Method for removing vanadium in titanium tetrachloride

A technology of titanium tetrachloride and titanium trichloride, applied in titanium halide and other directions, can solve the problems of flying into the air, aluminum powder is expensive, easy to burn, etc., and achieves the effect of improving equipment production capacity, low cost, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

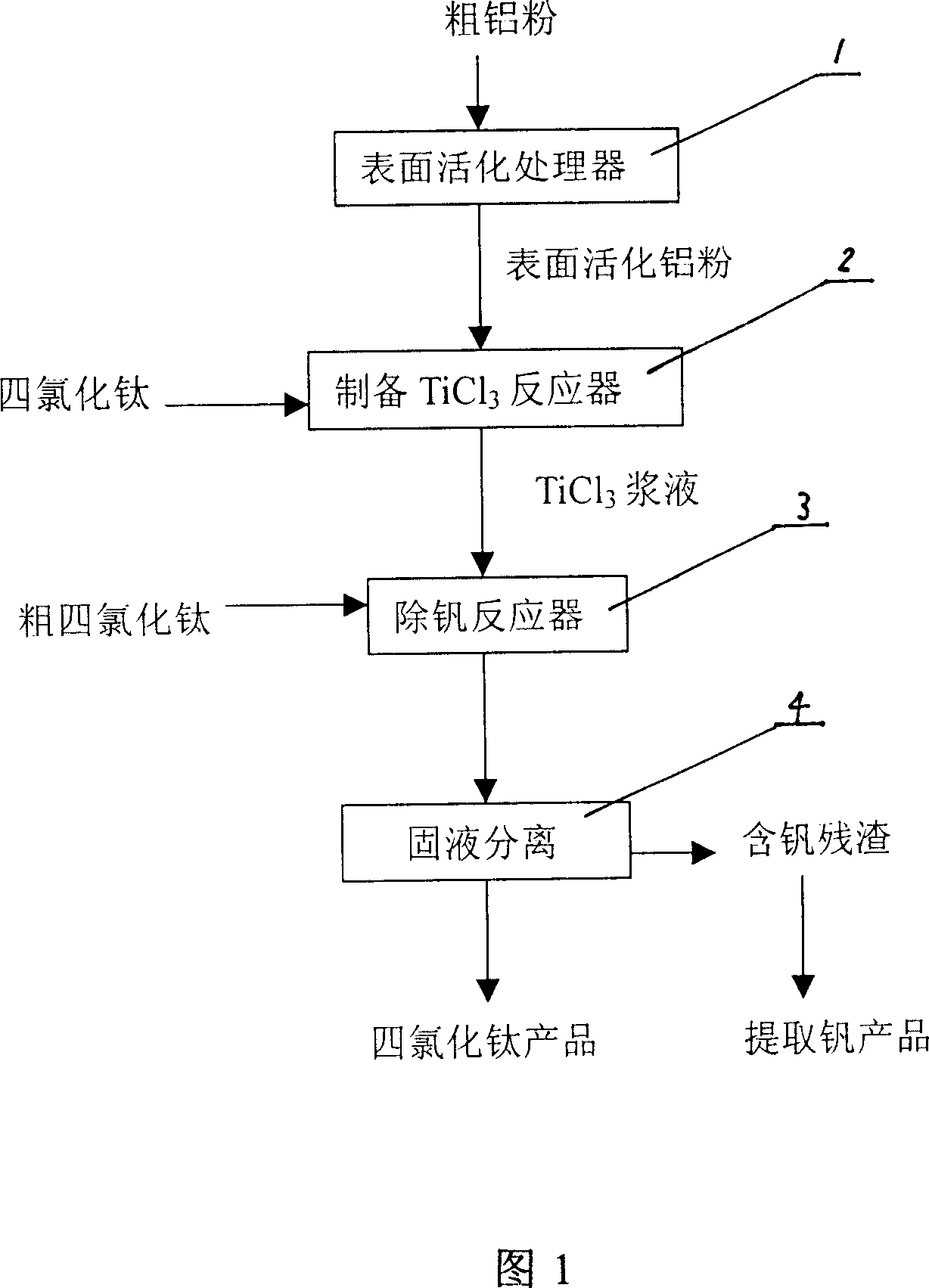

Image

Examples

Embodiment 1

[0028] 10kg of spherical coarse aluminum powder with an average particle diameter of 142 μm was added to the surface activation processor, 20 kg of gasoline and 0.4 kg of stearic acid were added, mechanically ground for 5 hours under airtight conditions, and most of the surface active agents were removed by evaporation after grinding to obtain 10.2 kg flake aluminum powder with an average particle size of 110 μm, containing 1.5% surfactant.

Embodiment 2

[0030] Add 10kg of spherical coarse aluminum powder with an average particle size of 125μm into the surface activation processor, add 10kg of gasoline and 0.5kg of mineral oil, and mechanically grind for 7 hours under airtight conditions. After grinding, use evaporation to remove most of the surface active agent to obtain 10.2kg Flaky aluminum powder with an average particle size of 102 μm, containing 2.5% surfactant.

Embodiment 3

[0032] In 1000gTiCl 4 Add 7g AlCl to 3 and 10 g of surface-activated aluminum powder (average particle size: 110 μm), mix uniformly under mechanical stirring and heat to boiling (135° C. to 137° C.), and keep the reaction temperature for 1.5 h. The reaction produces a reddish-purple solid. After analysis, the finally formed titanium tetrachloride liquid contains TiCl in the slurry of solid titanium trichloride and aluminum trichloride (referred to as titanium trichloride slurry). 3 Content 12.6% (weight%), AlCl 3 Content 4.3% (weight %). The calculated reaction utilization rate of the aluminum powder is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com