Patents

Literature

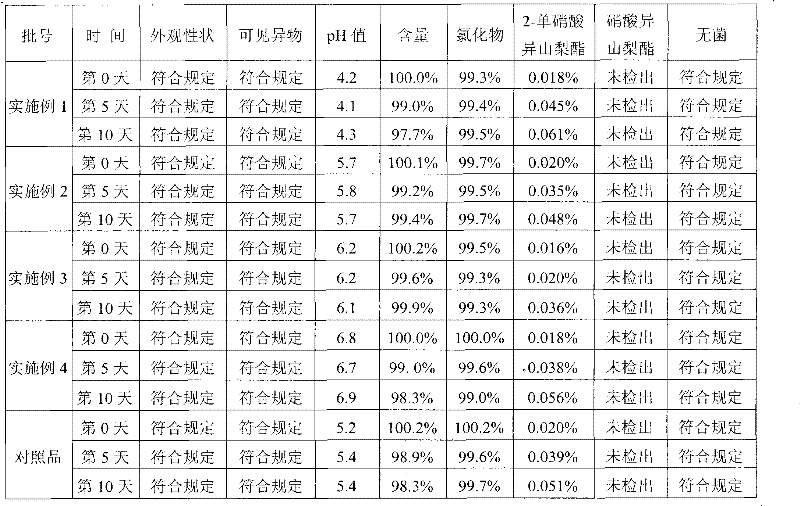

30results about How to "Simple waste treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing vanadium in titanium tetrachloride

InactiveCN101054201ASimple processSimple waste treatmentTitanium halidesTetrachlorideBiological activation

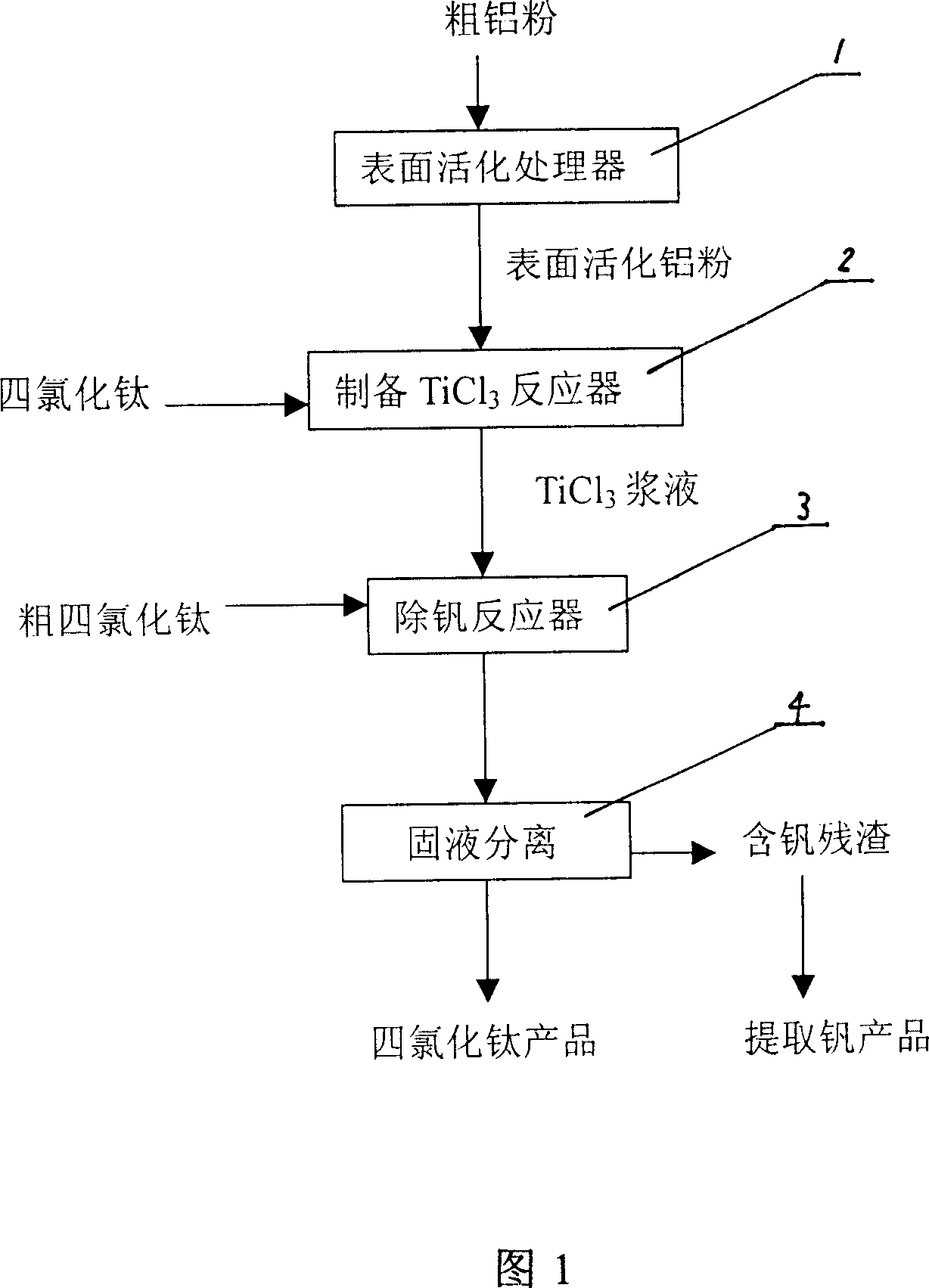

The invention relates to a method for removing vanadium impurity from titanic tetrachloride. The invention prepares titanium trichloride serum by the reaction between the cost aluminum powders with the average grain size no bigger than 150mum after surface activation treatment. TiCl3 in the serum reduces VOCl3 in the titanic tetrachloride to be VOCl2 deposit so as to remove the vanadium. And the titanic tetrachloride after removing the vanadium contains no more than 0.0007% vanadium. The process of vanadium removal can be implemented together with rectification process in order to realize continuous operation. The invention has the advantages of simple in process, low in cost, safe in operation, high in product quality and recovery rate and simple in treating the ''three-waste'' pollution.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

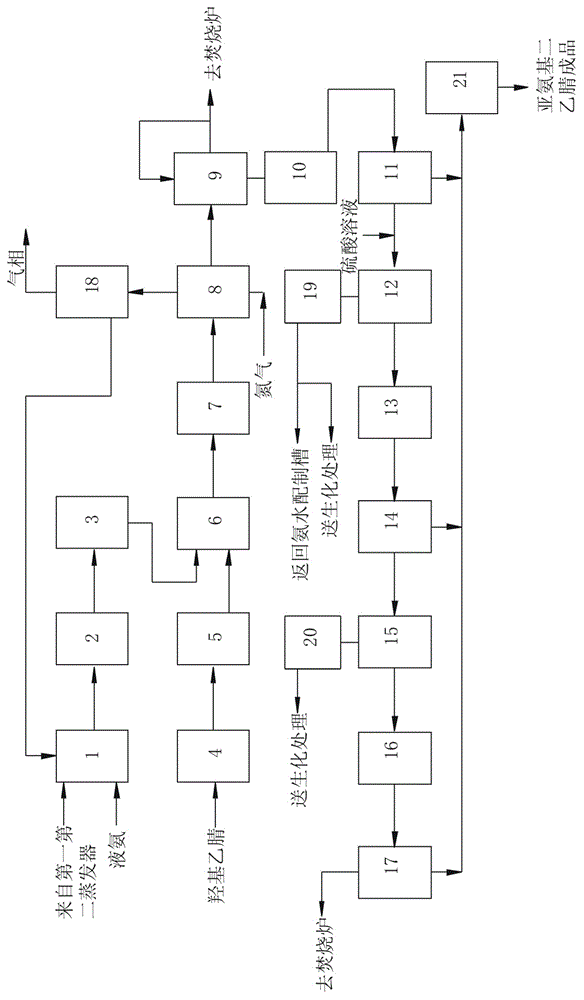

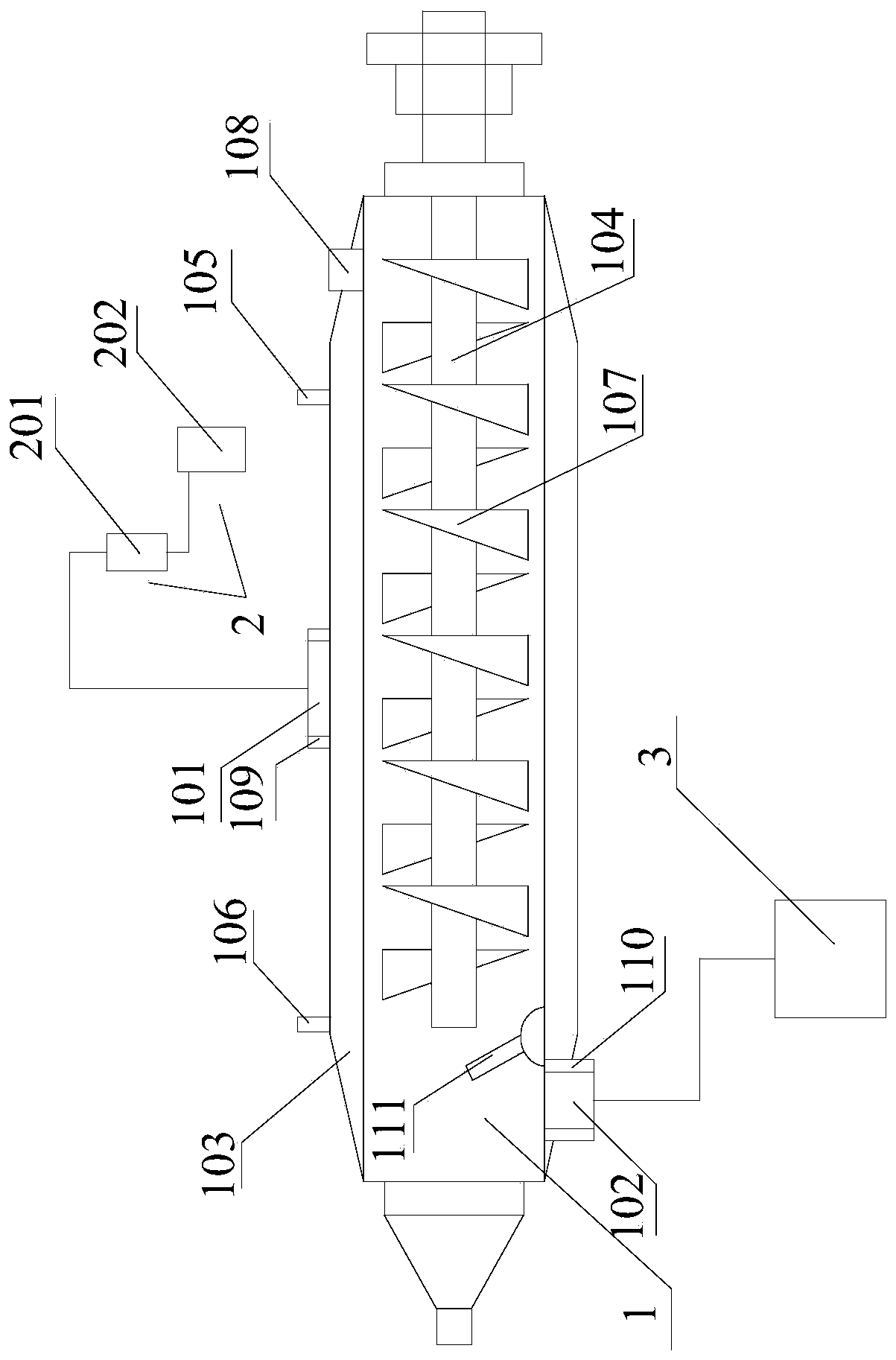

New process for producing high-purity iminodiacetonitrile

ActiveCN101914037AImprove conversion rateHigh yieldOrganic compound preparationCarboxylic acid nitrile purification/separationAcetonitrileWaste treatment

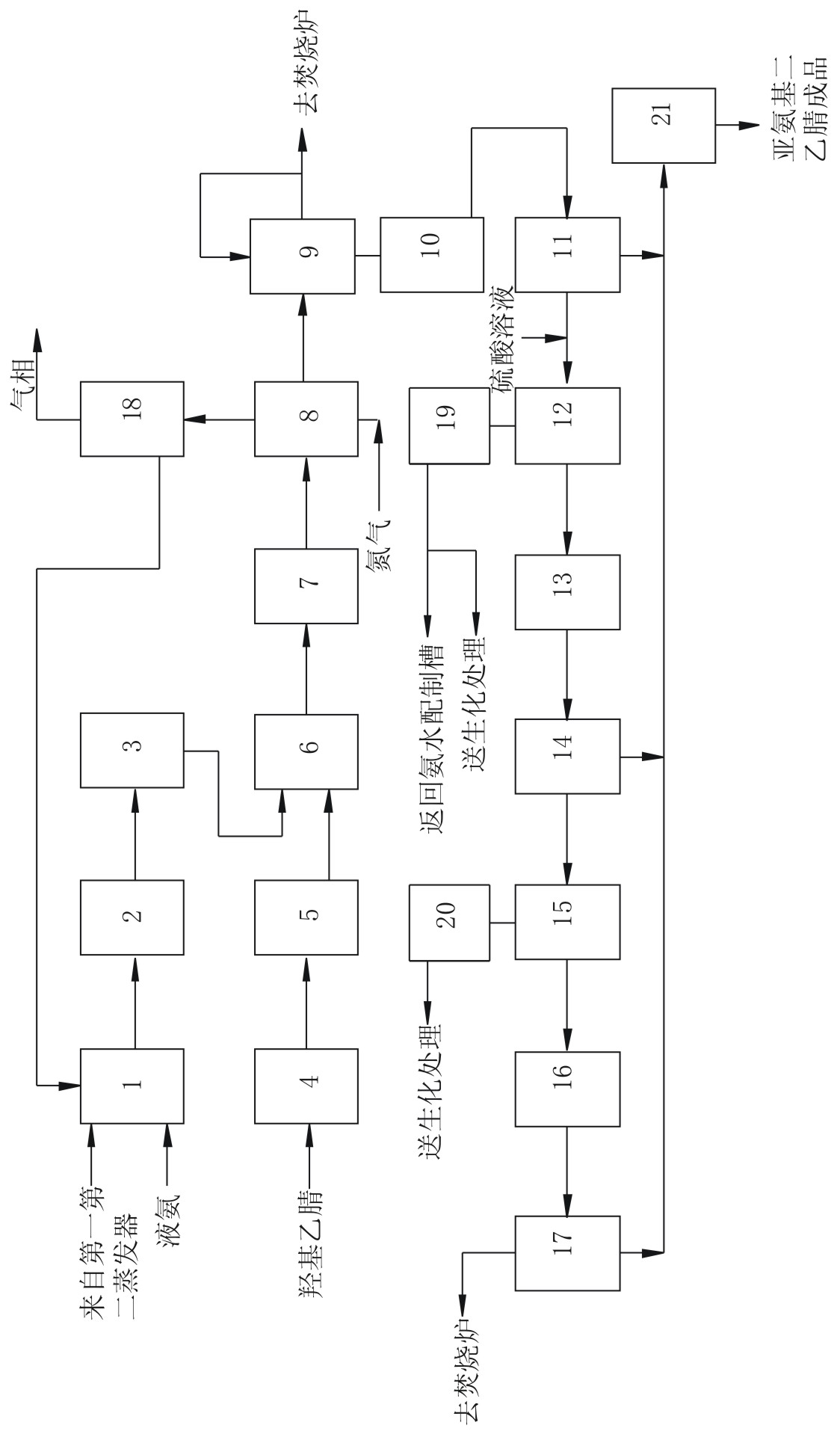

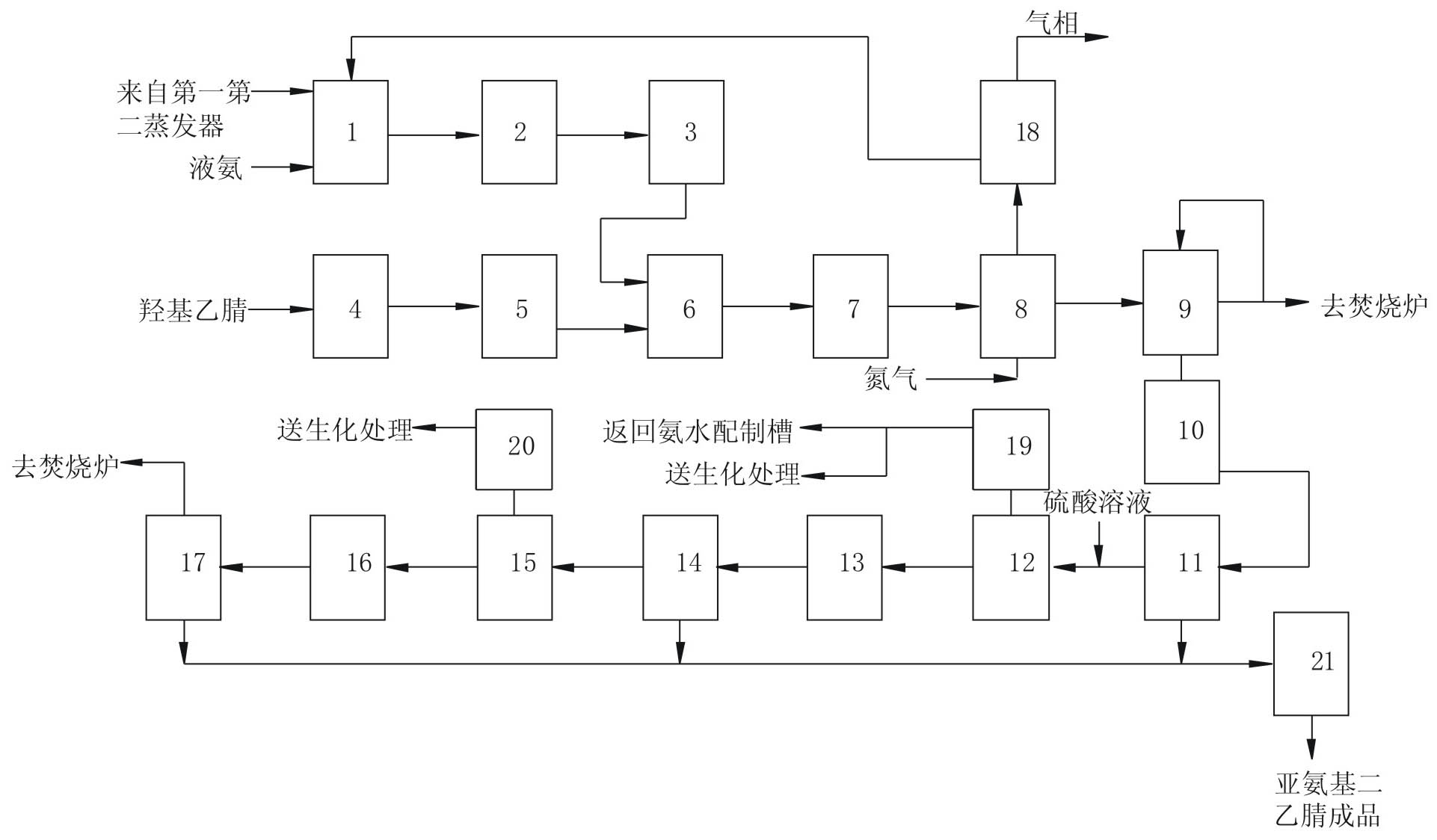

The invention relates to a new process for producing high-purity iminodiacetonitrile. The new process is characterized in that: high-purity reaction liquid is obtained by using a process for synthesizing iminodiacetonitrile at high conversion rate; and white or pale yellow high-purity iminodiacetonitrile with iminodiacetonitrile content of over 99 percent is produced by using a synthesis reaction liquid decolorizing process, an impurity removal process and three crystallization processes, wherein a part of thin waste liquid produced during the production is returned to a raw material preparation system, the rest part of waste liquid is conveyed to a biochemical device for processing, and the produced thick waste liquid is directly conveyed to an incinerator for processing, so that pollution-free production of the entire process is realized. The new process has the advantages of high product quality, white color, purity of over 99 percent high product yield, iminodiacetonitrile yield of about 90 percent during the entire production process and low three-waste treatment difficulty.

