Preparation method of 3-mercaptopropionic acid

A technology of mercaptopropionic acid and sodium acrylate, which is applied in the fields of mercaptan preparation, thioether preparation, organic chemistry, etc., can solve the problems of difficult acquisition of 3-chloropropionic acid, difficult treatment of waste water or waste liquid, and high equipment requirements, and achieves high yield The efficiency and cracking efficiency are improved, the yield and purity are improved, and the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

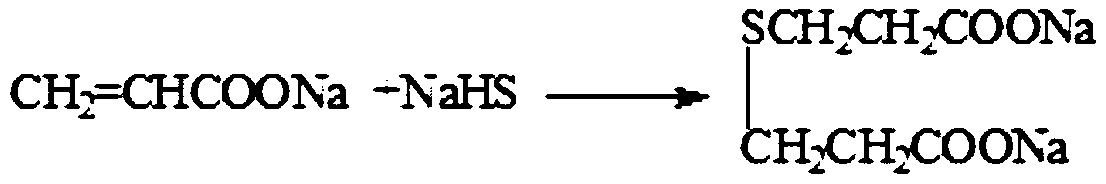

Method used

Image

Examples

Embodiment 1

[0054] Add 1mol sodium acrylate and 0.8mol sodium sulfide to a 500mL four-necked bottle, add water and stir to dissolve, react at 50°C for 1h, and the reaction pressure is 0.2MPa;

[0055] Add 0.6mol of sodium sulfide and 0.02mol of sulfur powder, raise the temperature to 100°C, and the reaction pressure is 0.2MPa, and continue to react for 1h;

[0056] After the reaction is completed, cool, crystallize, add 1mol sulfuric acid to the crystals after suction filtration, and acidify the crystals. The acidification temperature is 60°C, and the acidification time is 1.5h to obtain a solution of 3-mercaptopropionic acid; After washing the crystals, dry them to obtain sodium sulfate crystals, which can be used as industrial products;

[0057] Add chlorobenzene to the solution of the obtained 3-mercaptopropionic acid for extraction, reclaim the organic phase, and carry out vacuum distillation to the organic phase; the former fraction is the reclaimed solvent which can be extracted and...

Embodiment 2

[0060] Add 1mol sodium acrylate and 0.2mol sodium hydrosulfide to a 500mL four-necked flask, add water and stir to dissolve, react at 50°C for 1 hour, and the reaction pressure is 0.15MPa;

[0061] Add 1.2mol of sodium sulfide and 0.01mol of sulfur powder, raise the temperature to 110°C, and the reaction pressure is 0.15MPa, and continue to react for 1h;

[0062] After the reaction is completed, cool and crystallize, add 1 mol of sulfuric acid to the crystals for acidification after suction filtration, the acidification temperature is 60°C, and the acidification time is 1h to obtain a solution of 3-mercaptopropionic acid;

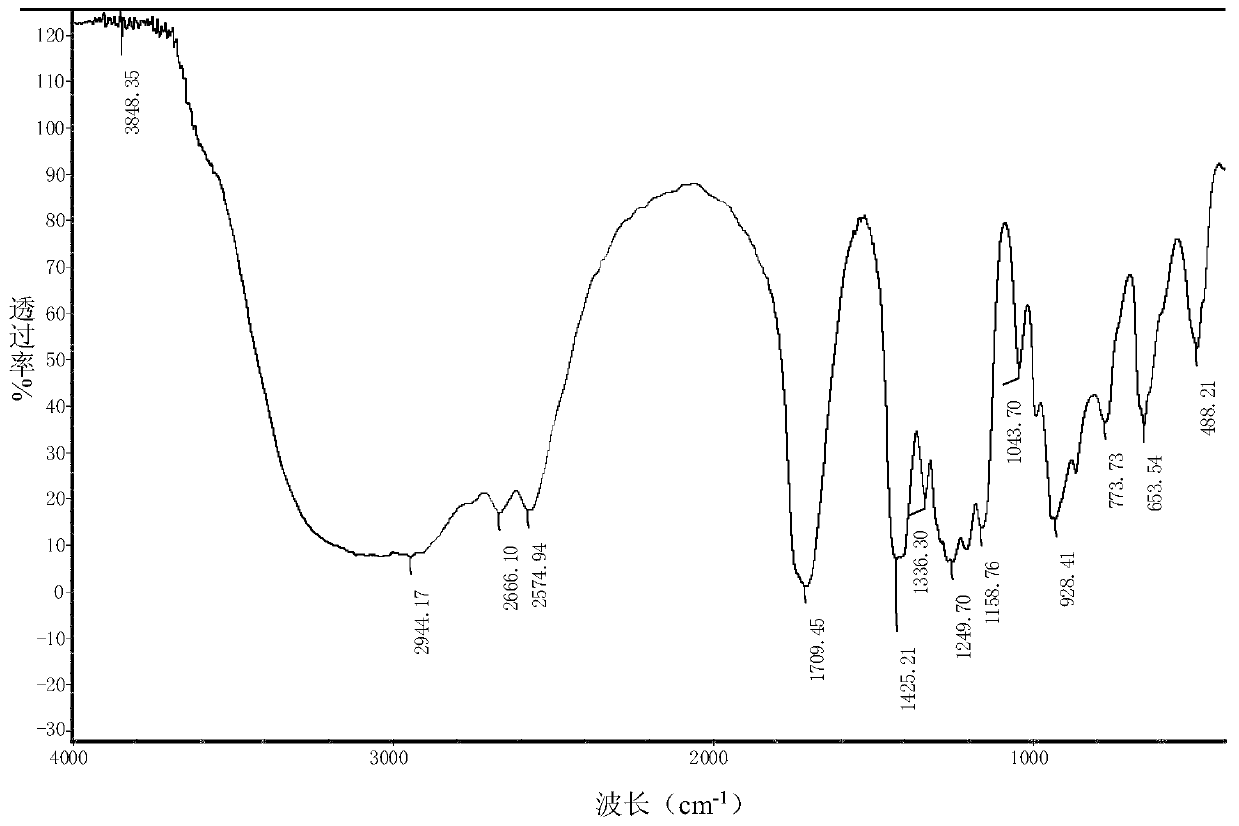

[0063] Add toluene to the solution of the obtained 3-mercaptopropionic acid for extraction, reclaim the organic phase, and carry out vacuum distillation to the organic phase to obtain a colorless liquid, i.e. 3-mercaptopropionic acid; its purity is 99.5%, and its refractive index is 1.492; its infrared spectrum is shown in figure 1 , you can know by compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com