A kind of extraction method of 1,5-pentanediamine

A technology of pentamethylenediamine and pentamethylenediamine salt, which is applied in the field of extracting 1,5-pentanediamine, can solve the problems of high cost, low recovery rate, complicated process, etc., and achieve improved conversion rate, increased yield, and simplified process The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

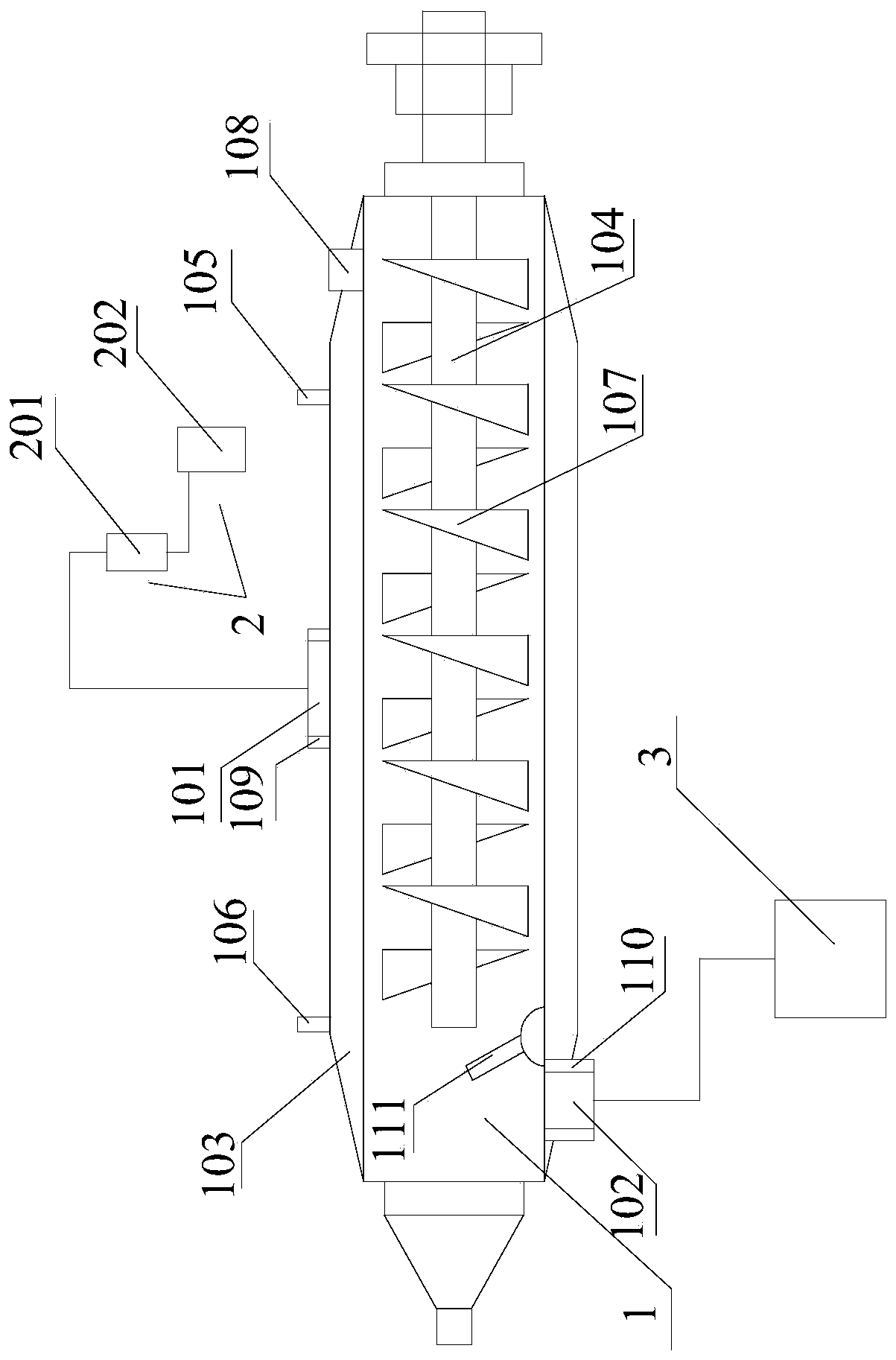

[0093] The 1,5-pentanediamine concentration of 1,5-pentamethylenediamine was determined to be 15.1% in the concentrated solution of 1,5-pentamethylenediamine sulfatase conversion liquid with 1000 kg of lysine decarboxylase cells. Add 110kg of calcium oxide powder (content above 95%), control the temperature at about 90°C, stir thoroughly for 180 minutes, and then gradually send the resulting mixed solution system into figure 1 The combination of pentamethylenediamine extraction devices shown in the figure has a rotating speed of 20rpm, a vacuum degree of -0.09~-0.08Mpa is controlled, a heat conduction oil temperature is 200°C, and evaporated gas condensate is collected. The final yield of 1,5-pentanediamine was 95.6%, and loose solid powder remained in the paddle vacuum drying device without agglomeration and wall formation.

Embodiment 2

[0095] The 1,5-pentanediamine concentration of 600kg of the 1,5-pentanediamine carbonatase conversion liquid concentrate with lysine decarboxylase cells was determined to be 25%. Add 102kg of calcium oxide powder (content above 95%), control the temperature at 80-90°C, fully stir for 120 minutes, then gradually send the resulting mixed solution system into a rake-type vacuum dryer (ZPG-1000) to heat, stir and evaporate at a speed of 12rpm , control the vacuum degree -0.095~-0.09Mpa, the temperature of the material in the barrel is 170°C±10°C, and collect the evaporated gas condensate. The final yield of 1,5-pentanediamine was 93.9%. Loose solid powder remains in the rake vacuum dryer without agglomeration and wall formation.

Embodiment 3

[0097] The mixed solution of 600kg 1,5-pentamethylenediamine phosphate and 1,5-pentamethylenediamine hydrochloride enzymatic conversion solution (the molar ratio of pentamethylenediamine contained in the two salts is 1:1), and the determination of 1,5 - Total concentration of pentamethylenediamine 31%. According to the effective molar concentration of 1,5-pentamethylenediamine and magnesium hydroxide 1:1.1, add magnesium hydroxide powder (content above 98%), control the temperature at 80-90°C, stir thoroughly for 120 minutes, and then gradually mix the obtained mixed solution system feed into figure 1 The combination of pentamethylenediamine extraction devices shown, the speed is 15rpm, the vacuum degree is controlled to -0.095Mpa, the temperature of the material in the barrel is 170°C±10°C, and the evaporated gas condensate is collected. The final yield of 1,5-pentanediamine was 92%, and loose solid powder remained in the rake vacuum dryer without agglomeration and wall form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com