Patents

Literature

96 results about "Melibionic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melibionic acid is a disaccharide consisting alpha-D-galactosyl and D-gluconic acid residues joined by a (1->6)-linkage. It is a carbohydrate acid and a disaccharide. It derives from a melibiose.

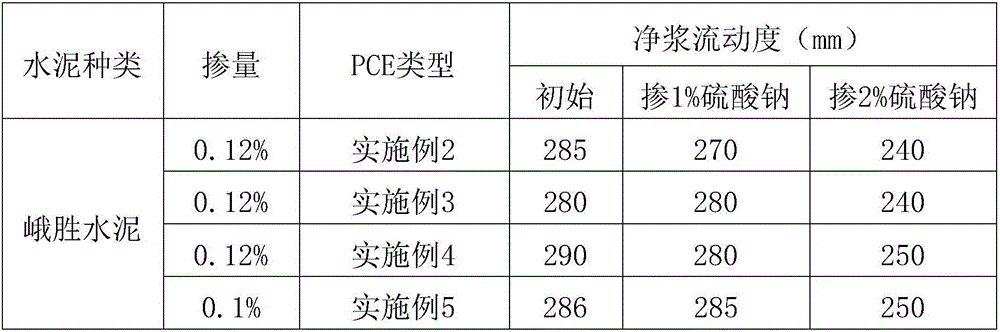

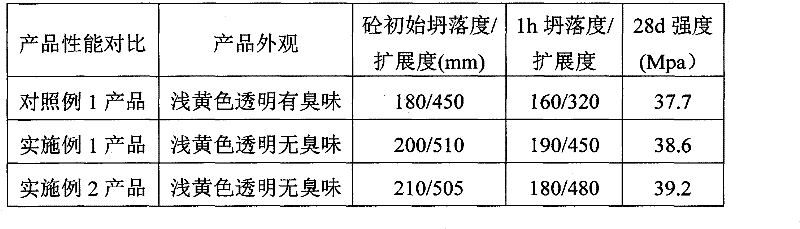

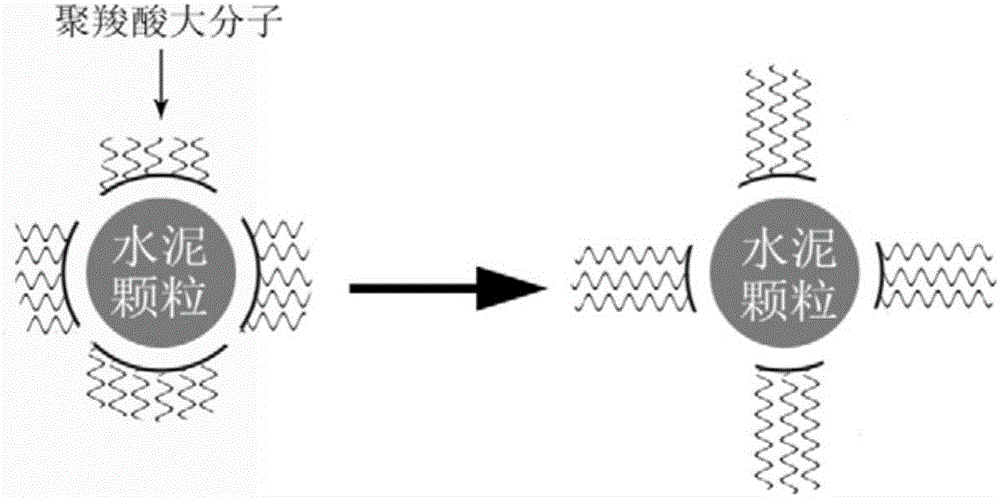

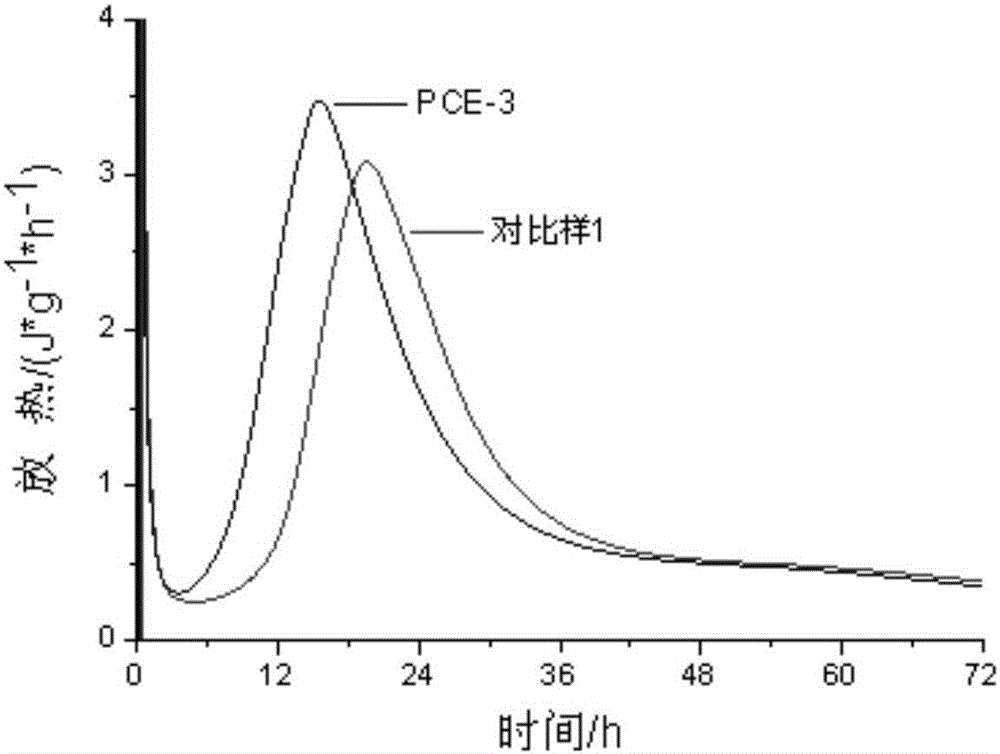

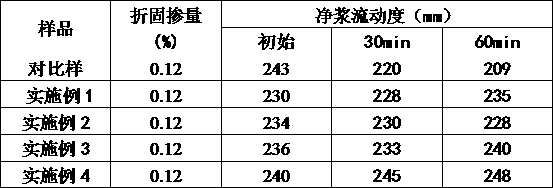

Phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and preparation method thereof

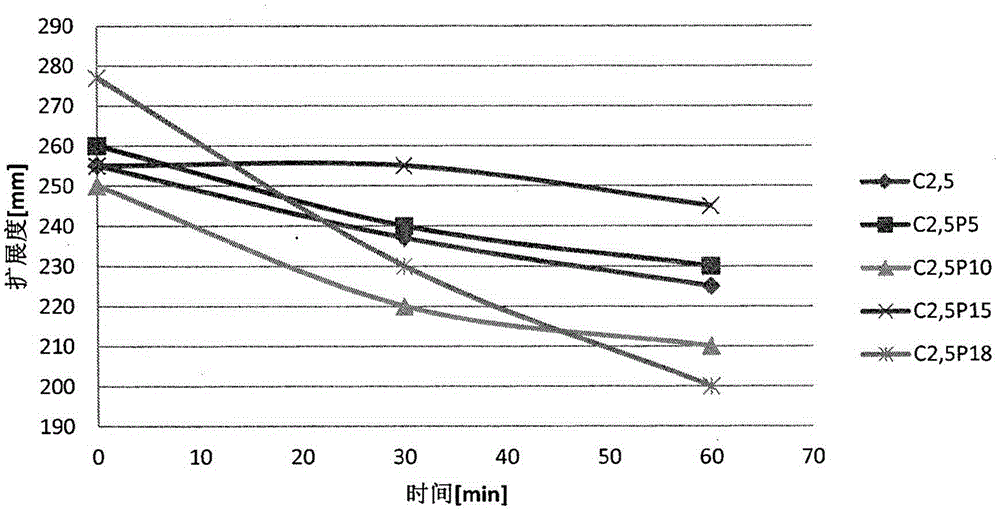

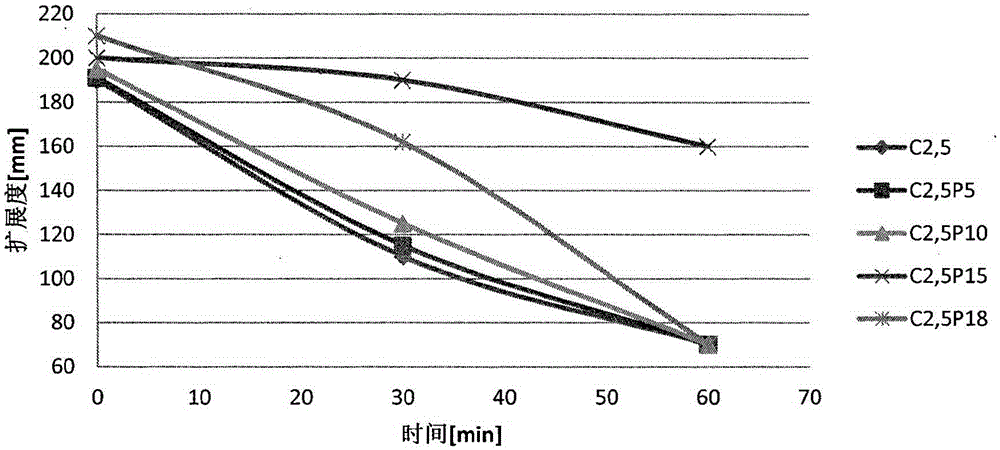

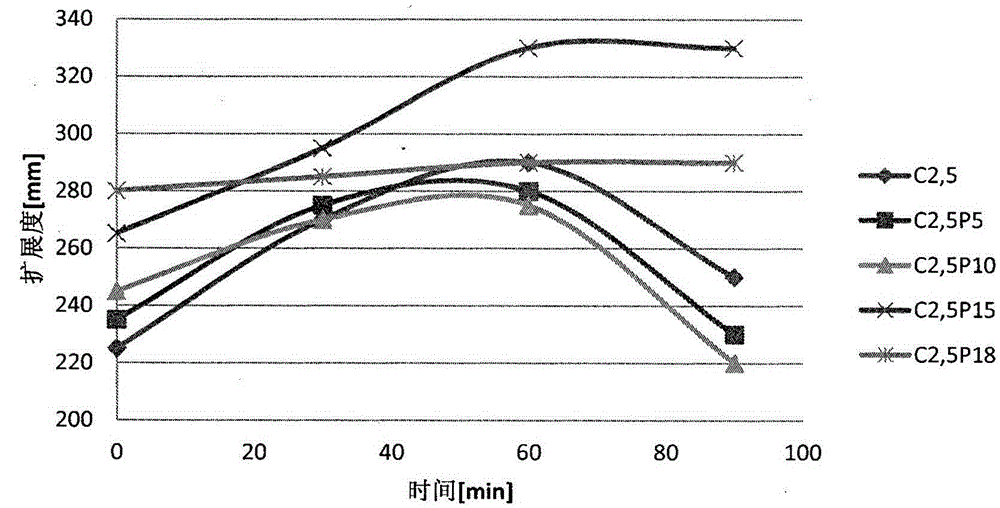

The invention discloses a phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and a preparation method thereof. The water reducer is prepared from the following raw materials: isopentenol polyoxyethylene ether, hydrogen peroxide, acrylic acid, an unsaturated phosphoric acid monomer, deionized water, a reducing agent, and a chain transferring agent. The chain transferring agent is one of mercaptoethanol, mercaptoacetic acid and mercaptopropionic acid. The unsaturated phosphoric acid monomer is prepared from 2-phosphono-1,2,4-butanetricarboxylic acid, p-toluenesulfonic acid and hydroquinone. The preparation method for the water reducer comprises adding isopentenol polyoxyethylene ether and deionized water into a reaction vessel, uniformly stirring, heating, keeping warm, adding oxygen peroxide, then dropwise adding a material solution by employing a constant-flow pump, continuing to keep warm for reacting for 1-1.5 h after dropwise adding of the material solution is finished, naturally cooling to room temperature, and adjusting the pH value of the obtained product to 5-6 by using an alkaline solution. The phosphoric-acid-base modified polycarboxylic-acid water reducer possesses good sulfate ion resisting capability and sludge resisting capability, thereby satisfying engineering demand.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

