New process for producing high-purity iminodiacetonitrile

A high-purity technology of iminodiacetonitrile, applied in the field of producing high-purity iminodiacetonitrile, can solve the problems of long residence time, waste, low product purity, etc., achieve high conversion rate, increase product yield, iminodiacetonitrile The effect of high yield of acetonitrile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

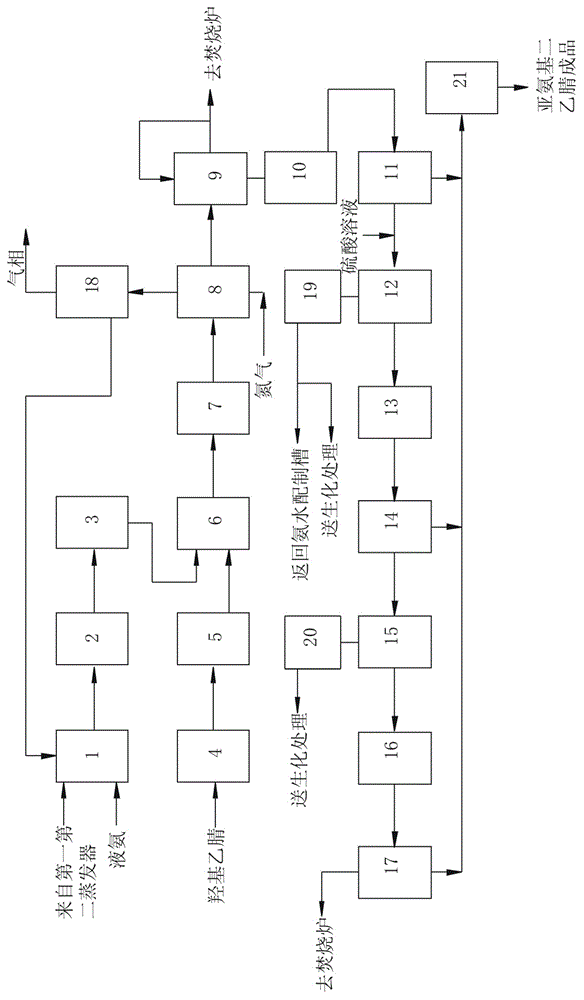

Image

Examples

Embodiment 1

[0069] A 20,000-ton / year iminodiacetonitrile industrial plant. Run according to the scheme provided by the present invention, its operation parameter and index control are as follows:

[0070] The flash condenser 18, the first evaporator condenser 19, and the condensed water produced by the second evaporator condenser 20 total 5660kg / h, wherein 1639kg / h condensed water is pumped to the ammonia preparation tank 1, and 555kg / h The liquid ammonia with a purity of 99.5% is mixed to generate 2194kg / h of dilute ammonia water, and the concentration of the ammonia water is 25.3% after testing. After being metered by the ammonia water metering pump 3, it enters the ammonia water preheater 4 and is preheated to 90~120°C with a pressure of 0.8MPa. 50% raw material hydroxyacetonitrile with a pH of 2.0~3.0 adjusted by ammonium phosphate buffer solution or ammonium sulfate buffer solution 7407kg / h Hydroxyacetonitrile metering pump controlled by automatic feeding system 4 According to hydro...

Embodiment 2

[0081] In the same set of equipment, the reaction liquid purification and decolorization process is changed to activated carbon adsorption decolorization, and the other processes remain unchanged. Assess the output in 1 hour:

[0082] The white iminodiacetonitrile product with a purity of 99% is 2718kg / h, calculated in terms of hydroxyacetonitrile, and the total yield is 87.2%.

[0083] Send 4880kg / h of dilute waste liquid for biochemical treatment.

[0084] The concentrated waste liquid sent to the incinerator for treatment is 175kg / h in total.

[0085] Consumption specific surface area 600m 2 / g activated carbon 100kg / h.

Embodiment 3

[0087] In the same set of equipment, the reaction solution purification and decolorization process is changed to ion exchange resin decolorization, and other processes remain unchanged. Assess the output in 1 hour:

[0088] The white iminodiacetonitrile product with a purity of 99% is 2685kg / h, and the total yield is 86.0% based on hydroxyacetonitrile.

[0089] Send 4980kg / h of dilute waste liquid for biochemical treatment.

[0090] A total of 165kg / h of concentrated waste liquid will be sent to the incinerator for treatment.

[0091] Consumption of waste water treatment resin 500kg / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com