Owner:SICHUAN LUTIANHUA

Method of removing vanadium from titanium tetrachloride by aluminum powder as direct reducer

InactiveCN1927723ASimple process equipmentSimple waste treatmentTitanium halidesAs DirectedBoiling point

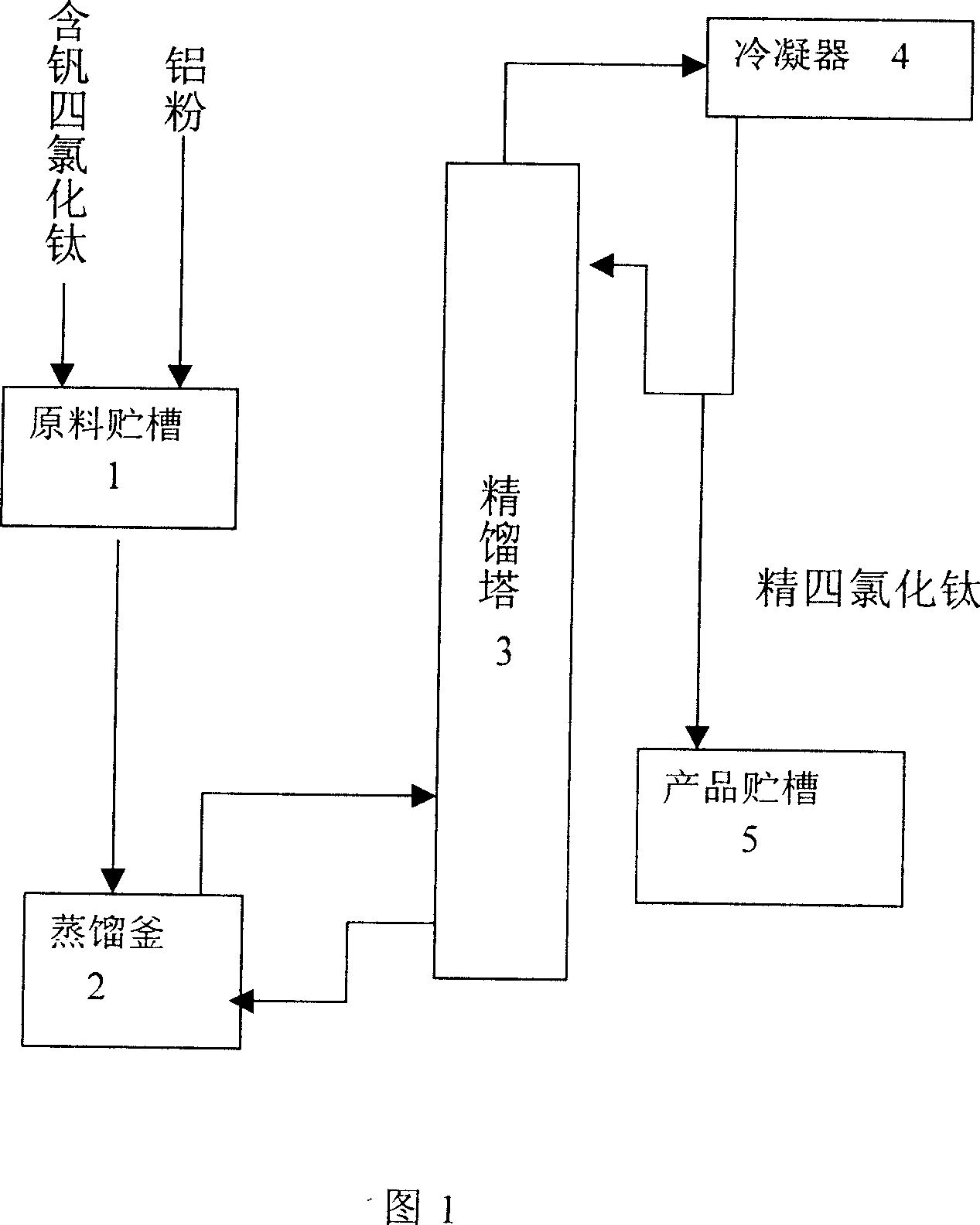

The process of eliminating vanadium impurity from titanium tetrachloride (TiCl4) product with aluminum powder as direct reductant includes the following steps: feeding TiCl4 solution to be refined and surface activated aluminum powder into rectification tower, adding AlCl3 as catalyst and heating to boiling point to produce vanadium eliminating reaction; evaporating TiCl4 containing AlCl3 and high boiling point impurity inside the rectification tower to eliminate AlCl3 and high boiling point impurity, and condensing TiCl4 vapor escaping through the tower top to obtain refined TiCl4 product; and exhausting tower solution regularly or continuously to maintain the required AlCl3 concentration inside the tower. The said process can eliminate vanadium and high boiling point impurity simultaneously, and has continuous operation, low cost, high product quality and other advantages.