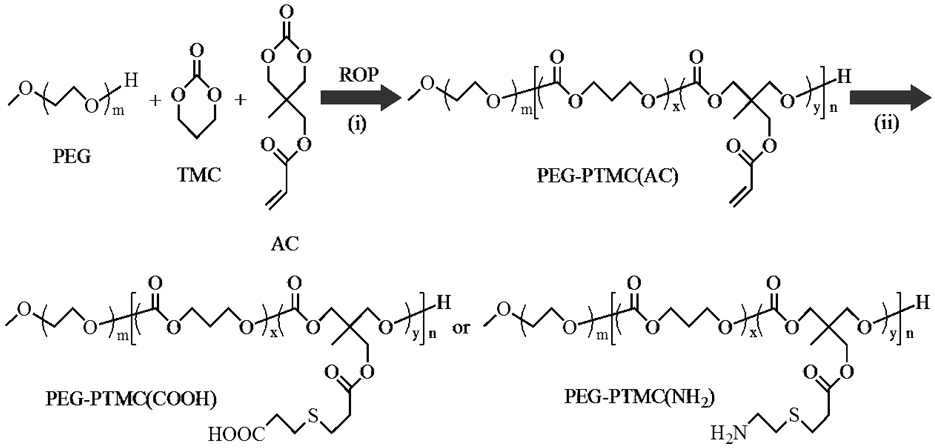

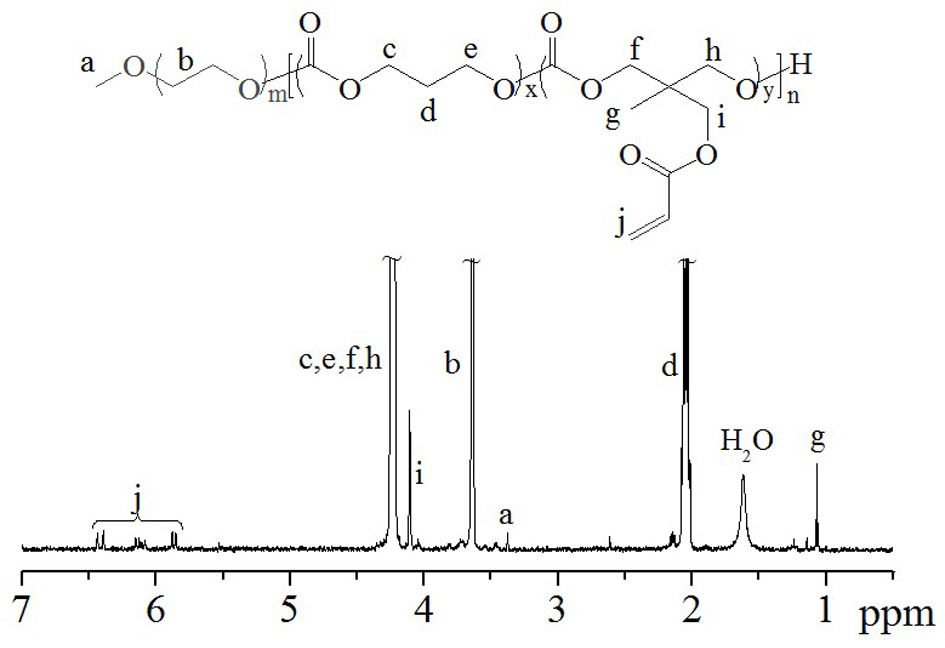

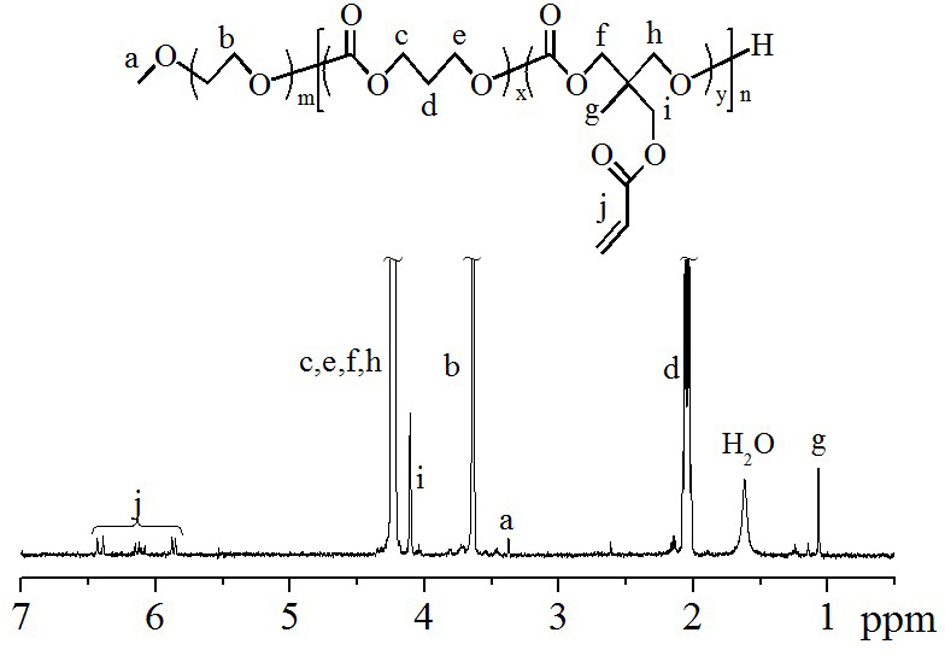

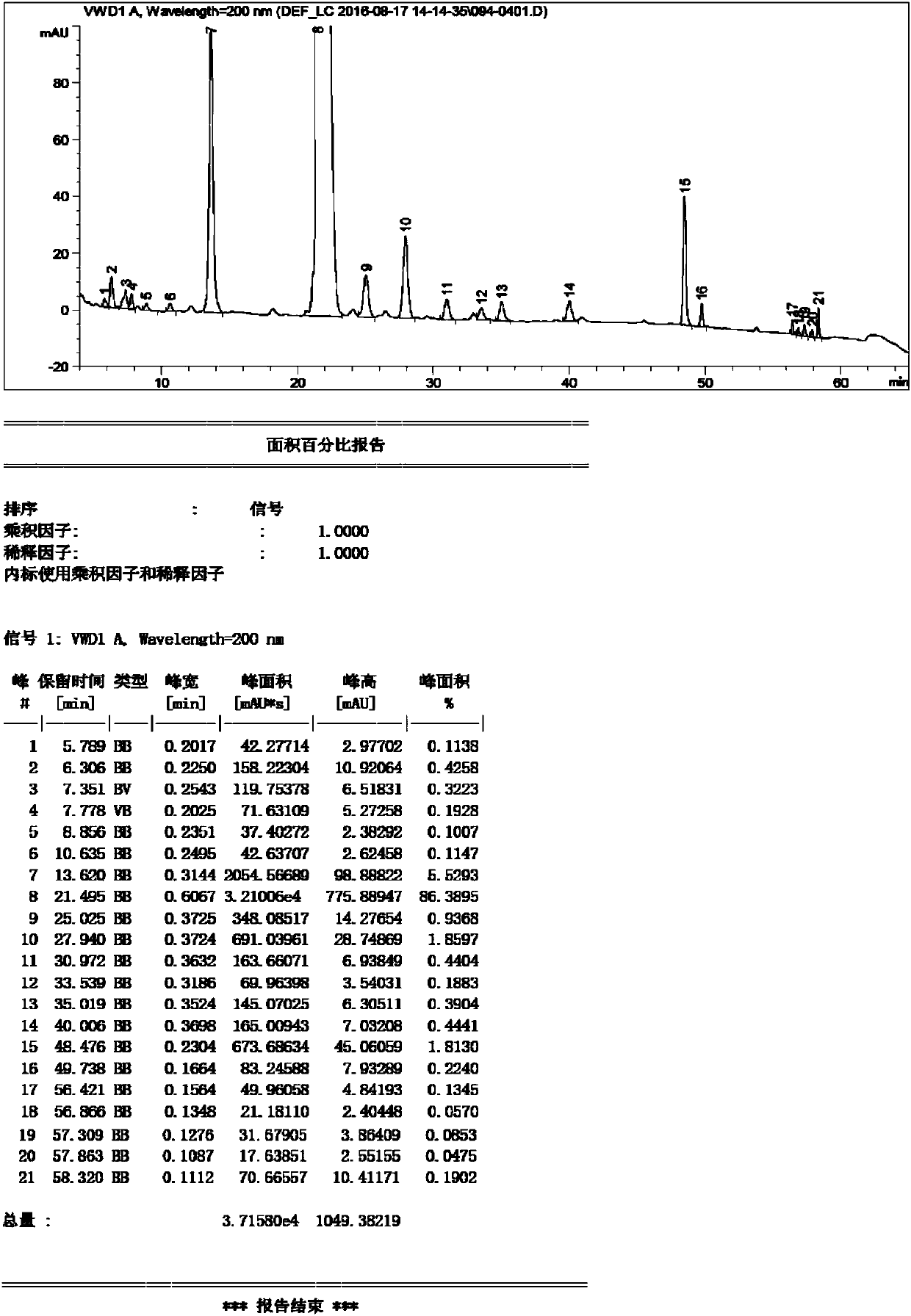

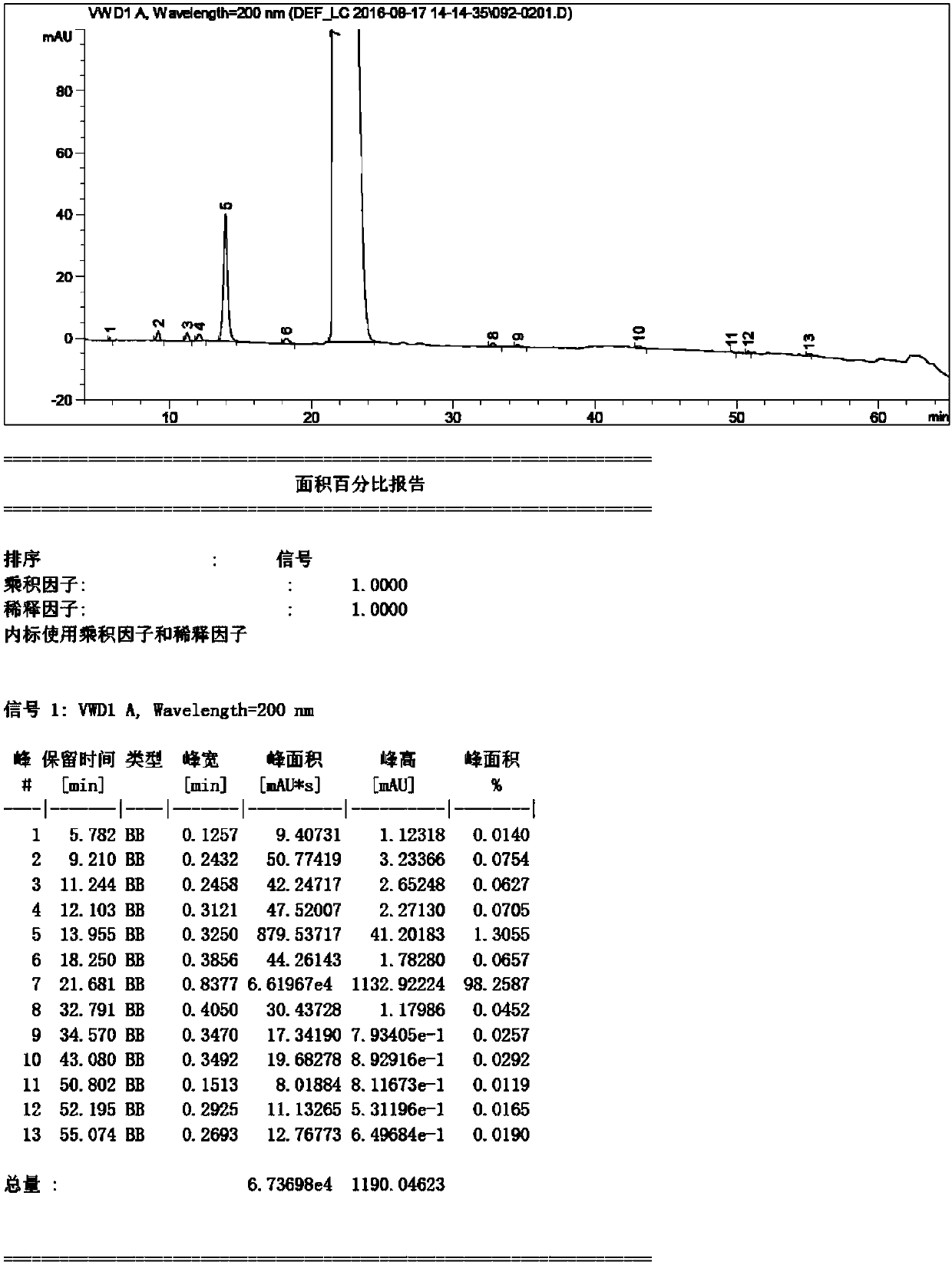

Vesicles consisting of amphiphilic polymer and application of vesicles

InactiveCN102657873AEasy to packEfficient packagingGenetic material ingredientsPharmaceutical non-active ingredientsBackbone chainDouble bond

The invention discloses vesicles consisting of amphiphilic polymer and application of the vesicles. A main chain of the amphiphilic polymer consists of a hydrophilic chain segment and a biodegradable hydrophobic chain segment, wherein the molecular weight of the hydrophilic chain segment is 4 to 6kDa; the molecular weight of the hydrophobic chain segment is 3 to 5 times that of the hydrophilic chain segment; the hydrophobic chain segment is formed by performing random copolymerization on a monomer A and a monomer B in a molar ratio of (5-20):1; the monomer A is trimethylene carbonate or cyclic carbonate; the monomer B is acrylate-based carbonate or vinyl sulfone-based carbonate; the hydrophobic chain segment is grafted with a short branched chain; the grafting position is a double bond of the monomer B; a monomer forming the short branched chain is 3-mercaptopropionic acid, cysteamine hydrochloride or cysteine; and the grafting rate is 0.3 to 1. The vesicles are directly prepared from the amphiphilic polymer in an aqueous solution and used as a carrier and a release system of a protein medicine, the encapsulating efficiency and bioavailability of the protein medicine can be improved, and the stability of the encapsulated protein is enhanced.

