Preparation method of oxygen-producing photocatalyst of composite oxides

A composite oxide and photocatalyst technology, which is applied in the field of visible light catalysis, can solve the problems of reducing catalytic effect, noise and dust pollution, and large human injury, and achieves the effects of simple process, low energy consumption, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

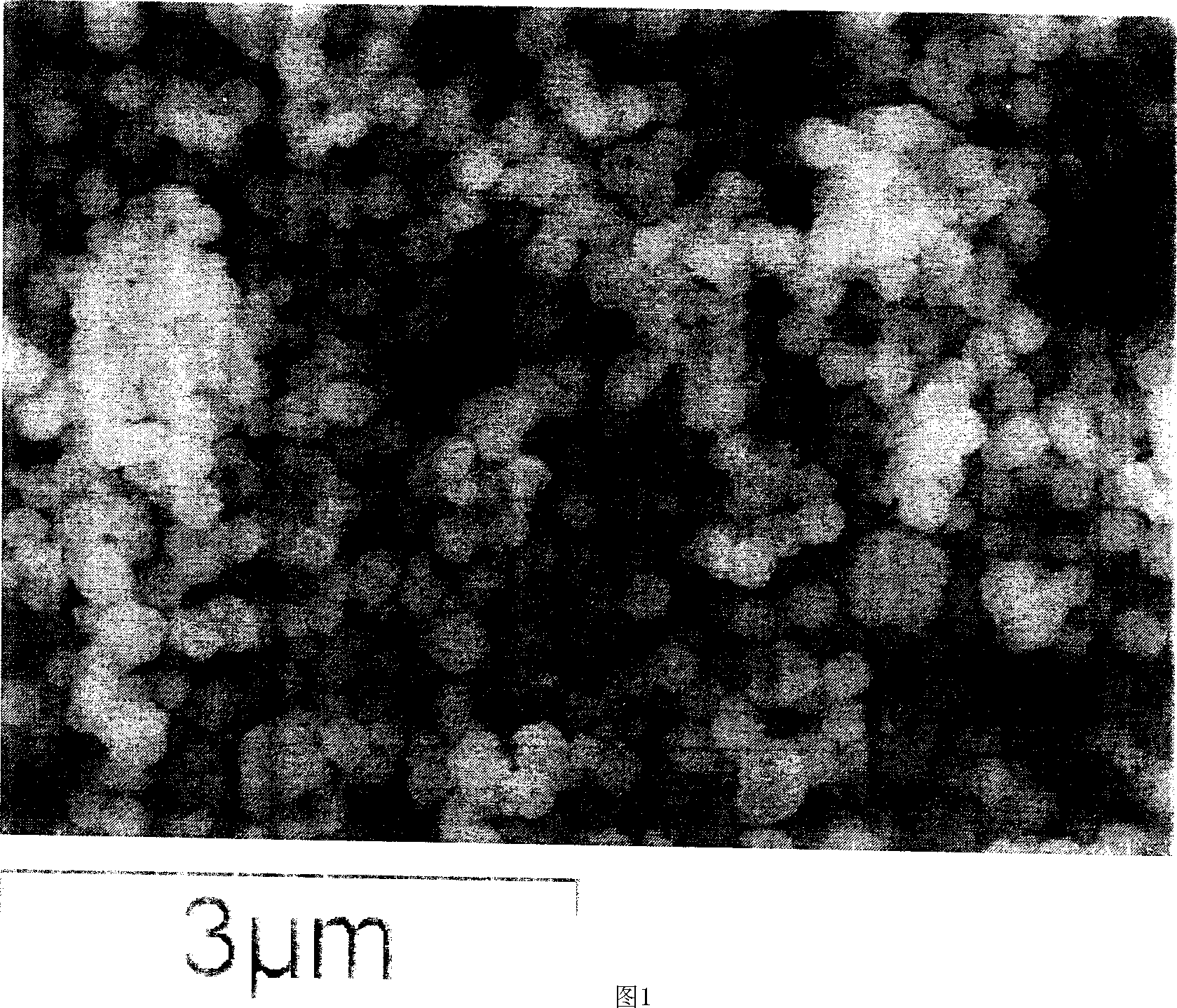

[0021] Example 1: Dissolve 3.69g of bismuth nitrate in 50ml of nitric acid with a concentration of 2M, dissolve 0.89g of ammonium metavanadate in 50ml of 40°C water, mix, add 0.06g of sodium lauryl sulfate, stir well, and use nitric acid Adjust pH=0. Transfer the solution into an autoclave, react at 190°C for 50 hours, cool, filter with suction, wash, and dry (corresponding to SEM Figure 1, TEM Figure 6 and Electron Diffraction Figure 7), and the prepared monoclinic scheelite The bismuth vanadate catalyst catalytically decomposes water to produce oxygen under the irradiation of a 300-watt mercury lamp (wavelength range 300-380 nm) and a 300-watt xenon lamp (wavelength greater than 420 nm). The oxygen production rate of the catalyst. The yield of ultraviolet photocatalytic oxygen production is 50umol / h, and the yield of visible light catalytic oxygen production is 70umol / h.