Owner:GRIMAT ENG INST CO LTD

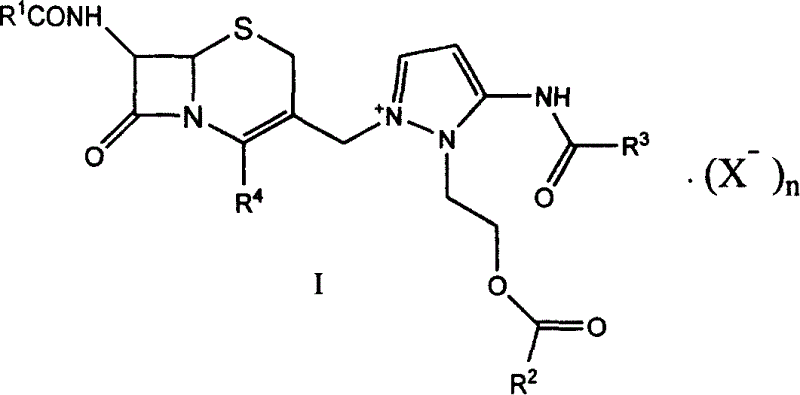

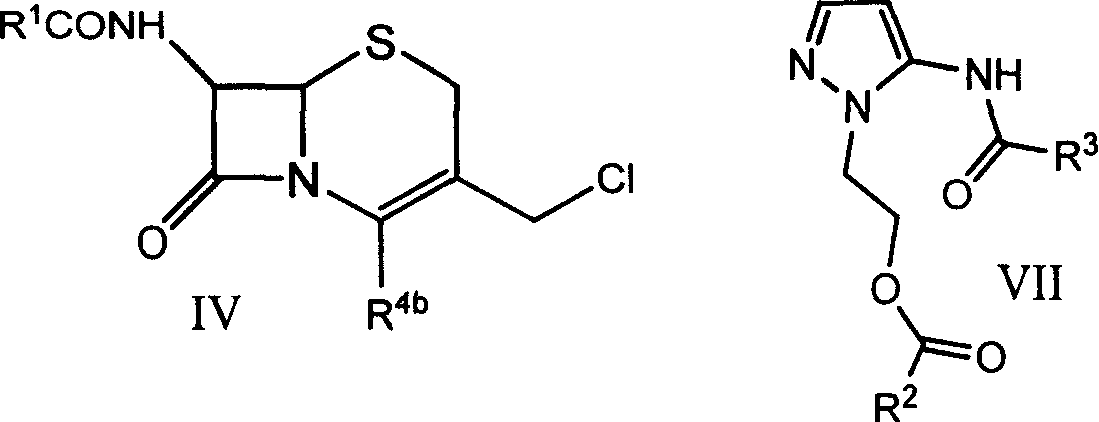

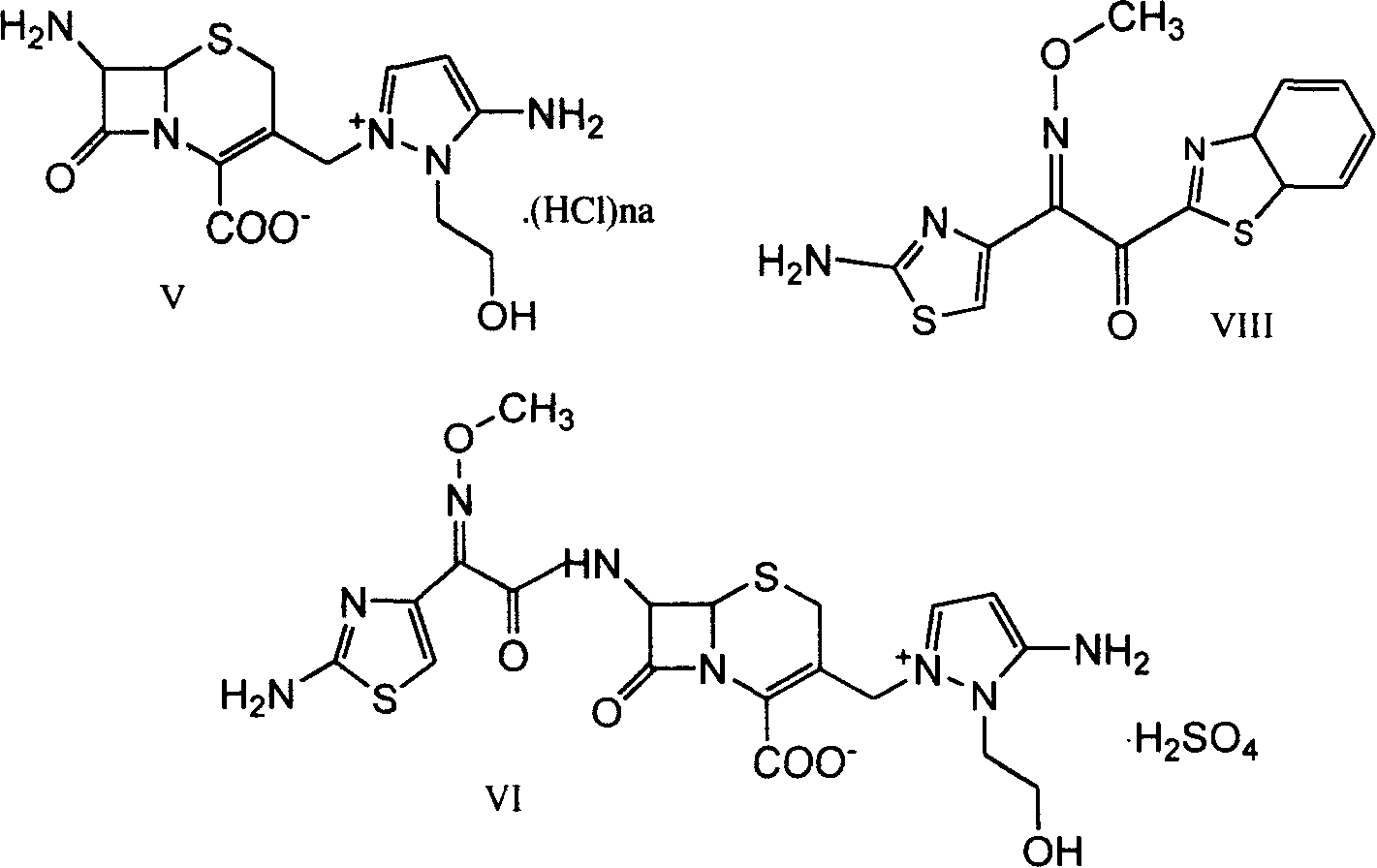

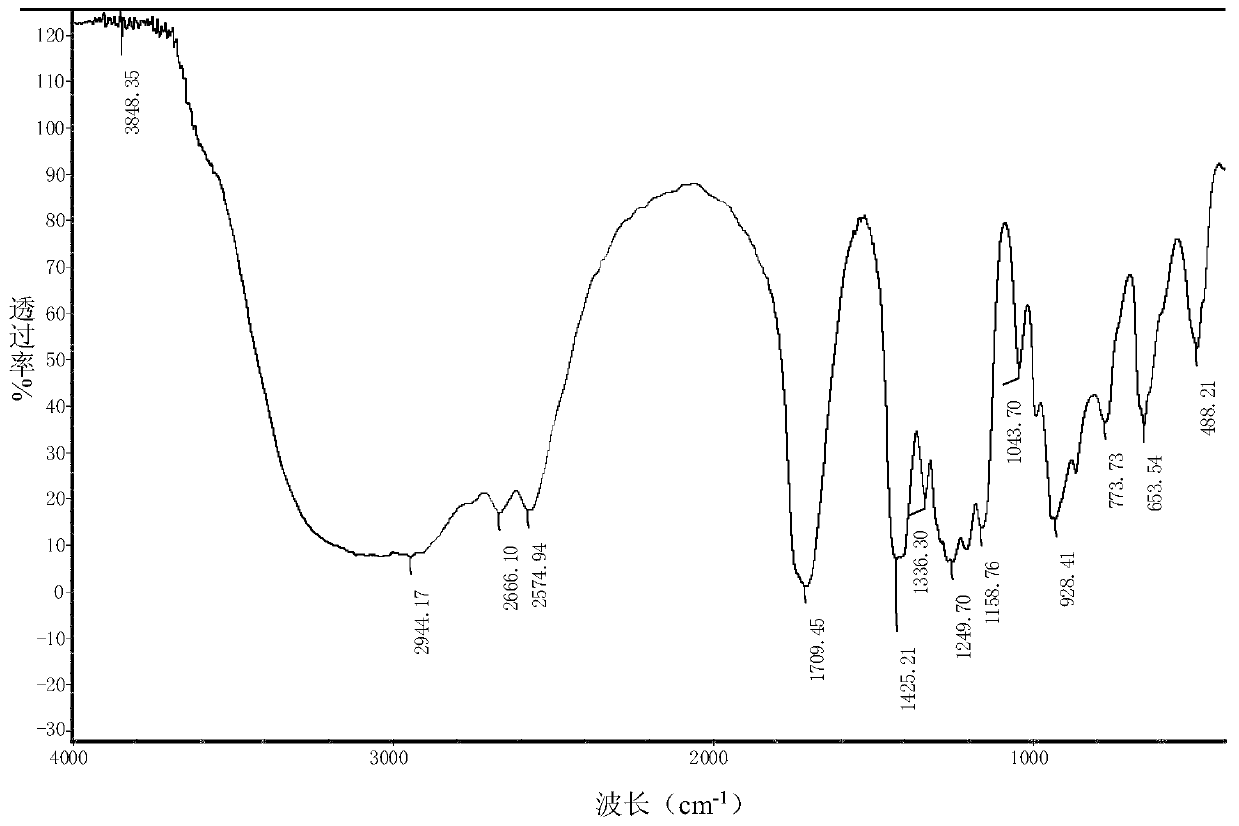

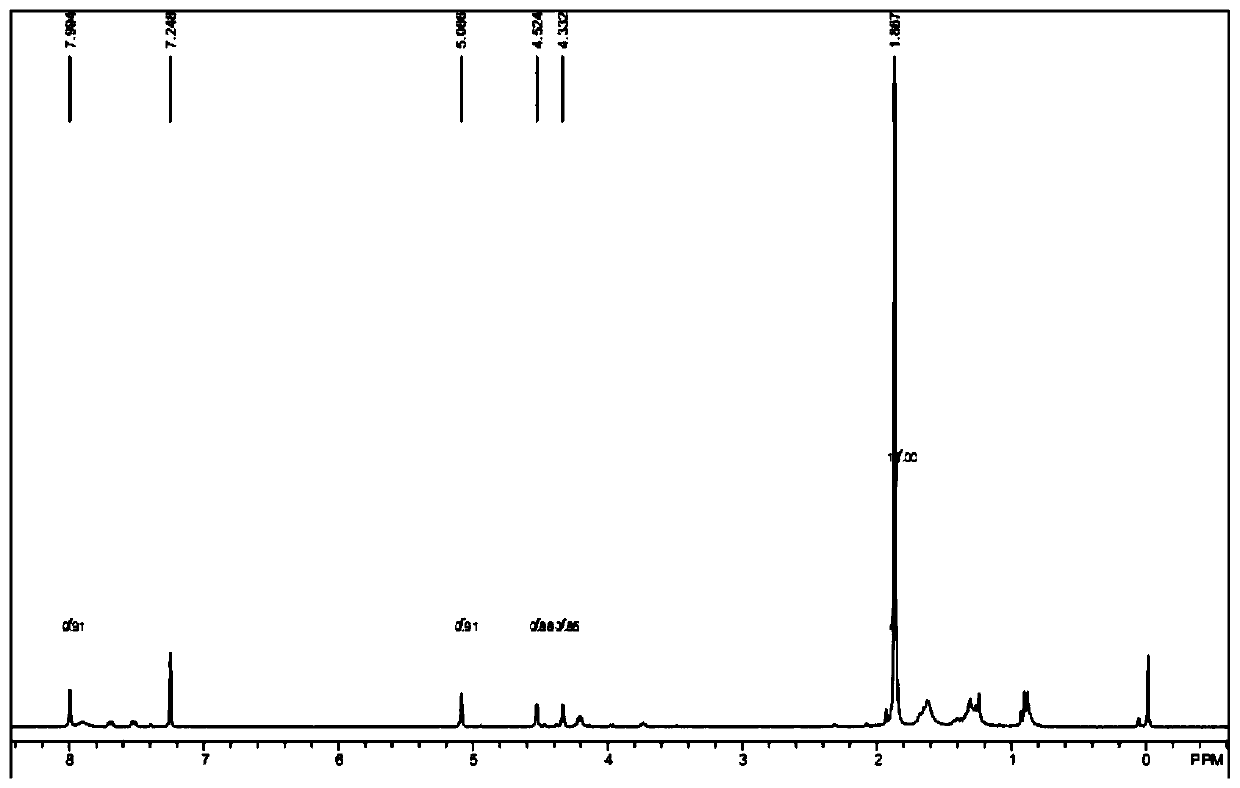

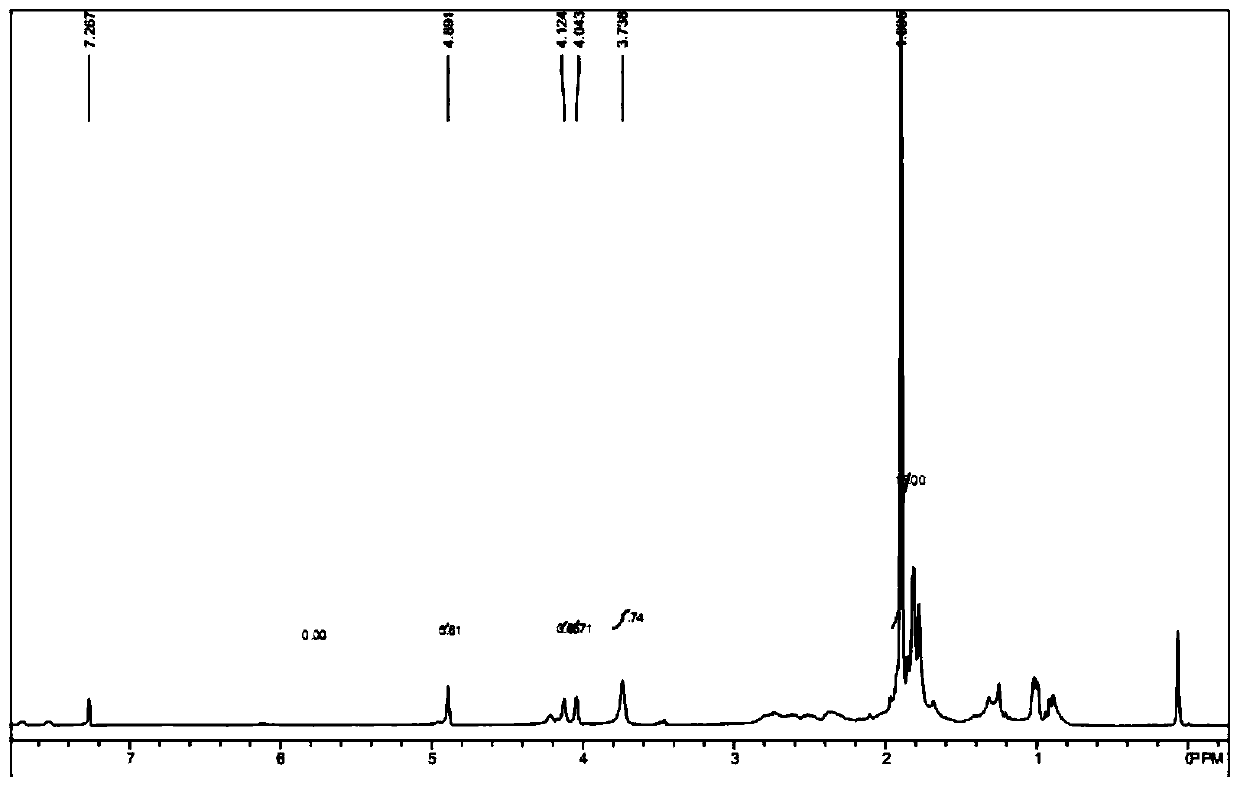

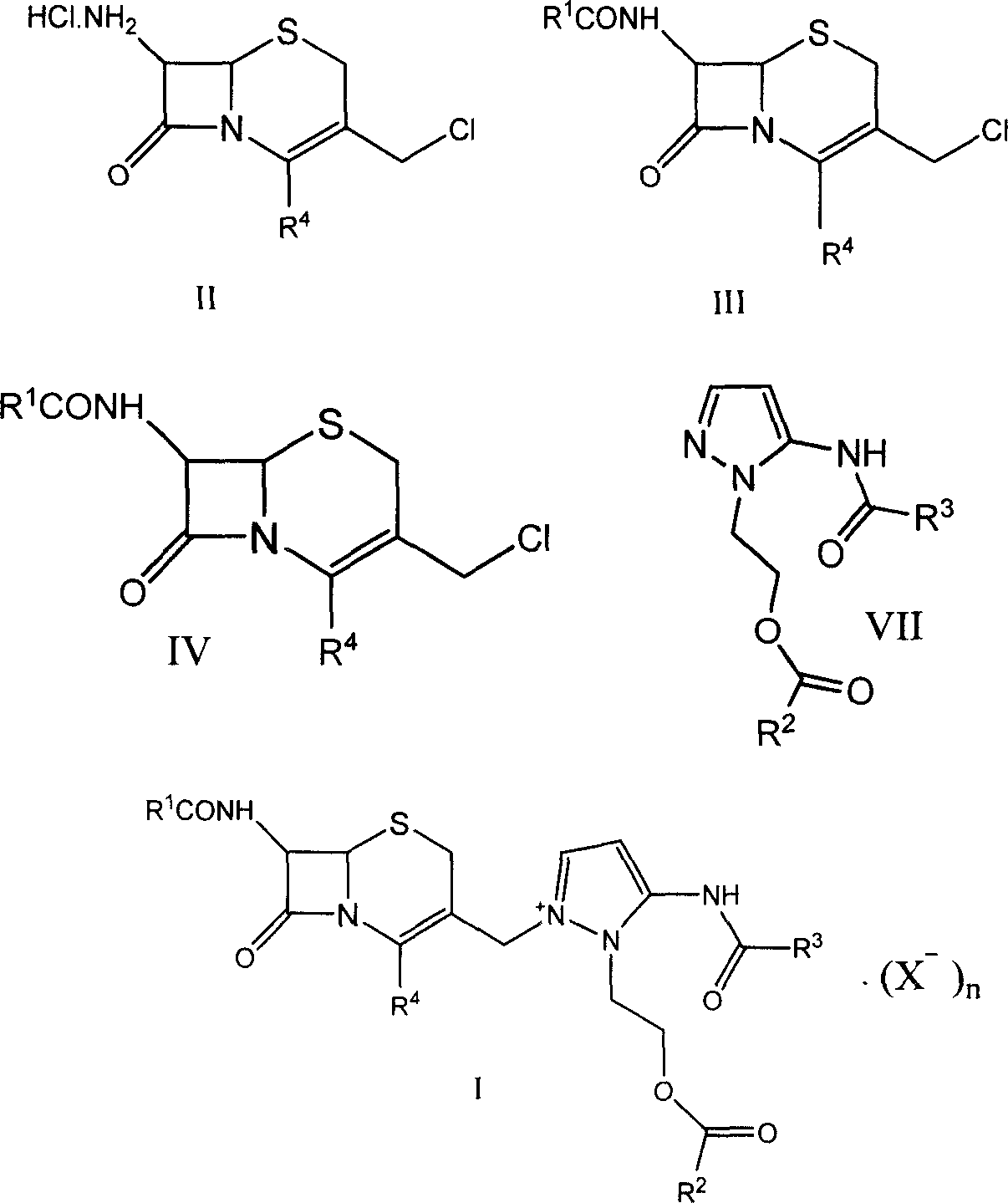

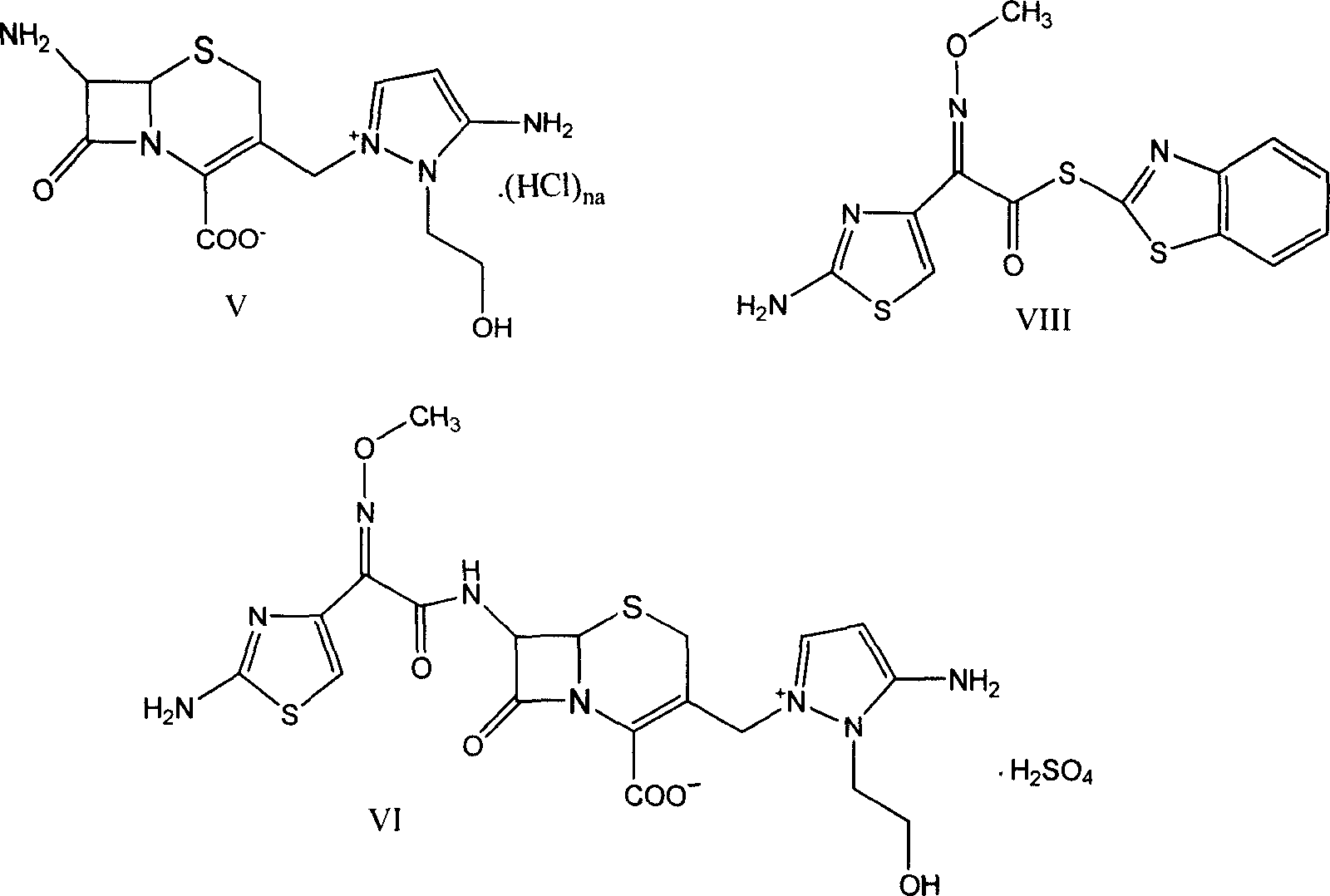

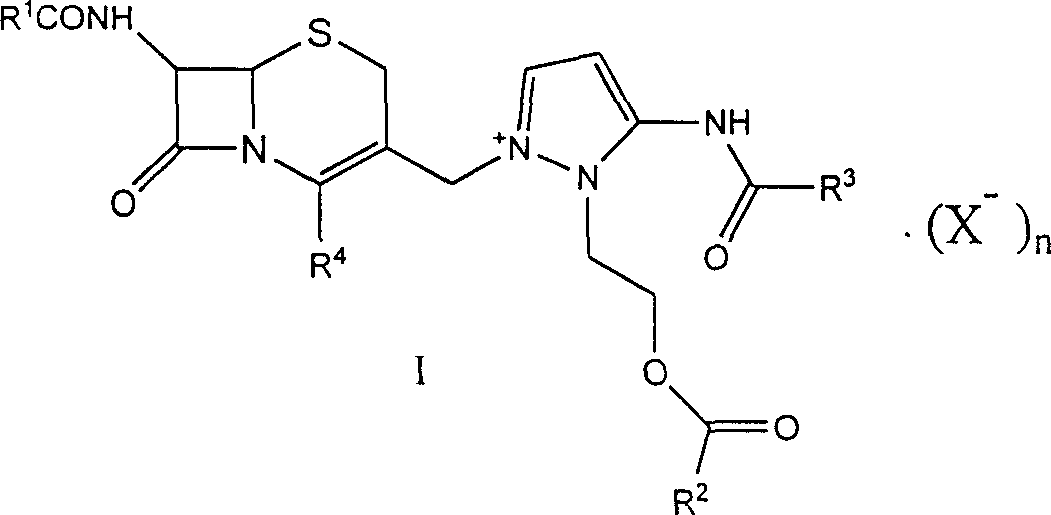

Cephaene onium salt compound and its preparation, and synthesis of cephapyrazde sulfate therefrom

This invention relates to cephalene onium salt compound and its preparation and synthesis of cephapyrazole sulfate therefrom. It is produced from 7beta-alkyl amido-3-[3-alkyl amido-2-(2-alkyl acyl oxethyl)-1-pyrazole onium group]methyl-3-cephalene- 4-carboxylic salt as intermediate by hydrolyzing it and reacting with alpha-(2-amino thiazole-4-radicle)-alpha-(Z)-methoxy imino acetic acid(benzo thiazole-2-radicle)hydrosulfate. The reacting condition is moderate, its raw materials can be obtained easily, and no expensive and strong irritant reagent is needed.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

Surface treatment method for bismuth telluride base thermoelectric material wafer

InactiveCN107227475AEasily brokenMany conversion linksSemiconductor devicesBismuth tellurideRoom temperature

The invention discloses a surface treatment method for a bismuth telluride base thermoelectric material wafer. The surface treatment method includes the following steps that the wafer is put into oil removing liquid for oil removing, and cold water is used for thorough flushing; activating liquid is firstly used for conducting room-temperature activating; then an electrolyte the same as the oil removing liquid is used for treatment; finally, pre-nickel-plating activating liquid is used for treatment; nickel plating liquid is used for electroplating, the wafer is taken out after nickel plating, and cold water is used for thorough flushing; and tin bismuth plating liquid is used for electroplating, the wafer is taken out after tin bismuth plating is over, cleaning and drying are conducted, and surface treatment of a bismuth telluride base thermoelectric material is completed. By means of the surface treatment method, a multi-step activating treatment process is adopted for ensuring the activating effect of the surface of the wafer, and the plating combining strength is high.

Owner:GUANGDONG INST OF RARE METALS

Synthesis of potassium acetylsulfanilate

The present invention relates to the preparation of acetyl potassium sulfanilate; preparation of substituted phenoxy sulfamide; preparation of acetyl acetoamino-N-sulfuryl-substituted phenoxyl; preparation of acetyl potassium sulfanilate. The present invention is simple in technology, relatively short reaction time, easy treatment of wastes.

Owner:张元宾 +1

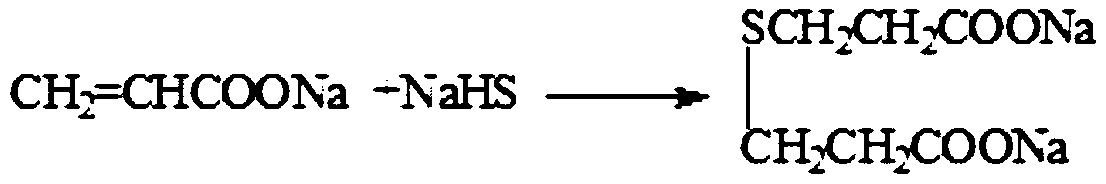

Preparation method of 3-mercaptopropionic acid

ActiveCN110372551AHigh yieldHigh purityThiol preparationOrganic compound preparationSodium bisulfideSulfur

