New process for producing high-purity iminodiacetonitrile

A technology of iminodiacetonitrile and a new process, which is applied in the field of producing high-purity iminodiacetonitrile, can solve the problems of sharp decline in product quality, increase in three waste treatment costs, high impurity content in mother liquor, etc., and achieve good product quality, high conversion rate, The effect of simple ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

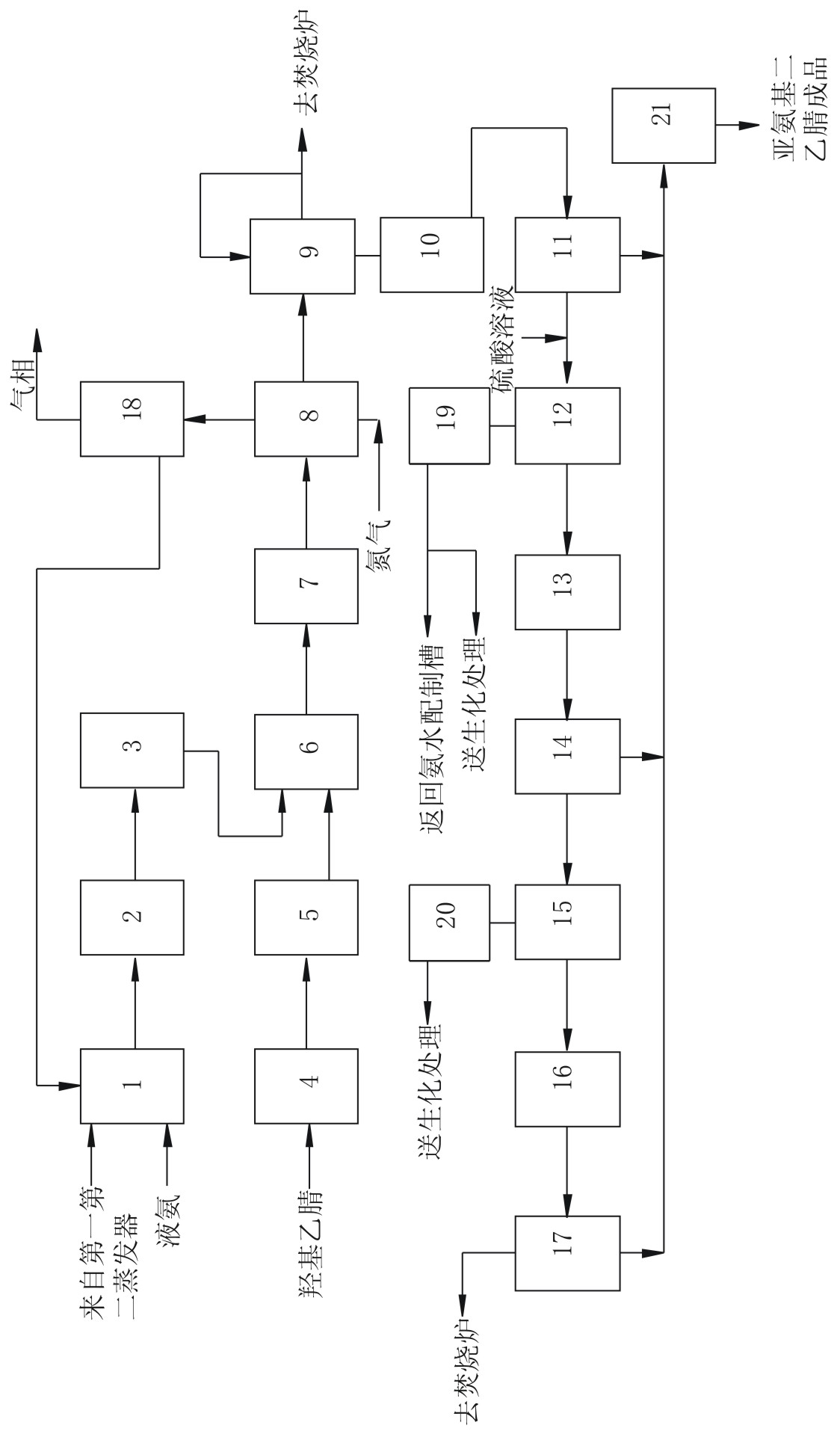

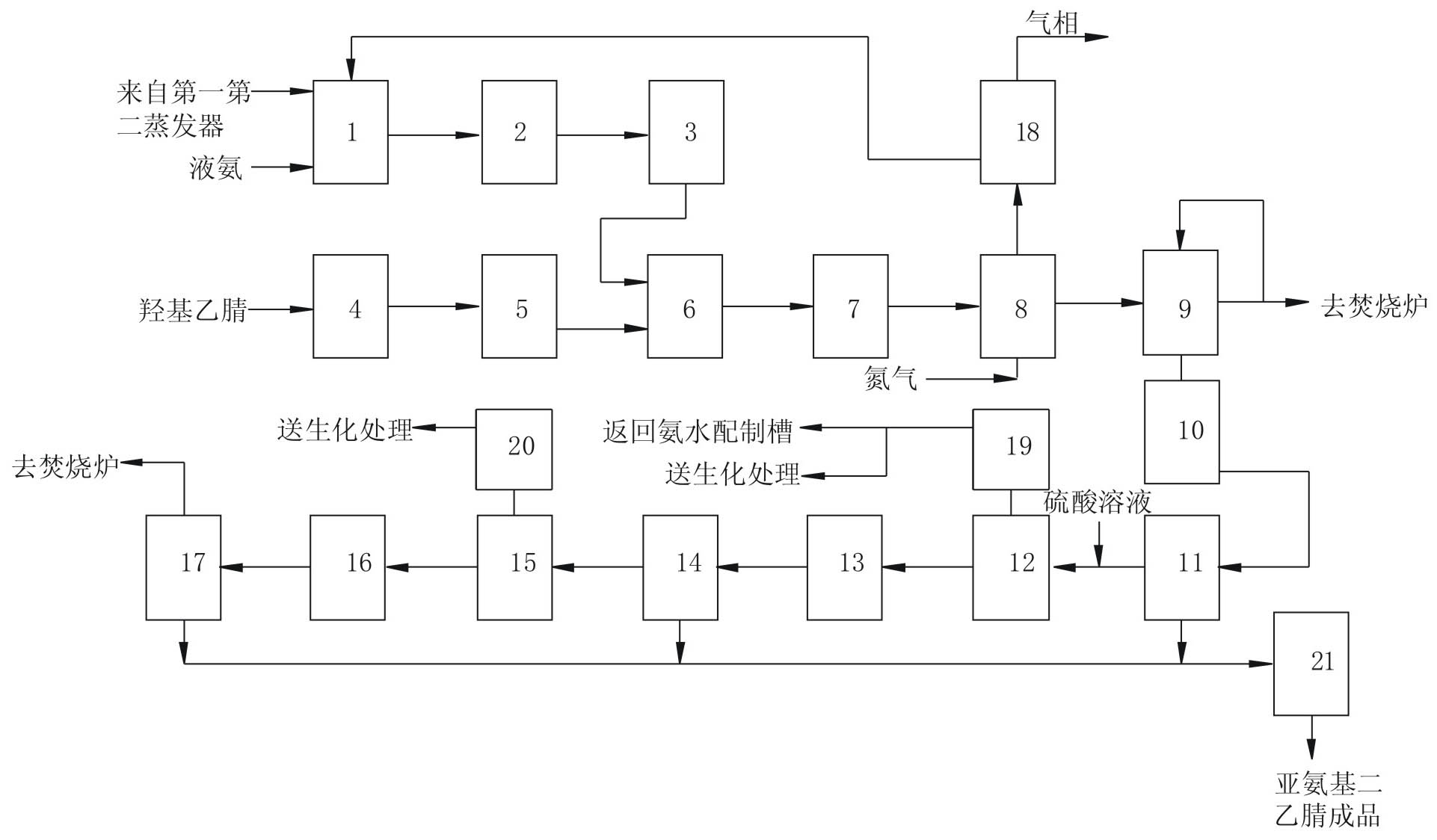

Image

Examples

Embodiment 1

[0069] A 20,000-ton / year iminodiacetonitrile industrial plant. Run according to the scheme provided by the present invention, its operation parameter and index control are as follows:

[0070] The flash condenser 18, the first evaporator condenser 19, and the condensed water produced by the second evaporator condenser 20 total 5660kg / h, wherein 1639kg / h condensed water is pumped to the ammonia preparation tank 1, and 555kg / h The liquid ammonia with a purity of 99.5% is mixed to generate 2194kg / h of dilute ammonia water, and the concentration of the ammonia water is 25.3% after testing. After being metered by the ammonia water metering pump 3, it enters the ammonia water preheater 4 and is preheated to 90~120°C with a pressure of 0.8MPa. 50% raw material hydroxyacetonitrile with a pH of 2.0~3.0 adjusted by ammonium phosphate buffer solution or ammonium sulfate buffer solution 7407kg / h Hydroxyacetonitrile metering pump controlled by automatic feeding system 4 According to hydro...

Embodiment 2

[0081] In the same set of equipment, the reaction liquid purification and decolorization process is changed to activated carbon adsorption decolorization, and the other processes remain unchanged. Assess the output in 1 hour:

[0082]The white iminodiacetonitrile product with a purity of 99% is 2718kg / h, calculated in terms of hydroxyacetonitrile, and the total yield is 87.2%.

[0083] Send 4880kg / h of dilute waste liquid for biochemical treatment.

[0084] The concentrated waste liquid sent to the incinerator for treatment is 175kg / h in total.

[0085] Consumption specific surface area 600m2 / g activated carbon 100kg / h.

Embodiment 3

[0087] In the same set of equipment, the reaction solution purification and decolorization process is changed to ion exchange resin decolorization, and other processes remain unchanged. Assess the output in 1 hour:

[0088] The white iminodiacetonitrile product with a purity of 99% is 2685kg / h, and the total yield is 86.0% based on hydroxyacetonitrile.

[0089] Send 4980kg / h of dilute waste liquid for biochemical treatment.

[0090] A total of 165kg / h of concentrated waste liquid will be sent to the incinerator for treatment.

[0091] Consumption of waste water treatment resin 500kg / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com