Alum extracting technique for clay ore by wet method

A clay ore and wet process technology, which is applied in the field of clay ore wet extraction of vanadium, and wet extraction of vanadium valuable metals, can solve the problem of low vanadium leaching rate and vanadium recovery rate, high vanadium extraction cost and long leaching time. and other problems, to achieve the effect of high recovery rate, easy and controllable treatment of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

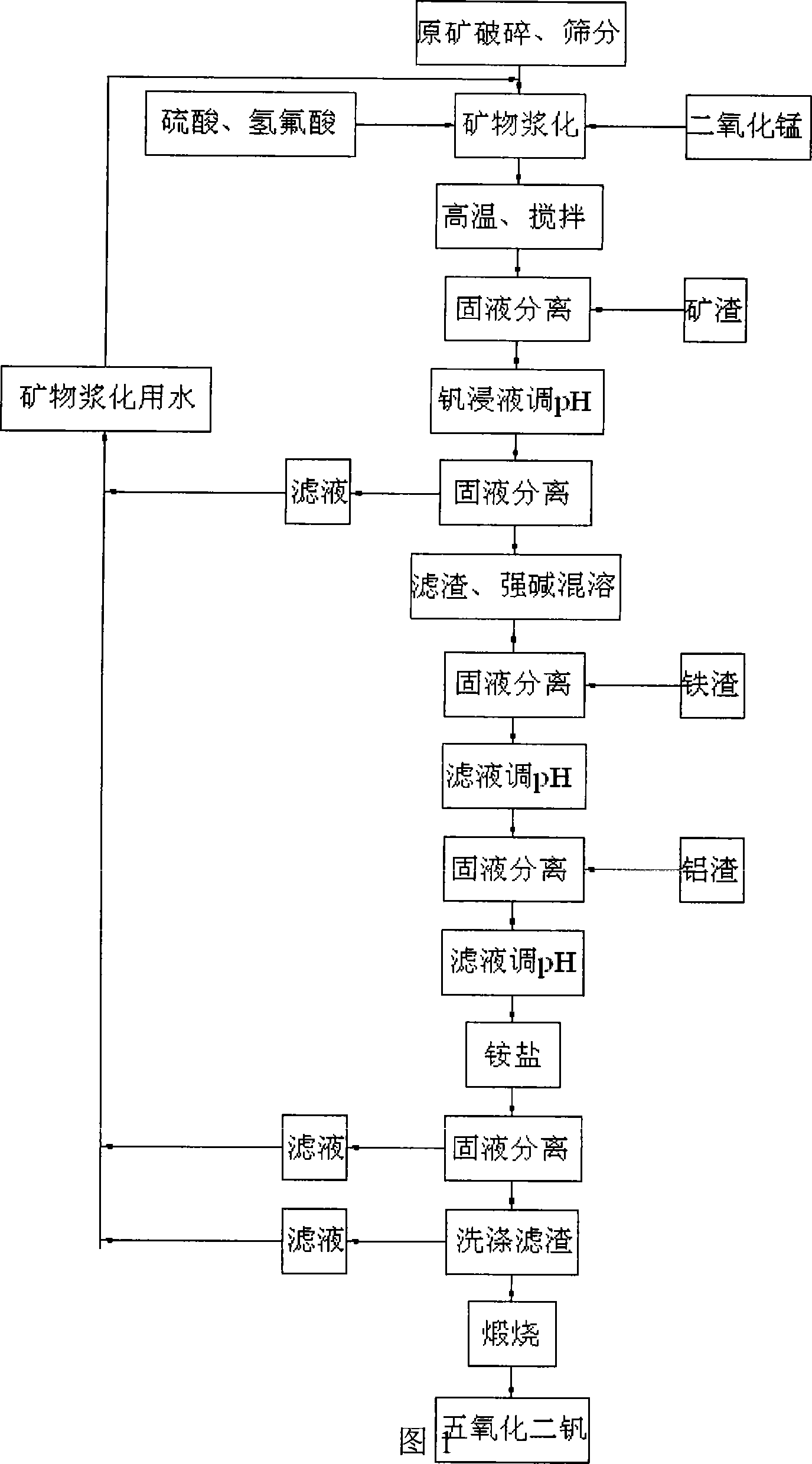

Image

Examples

Embodiment 1

[0024] 1. The original clay ore is crushed to 0.15mm to make mineral powder;

[0025] 2, 500 grams of solid powder, clay mineral powder 78% by weight percentage, manganese dioxide 2%, sulfuric acid 18%, hydrofluoric acid 2%, add water until the liquid-solid volume ratio is 4: 1 and stir evenly to prepare ore-forming slurry;

[0026] 3. Put the well-stirred ore pulp into a constant temperature stirring tank for acid leaching. The time is 10 hours, the temperature is 90°C, the stirring speed is 800r / min, and the acid leaching rate of vanadium is 92.1%;

[0027] 4. The material after the leaching reaction is separated from solid and liquid through a suction filter, and the filter residue is washed and used for building materials or mine landfill;

[0028] 5. Add sodium carbonate to the separated filtrate to adjust the pH value to 2.5. The vanadium compound, iron, aluminum and some silicon in the filtrate form co-precipitation, the precipitate is clarified, and the solid-liquid s...

Embodiment 2

[0035] 1. The original clay ore is crushed to 0.1mm to make mineral powder;

[0036] 2, 500 grams of solid powder, by weight percentage, clay mineral powder 72%, manganese dioxide 3%, sulfuric acid 20%, hydrofluoric acid 5%, add water until the liquid-solid volume ratio is 5: 1 and stir evenly;

[0037] 3. Put the well-stirred ore pulp into a constant temperature stirring tank for acid leaching. The time is 10 hours, the temperature is 100°C, the stirring speed is 800r / min, and the acid leaching rate of vanadium is 93.2%.

[0038]4. The material after the leaching reaction is separated from solid and liquid through a suction filter, and the filter residue is washed and used for building materials or mine landfill;

[0039] 5. Add sodium carbonate to the separated filtrate to adjust the pH value to 2.5. The vanadium compound, iron, aluminum and some silicon in the filtrate form co-precipitation, the precipitate is clarified, and the solid-liquid separation is carried out throug...

Embodiment 3

[0046] 1. Clay ore is crushed to 0.1mm to make mineral powder;

[0047] 2. 500 grams of solid powder, 80% by weight of clay mineral powder, 2% sodium chlorate, 15% sulfuric acid, 3% hydrofluoric acid, add water until the liquid-solid volume ratio is 3: 1 and stir evenly;

[0048] 3. Put the evenly stirred pulp into a constant temperature stirring tank for acid leaching. The time is 8 hours, the temperature is 80°C, the stirring speed is 900r / min, and the acid leaching rate of vanadium is 90.3%;

[0049] 4. The material after the leaching reaction is separated from solid and liquid through a suction filter, and the filter residue is washed and used for building materials or mine landfill;

[0050] 5. Add sodium carbonate to the separated filtrate to adjust the pH value to 3. The vanadium compound, iron, aluminum and some silicon in the filtrate form co-precipitation, the precipitate is clarified, and the solid-liquid separation is carried out through the suction filter, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com