Owner:HEBEI HOFMANN NEW MATERIAL TECH CO LTD

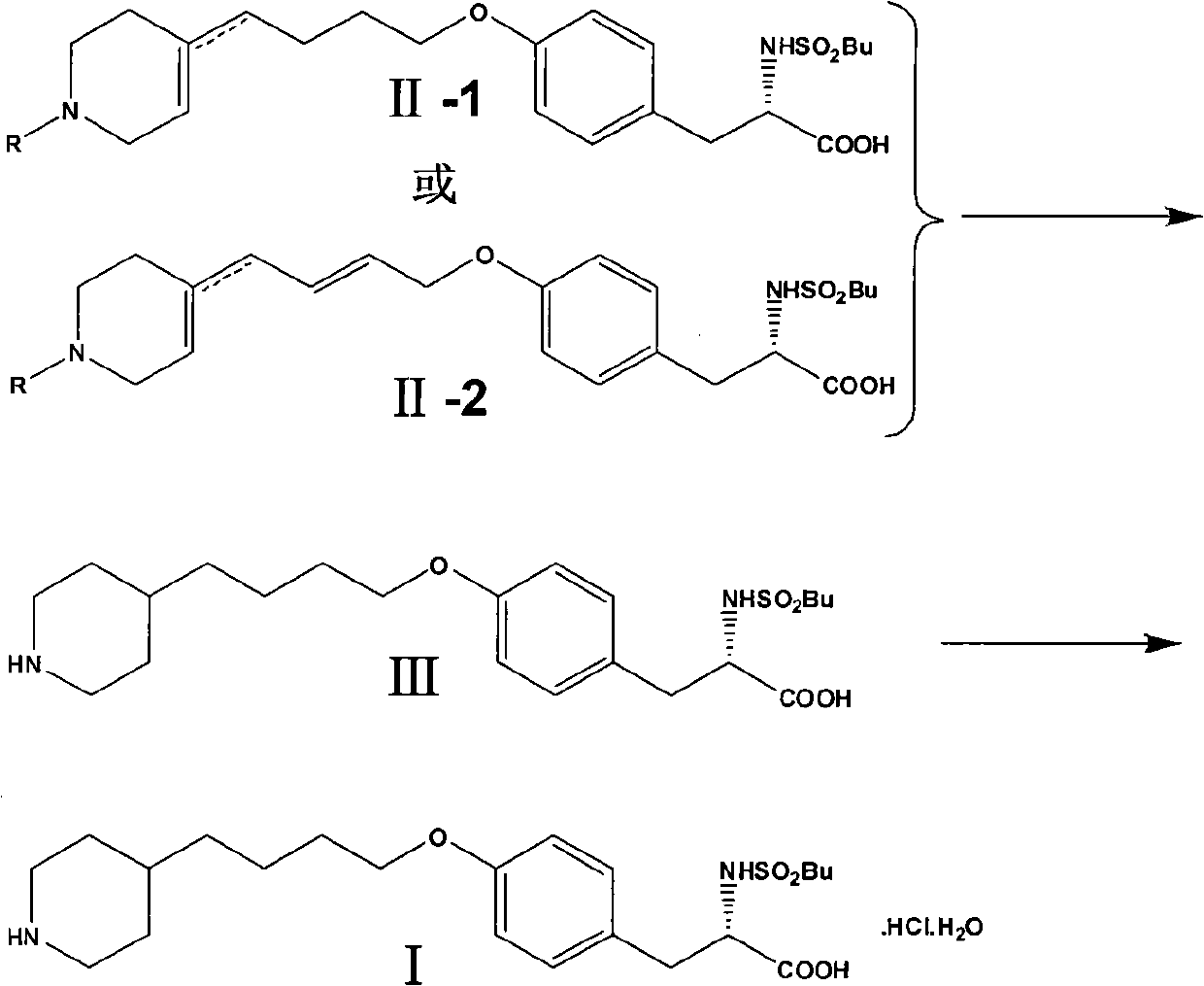

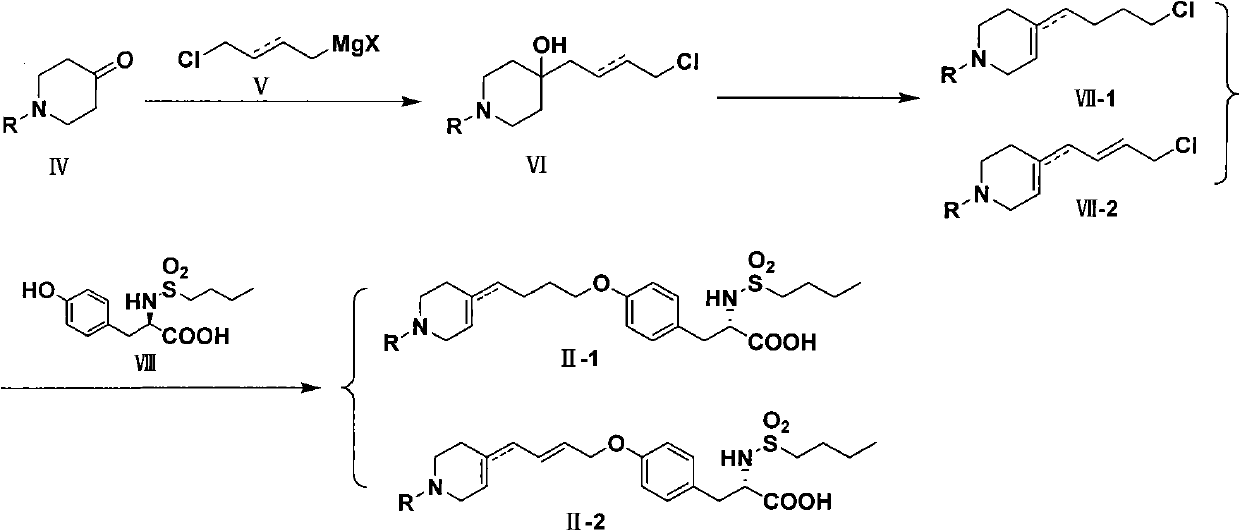

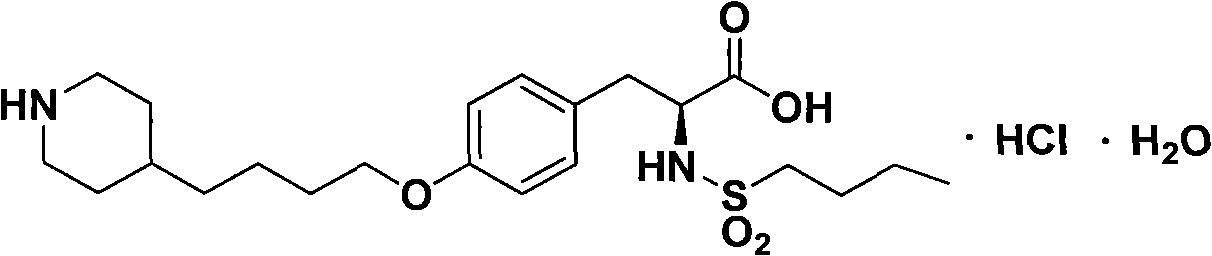

Method for preparing tirofiban hydrochloride

InactiveCN102241622ASafe preparationMild reaction conditionsOrganic chemistryTirofiban HydrochlorideMedicinal chemistry

The invention discloses a method for preparing tirofiban hydrochloride. The method comprises the following steps: reducing a compound represented by a formula II-1 or a compound represented by a formula II-2 to obtain tirofiban represented by a formula III; carrying out salt formation for the tirofiban to transform into the target compound tirofiban hydrochloride (I). The method provided by the present invention has advantages of safe preparation process, mild reaction conditions, few steps, easy operation, high yield, cheap and available raw materials, easy treatment of three waste and convenience of industrial implementation. The reaction formulas for preparing the tirofiban hydrochloride are as follows.

