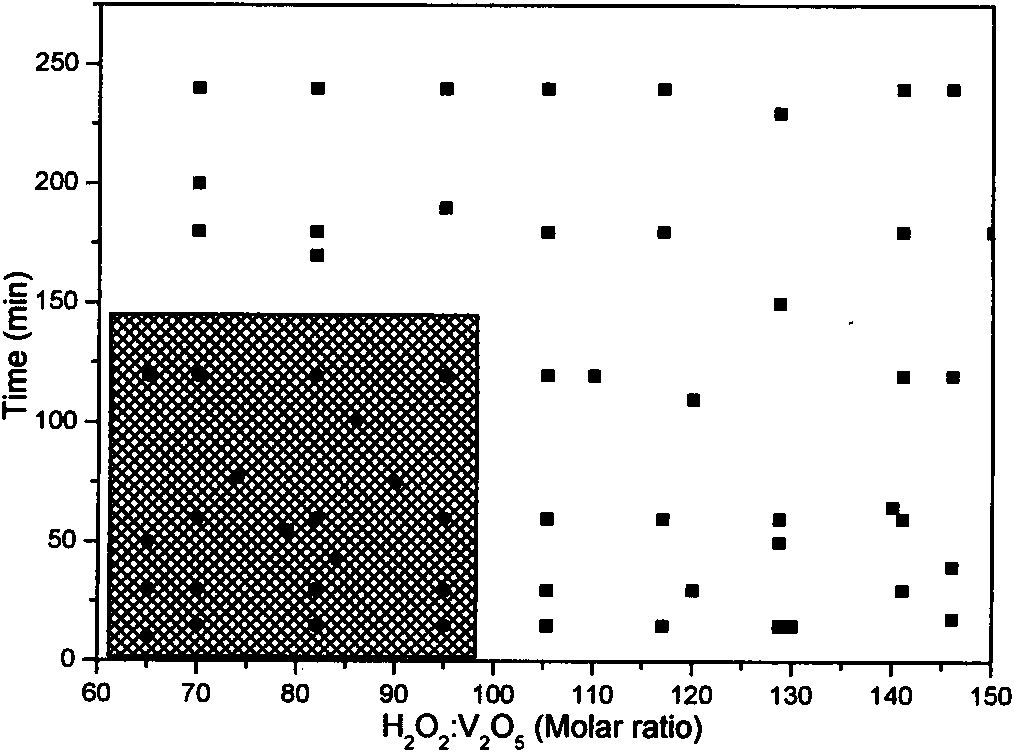

[0032] 1. Preparation of sol

[0033] The sol was prepared by the sol-gel method, and the V 2 o 5 The powder and hydrogen peroxide were mixed at a molar ratio of 1:90, placed in an ice-water mixing bath at 0° C., and magnetically stirred for 1 hour to obtain a reddish-brown homogeneous sol. The sol was taken out from the ice-water mixed bath, left at room temperature for 30 minutes, and then boiled to form a wet gel while releasing a lot of heat and gas. The wet gel was sealed and stored at 30°C.

[0034] Second, the aging of the sol

[0035] The sol was stored in an oven at 30°C for 3 days to form a uniform gel.

