Method of removing vanadium from titanium tetrachloride by aluminum powder as direct reducer

A technology of titanium tetrachloride and reducing agent, applied in titanium halide and other directions, can solve problems such as troublesome and difficult transportation and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

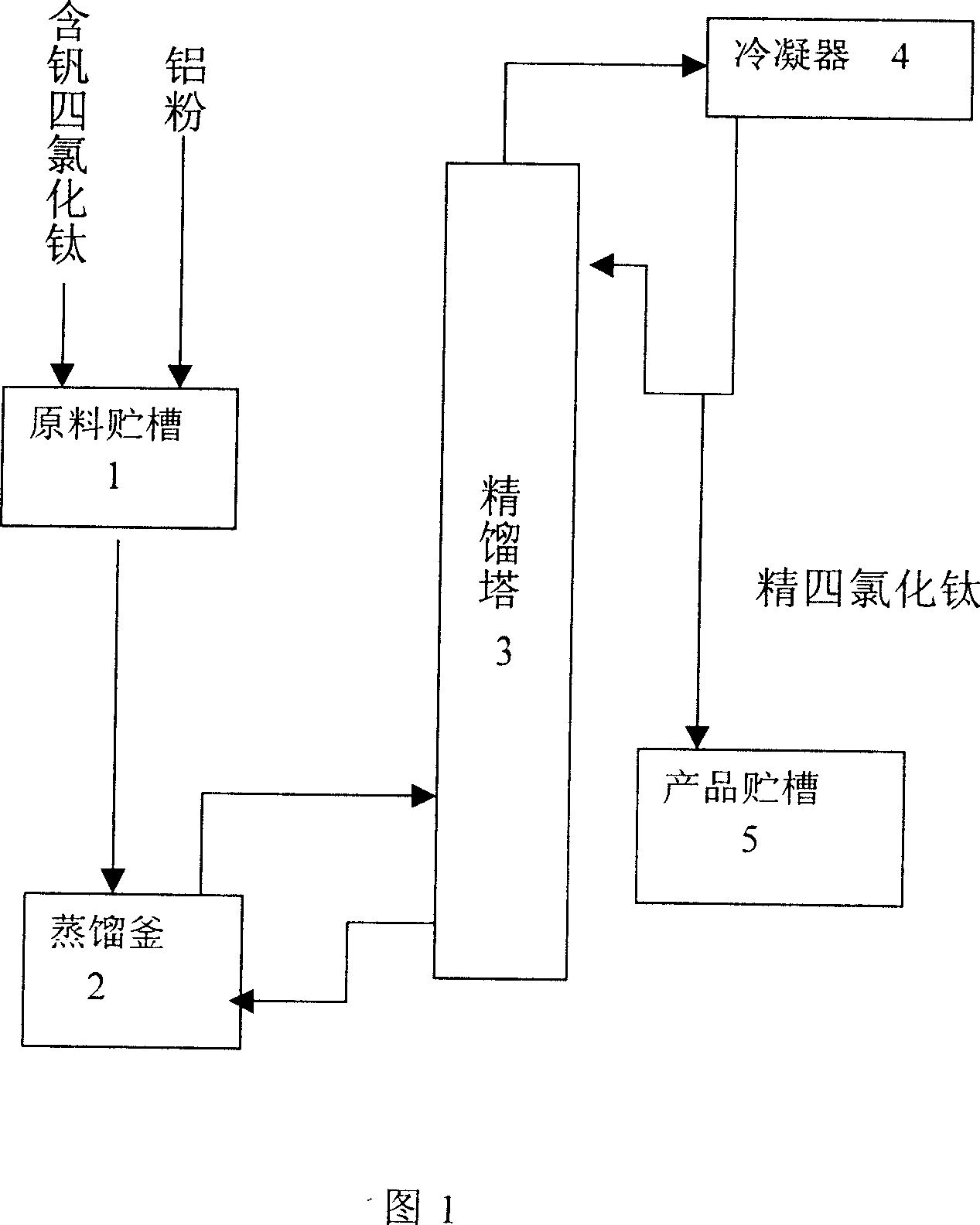

Image

Examples

Embodiment 1

[0028]Add 5kg of spherical aluminum powder with an average particle diameter of 80 μm into a closed surface activation processor, add 0.2 kg of stearic acid, and mechanically grind for 6 hours under the protection of an argon atmosphere to obtain 5.2 kg of flake aluminum powder with an average particle diameter of 40 μm, wherein Contains 3.6% surfactant

Embodiment 2

[0030] In a reactor with a condensing reflux device, titanium tetrachloride containing vanadium impurities (where VOCl 3 0.10%) 500g, anhydrous AlCl 3 3 g and 250 mg of surface-activated aluminum powder (average particle size 40 μm) were mixed, the mixture was heated to boiling (137° C. to 138° C.), and kept in a boiling reflux state for 30 minutes. After the vanadium removal reaction was completed, the reaction mixture was settled and cooled to 0°C, and the upper clear liquid 250ml and the underflow (containing AlCl 3 and VOCl 2 ) 40ml, after analysis the supernatant liquid V content is 3ppm.

Embodiment 3

[0032] In a reactor with a condensing reflux device, titanium tetrachloride containing vanadium impurities (where VOCl 3 0.10%) 500g, 40ml of underflow separated in Example 2 and 100mg of surface-activated aluminum powder (average particle diameter 40 μm) were mixed, and the mixture was heated to boiling (137°C-139°C), and kept in a boiling reflux state for 30 minutes. After the vanadium removal reaction was completed, the reaction mixture was settled and cooled to 0°C, and the upper clear liquid 280ml and the underflow (containing AlCl 3 and VOCl 2 ) 50ml, after analysis the supernatant liquid V content is 3.5ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com