Embodiment 2

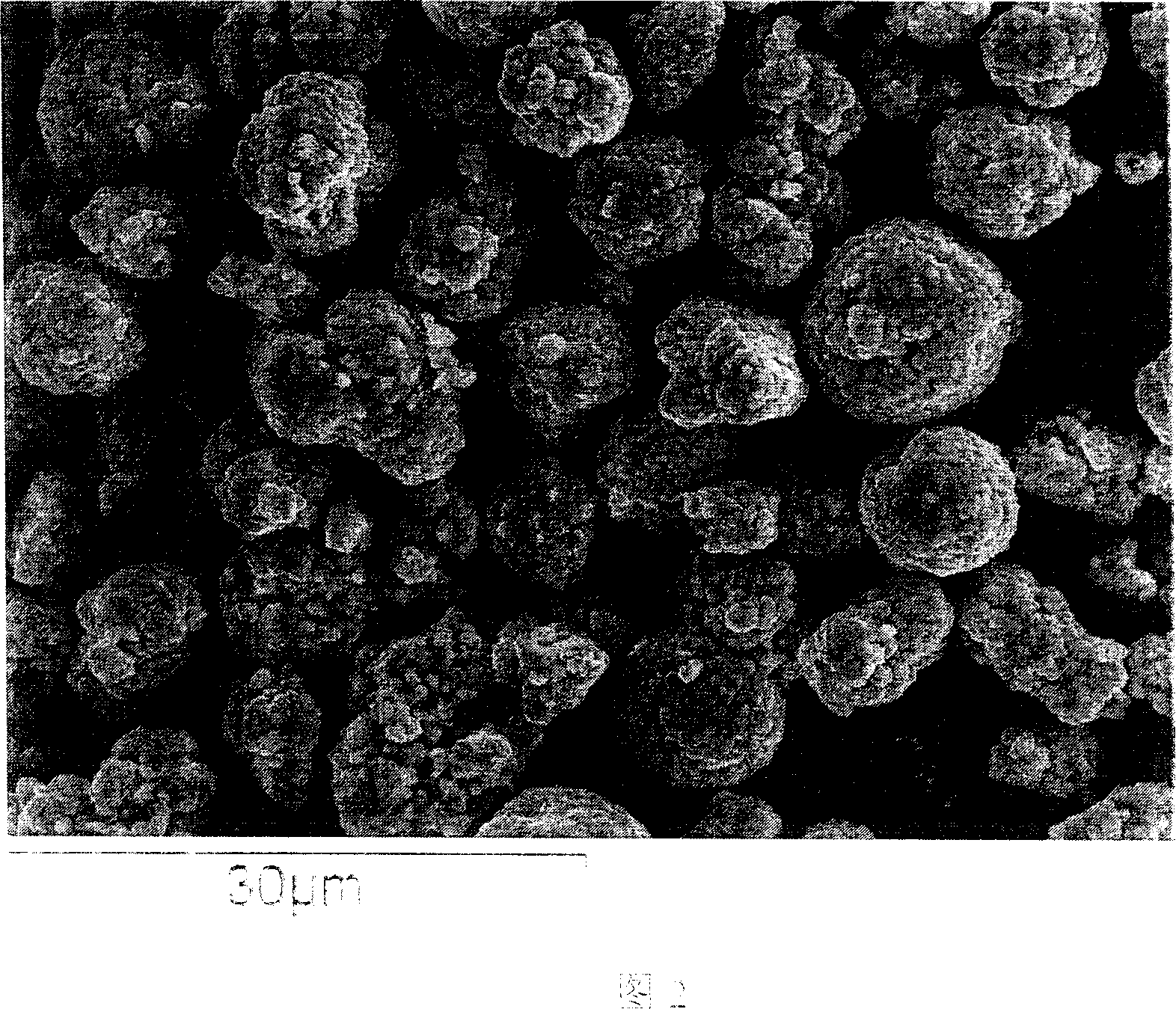

[0022] Embodiment 2: 7.37g bismuth nitrate is dissolved in 50ml concentration and is the nitric acid of 2.5M, and 1.78g ammonium metavanadate is dissolved in 50ml 45 ℃ water, mix, add sodium dodecylsulfonate 0.13g, stir well, Adjust the pH to 1 with nitric acid; transfer the solution into an autoclave, react at 220° C. for 40 hours, cool, filter with suction, wash and dry. (corresponding to scanning electron microscope Figure 2), the photocatalytic test method is the same as in Example 1, the yield of ultraviolet photocatalytic oxygen production is 40umol / h, and the yield of visible light catalytic oxygen production is 140umol / h.