Owner:SUZHOU UNIV

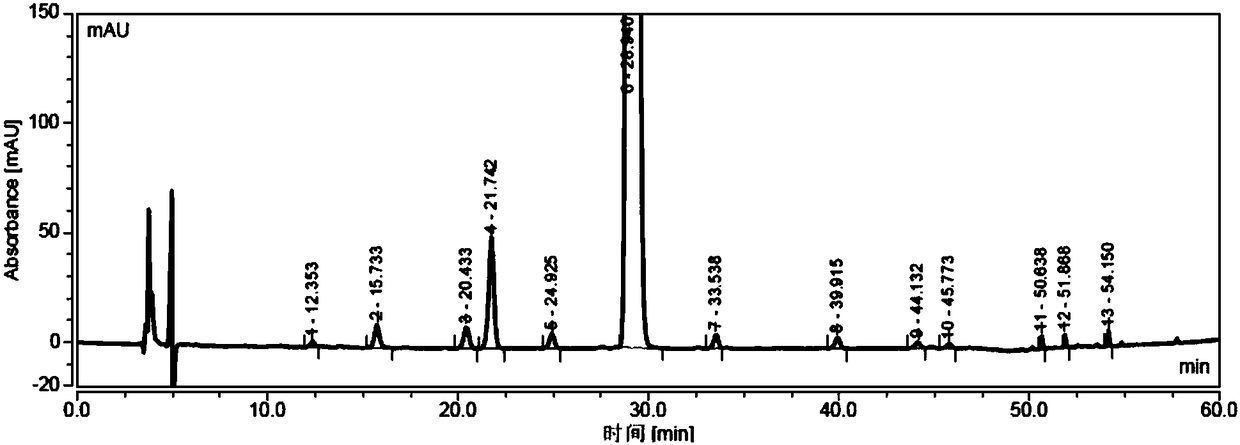

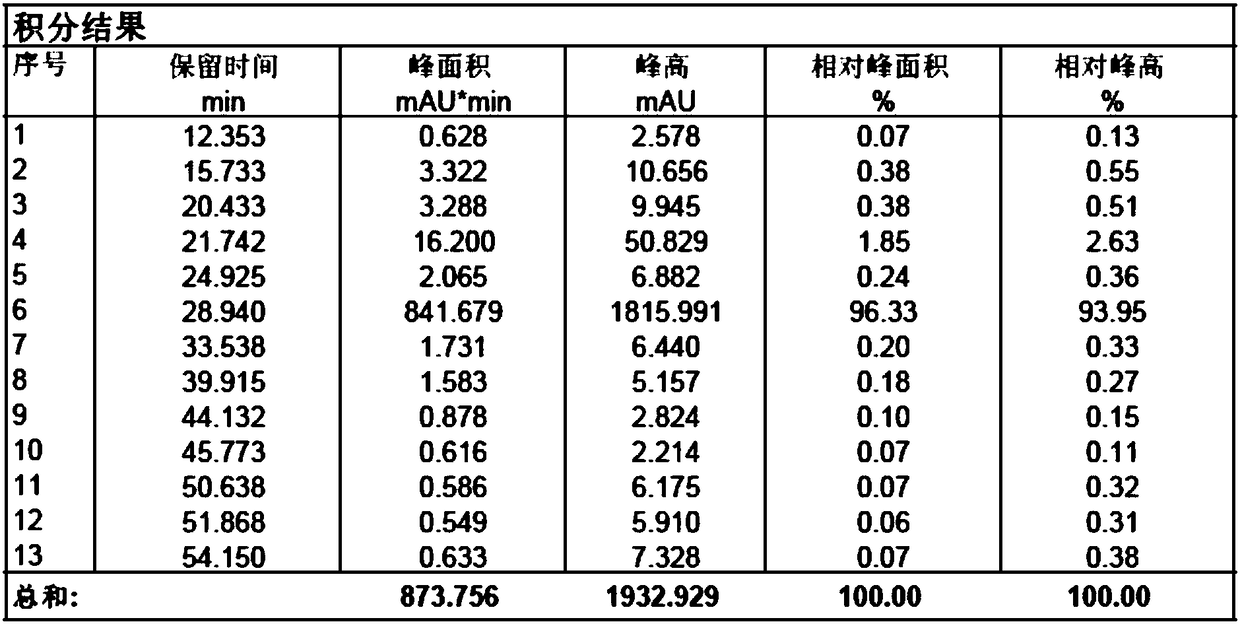

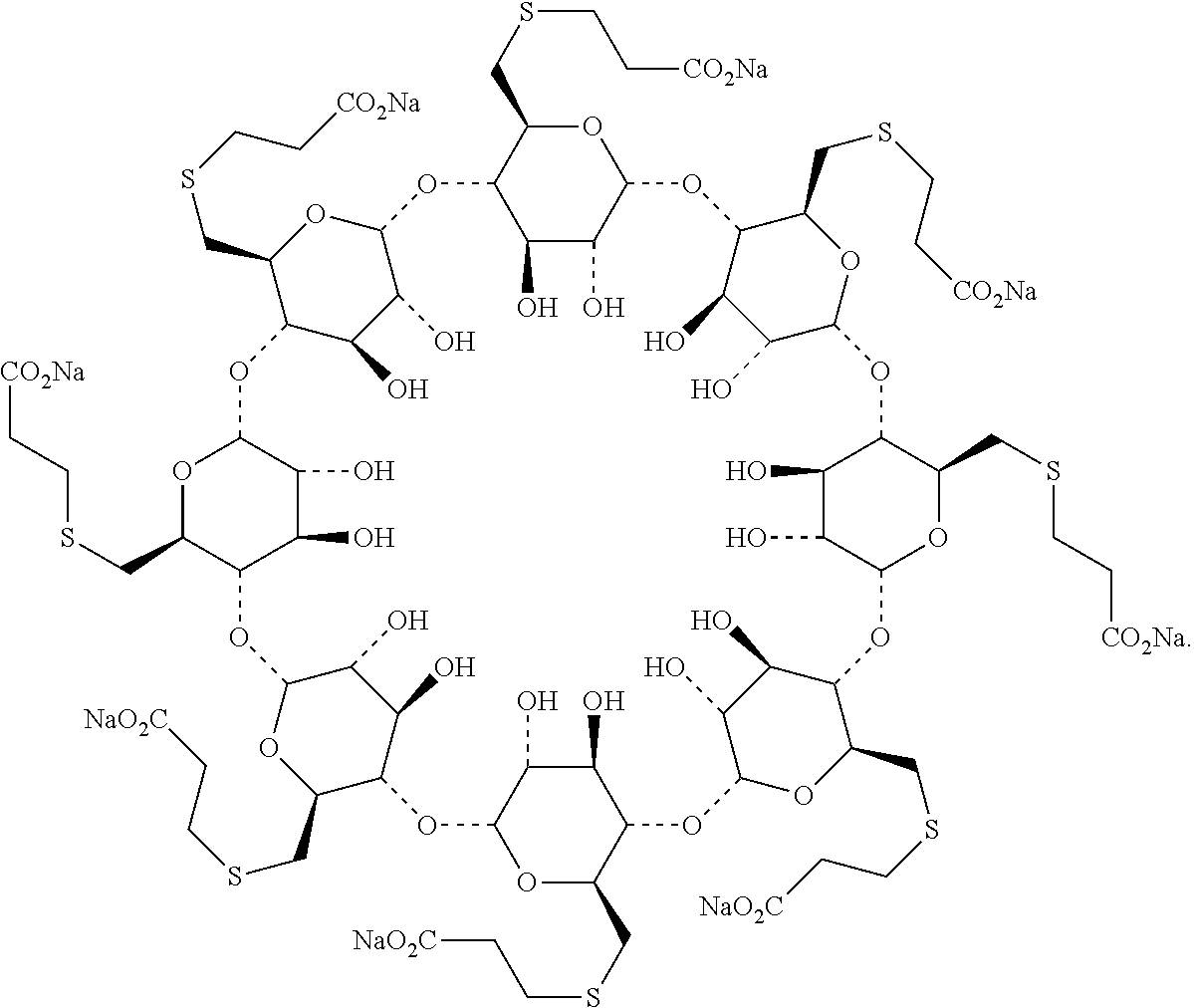

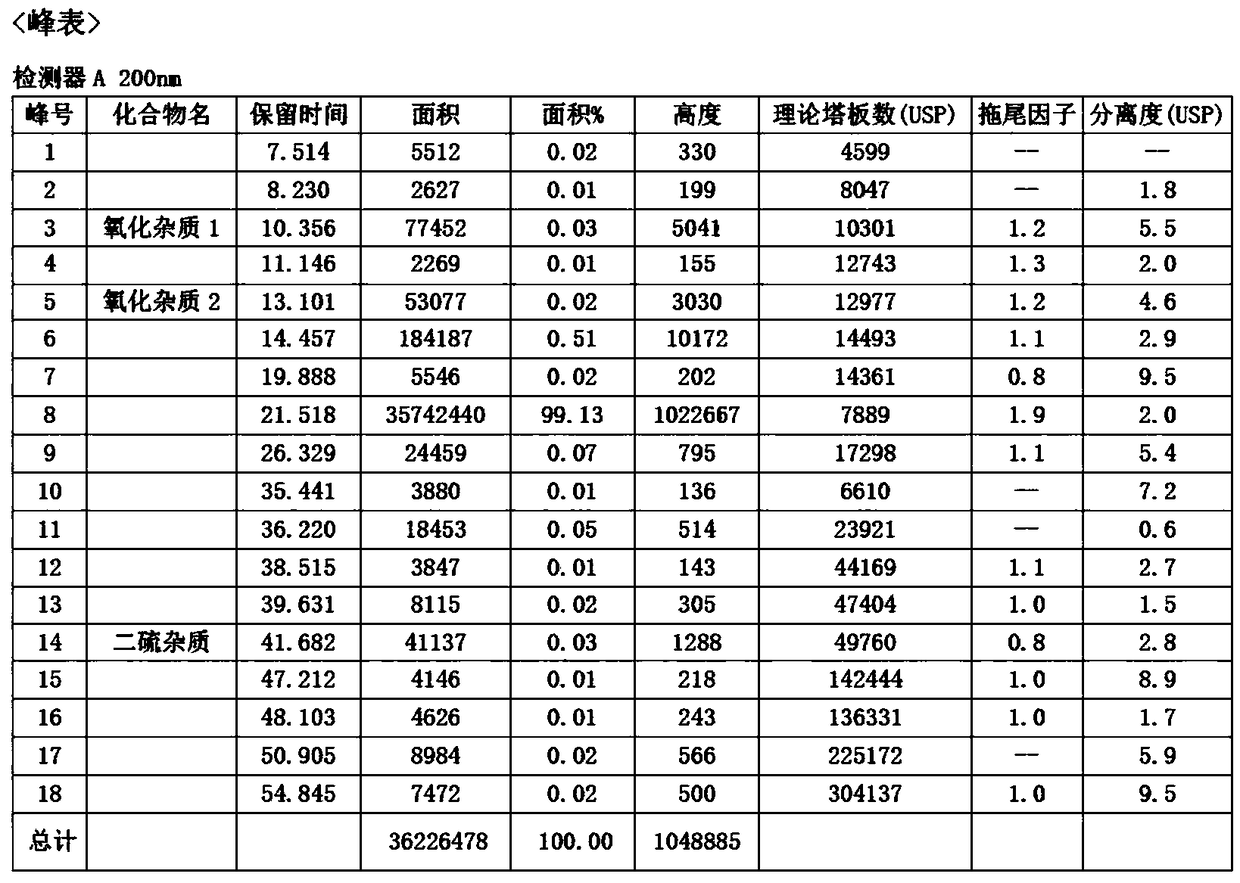

Method for refining sugammadex sodium

The invention discloses a method for re-crystallizing, refining and purifying sugammadex sodium. The method comprises the following steps: adding a protective agent to crude sugammadex sodium, and performing re-crystallizing under the protection of an inert gas to obtain pure sugammadex sodium, wherein the protective agent is selected from one or a mixture of two or more of mercaptoethanol, mercaptoacetate, mercaptoacetate ester, mercaptopropionate, mercaptopropionate ester, glutathione, cysteine, cystamine, dithioerythritol, dithiothreitol, trisubstituted organophosphorus compounds and trisubstituted organophosphorus compound salts. The method has the advantages of simplicity in operation, high product purity, good economy, and suitableness for industrial production.