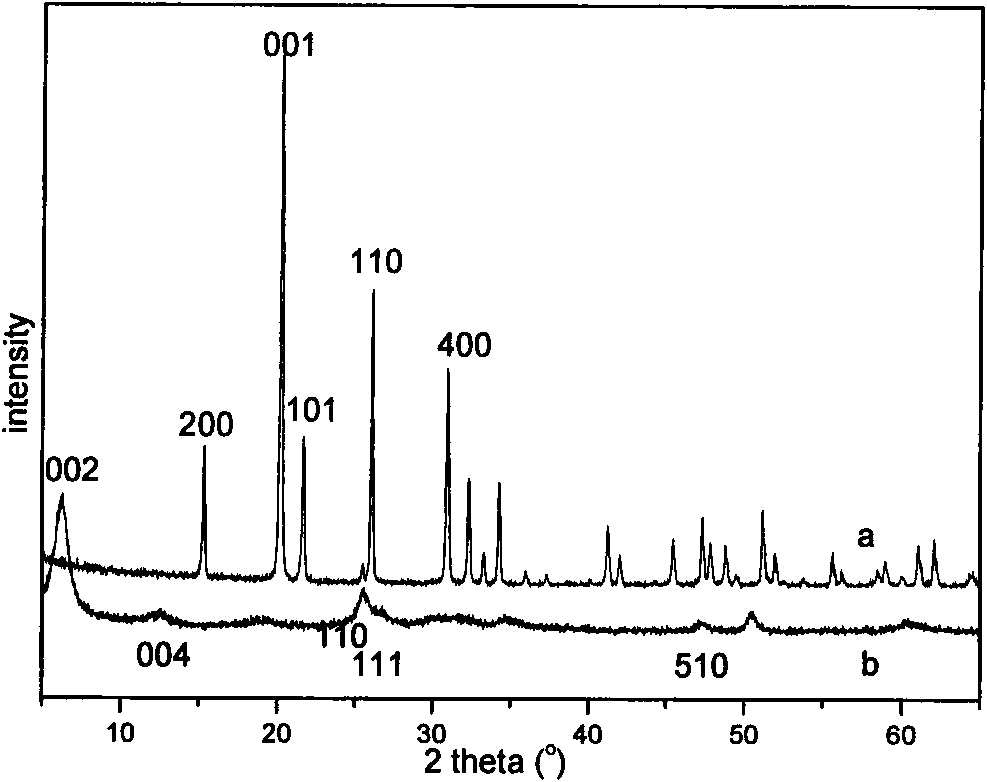

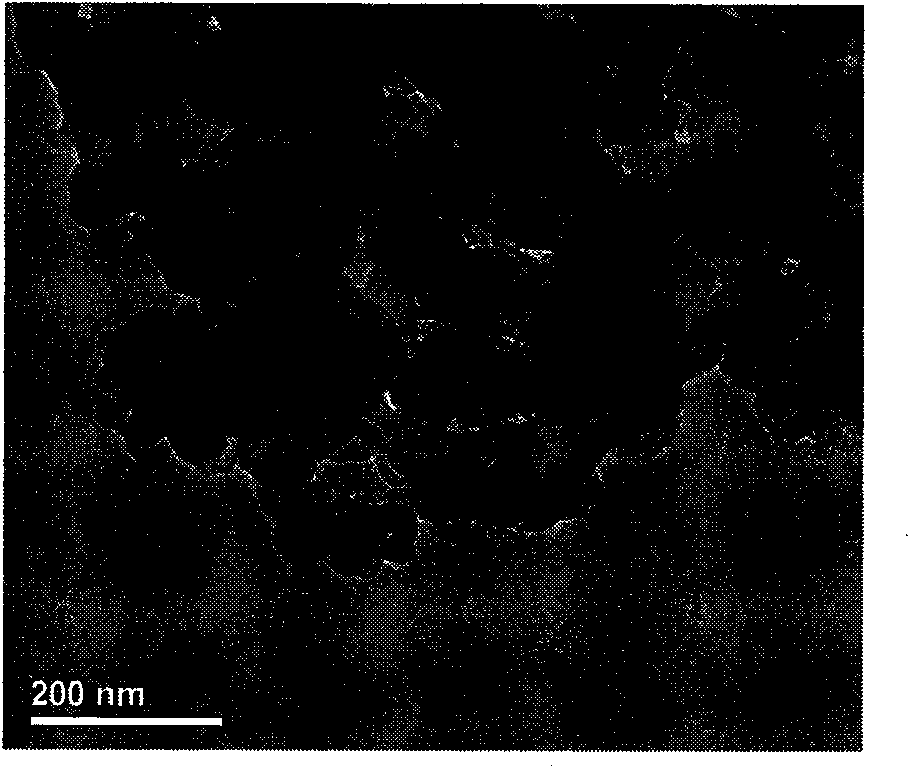

[0036] 3. Preparation of sample V by solvent replacement and atmospheric pressure drying 10 o 24 12H 2 o

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com