Owner:SHANGHAI INST OF PHARMA IND CO LTD

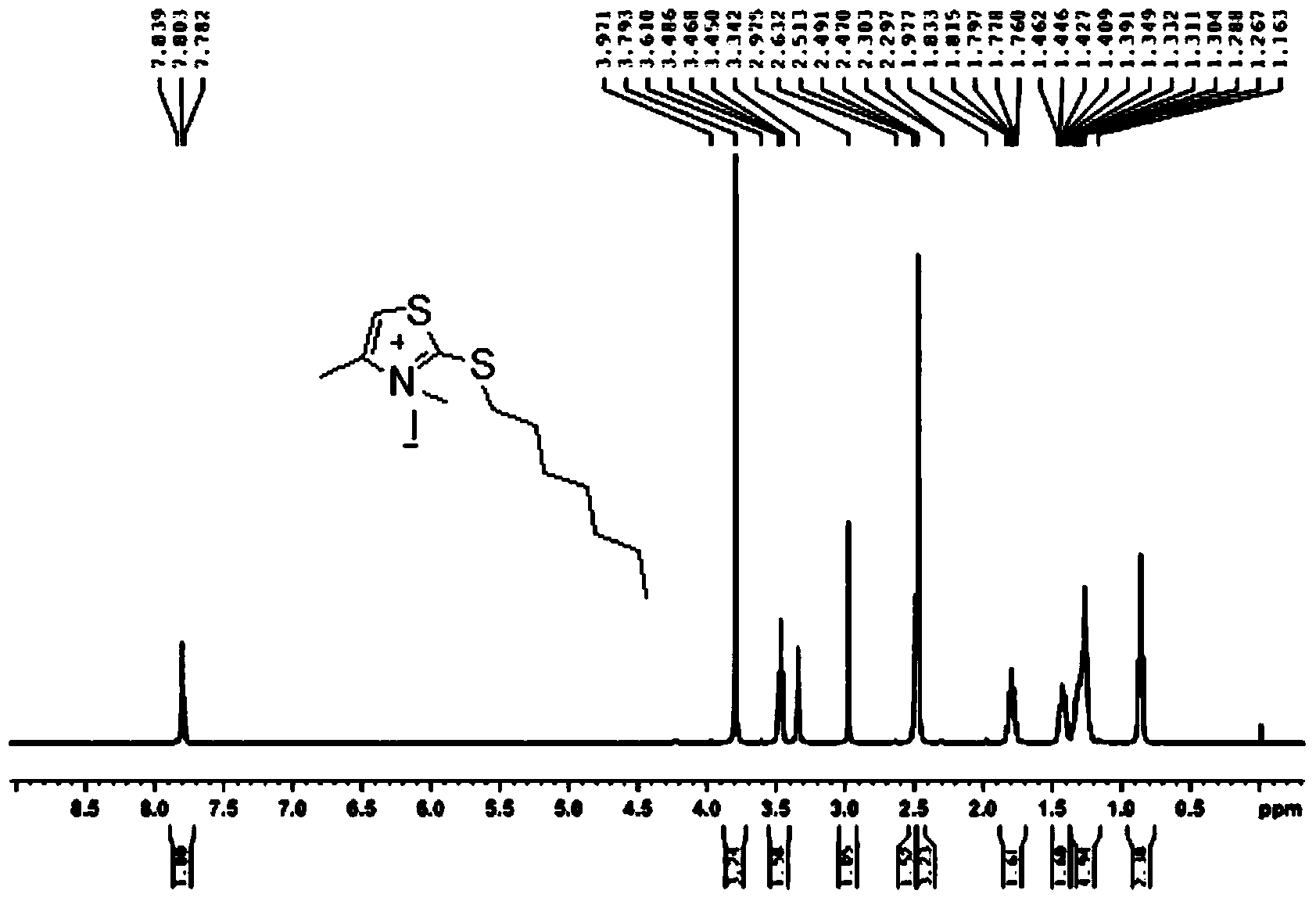

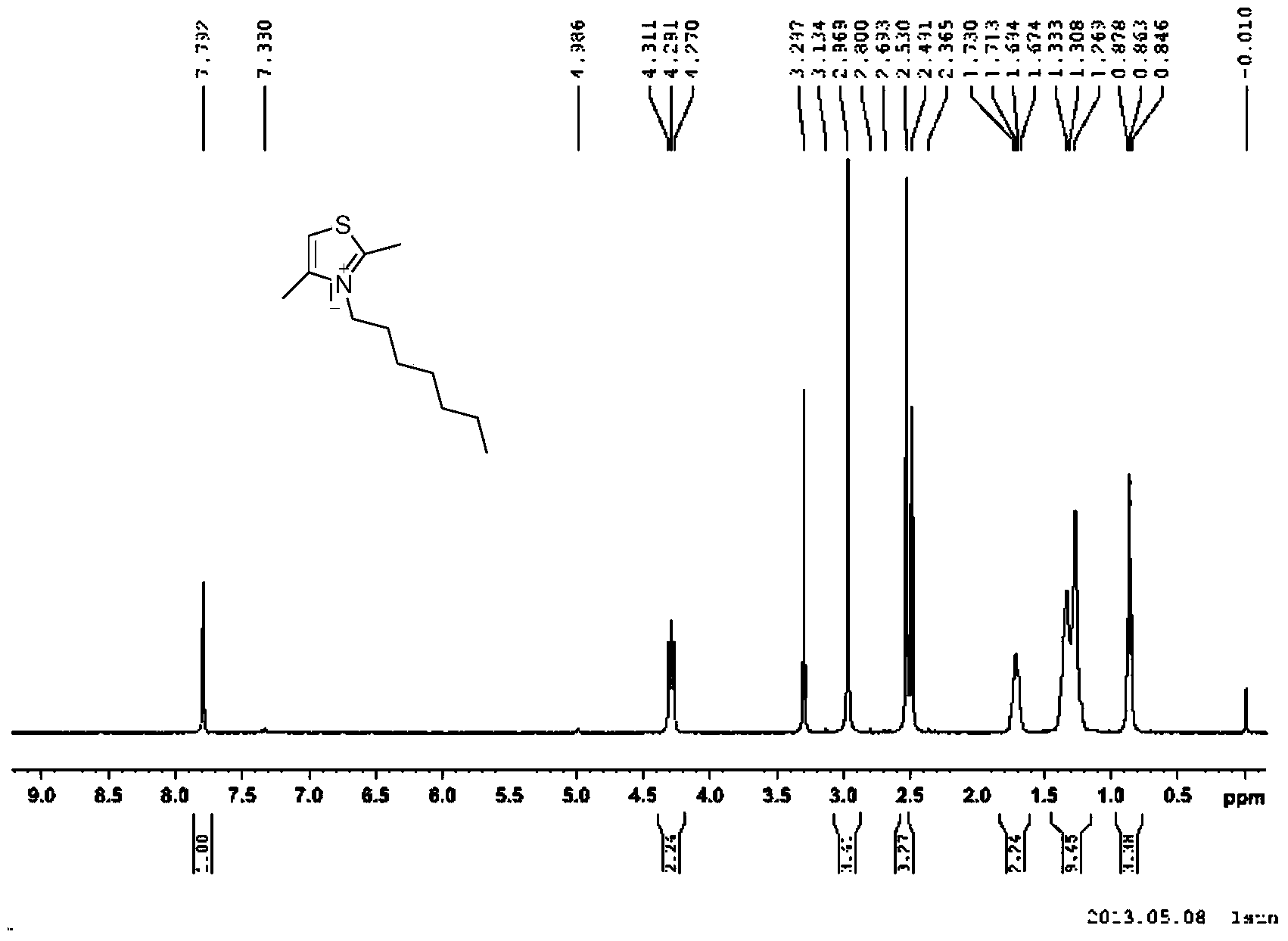

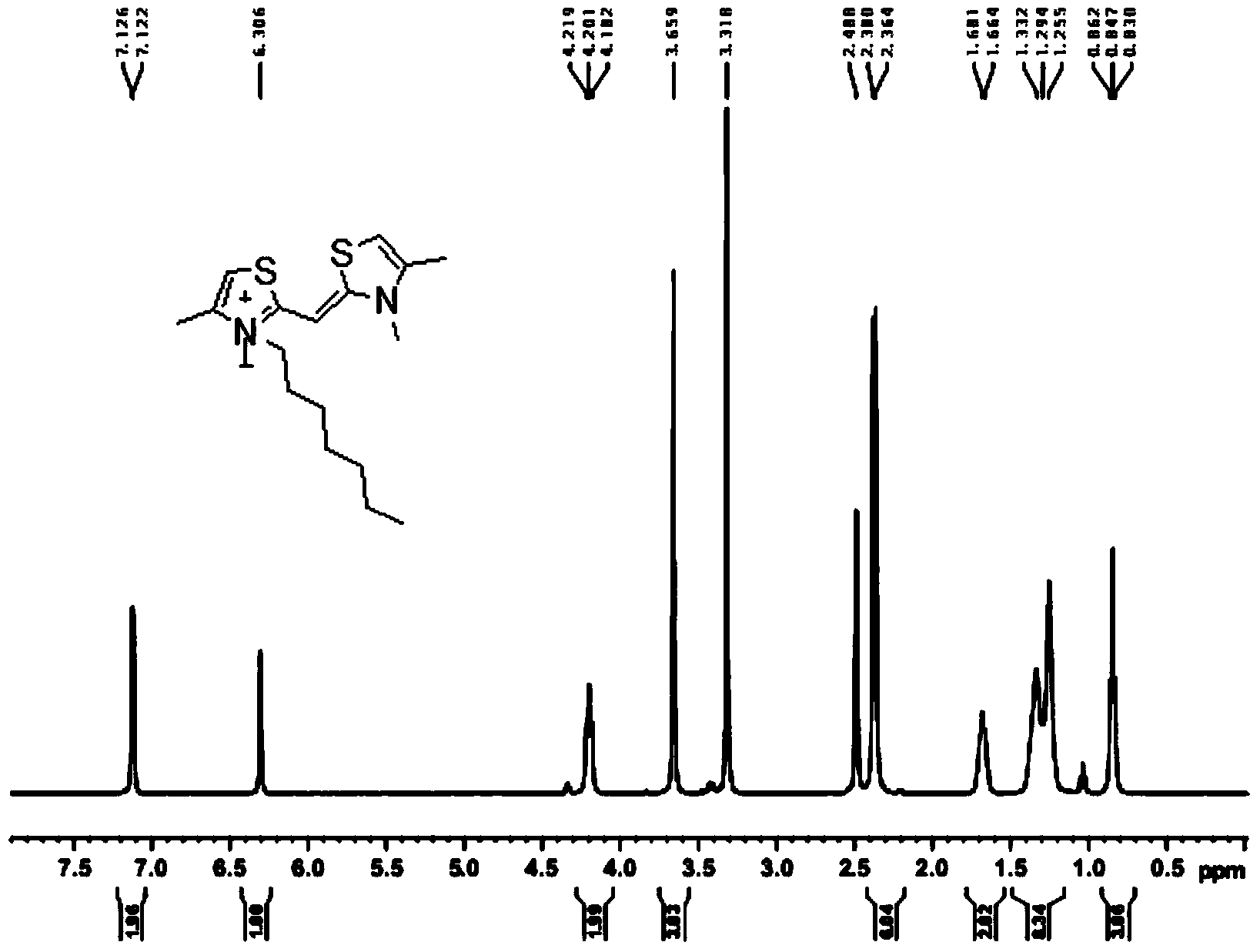

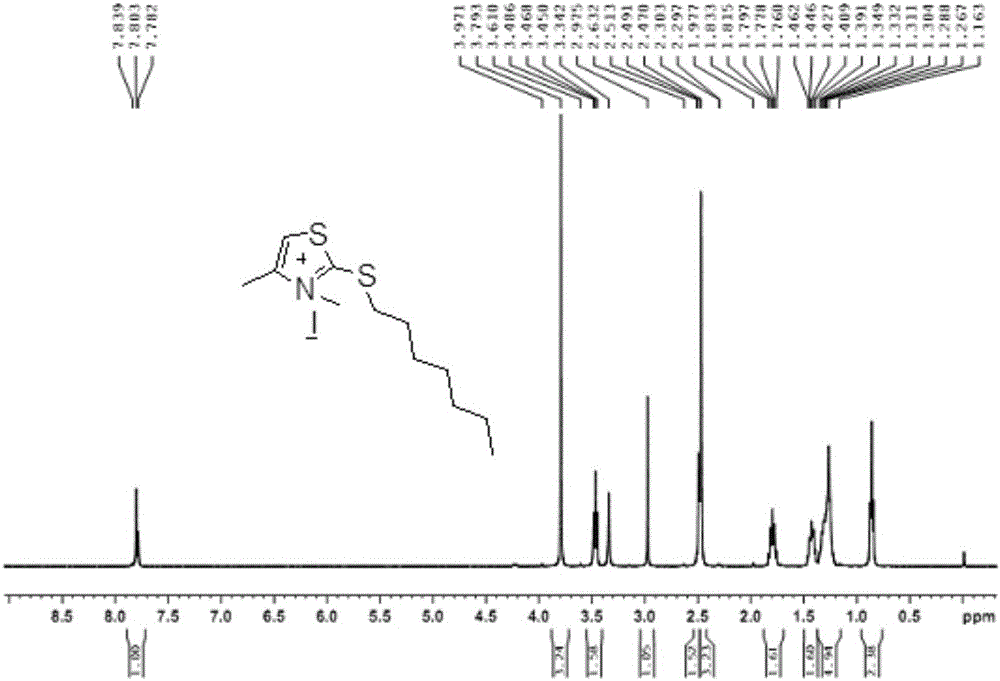

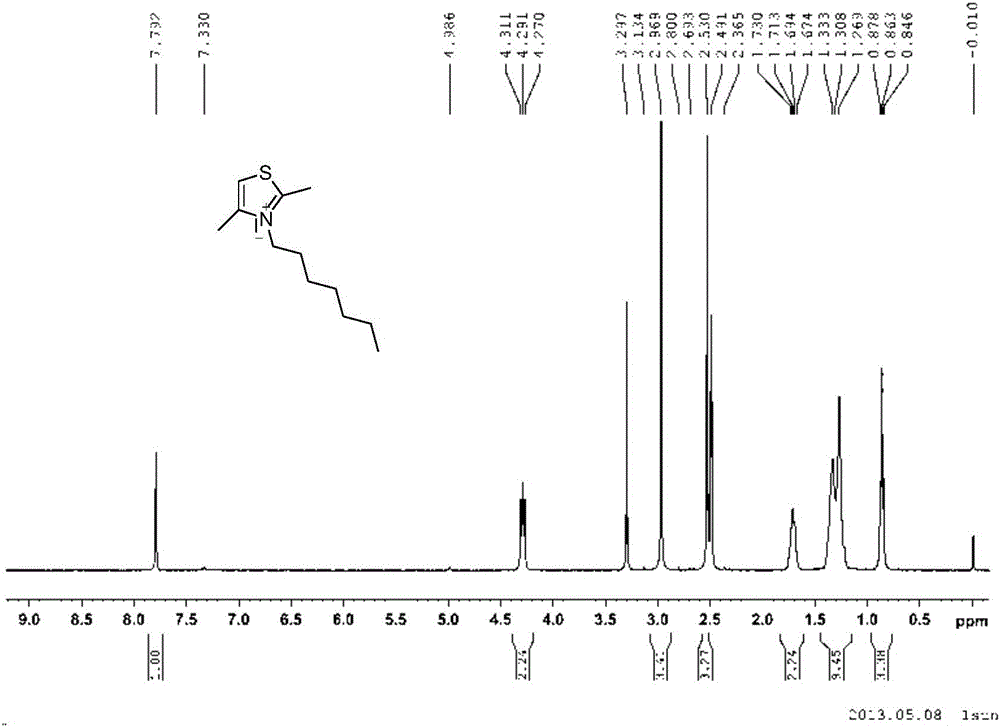

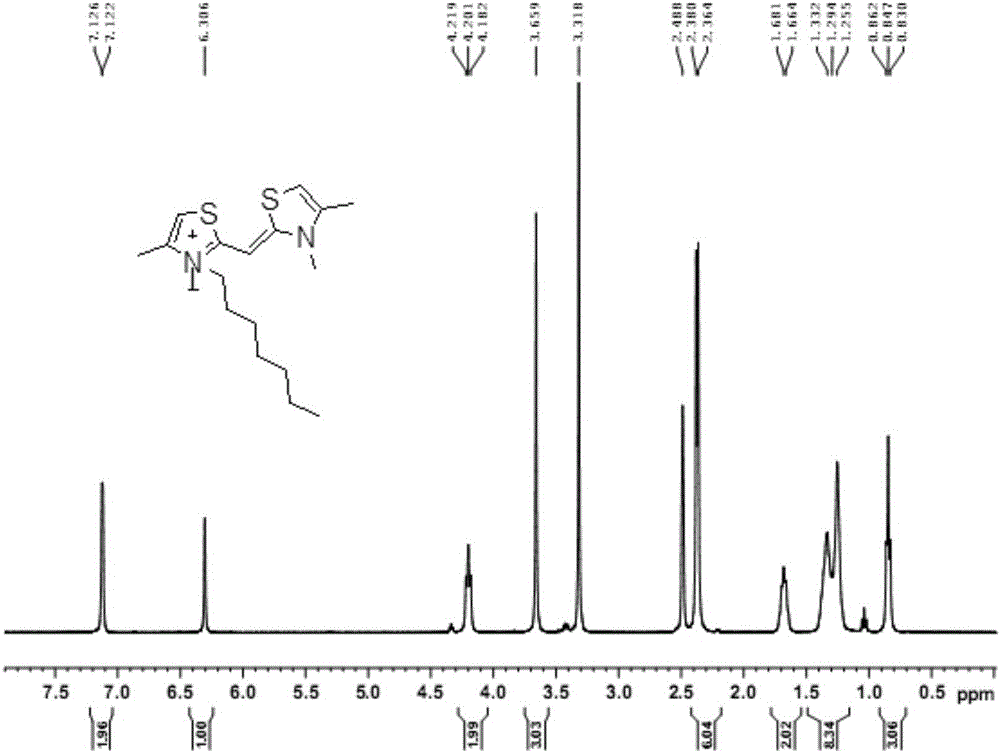

Synthesis method of dithiazole quaternary ammonium salt

The invention provides a synthesis method of a dithiazole quaternary ammonium salt, which comprises the following steps of: when R is equal to R', step one, adding iodo n-heptane in 2,4-dimethylthiazole for reaction to obtain 2,4-dimethyl-3-heptyl thiazole-3-onium iodo salt, step two, carrying out reaction on 4-methylthiazole-2-mercaptan and iodo n-heptane to obtain a product 3-heptyl-4-methylthiazole-2(3H)-sulfoketone, step three, carrying out reaction on the product in the step two and iodo n-heptane to obtain an intermediate 3-heptyl-2-heptyl sulfenyl-4-methylthiazole-3-onium iodo salt, and step four, carrying out reaction on the products in the steps three and one in the presence of organic alkali to obtain yellow dithiazole quaternary ammonium salt; and when R is not equal to R', replacing the alkyl substituent group R' on N in the step two by R' different from the step one. According to the synthesis method, the generation of by-products is avoided, the final product is easy to separate, and the purity and the yield are high, so that the synthesis method is easy for large-scale industrial production and application.

Owner:SHANGHAI LUGUAN BIOTECH

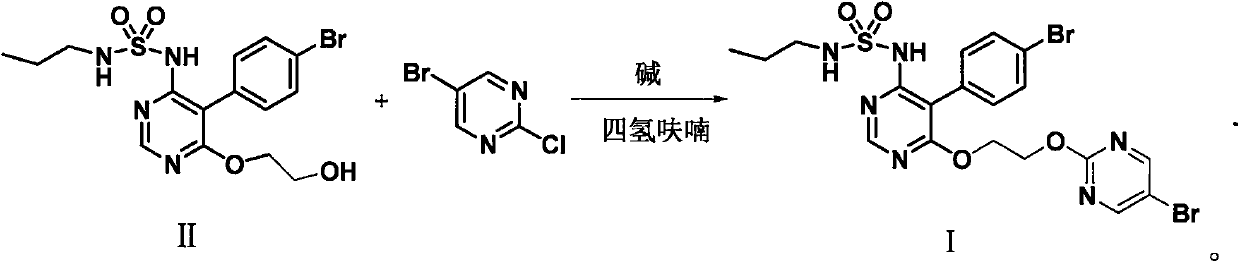

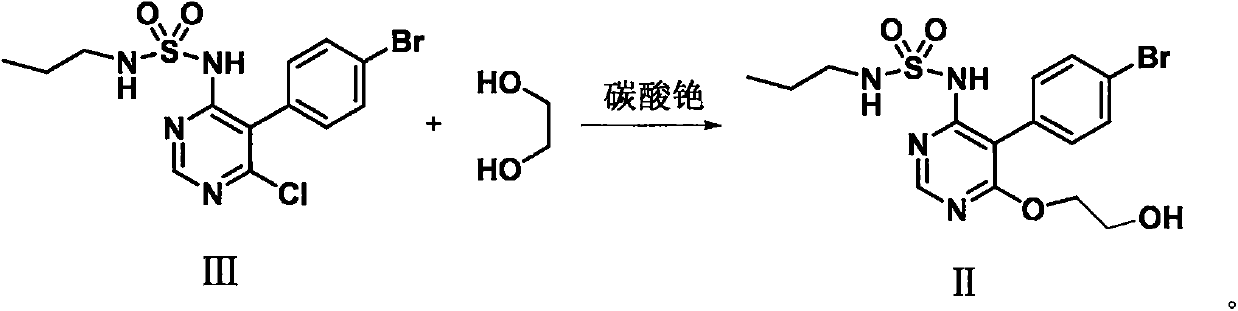

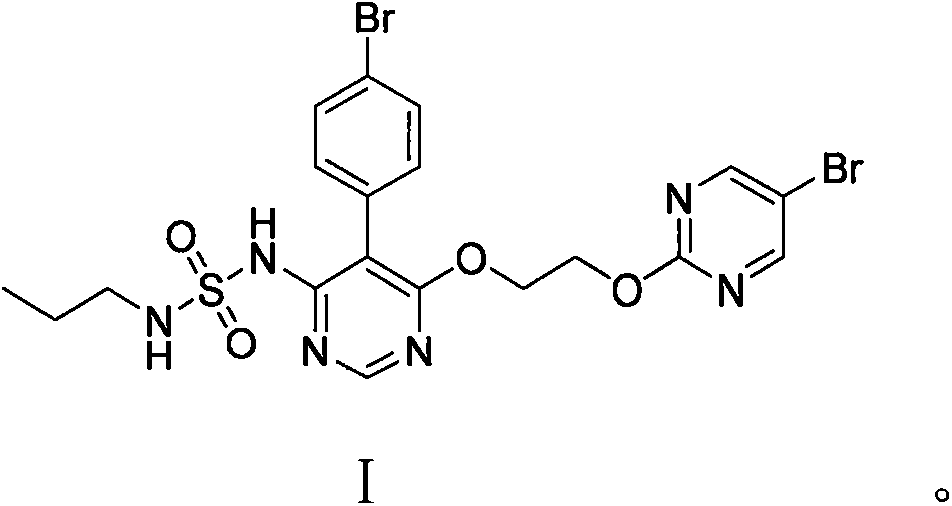

Macitentan preparation method

ActiveCN107868055ANot easy to accumulateQuality improvementOrganic chemistryBiochemical engineeringProcess engineering

The invention relates to a Macitentan preparation method. According to the preparation method, the process is simple, convenient and easy to control, reaction selectivity is good, product quality is high, and the method is suitable for industrial production.

Owner:SEASONS BIOTECHNOLOGY (TAIZHOU) CO LTD

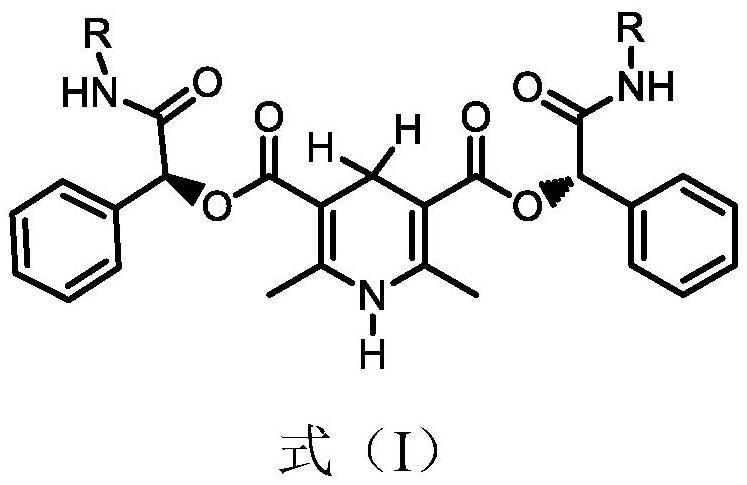

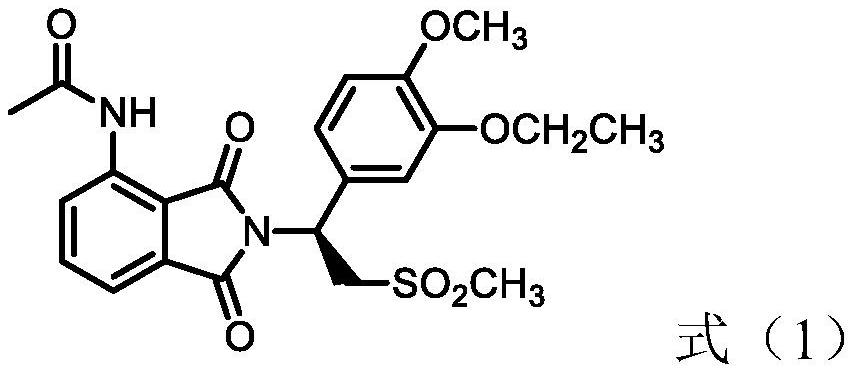

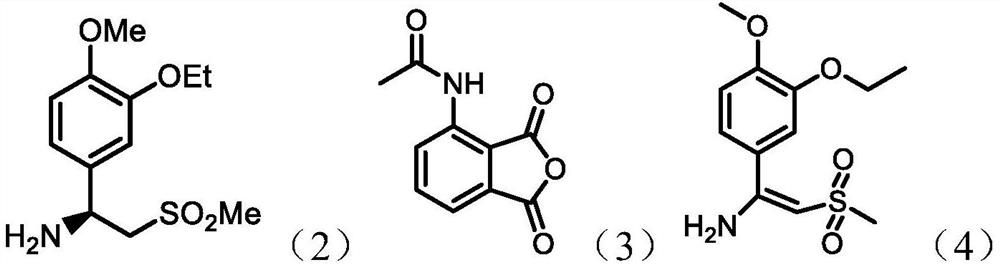

Synthetic method of (s)-1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl)ethylamine

ActiveCN112250533BHigh yieldEasy to separate and purifyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystAcyl group

The invention relates to a synthesis method of (S)-1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl)ethylamine. The method comprises the steps of: mixing 1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl) vinylamine, a chiral catalyst, an acid and a solvent, and reacting; the chiral catalyst The structural formula is shown in formula (I), R is selected from hydrogen atom, alkyl, aromatic ring, alkoxy, halogen atom, amino, cyano, hydroxyl, trifluoromethyl, nitro, ester or amido. (S)-1-(3-ethoxy-4-methoxyphenyl)-2-(methylsulfonyl)ethylamine with high chiral purity can be generated in one step, and the product is easy to separate and purify with high yield. In addition, the reaction condition is mild, the process is stable, the reaction operation is simple and safe, the production cost is low, the three wastes are easy to handle, the environment is friendly, the raw materials are easily available, the production cost is low, and the method is suitable for industrial production.

Owner:ENANTIOTECH CORP +1

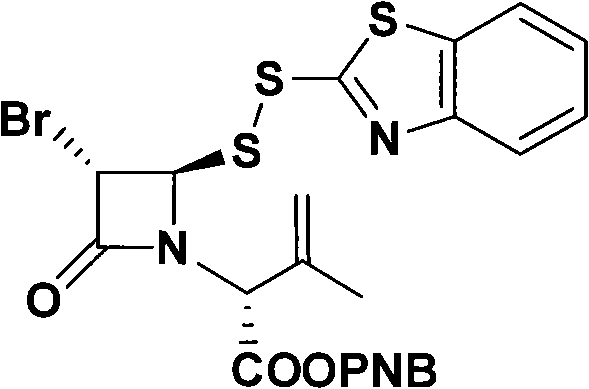

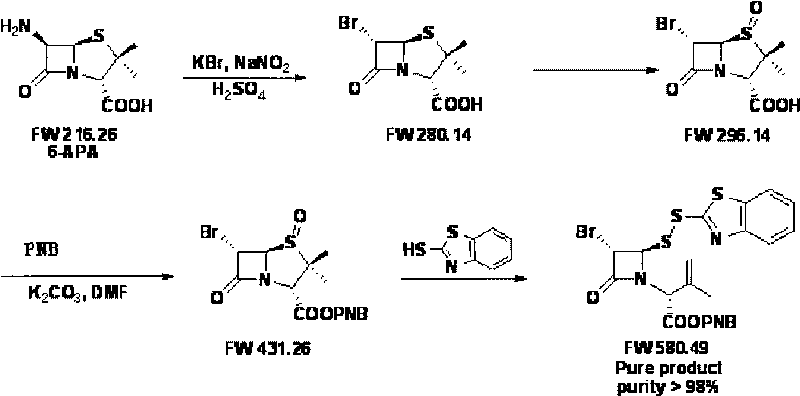

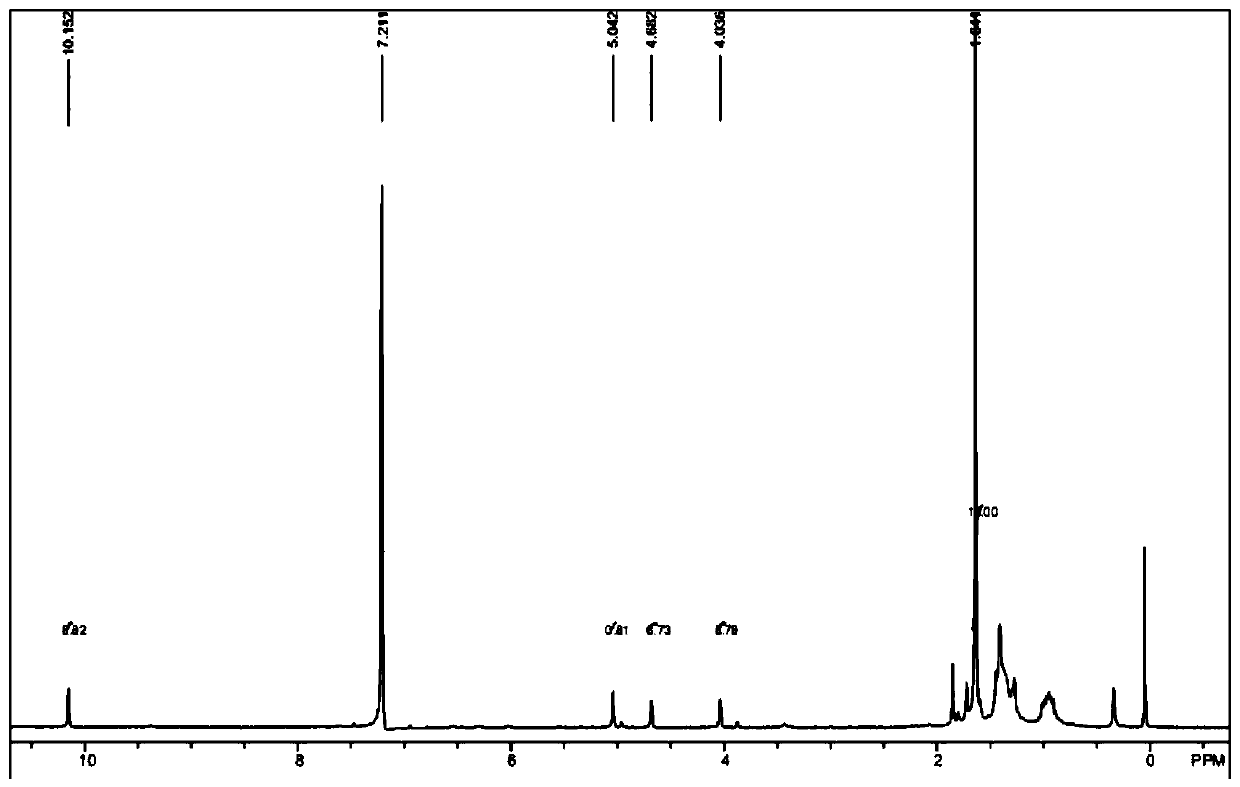

Synthesis method of single-ring imipenem p-nitro benzyl ester

InactiveCN101747328AEasy to makeEasy post-processingOrganic chemistryOrganic solventSynthesis methods

The invention belongs to the technical field of medicines and in particular discloses a synthesis method of single-ring imipenem p-nitro benzyl ester. In the method, 6-APA is used as a raw material, and the single-ring imipenem p-nitro benzyl ester is prepared through reactions of nitration, bromination, oxidation, esterification, ring-opening, and the like. The method is characterized in that noval reagents and catalysts are adopted during synthesis, a single aromatic organic solvent is used as a reaction solvent, and an obtained product is easy to recover and convenient to apply. In the synthesis process, a one-pot synthesis method is adopted, thereby simplifying the process flow and shortening the production period.