Owner:王炳永

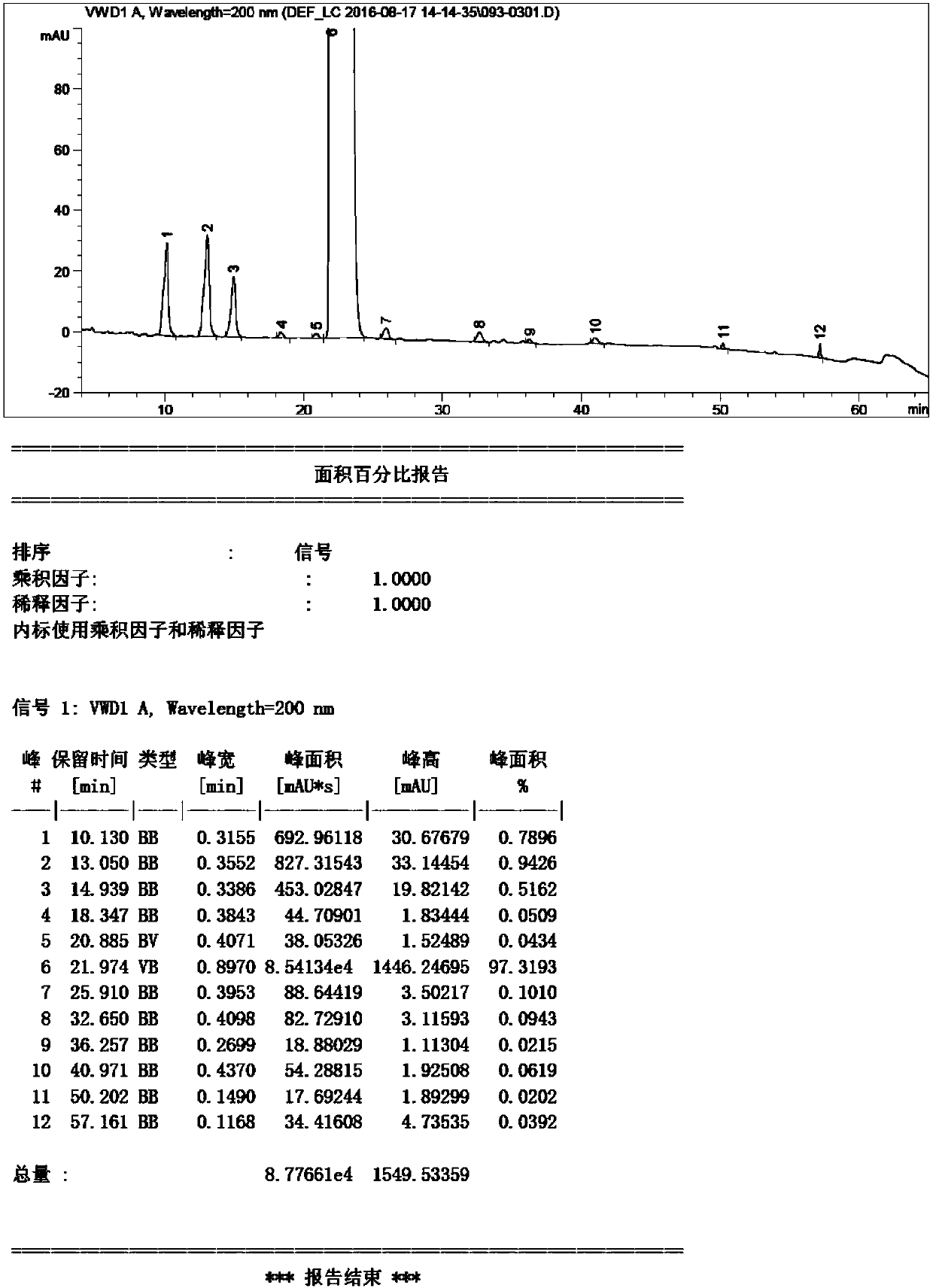

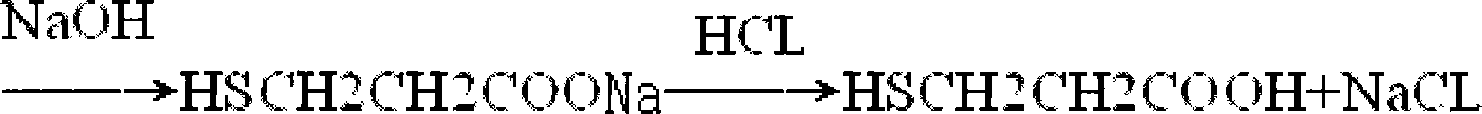

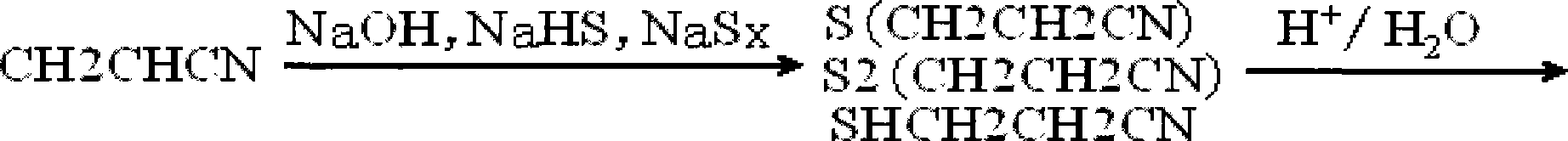

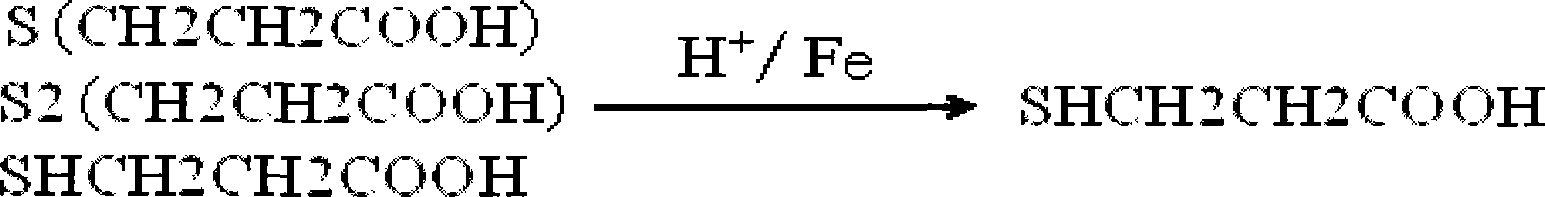

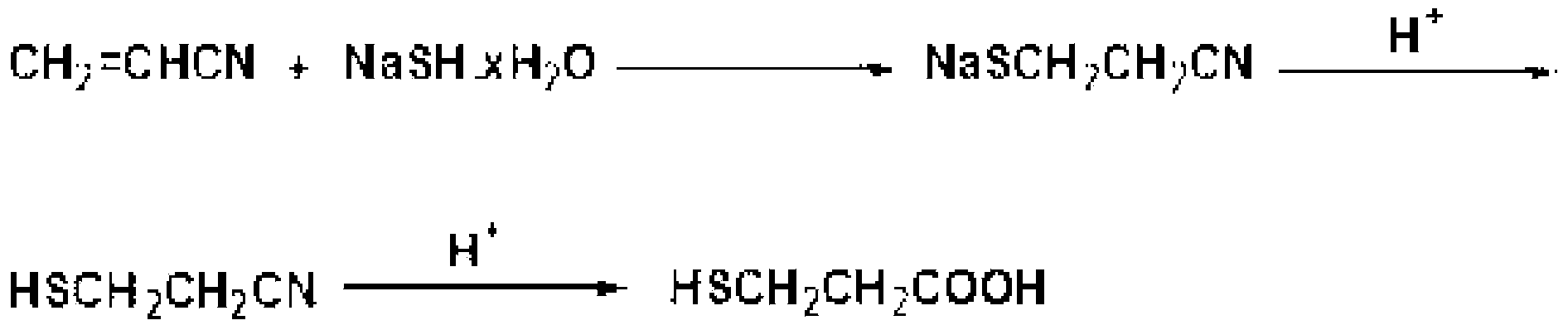

Method for preparing 3-mercaptopropionic acid

The invention relates to a preparation method of 3-mercaptopropionic acid. Sodium hydroxide solution, sodium hydrosulfide and sodium polysulfide (as catalyst) are mixed, then acrylonitrile is dripped into the mixture at the temperature of 20-70 DEG C to produce under insulated temperature the mixed solution of a plurality of intermediates, then hydrochloric acid is added for acidification and iron powder is added for deoxidization, thus acquiring the solution of 3-mercaptopropionic acid. The raw material sodium hydrosulfide selected in the reaction is cheap, reducing the production cost; hydrogen sulfide gas that is produced after the hydrochloric acid is added can be recycled to produce hydrogen sulfide nano, the production cost is further reduced; the final waste liquid mainly contains surplus hydrochloric acid and ammonia chloride, which is easy to be disposed; pollution is hardly caused during the whole reaction process.

