Method for growing large-area mono-crystal vanadium dioxide thin film by utilizing tubular furnace

A vanadium dioxide and tube furnace technology, which is applied in the field of oxide semiconductor material growth, can solve the problems of large growth film area and the influence of electrical and optical properties, and achieve the effects of good uniformity, improved photoelectric performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

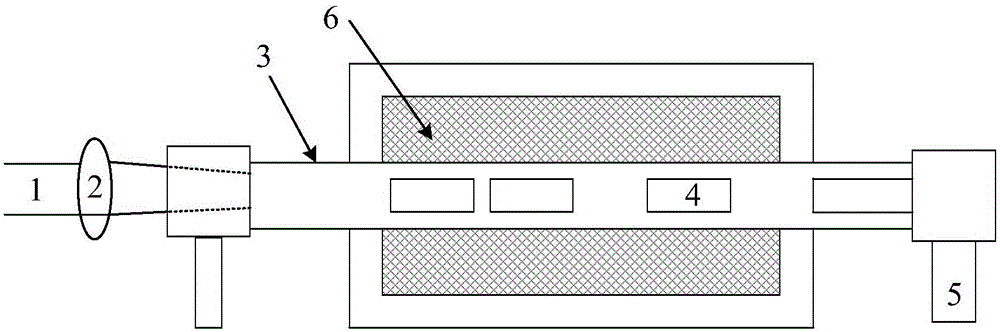

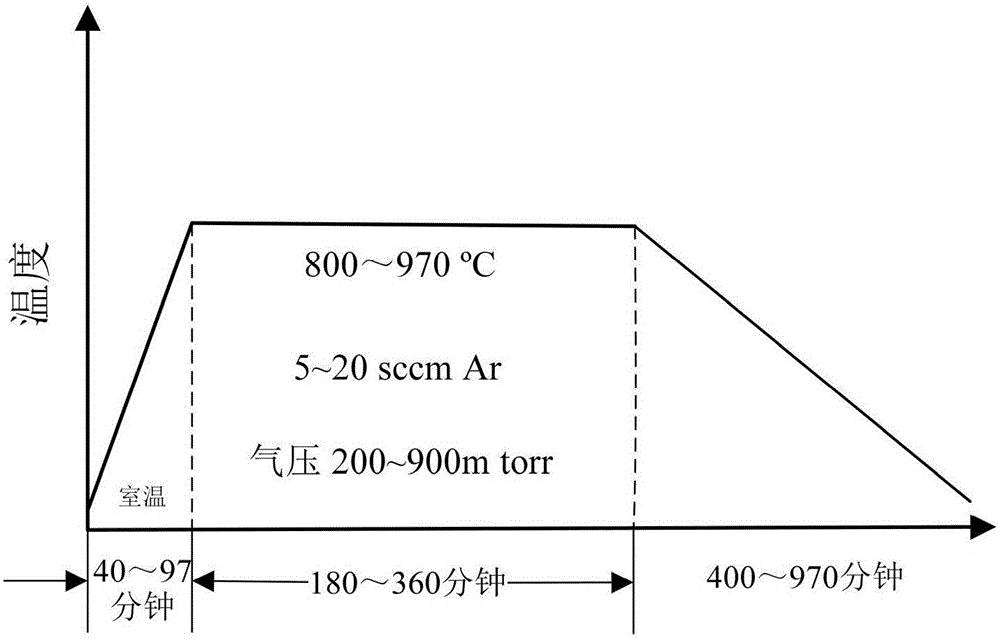

[0033] Such as figure 1 As shown, the growth of the vanadium dioxide film is completed in a strictly enclosed quartz tube 3. At both ends of the quartz tube 3 are the air inlet 1 and the air outlet 5; the temperature rise and fall rate of the experiment are controlled by the tube furnace control system 6. Setting: In order to prepare a high-quality single-crystal vanadium dioxide thin film, before the tube furnace starts to heat up, the quartz tube 3 is filled with argon for 1 to 2 times, and then it is evacuated to a vacuum state.

[0034] A method of using a tube furnace to grow a large-area single crystal vanadium dioxide thin film, which includes the following steps:

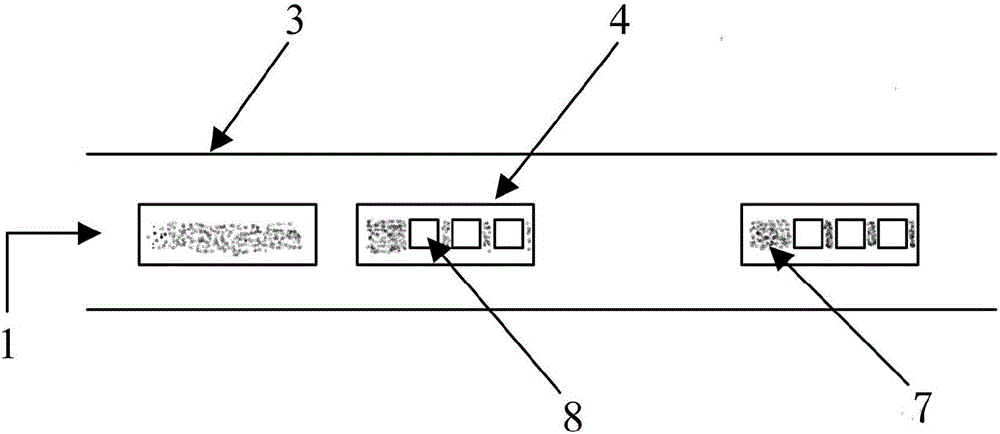

[0035] The size of the selected substrate is 10×10mm 2 SiO 2 / Si experimental substrate 8, this experimental substrate 8 is based on silicon as a substrate and a layer of 500~1000nm SiO is grown on its surface 2 Thin film; first check the SiO used 2 / Si experimental substrate 8 is cleaned, put the experimental su...

Embodiment 2

[0041] Use 200nm Si 3 N 4 / Si is used as the experimental substrate 8. The film preparation process is as described in Example 1. Vacuum to 50~80mTorr, then pass in argon gas at a flow rate of 15SCCM, and raise the temperature of the outer temperature zone and the inner temperature zone from room temperature respectively To 900°C and 800°C, the heating time is 40 minutes. The experimental temperature used by different materials is slightly different, generally ranging from 40 to 80 ℃. By observing the change of the air pressure in the quartz tube 3 during the heating process, adjust the air pressure valve of the air outlet 5 in time to control the air pressure in the quartz tube 3 within the range of 300-500mTorr. After reaching the temperature, the temperature will be maintained for 200 minutes. Then, the cooling time is controlled for 360 minutes. When the temperature is lower than 30°C, the quartz tube 3 is opened, and the experimental substrate 8 is taken out.

[0042] Such ...

Embodiment 3

[0044] Silicon is selected as the experimental substrate 8. The film preparation process is as described in Example 1. Vacuum to 50~80mTorr, and then argon gas with a flow rate of 20SCCM, and the temperature of the outer temperature zone and the inner temperature zone are respectively increased from room temperature To 950°C and 850°C, the heating time is 70 minutes. The experimental temperature used by different materials is slightly different, and the general range is between 40-100°C. By observing the change of the air pressure in the quartz tube 3 during the heating process, adjust the air pressure valve of the air outlet 5 in time to control the air pressure in the quartz tube 3 within the range of 200-400mTorr. After reaching the temperature, the temperature will be maintained for 100 minutes. Then, the cooling time is controlled for 500 minutes. When the temperature is lower than 30°C, the quartz tube 3 is opened, and the experimental substrate 8 is taken out.

[0045] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com