Owner:SHANDONG RUNZE PHARMA

Synthesis method of nitrogen-containing heterocycles ferrocene derivative

The invention relates to a synthesis method of a nitrogen-containing heterocycles ferrocene derivative. The synthesis method comprises the following steps of (I) introducing an aldehyde group into nitrogen-containing heterocycles in the chemical structure of a raw material a to obtain an intermediate b; (II) performing a hydroxylamine reaction on the aldehyde group in the chemical architecture ofan intermediate b to obtain a hydroxylamine group namely an intermediate c; and (III), performing a reduction reaction on the hydroxylamine group in the chemical architecture of the intermediate c, toobtain the nitrogen-containing heterocycles ferrocene derivative 1. The synthesis method is simple in steps, reagents and equipment which have risks for human bodies or environment do not need to beadopted, and mass production and application of the nitrogen-containing heterocycles ferrocene derivative are convenient.

Owner:FOSHAN ENANTIOSIC CORP LTD +1

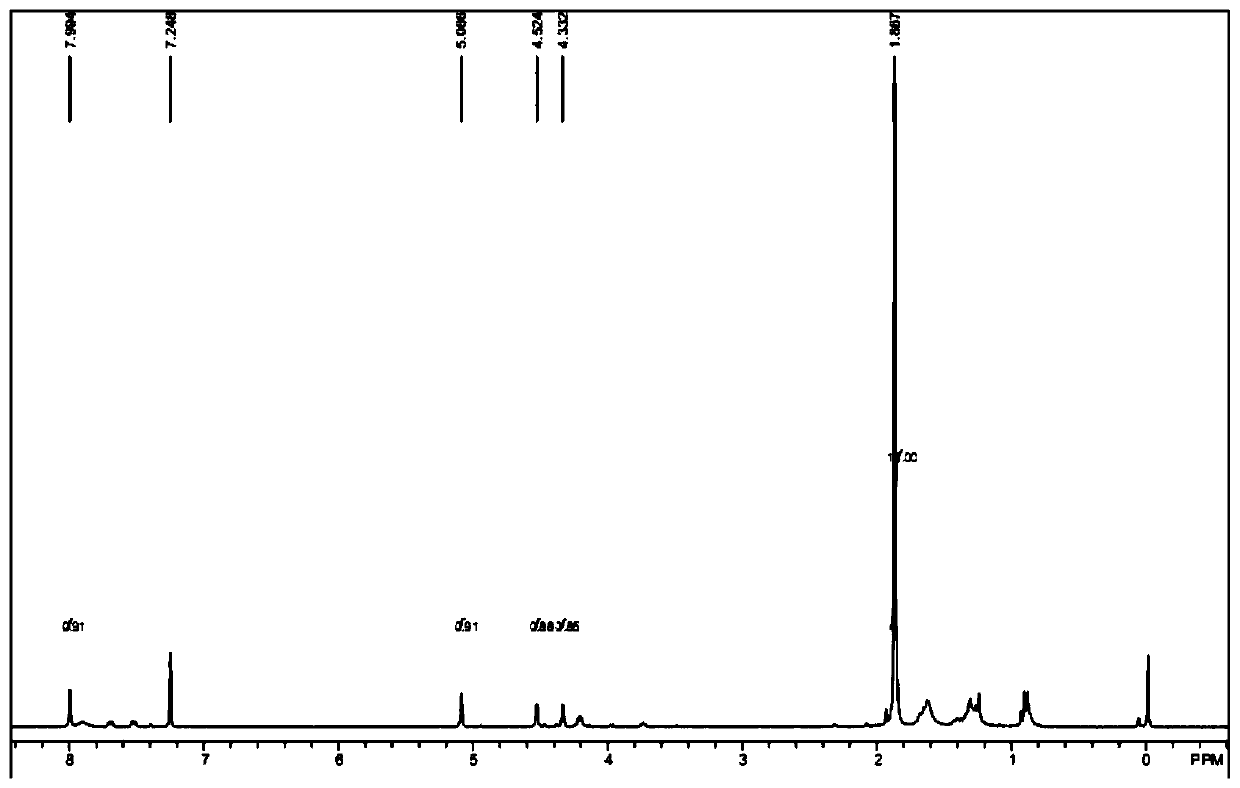

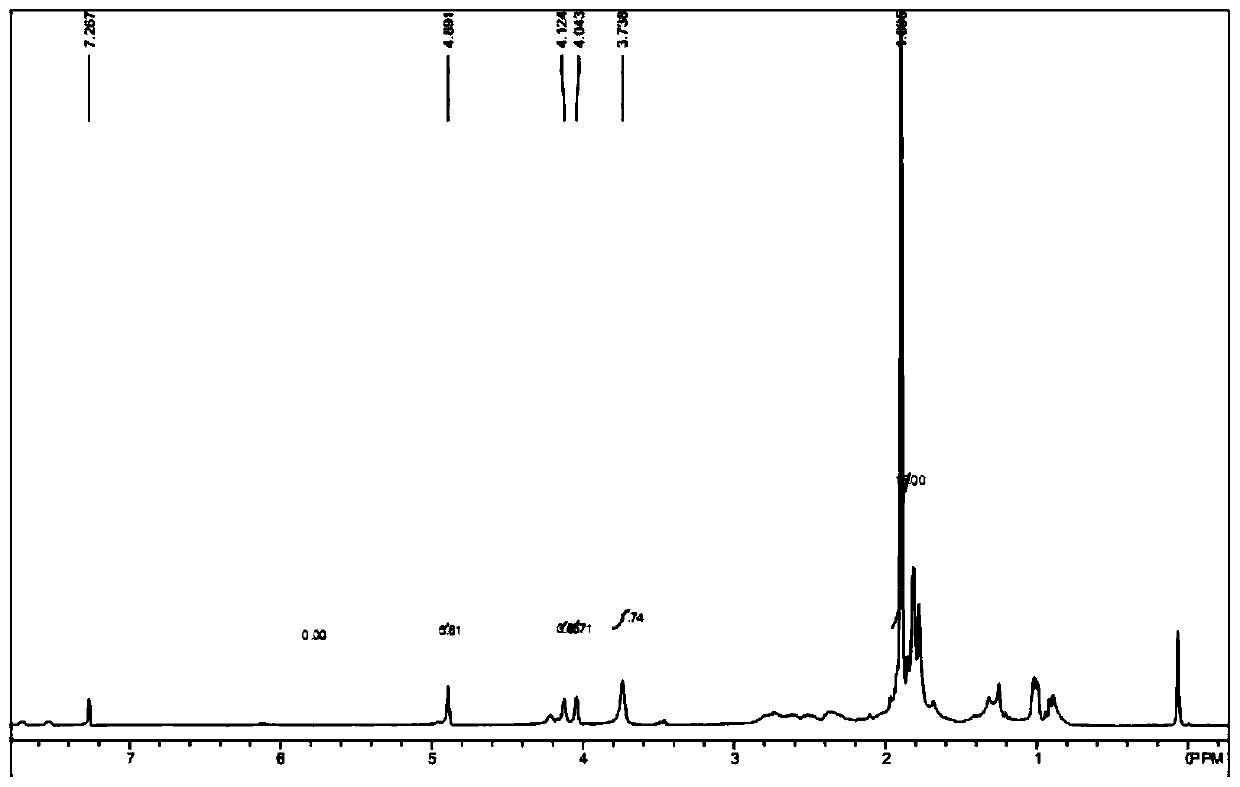

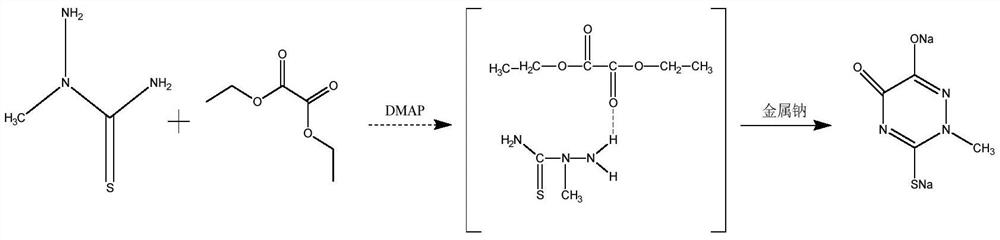

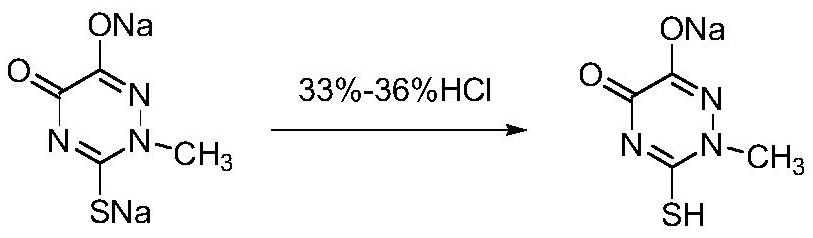

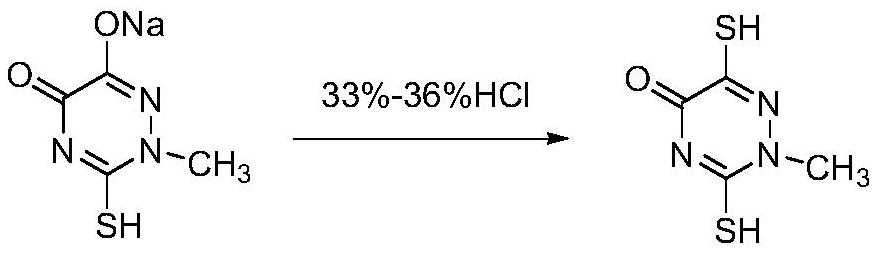

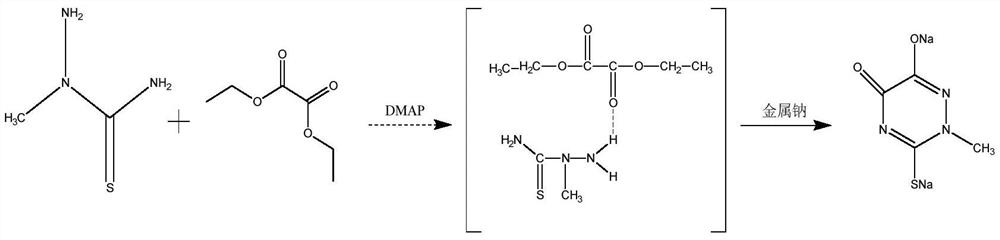

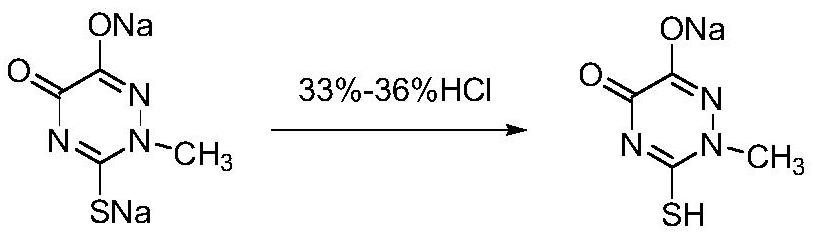

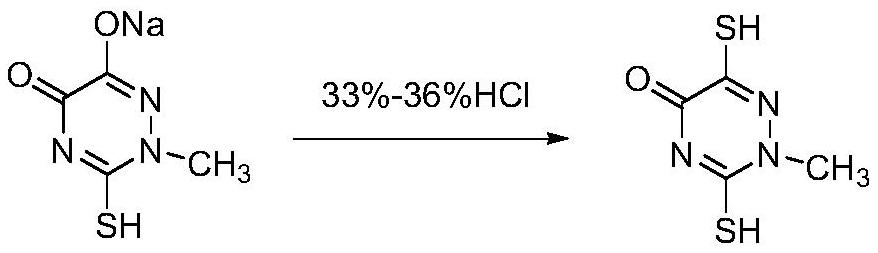

Preparation method of triazine ring

The invention belongs to the technical field of medicines, and particularly relates to a preparation method of a triazine ring. The method comprises the following steps: performing cyclization reaction on 2-methylthiosemicarbazide, diethyl oxalate, dimethylaminopyridine and metal sodium, adding hydrochloric acid for crystal transformation reaction after the cyclization reaction is finished to obtain a triazine ring sodium salt crude product, and adding hydrochloric acid into the triazine ring sodium salt crude product for refining reaction to obtain the triazine ring. The method has the advantages of simple raw materials, high yield, easy treatment and low cost.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

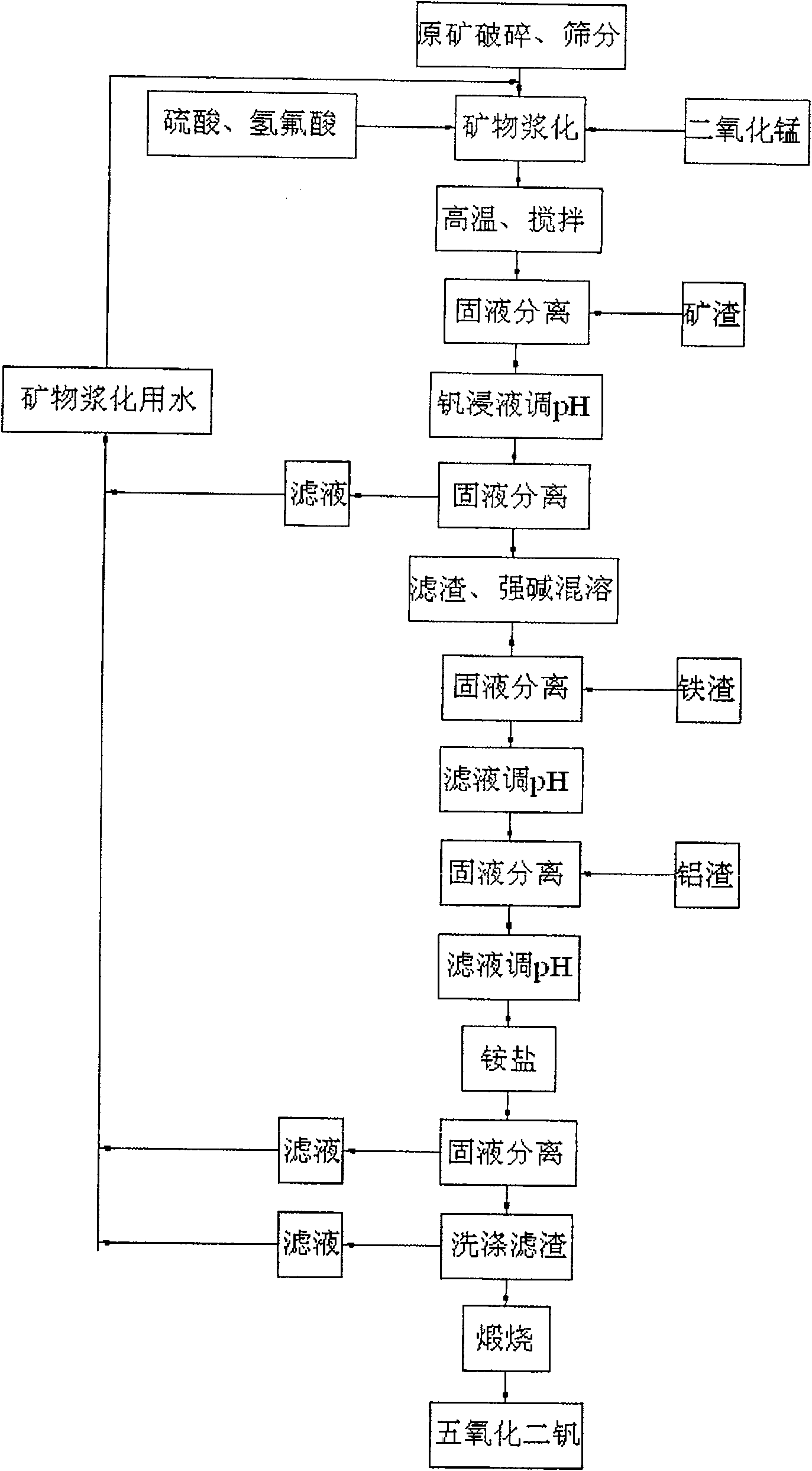

Alum extracting technique for clay ore by wet method

InactiveCN100588727CImprove use valueShort processVanadium oxidesProcess efficiency improvementFluohydric acidAmmonium metavanadate

The invention relates to a wet process vanadium extraction technology of clay ore, providing a valuable metal technology for extracting vanadium by wet process from vanadium clay ore, which belongs tothe non-ferrous metal metallurgical technology field. The invention is characterized in that disintegrating clay ore, proceeding thermostatic mixing acid leaching reaction as adding sulfuric acid, fluohydric acid and oxidation agent under certain liquid solid volumetric ratio, separating solid and liquid, removing out iron and aluminum and recycling to utilize after leaching solution being treated by multistep pH value regulation and alkali deposition solubilization reaction, depositing vanadium by ammonium salt after purified vanadium being regulated pH value, filtering, drying and calciningammonium metavanadate which is prepared to obtain vanadium pentoxide powder. The invention directly leaches clay ore mixing with acid, has high acid leaching rate, lower energy consumption, short technical process, easy operation and control, low productive cost, environment-friendly and safety, realizes zero discharge in the production process, has no waste gas generation, and recycles waste water and valuable metal, and the recycle rate of vanadium reaches 70-75%, purity of vanadium pentoxide of the product is larger than 99%.