Owner:顾建荣

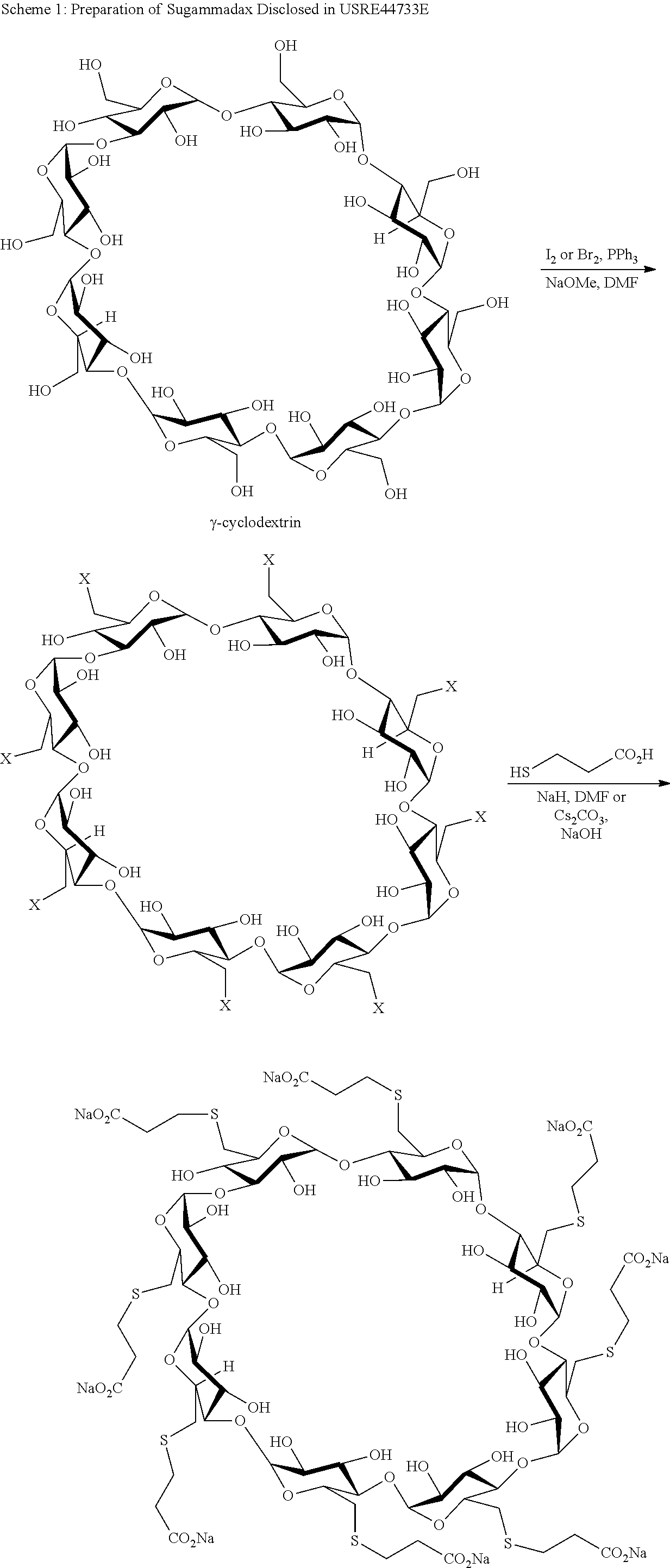

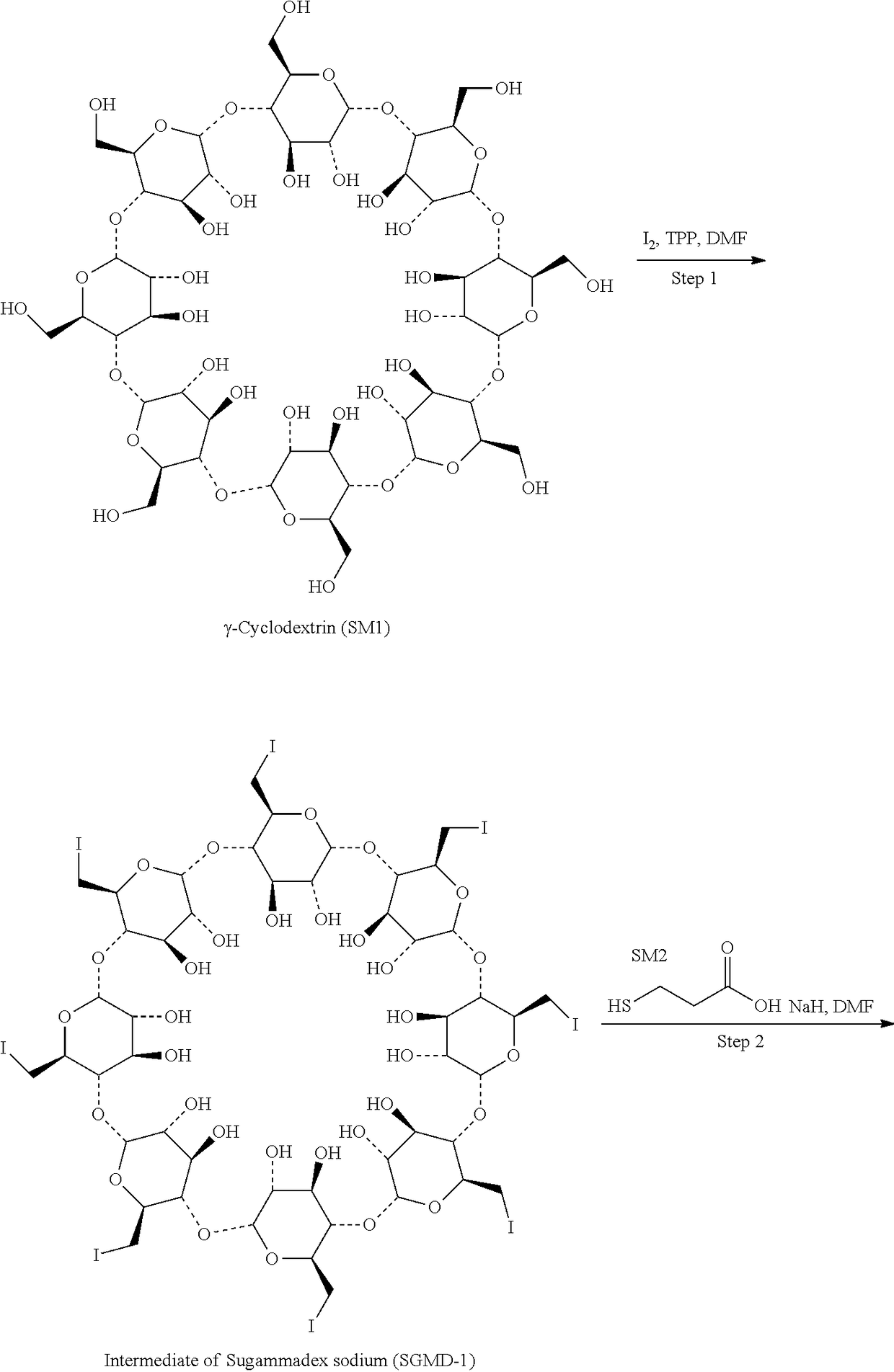

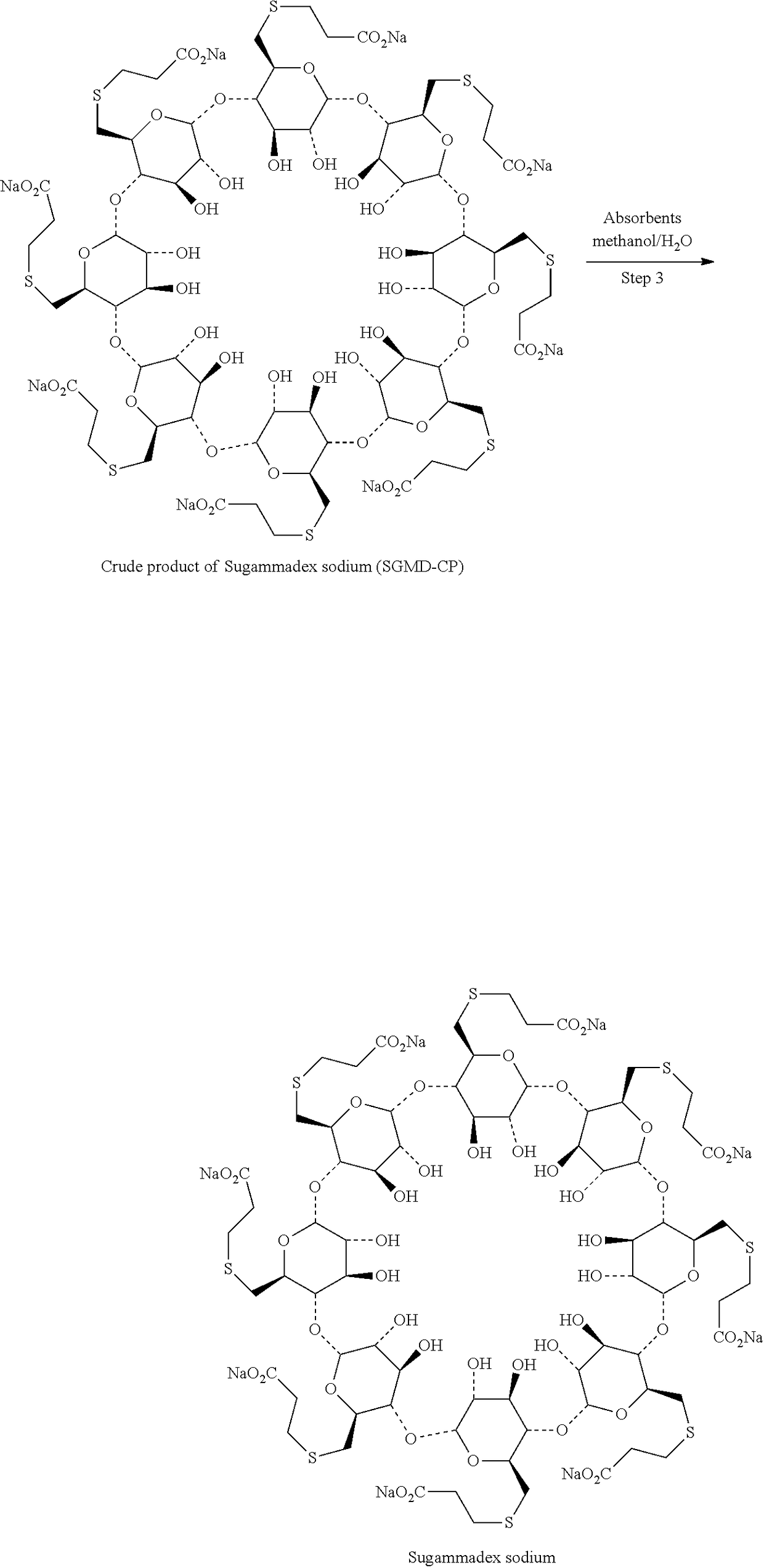

Sugammadex preparation and purification method

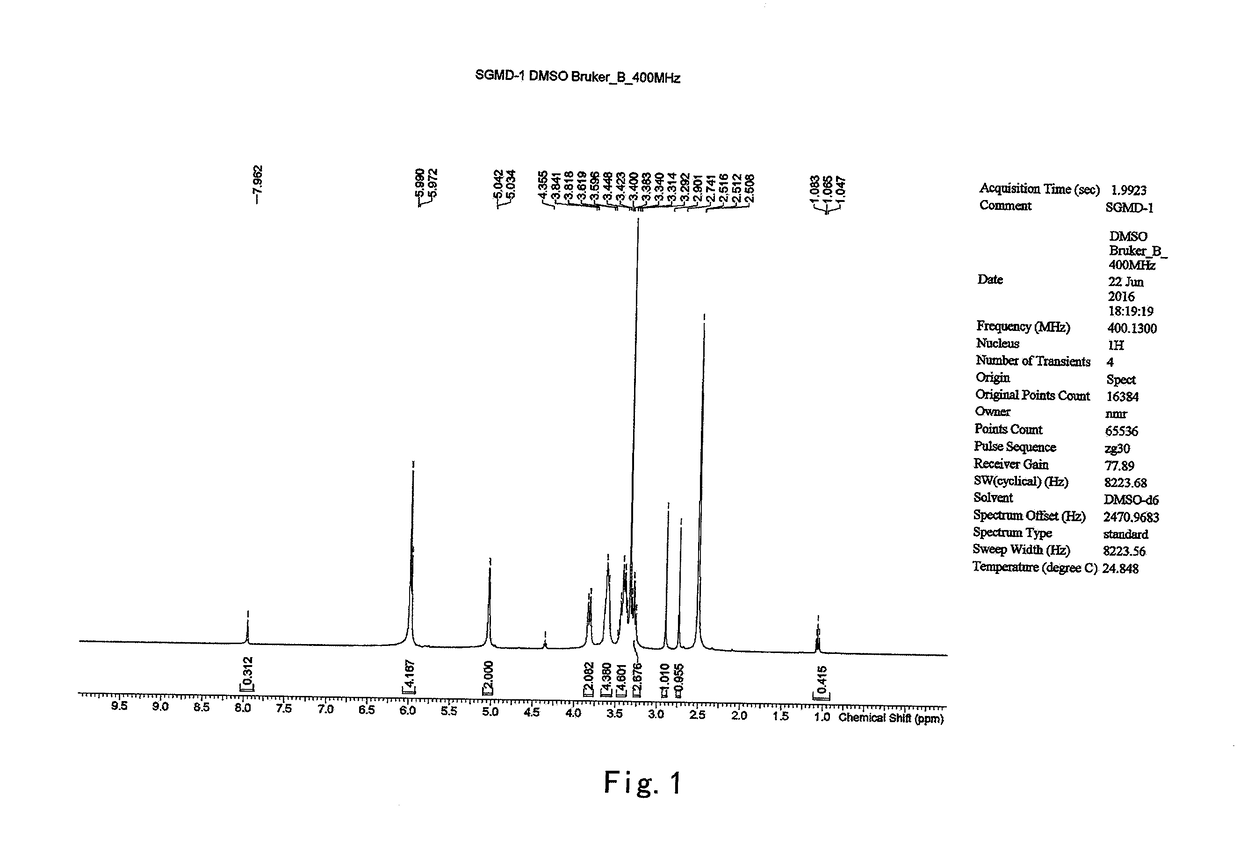

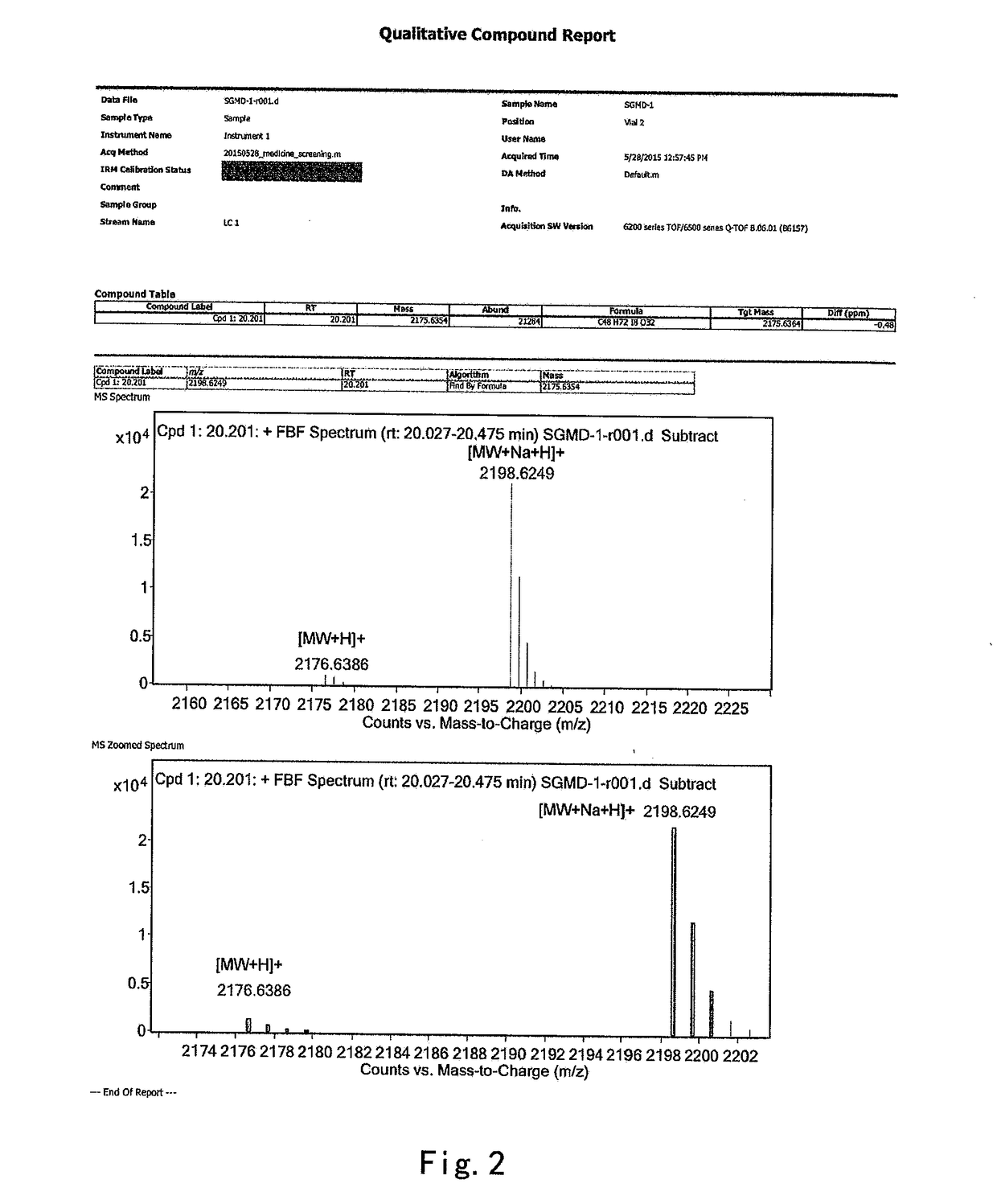

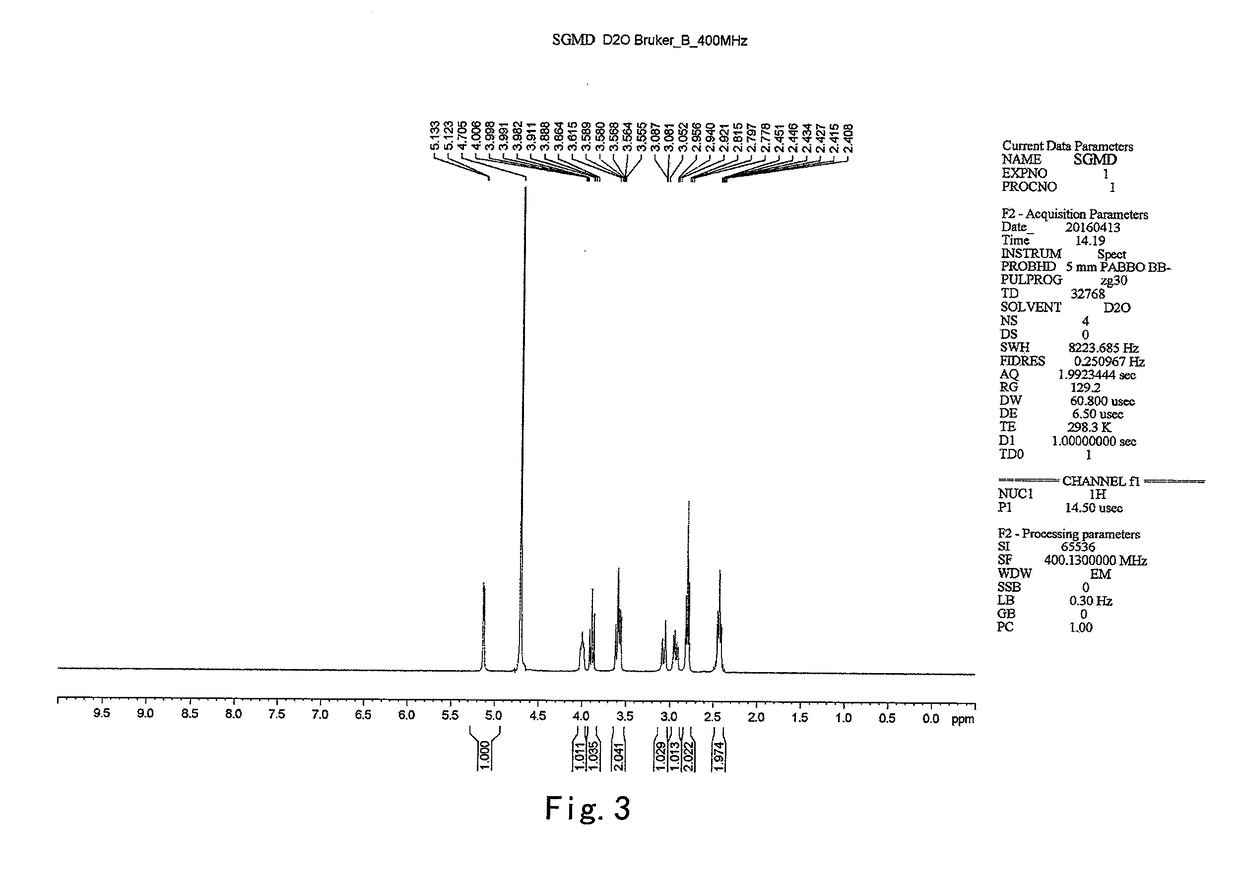

InactiveUS20180016359A1Quality improvementSimple processNervous disorderSodium methoxidePurification methods

