Polyaniline in-situ polymerization intercalated vanadium pentoxide and preparation method and application thereof

A vanadium pentoxide, in-situ polymerization technology, applied in the direction of vanadium oxide, hybrid capacitor electrodes, electrical components, etc., can solve the problems of decreased cycle stability, hindered ion diffusion, unstable structure, etc., to increase the interlayer distance and Effects of internal surface area, enhanced diffusion rate, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a method for preparing polyaniline in-situ polymerization intercalation vanadium pentoxide, comprising the following steps:

[0027] 1) mixing vanadium pentoxide powder, water and hydrogen peroxide to obtain solution a;

[0028] 2) After mixing the aniline monomer and water, use an acid solution to adjust the pH value to obtain solution b;

[0029] 3) react after mixing solution a and solution b to obtain polyaniline in-situ polymerization intercalation vanadium pentoxide.

[0030] The ratio of vanadium pentoxide powder, water and hydrogen peroxide in step 1) of the present invention is preferably 1-20mmol: 1-200mL: 1-20mL, more preferably 5-15mmol: 50-150mL: 5-15mL, more preferably 10~12mmol: 100~120mL: 10~12mL.

[0031] The mixing time in step 1) of the present invention is preferably 1-24 hours, more preferably 10-20 hours, more preferably 15-18 hours; the mass fraction of the hydrogen peroxide is preferably 20-40%, more preferably 30%; The ...