Owner:UNIV OF SCI & TECH BEIJING

A kind of method for removing chlorosulfonic acid in the production of pentachlorobenzoyl chloride

ActiveCN106380396BSimple processEasy to operate and controlOrganic compound preparationCarboxylic compound preparationSodium bicarbonateChlorosulfuric acid

A method of removing chlorosulfonic acid in pentachlorobenzoyl chloride production is disclosed. The method includes (1) feeding chlorine and reacting to produce pentachlorobenzoyl chloride by adopting benzoyl chloride as a raw material and chlorosulfonic acid as a solvent, (2) subjecting the chlorination solution generated in the step (1) to vacuum recovering, (3) cooling the recovered solution to 60-100 DEG C by jacket water cooling, sampling and detecting the content of residual high-oxidizability acids, (4) allowing the mole ratio of sulfuric acid in the recovered solution to sodium chloride to be 1:(2.10-2.5) and reacting the sulfuric acid and the sodium chloride to generate HCl and sodium sulfide, (5) allowing the mole ratio of the chlorosulfonic acid in the recovered solution to sodium bicarbonate to be 1:(0.9-1.0), and (6) allowing the mixture to stand, depositing, centralizing, and subjecting solid to filtration and washing with a solvent to further recover a product. The method has characteristics of cost saving, good product quality, a simple process, easy operation, low environment pollution, and the like.

Owner:ZHEJIANG KANGFENG CHEM

The synthetic method of bithiazole quaternary ammonium salt

The invention provides a synthesis method of a dithiazole quaternary ammonium salt, which comprises the following steps of: when R is equal to R', step one, adding iodo n-heptane in 2,4-dimethylthiazole for reaction to obtain 2,4-dimethyl-3-heptyl thiazole-3-onium iodo salt, step two, carrying out reaction on 4-methylthiazole-2-mercaptan and iodo n-heptane to obtain a product 3-heptyl-4-methylthiazole-2(3H)-sulfoketone, step three, carrying out reaction on the product in the step two and iodo n-heptane to obtain an intermediate 3-heptyl-2-heptyl sulfenyl-4-methylthiazole-3-onium iodo salt, and step four, carrying out reaction on the products in the steps three and one in the presence of organic alkali to obtain yellow dithiazole quaternary ammonium salt; and when R is not equal to R', replacing the alkyl substituent group R' on N in the step two by R' different from the step one. According to the synthesis method, the generation of by-products is avoided, the final product is easy to separate, and the purity and the yield are high, so that the synthesis method is easy for large-scale industrial production and application.

Owner:SHANGHAI LUGUAN BIOTECH

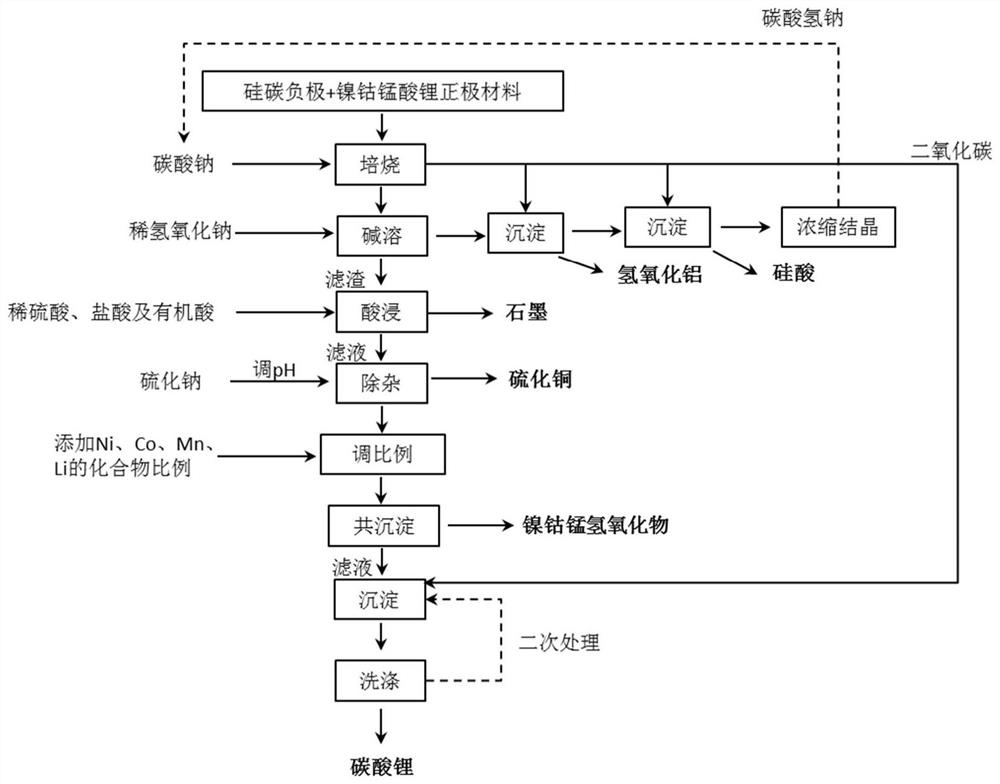

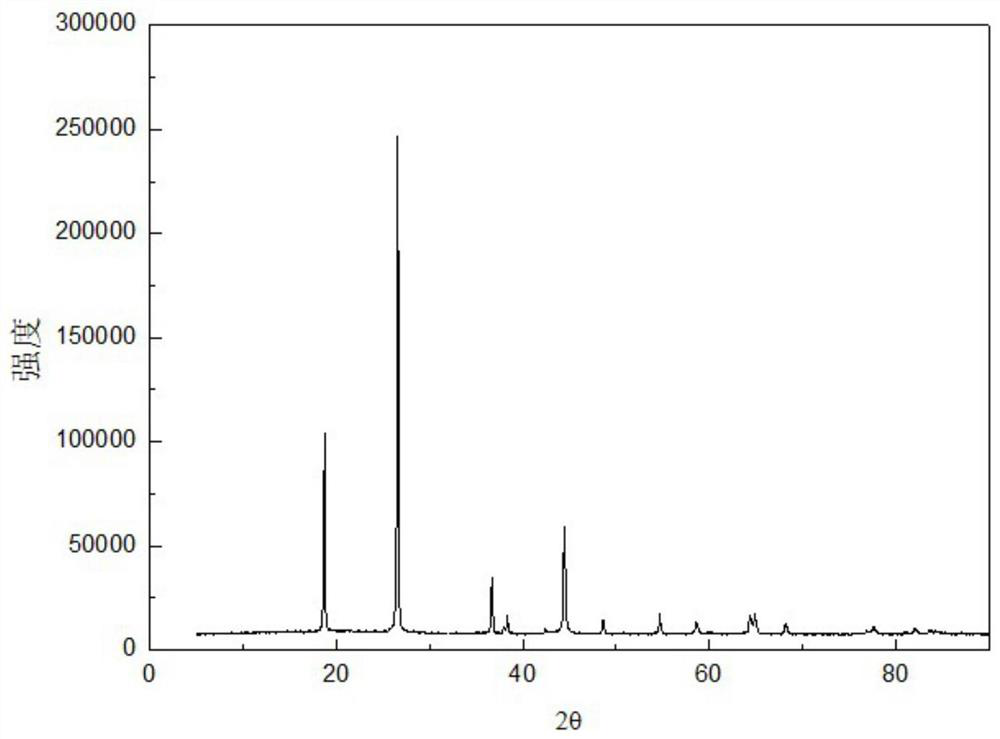

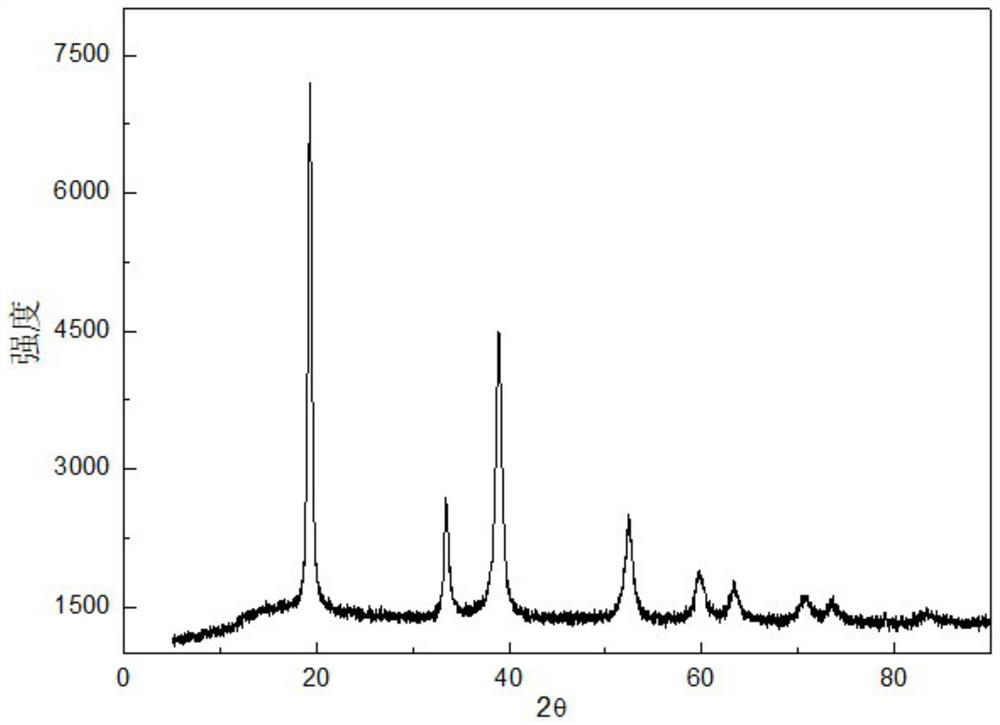

Recycling method of positive and negative mixed materials of waste ternary lithium ion battery

ActiveCN111129632BSimplified disassemblyReduced dismantling timeWaste accumulators reclaimingProcess efficiency improvementElectrical batteryManganate

The invention provides a method for recycling the positive and negative mixed materials of waste ternary lithium-ion batteries, comprising the steps of: disassembling the waste lithium-ion batteries after discharge to obtain mixed powder of nickel-cobalt lithium manganese oxide positive electrode and silicon-carbon negative electrode, battery casing, Copper foil, aluminum foil and diaphragm; the mixed powder and carbonate are ball-milled and then roasted to recover the CO generated during the reaction 2 ; Put the calcined mixture into the dilute alkali solution and filter it, then pass it into CO 2 , the silicon and aluminum in the filtrate are separated, the filter residue is dissolved in acid, and the Li in the filter residue is leached + 、Ni 2+ 、Co 2+ , Mn 2+ and Cu 2+ , after filtering to remove graphite, recover negative electrode material carbon by solid phase method; add sulfide to the leaching solution, adjust the pH value to remove impurity copper, and then prepare nickel-cobalt-manganese hydroxide ternary precursor by co-precipitation method; CO 2 Pass into the filtrate, heat up, concentrate and crystallize to prepare lithium carbonate. The invention has a simple process, can realize the recovery of all components of the nickel-cobalt lithium manganese oxide positive electrode and the silicon-carbon negative electrode mixed material, has low cost, high recovery rate, and the resources can be recycled.

Owner:SHENZHEN QINGYAN EQUIP TECH CO LTD

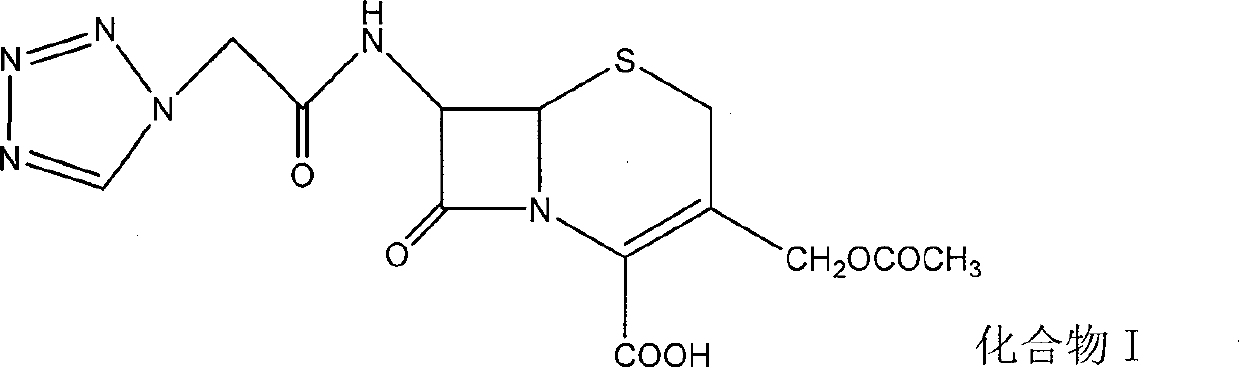

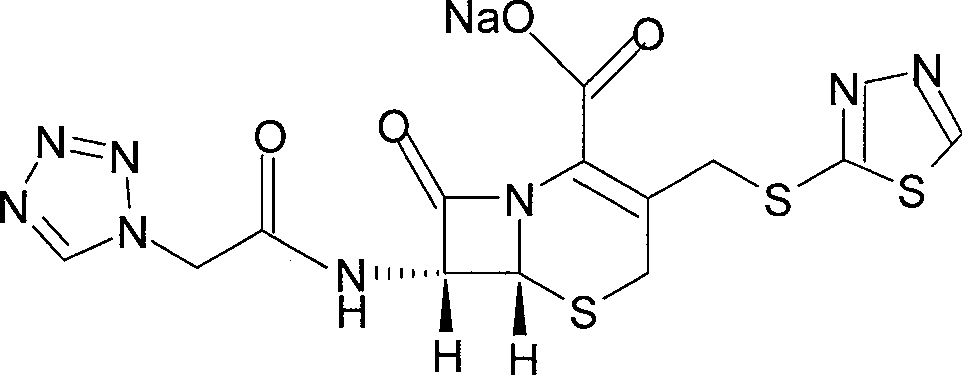

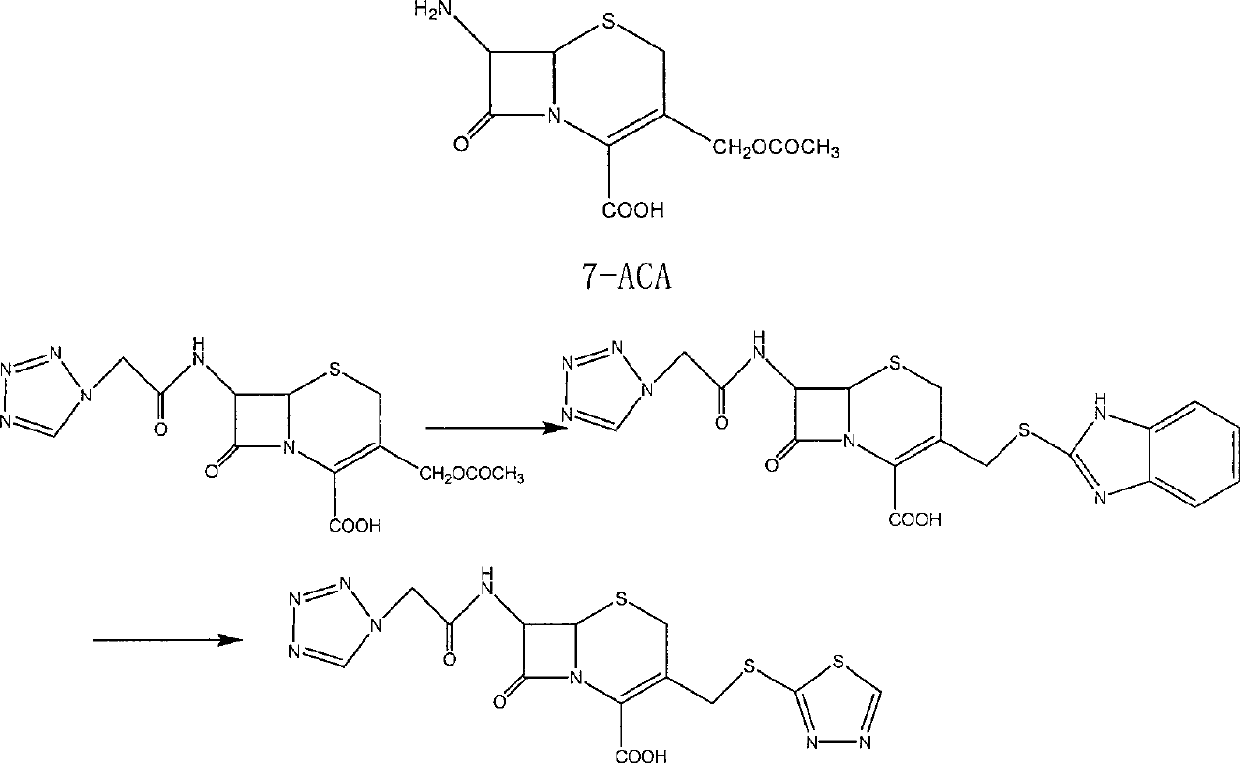

Ceftezole sodium powder injection and synthesizing method thereof

ActiveCN100506210CHigh purityImprove stabilityAntibacterial agentsPowder deliveryCeftezole SodiumReaction intermediate