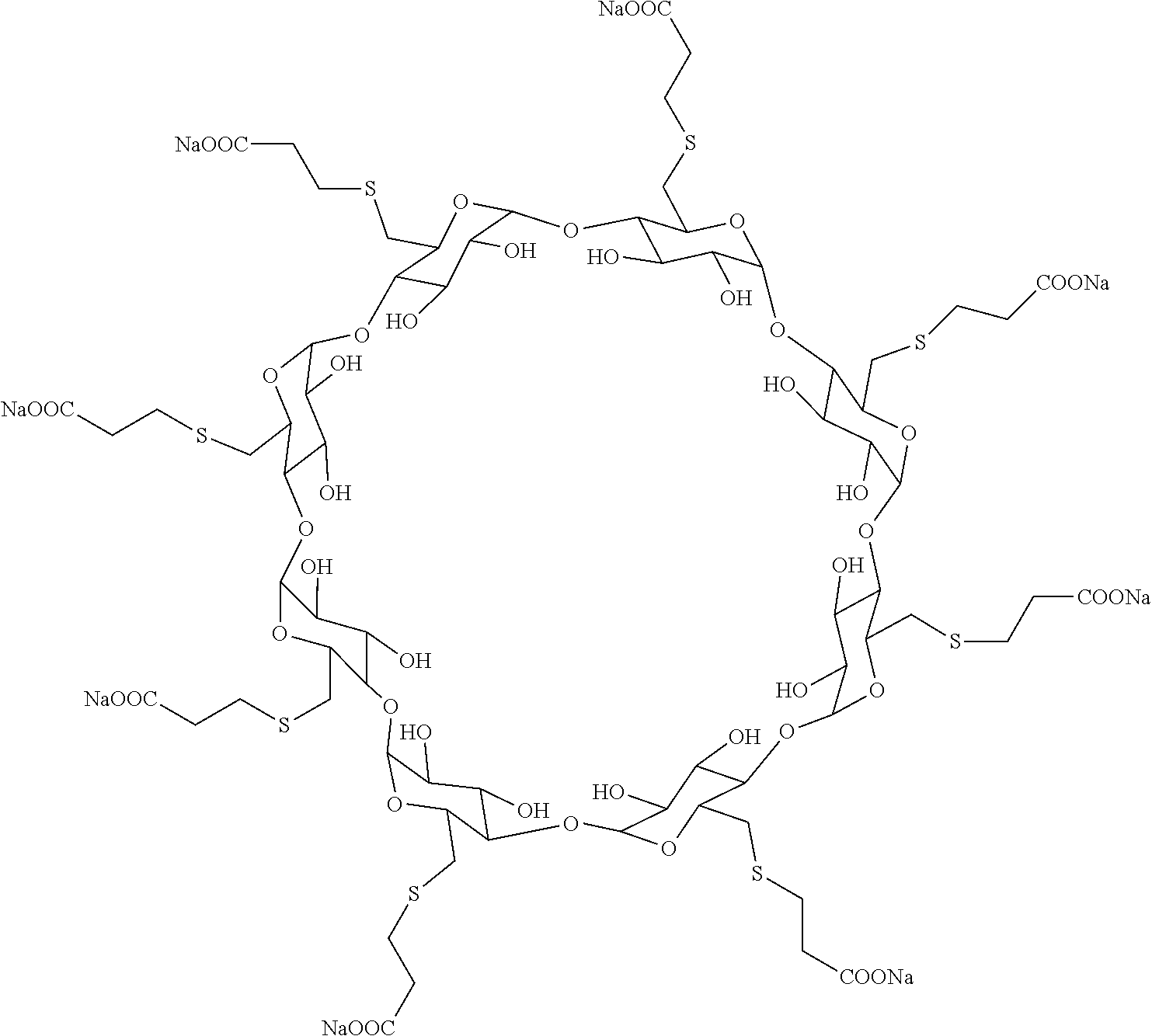

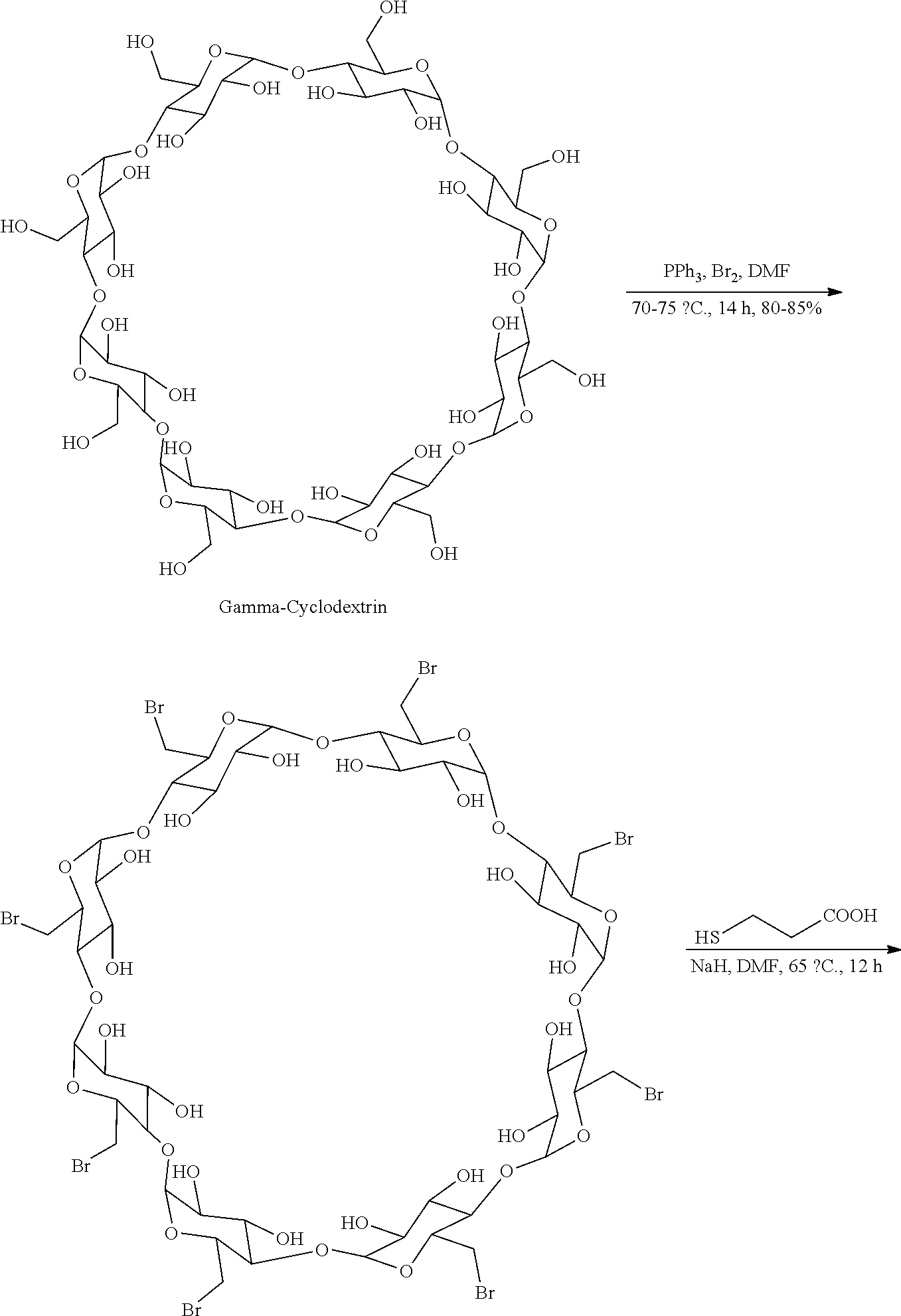

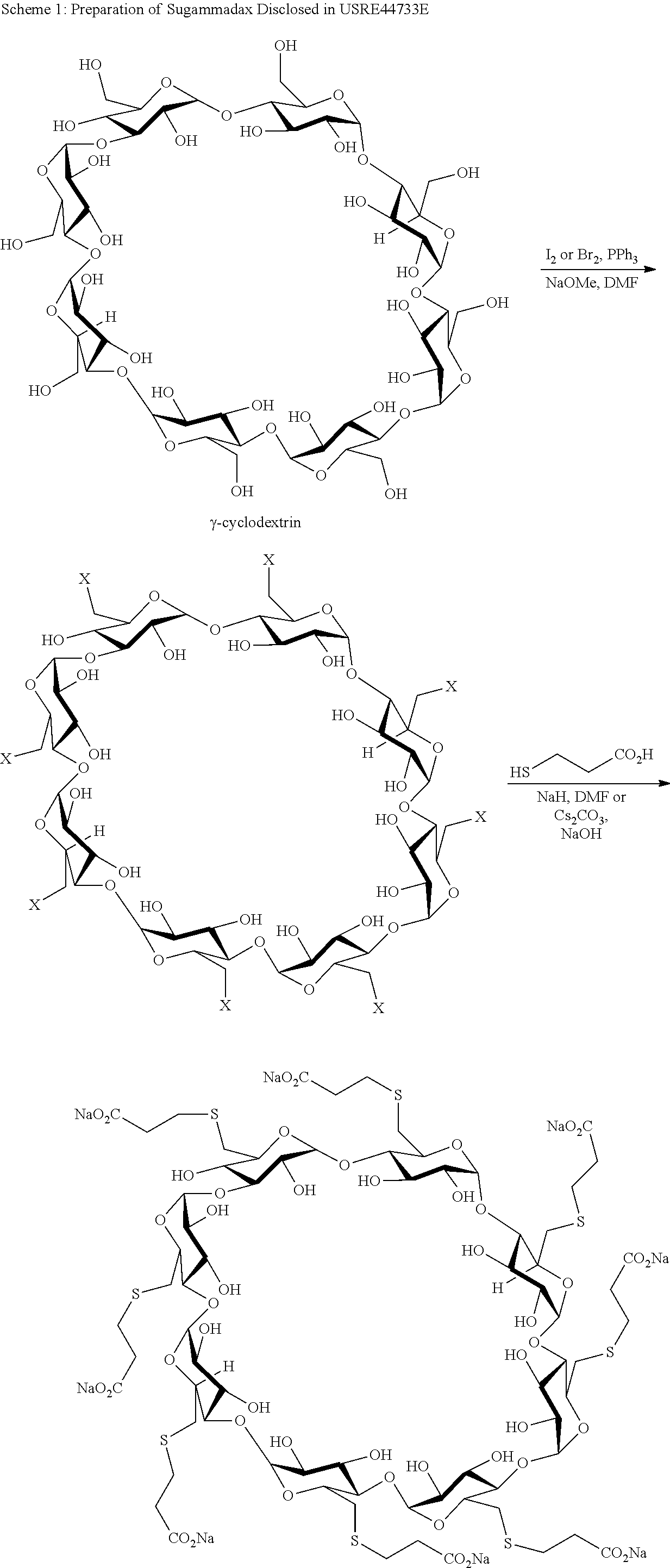

The present invention provides a process for the preparation of (6-per-deoxy-6-per-(2-carboxyethyl)thio-γ-cyclodextrin) sodium salt, comprising the steps of:reacting γ-cyclodextrin (SM1) with iodine in the presence of triphenylphosphine in an organic solvent to afford an intermediate, 6-per-deoxy-6-iodo-γ-cyclodextrin (abbreviated as SGMD-1);adding methanol solution of sodium methoxide into the reaction system followed by the addition of acetone without removal of the solvent under reduced pressure to obtain the crude SGMD-1 as a solid after filtration;purifying the crude SGMD-1 by recrystallization;reacting a obtained recrystallized intermediate (SGMD-1) with 3-mercaptopropionic acid in basic medium e.g., sodium hydride, to obtain the crude 6-per-deoxy-6-per-(2-carboxyethyl)thio-γ-cyclodextrin sodium salt (abbreviated as SGMD);purifying the crude SGMD by passing through adsorbents followed by recrystallization.

Owner:BEIJING CREATRON INST OF PHARMA RES CO LTD

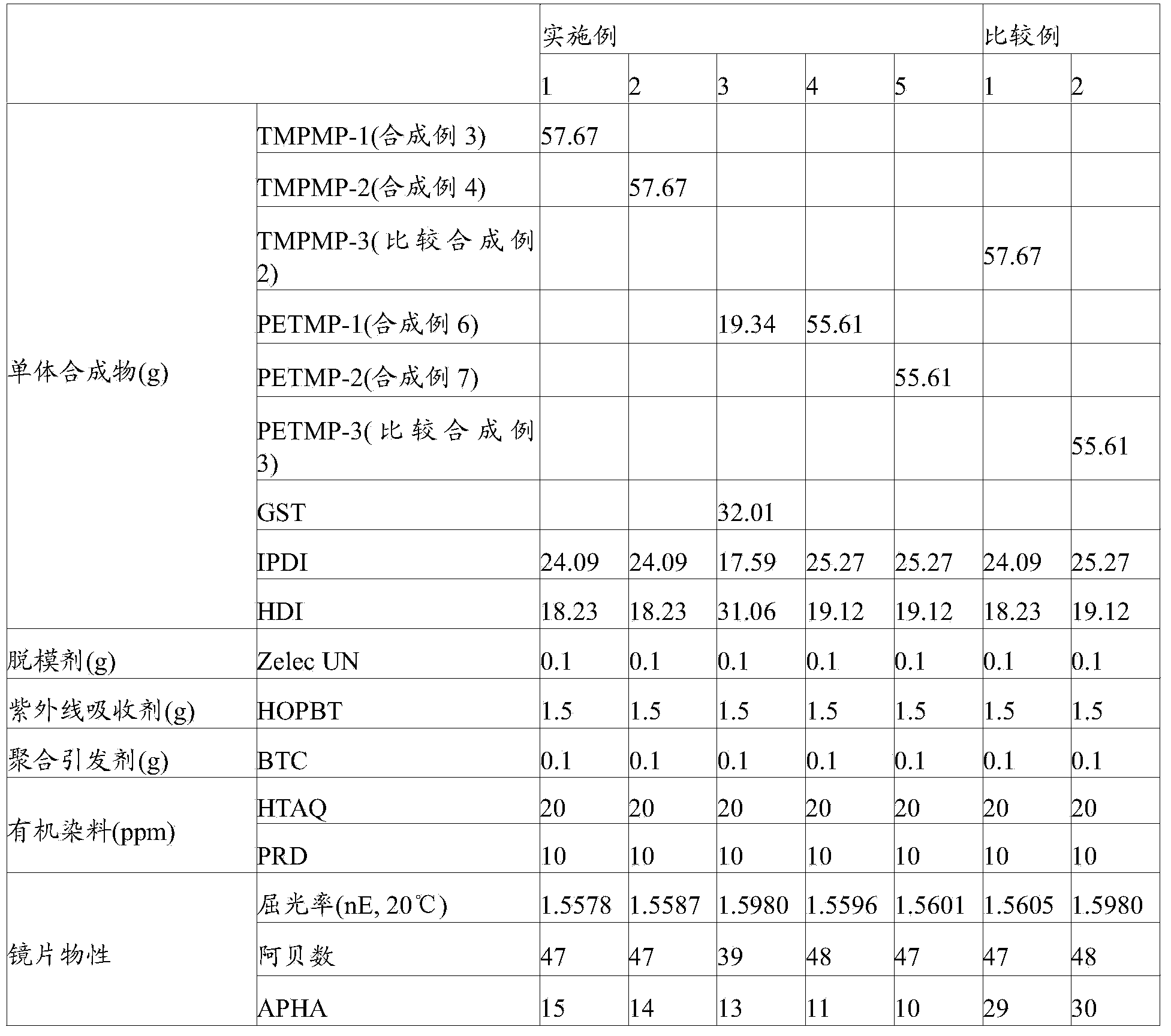

Polymerizable composition for optical material, optical material and method for producing optical material

Disclosed is a polymerizable composition for o an optical material containing tolylene diisocyanate, hexamethylene diisocyanate, and one or more polythiol compounds selected from the group consisting of 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane,4,8-, 4,7- or 5,7-dimercaptomethyl-1,11-dimercapto-3,6,9-trithiaundecane, pentaerythritol tetrakismercaptoacetate, pentaerythritol tetrakismercaptopropionate, 2,5-bis(mercaptomethyl)-1,4-dithiane, bis(mercaptoethyl)sulfide, 1,1,3,3-tetrakis(mercaptomethylthio)propane, 4,6-bis(mercaptomethylthio)-1,3-dithiane and 2-(2,2-bis(mercaptomethylthio)ethyl)-1,3-dithietane.