Embodiment 3

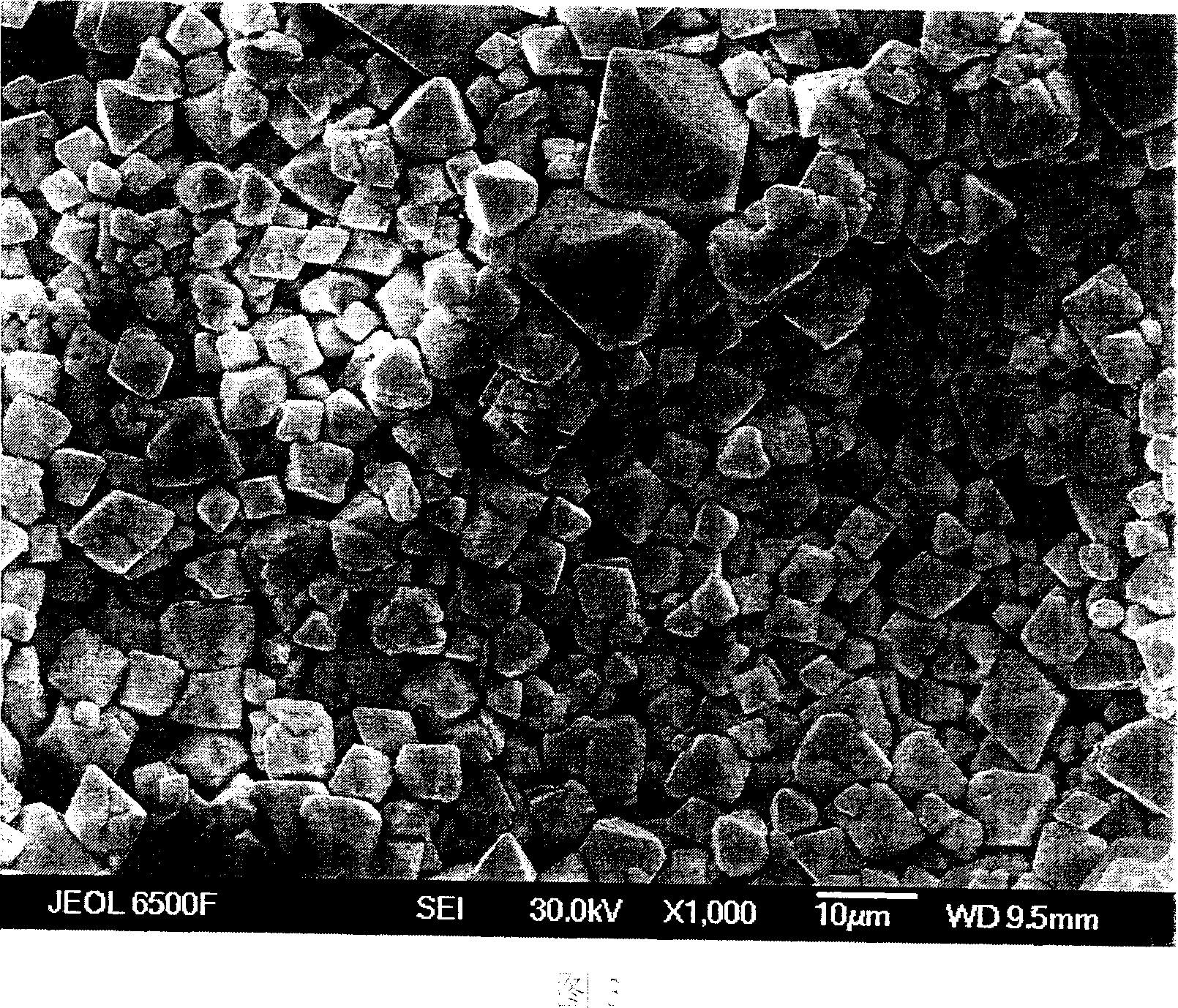

[0023] Example 3: Dissolve 14.74g of bismuth nitrate in 50ml of nitric acid with a concentration of 2.5M, dissolve 3.56g of ammonium metavanadate in 50ml of 50°C hot water, mix, add 0.24g of sodium lauryl sulfate, and stir evenly , adjust pH=2 with nitric acid, transfer the solution into autoclave, react at 260°C for 30 hours, cool, filter with suction, wash and dry. (corresponding to XRD Figure 5, and SEM Figure 3 and Figure 4), the photocatalytic test method is the same as in Example 1, the ultraviolet photocatalytic oxygen production rate is 90umol / h, and the visible light photocatalytic photocatalytic oxygen production rate is 355umol / h.

[0024] The existing hydrothermally synthesized photocatalyst has an oxygen production activity of 30-40umol / h under ultraviolet light catalysis and 60-70umol / h of oxygen production under visible light catalysis. The invention increases the catalytic activity of producing oxygen by photolyzing water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com