The invention provides a ceftezole sodium powder injection and a synthesis method thereof. The powder injection is composed of more stable ceftezole sodium crystals. The method reacts tetrazoleacetic acid, N, N'-dicyclohexylcarbodiimide and 7-aminocephalosporanic acid in a ratio of 1.4~1.7:1~1.3:1 in dimethyl sulfoxide, and then The reaction intermediate is reacted with 1.1-1.3 times of thiadiazole mercaptan to prepare ceftezole, and after recrystallization with acetone, ceftezole sodium is prepared in aqueous sodium bicarbonate solution. The method is simple and easy, and the total yield is as high as 55.5%.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD

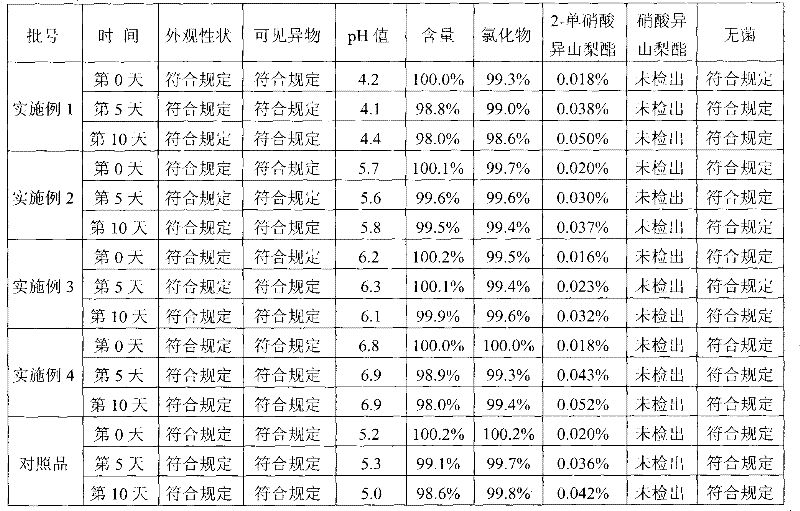

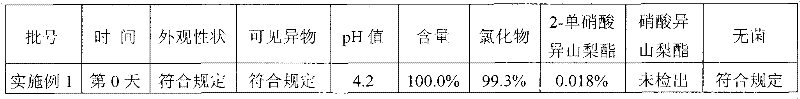

Isosorbide mononitrate sodium chloride injection

ActiveCN101708157BStable and stableImprove stabilityInorganic non-active ingredientsPharmaceutical delivery mechanismSodium Chloride InjectionIsosorbide mononitrate

The invention relates to isosorbide mononitrate sodium chloride injection which belongs to the field of medical preparation. The isosorbide mononitrate sodium chloride injection is prepared from 10-40mg of isosorbide mononitrate, 450-1800mg of sodium chloride, an amount of pH regulator which regulates the pH to 4.0-7.0 and water for injection, wherein the volume of the water for injection is fixed to 100ml. The isosorbide mononitrate sodium chloride injection has high stability and simple preparation process.

Owner:LUNAN PHARMA GROUP CORPORATION

Preparation method of fludioxonil

ActiveCN111285854AMild reaction conditionsHigh yieldOrganic chemistryMethyl isocyanideMethyl benzene

The invention relates to the field of bactericides, and discloses a preparation method of fludioxonil. The preparation method of fludioxonil comprises the following steps: carrying out a first contactreaction on 2,2-difluoro-1,3-benzodioxo-4-aldehyde and cyanoacetate under the catalysis of a first alkali to obtain a product after the first contact reaction, and directly carrying out a second contact reaction on the product after the first contact reaction and tosylmethyl isocyanidee. According to the technical scheme, the preparation method used for obtaining fludioxonil and having the advantages of easiness in industrialization, cheap and easily available raw materials, less three wastes, high reaction yield and high purity can be provided.

Owner:NUTRICHEM LAB CO LTD

Preparation method of fludioxonil

ActiveCN111285854BMild reaction conditionsHigh yieldOrganic chemistryMethyl benzeneBiochemical engineering

Owner:NUTRICHEM LAB CO LTD

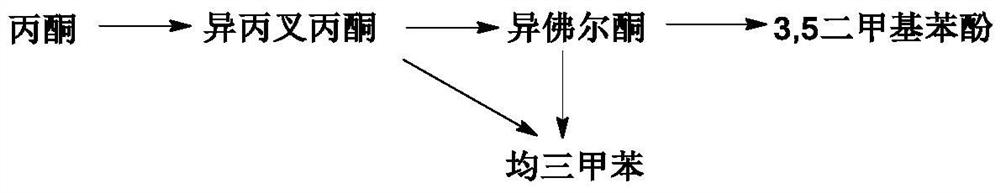

Solid base catalyst for synthesis of 3, 5-dimethylphenol from acetone by vapor phase method, and preparation method and application thereof

PendingCN114534734AHigh catalytic activityHigh selectivityOrganic compound preparationHeterogenous catalyst chemical elementsPtru catalystMethyl benzene

The invention discloses a solid base catalyst for synthesizing 3, 5-dimethylphenol from acetone by using a gas phase method as well as a preparation method and application of the solid base catalyst. The solid base catalyst comprises a ZrO2 / La2O3 composite carrier and active components, namely SrO, CaO and CoO, based on the total mass of the catalyst, the content of the ZrO2 / La2O3 composite carrier is 75-95%, and the content of the La element is 0.1-1%; in the active component, the content of SrO is 1-10%, the content of CaO is 1-10%, and the content of CoO is 0.1-3%. The solid base catalyst is used for catalyzing acetone gas phase synthesis of 3, 5-dimethylphenol, the acetone conversion rate can reach 80-90%, the product selectivity can reach 80-90%, and the carbon deposition amount is small. The process has the advantages of low cost, less carbon deposition, simple product separation, low equipment and material investment and simple three-waste treatment.

Owner:WANHUA CHEM GRP CO LTD

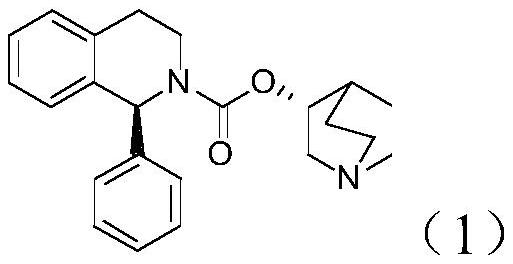

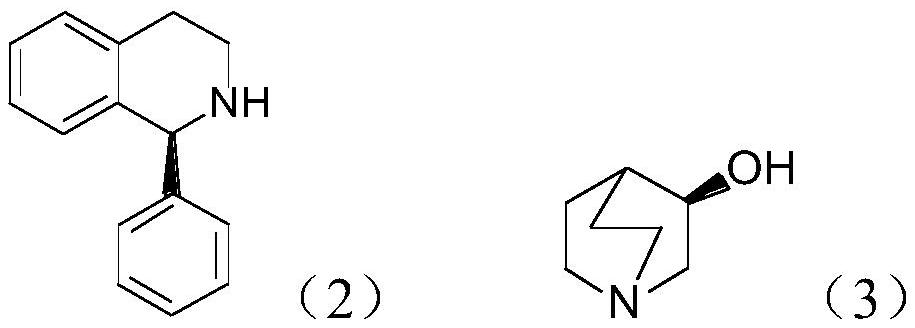

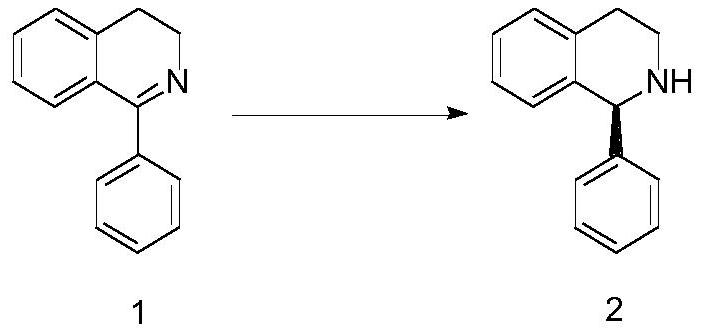

(s) Synthetic method of 1-phenyl-1,2,3,4-tetrahydroisoquinoline

ActiveCN110683986BEasy to separate and purifyHigh chiral purityOrganic chemistry methodsIsoquinolinePtru catalyst

The present invention relates to a kind of synthetic method of (S)1-phenyl-1,2,3,4-tetrahydroisoquinoline, the reaction route of described synthetic method is as follows; Described synthetic method comprises the following steps: 1) making The raw material 1 is dissolved in a solvent, and a base and a catalyst are added; 2) hydrogen gas is used for gas replacement to form a hydrogen atmosphere, and a pressurized reaction is carried out to obtain (S)1-phenyl-1,2,3,4-tetrahydroisoquinoline 2 ; Wherein, the catalyst is a BIAMH system catalyst, a D-BIMAH system catalyst or a P-BIMAH system catalyst.

Owner:ENANTIOTECH CORP +1

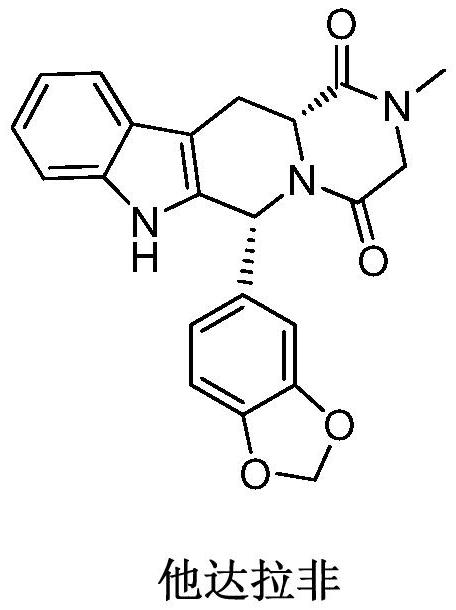

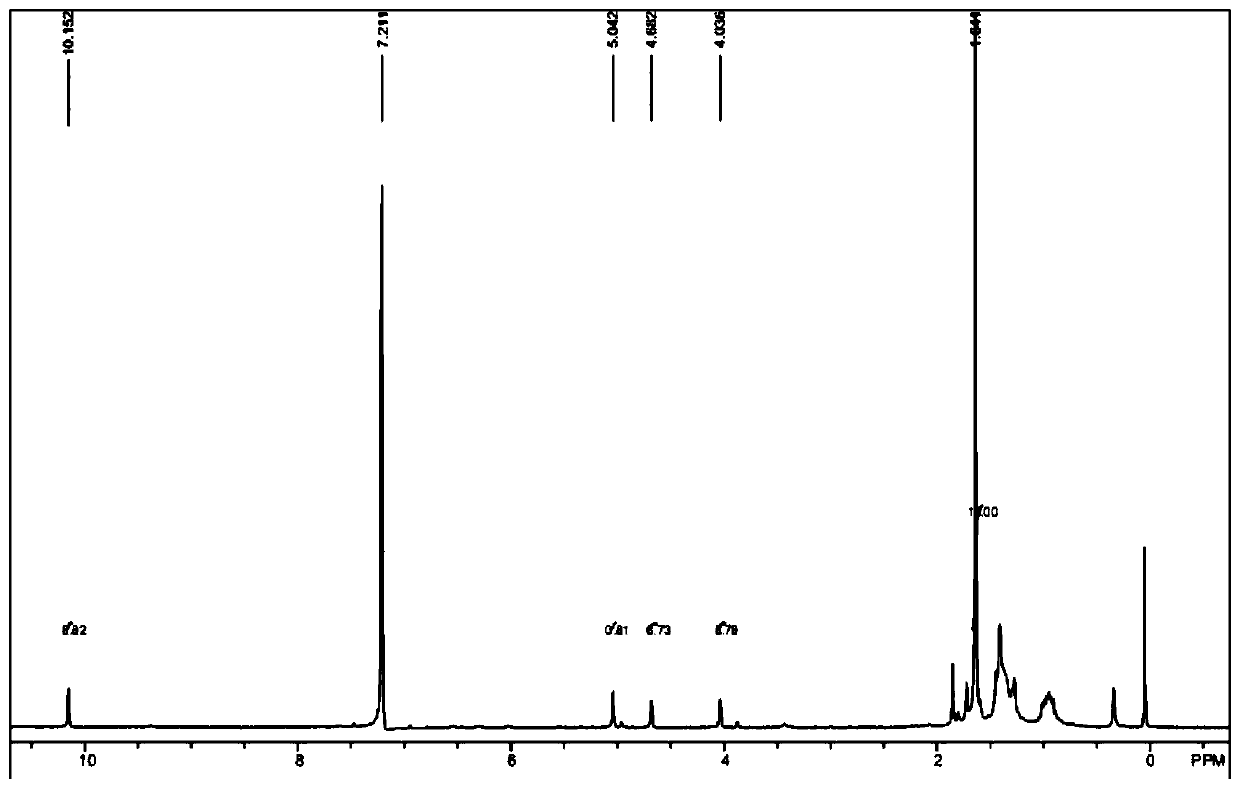

A kind of preparation method of tadala amorphous form I

ActiveCN108299434BAvoid conditions such as reflux (90-110°C)Suitable for industrial productionOrganic chemistry methodsTadalafilPhysical chemistry

The invention provides a preparation method of Tadalafil crystal form I. The preparation method comprises the following steps: dissolving a Tadalafil crude product and SDS (Sodium Dodecyl Sulphate) inacetonitrile water together, and evaporating, decreasing temperature and crystallizing to prepare the Tadalafil crystal form I. According to the preparation method of the Tadalafil crystal form I, the using amount of a solvent is improved from existing 50 to 80 times to 8 to 20 times by introducing the SDS, so that the using amount of an organic solvent is greatly reduced. Moreover, the method provided by the invention is easy to operate, high in yield, short in production period and lower in cost, and is more suitable for industrial production.

Owner:SHANDONG MINGREN FURUIDA PHARMA

New process for producing high-purity iminodiacetonitrile

ActiveCN101914037BImprove conversion rateHigh yieldOrganic compound preparationCarboxylic acid nitrile purification/separationProcess engineeringEnvironmental engineering

The invention relates to a new process for producing high-purity iminodiacetonitrile. The new process is characterized in that: high-purity reaction liquid is obtained by using a process for synthesizing iminodiacetonitrile at high conversion rate; and white or pale yellow high-purity iminodiacetonitrile with iminodiacetonitrile content of over 99 percent is produced by using a synthesis reactionliquid decolorizing process, an impurity removal process and three crystallization processes, wherein a part of thin waste liquid produced during the production is returned to a raw material preparation system, the rest part of waste liquid is conveyed to a biochemical device for processing, and the produced thick waste liquid is directly conveyed to an incinerator for processing, so that pollution-free production of the entire process is realized. The new process has the advantages of high product quality, white color, purity of over 99 percent high product yield, iminodiacetonitrile yield of about 90 percent during the entire production process and low three-waste treatment difficulty.

Owner:SICHUAN LUTIANHUA

A kind of extraction method of 1,5-pentanediamine

ActiveCN107043331BEasy to operateEasy to transportAmino compound purification/separationCalcium hydroxidePhosphate

The invention provides a method of extracting 1,5-pentanediamine from a 1,5-pentanediamine salt solution system. An alkaline compound is added into the 1,5-pentanediamine salt solution system to form a solution system containing free-state 1,5-pentanediamine, and then the solution system containing the free-state 1,5-pentanediamine is distilled / evaporated in a paddle dryer or a rake dryer. The 1,5-pentanediamine salt at least comprises one or more of 1,5-pentanediamine sulfate, carbonate and phosphate. The alkaline compound at least comprises solid-state calcium hydrate, magnesium hydroxide, calcium oxide and magnesium oxide. The method is high in practicality, simple and convenient to operate and environmentally friendly, and obviously reduces the raw material cost and operation cost of the whole process. The 1,5-pentanediamine recovery rate of the method is high. The method is environmentally friendly and more suitable for industrial production.

Owner:CATHAY R&D CENT CO LTD +2

Synthetic method of nitrogen-containing heterocyclic ferrocene derivatives

The invention relates to a synthesis method of a nitrogen-containing heterocycles ferrocene derivative. The synthesis method comprises the following steps of (I) introducing an aldehyde group into nitrogen-containing heterocycles in the chemical structure of a raw material a to obtain an intermediate b; (II) performing a hydroxylamine reaction on the aldehyde group in the chemical architecture ofan intermediate b to obtain a hydroxylamine group namely an intermediate c; and (III), performing a reduction reaction on the hydroxylamine group in the chemical architecture of the intermediate c, toobtain the nitrogen-containing heterocycles ferrocene derivative 1. The synthesis method is simple in steps, reagents and equipment which have risks for human bodies or environment do not need to beadopted, and mass production and application of the nitrogen-containing heterocycles ferrocene derivative are convenient.

Owner:FOSHAN ENANTIOSIC CORP LTD +1

Cephaene onium salt compound and its preparation, and synthesis of cephapyrazde sulfate therefrom

This invention relates to cephalene onium salt compound and its preparation and synthesis of cephapyrazole sulfate therefrom. It is produced from 7beta-alkyl amido-3-[3-alkyl amido-2-(2-alkyl acyl oxethyl)-1-pyrazole onium group]methyl-3-cephalene- 4-carboxylic salt as intermediate by hydrolyzing it and reacting with alpha-(2-amino thiazole-4-radicle)-alpha-(Z)-methoxy imino acetic acid(benzo thiazole-2-radicle)hydrosulfate. The reacting condition is moderate, its raw materials can be obtained easily, and no expensive and strong irritant reagent is needed.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

The preparation method of triazine ring

The invention belongs to the technical field of medicine, and in particular relates to a preparation method of a triazine ring. 2‑Methylthiosemicarbazide, diethyl oxalate, dimethylaminopyridine and metal sodium carry out ring closure reaction, after the ring closure reaction is completed, hydrochloric acid is added to carry out crystallization reaction to obtain the crude product of triazine ring sodium salt, triazine ring sodium salt Hydrochloric acid was added to the crude product for refining reaction to obtain a triazine ring. The invention has simple raw materials, high yield, easy handling and low cost.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com