Owner:MITSUI CHEM INC

Silane polycarboxylate water-reducing agent and preparation method thereof

The invention relates to a method for preparing a silane polycarboxylate water-reducing agent, relates to a water-reducing agent in a concrete admixture and belongs to the technical field of building materials. The silane polycarboxylate water-reducing agent is prepared from polyoxyethylene ether macromonomer, sodium acrylate or a derivative monomer thereof, chain transfer agents, initiators, a silane functional monomer, 2-acryloyl amino-2-methyl-1-propane sulfonic acid and deionized water. The chain transfer agents are thioglycolic acid, mercaptopropionic acid, sodium methallyl sulfonate and sodium allylsulfonate. The initiators are sodium persulfate and ammonium persulfate. Silane monomer maleic anhydride and triethoxy silane propylamine are prepared through amidation. The silane polycarboxylate water-reducing agent is novel in molecular structure design, high in sulfate resistance and good in concrete material adaptability. The product has an obvious sulfate resistance effect while having a high performance water-reducing effect.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Water-based hydroxyl acrylic resin facilitating deep machining and water-based acrylic amino baking finish and preparation method and metal workpiece

The invention discloses a water-based hydroxyl acrylic resin facilitating deep machining, a water-based acrylic amino baking finish, a preparation method and a metal workpiece. The water-based hydroxyl acrylic resin is prepared from acrylic acid, methyl methacrylate, butyl acrylate, butyl methacrylate, vinyl versatate, cyclohexyl methacrylate, hydroxyethyl acrylate, 3-thiohydracrylic acid, an initiator, an oxidizing agent, a reducing agent, an organic solvent and water. The vinyl versatate and the 3-thiohydracrylic acid are introduced to a monomer part of the water-based hydroxyl acrylic resin, and branched chains in the vinyl versatate and the 3-thiohydracrylic acid make resin molecule arranged smoothly, so that a coating prepared by adopting the prepared water-based hydroxyl acrylic resin is very good in coating toughness, and a metal surface has good toughness after being coated. Therefore, the requirements of deep machining of a lot of metal workpieces can be met.

Owner:广东海顺新材料科技有限公司

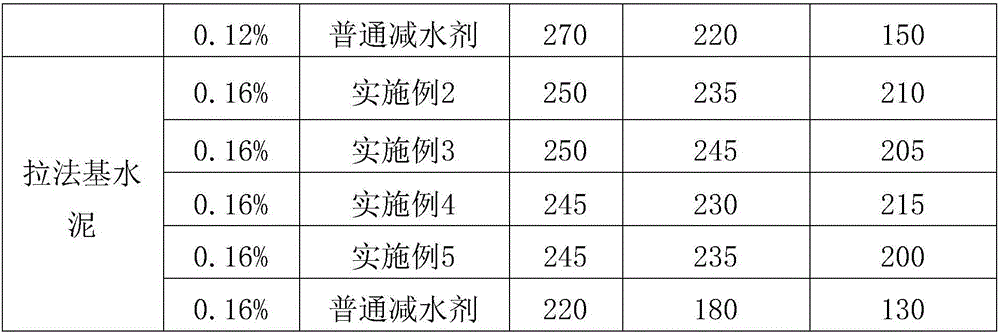

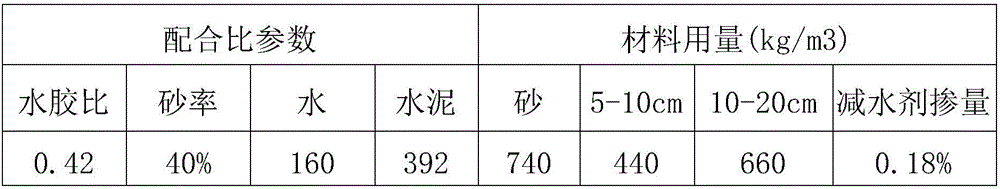

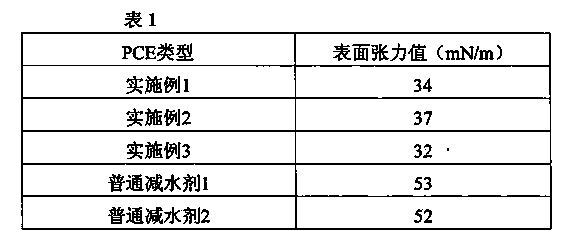

Polycarboxylate water reducer with defoaming function and preparation method of water reducer

The invention discloses a polycarboxylate water reducer with a defoaming function and a preparation method of the water reducer. The water reducer is prepared from the following raw materials: polyoxyethylene ether macromonomers, acrylic acid or derivative monomers of acrylic acid, a chain transfer agent, an initiator, defoaming monomers and de-ionized water, wherein the chain transfer agent is selected from thioglycollic acid, thiohydracrylic acid, sodium methallylsulphonate and sodium allysulfonate; the initiator is selected from hydrogen peroxide, ascorbic acid, sodium persulfate and ammonium persulfate; the defoaming monomers are polyoxyethylene-polyoxypropylene block copolymers. The preparation method comprises the following steps of pouring the polyoxyethylene ether macromonomers and the de-ionized water into a three-mouth flask, and adding the chain transfer agent; dissolving the initiator in the de-ionized water to prepare a solution A; dissolving acrylic acid or the derivative monomers of acrylic acid and the defoaming monomers in the de-ionized water to prepare a solution B; dropwise adding the solution A and the solution B by adopting a constant flow pump at the same time, performing insulation reaction, naturally cooling, and adjusting the pH value to obtain the water reducer. The water reducer has a defoaming function while having a high-performance water reducing effect.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

An Improved Process for Preparation of Sugammadex Sodium

The present invention provides a process for the preparation of sugammadex sodium involving the step of: reacting 6-perdeoxy-6-per-halo-gamma-cyclodextrin with 3-mercapto propionic acid in the presence of alkali metal alkoxide in an organic solvents. The invention also provides a process for purifying the sugammadex or its pharmaceutically acceptable salts using water and organic solvents.

Owner:NEULAND LABORATORIES LTD

Preparation method for green and environmentally friendly sugammadex sodium

The invention belongs to the field of pharmacy, and especially relates to a preparation method for green and environmentally friendly sugammadex sodium. The preparation method obtains a crude productof sugammadex sodium through preparation for the first time by taking 3-mercaptopropionic acid, alkali and 6-deoxy-6-perhalogeno-gamma-cyclodextrin as raw materials; and high purity sugammadex sodiumcan be obtained after desolvation through recrystallization and column chromatography purification. Compared with the prior art, a reaction solvent of the preparation method can replace organic solvents like N,N-dimethylformamide used by traditional methods by only using water, so that disadvantages of hard recovery and large pollution caused by large amount of high boiling organic solvents can beimproved; and the sugammadex sodium is clean and environmentally friendly, green and efficient, has advantages of being mild in reaction condition, high in product purity, simple in post-treatment step, high in product yield, low in cost and convenient for industrialization, and has good application prospects.

Owner:HEFEI BOSIKC PHARMTECH CO LTD

Method for preparing polycarboxylic acid water reducing agent by using sodium methyl acryl sulfonate as chain transfer agent

The invention discloses a method for preparing a polycarboxylic acid water reducing agent by using sodium methyl acryl sulfonate as a chain transfer agent. The method comprises the following steps of: firstly, adding water, sodium methyl acryl sulfonate and modified polyether in a reaction kettle; then mixing sodium methyl acryl sulfonate and acrylic acid with water to prepare an acrylic acid solution, mixing water with ammonium persulfate to prepare an ammonium persulfate solution; when the temperature of materials reaches 60 DGE C+ / -2 DEG C, simultaneously dropwise adding the ammonium persulfate solution and the acrylic acid solution; and carrying out heat insulation reaction for 1-3 hours and when cooling below 45 DEG C, adding 32% liquid caustic soda for neutralization so as to obtain the polycarboxylic acid water reducing agent having the PH value of 6-7 and 40% of solid content. Because sodium methyl acryl sulfonate is used as the chain transfer agent instead of mercaptoacetic acid or mercaptopropionic acid in the preparation process of the polycarboxylic acid water reducing agent, environment pollution and toxic action on a human body caused by stink odor and strong corrosivity of mercaptoacetic acid or mercaptopropionic acid can be avoided.

Owner:深圳市五山新材料股份有限公司

Process for the catalytic synthesis of bisphenol fluorene by using concentrated sulphuric acid

InactiveCN101735020AReduce dosageAvoid wastingOrganic chemistryOrganic compound preparationPropanoic acidSoftened water

The invention relates to a process for the catalytic synthesis of bisphenol fluorene by using concentrated sulphuric acid. Concentrated sulphuric acid is taken as catalyst, beta-mercapto propionic acid is taken as cocatalyst, phenol is taken as reactant and solvent, reaction with fluorenone is fully carried out under mild condition, one organic polar solvent and water are added, so as to cause unreacted phenol and product are layered with concentrated sulphuric acid; water phase is removed, the obtained organic phase is washed by alkaline solution and softened water step by step, condition is controlled and reduced pressure distillation is carried out to obtain the organic polar solvent and phenol respectively, temperature reduction is carried out, then recrystallization solvent is added for recrystallization, thus obtaining bisphenol fluorine white solid the purity of which is more than 99.0%. The process has low reaction temperature, short time, high productivity more than 90% and high purity more than 99.0%; besides, the used catalyst concentrated sulphuric acid and cocatalyst beta-mercapto propionic acid are low in cost, concentrated sulphuric acid consumption is low, phenol is easy to recycled, recovery rate reaches 80%, and environmental pollution is less, thus the method is applicable to industrialized production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

