Preparation method of fludioxonil

A fludioxonil and contact reaction technology, applied in the field of fungicides, can solve the problems of low yield and purity, high cost, rare raw materials and the like, and achieve the effects of high yield, less three wastes, and easy treatment of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

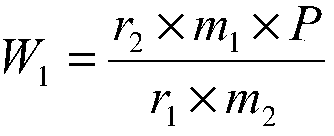

[0029] The invention provides a method for preparing fludioxonil, the method comprising: under the catalysis of the first base, 2,2-difluoro-1,3-benzodiox-4-aldehyde and cyanoacetate The step of obtaining the product after the first contact reaction through the first contact reaction, and the step of directly performing the second contact reaction with the obtained product after the first contact reaction with p-toluenesulfonylmethyl isonitrile.

[0030] According to the present invention, the product after the first contact reaction obtained by the first contact reaction is directly subjected to the second contact reaction with p-toluenesulfonylmethylisonitrile, so that the reaction can be carried out in a one-pot method. Moreover, because the preparation method of fludioxonil of the present invention has the characteristics of mild reaction conditions, high yield, less waste, and simplicity, it is very suitable for industrial production.

[0031] According to the present inv...

Embodiment 1

[0061] 5g of 2,2-difluoro-1,3-benzodiox-4-aldehyde (purity is 99% by weight, prepared according to the method in Example 2 of US5194628, the same below), catalytic amount of triethylamine and 23g Methanol is placed in the reaction bottle, and the pH is about 9.5 at this time, 2.66g methyl cyanoacetate (purity is 99% by weight) is added dropwise at room temperature for 1 hour, after the addition is completed, the reaction is stirred and reacted at room temperature for 6 hours, and the control is carried out during sampling. Finished, the normalized content of the main product was 98%, cooled to 0-5°C, added 5.3g of TosMIC (purity is 98% by weight), kept 0-10°C, added dropwise 2.1eq.21% by weight potassium hydroxide methanol solution ( 15.2g). After 1 hour of dripping, the dropwise addition is completed, the heat preservation reaction is carried out for 2 hours, the sample is controlled in the middle, and the reaction is completed, 5% by weight of dilute hydrochloric acid is add...

Embodiment 2

[0064] A trace of 21% by weight of potassium hydroxide methanol solution and 23g of methanol were placed in the reaction flask, and the pH was about 8.5 at this time, and 5g of 2,2-difluoro-1,3-benzodiox-4-aldehyde (purity of 99 % by weight), at room temperature, 2.66g methyl cyanoacetate (purity is 99% by weight) was added dropwise in 1 hour, after the dropwise addition was completed, the reaction was stirred and reacted at room temperature for 6 hours, and in the control of sampling, 0.04g methyl cyanoacetate was added, Stir the reaction for 2 hours, take a sample and control it, the reaction is completed, the normalized content of the main product is 98%, cool down to 0-5°C, add 5.3g of TosMIC (purity is 98% by weight), keep 0-10°C, add dropwise 1.8eq .21% by weight potassium hydroxide in methanol (12.9 g). After 1 hour of dripping, the dropping is completed, the reaction is kept for 2 hours, the sampling is controlled, and the reaction is completed, 5% by weight of dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com