Embodiment 1

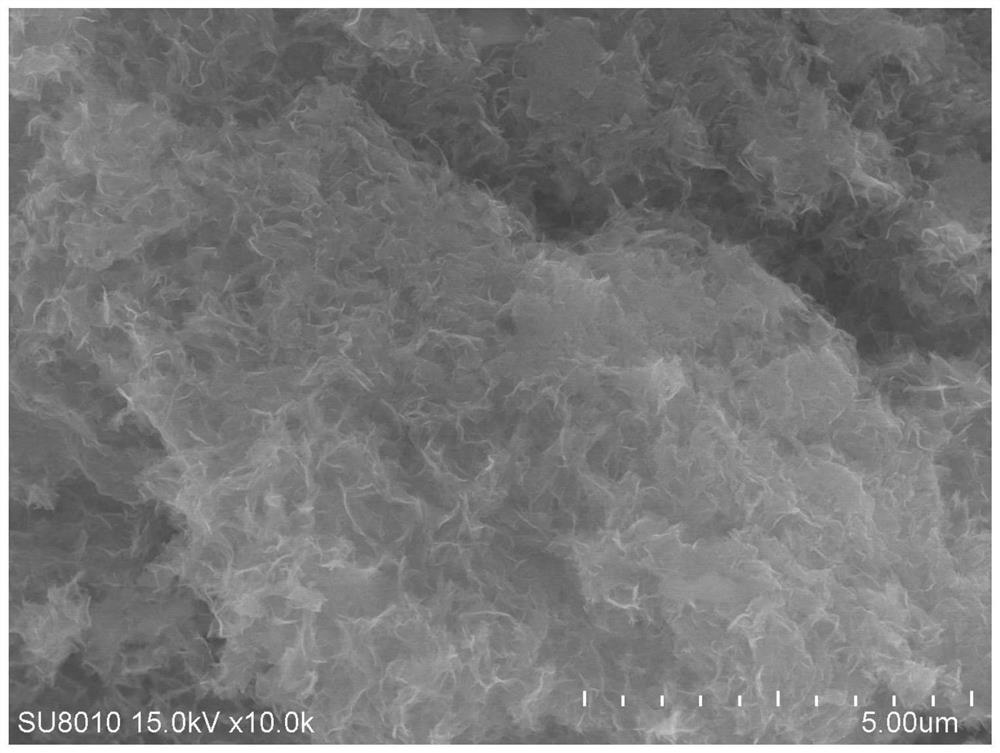

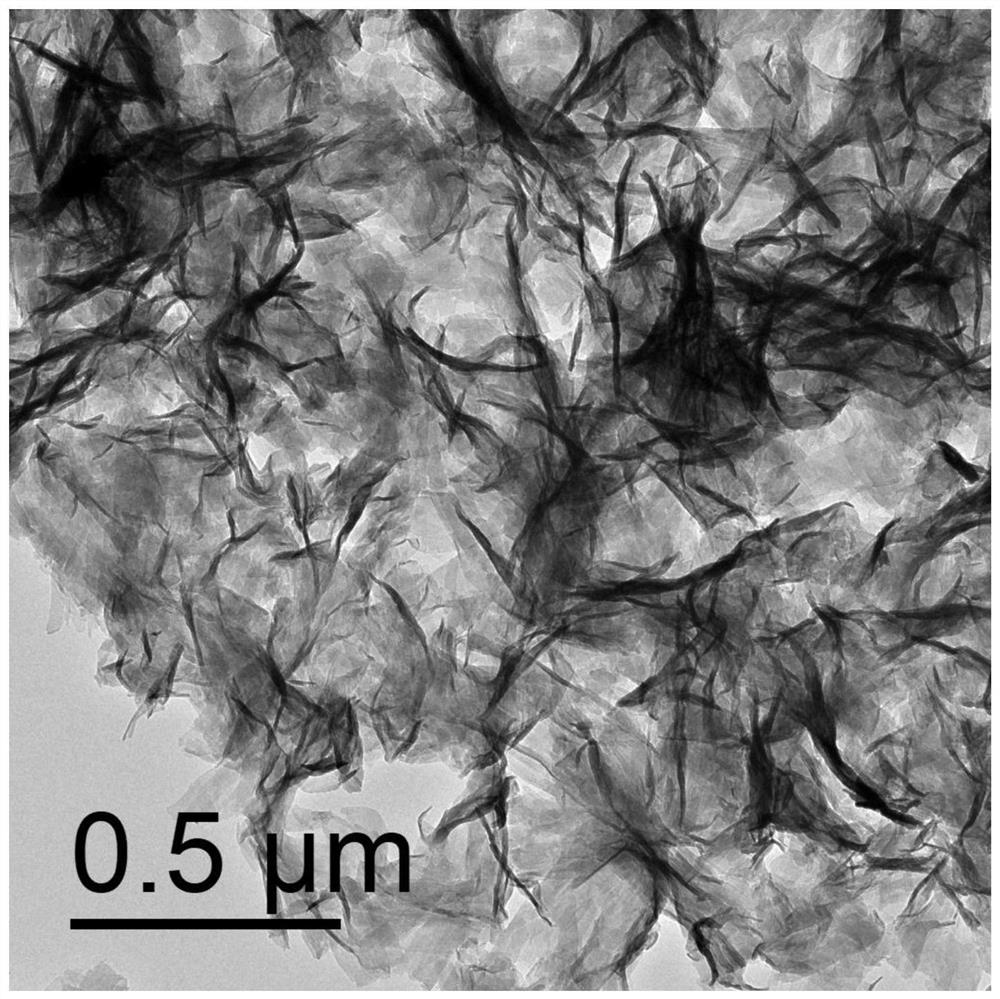

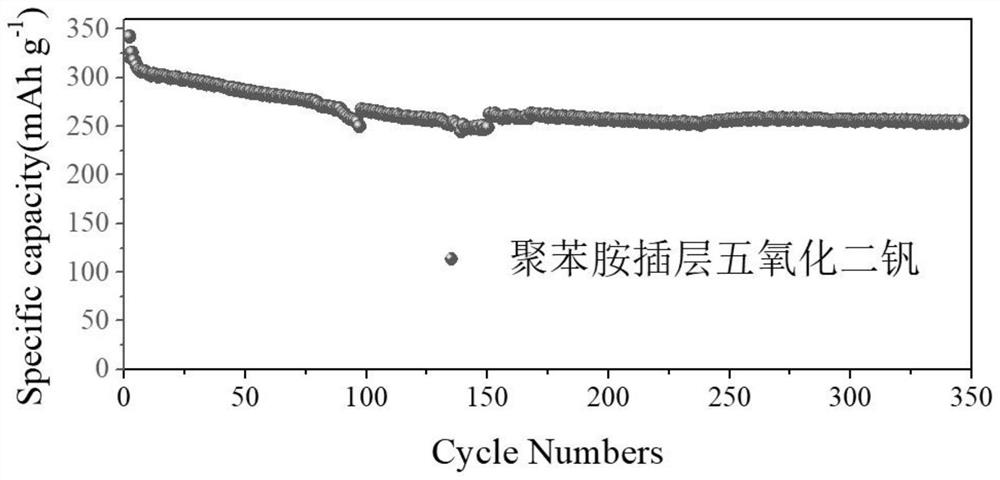

[0045]Add 10 mmol of vanadium pentoxide powder with a particle size of 10 μm into 120 mL of deionized water, then add 10 mL of 30% hydrogen peroxide and stir for 2 hours to obtain a uniform solution a. Dissolve 1 mmol of aniline monomer into 200 mL of deionized water, and adjust the pH value to 4 with 0.8 mol / L hydrochloric acid to obtain a homogeneous solution b. The homogeneous solution a was heated to 160°C under the condition of an oil bath and mixed with the homogeneous solution b, and the reaction was continued for 3 hours at 160°C under the condition of an oil bath. After the reaction, cool to room temperature, centrifuge the cooled product, wash it, freeze-dry it at -53°C for 72 hours, and store it in a vacuum oven at 120°C with a vacuum of 3KPa for 2h to obtain polyaniline with a mass fraction of 10%. 1. Polyaniline in-situ polymerized and intercalated vanadium pentoxide with a thickness of 50nm.

[0046] PVDF binder, conductive carbon black and active material (poly...

Embodiment 2

[0050] Add 15 mmol of vanadium pentoxide powder with a particle size of 50 μm into 160 mL of deionized water, then add 15 mL of hydrogen peroxide with a mass fraction of 30% and stir for 15 hours to obtain a homogeneous solution a. Dissolve 0.4 mmol of aniline monomer into 300 mL of deionized water, and adjust the pH value to 1 with 8 mol / L hydrochloric acid to obtain a homogeneous solution b. After heating the homogeneous solution a to 100°C under the oil bath condition, mix it with the homogeneous solution b, and continue to react at 100°C under the oil bath condition for 15 hours. After the reaction, cool to room temperature, centrifuge the cooled product, wash it, freeze-dry it at -55°C for 48 hours, and store it in a vacuum oven at 220°C with a vacuum of 4KPa for 1 hour to obtain polyaniline with a mass fraction of 35%. 1. Polyaniline in-situ polymerized and intercalated vanadium pentoxide with a thickness of 400nm.

[0051] PVDF binder, conductive carbon black and activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com