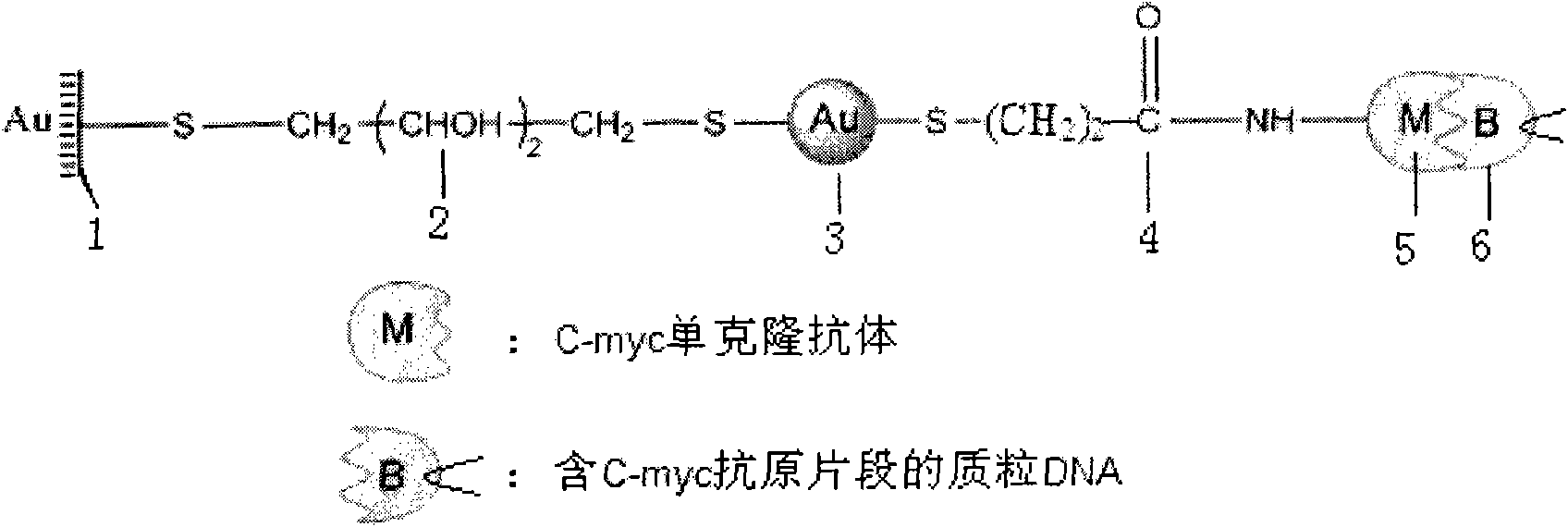

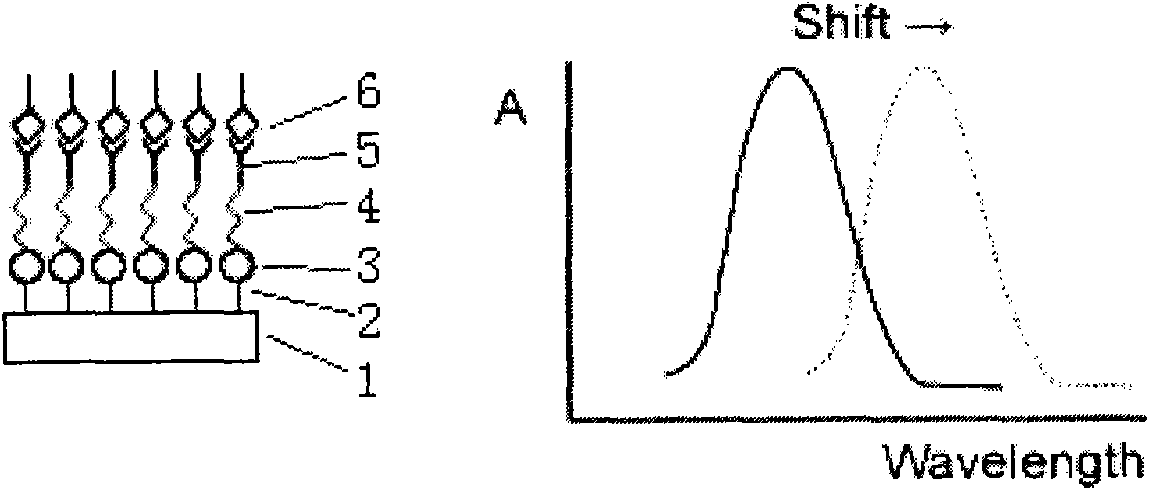

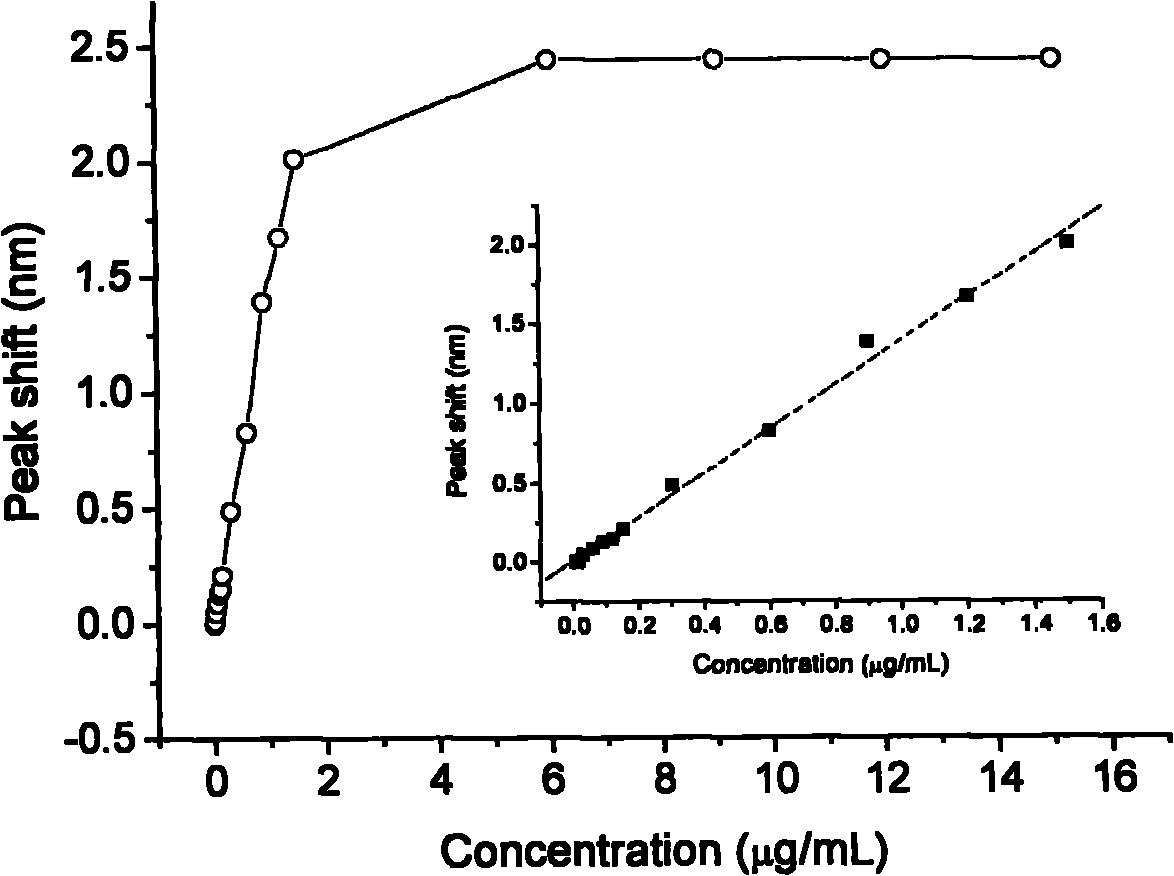

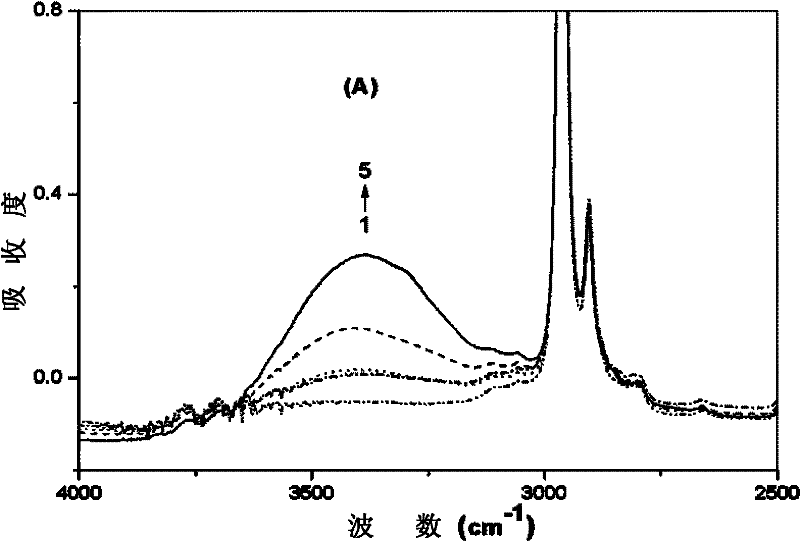

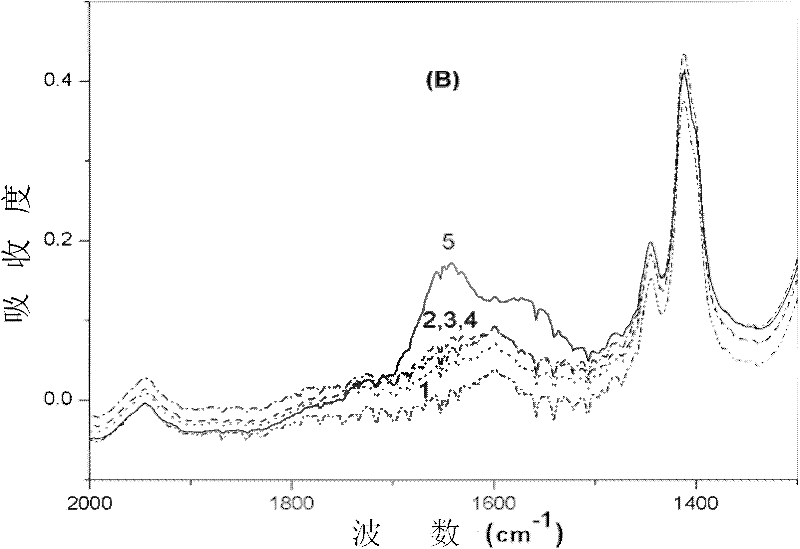

LSPR (Localized Surface Plasmon Resonance) sensing chip for detecting plasmid DNA (deoxyribonucleic acid) containing oncogene C-myc antigen fragment

The invention provides an LSPR (Localized Surface Plasmon Resonance) sensing chip for detecting plasmid DNA (deoxyribonucleic acid) containing an oncogene C-myc antigen fragment on the basis of LSPR. The LSPR sensing chip is characterized in that one DTT (Dithiothreitol) unimolecule layer (2) is assembled on the surface of a gold film (1) of the LSPR sensing chip; a gold nanoparticle layer (3) is accessed; the surface of the gold nanoparticle layer (3) is furnished with a 3-mercaptopropionic acid unimolecule layer (4); then DMAP-EDC [4-Dimethylamino pyridine-1-(3-Dimethylaminopropyl)-3-ethylcarbodiimide] activation ensures that the 3-mercaptopropionic acid unimolecule layer (4) is combined with a C-myc monoclonal antibody (5); and the immune response combination of the C-myc monoclonal antibody (5) and the plasmid DNA (6) containing the C-myc antigen fragment causes that the surface of the gold nanoparticle generates the displacement of a local surface plasma resonance absorption peak so as to detect the content of the plasmid DNA (6) containing the C-myc antigen fragment in canceration tissues. The invention has the beneficial effects that the LSPR sensing chip has the advantages of multiple-path detection, high sensitivity and good selectivity and repeatability, is simple and convenient to assemble and is quick to quantify. The LSPR sensing chip is superior to the LSPR sensing chip manufactured with the traditional chromatin immunoprecipitation (ChIP) method.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

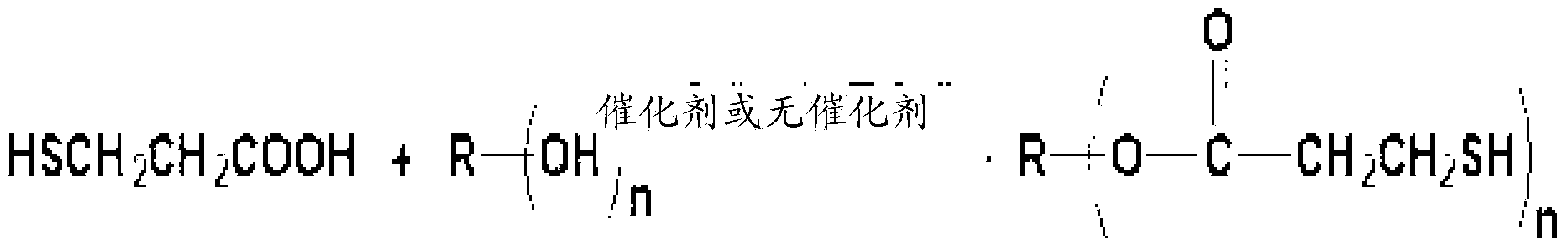

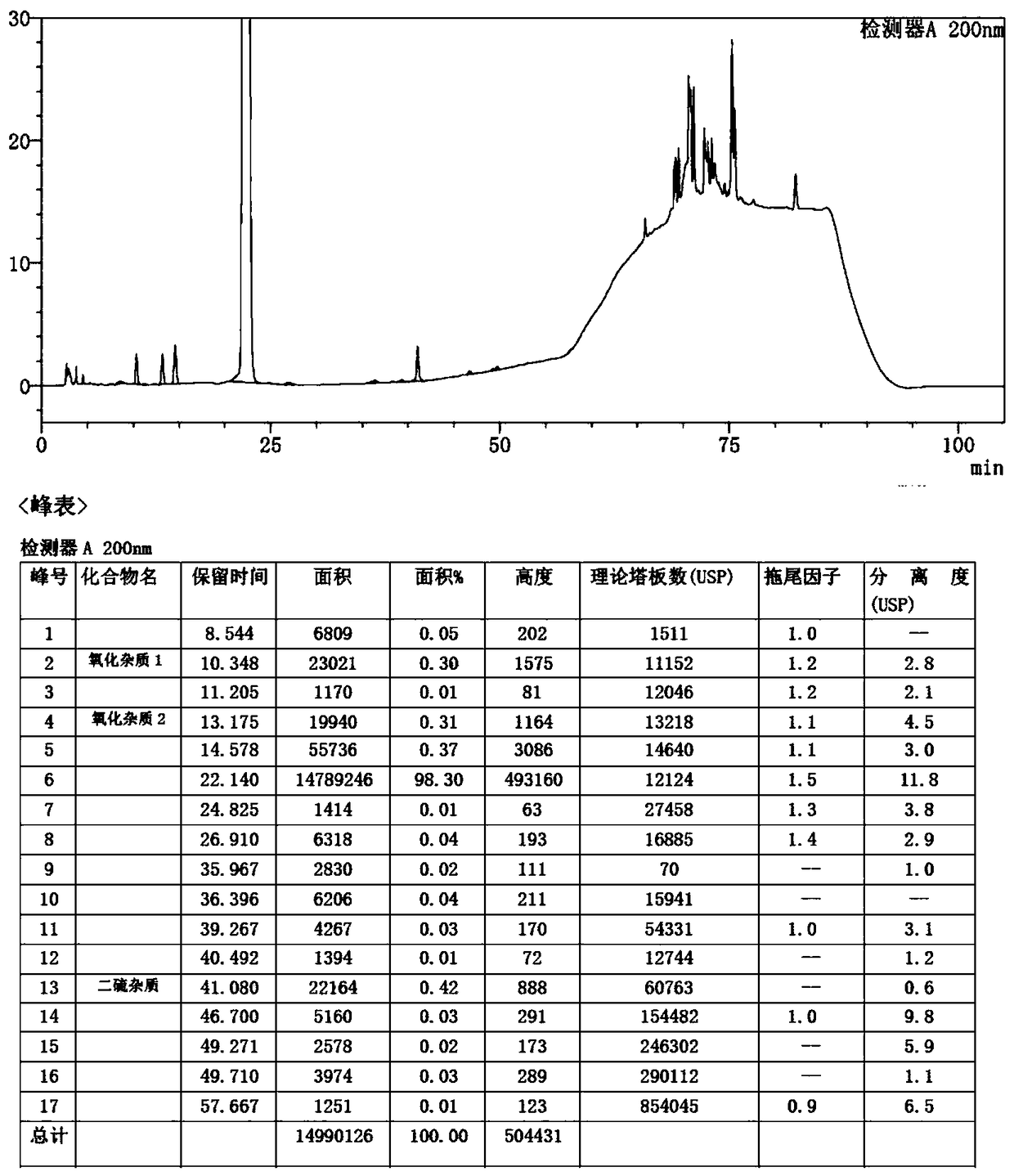

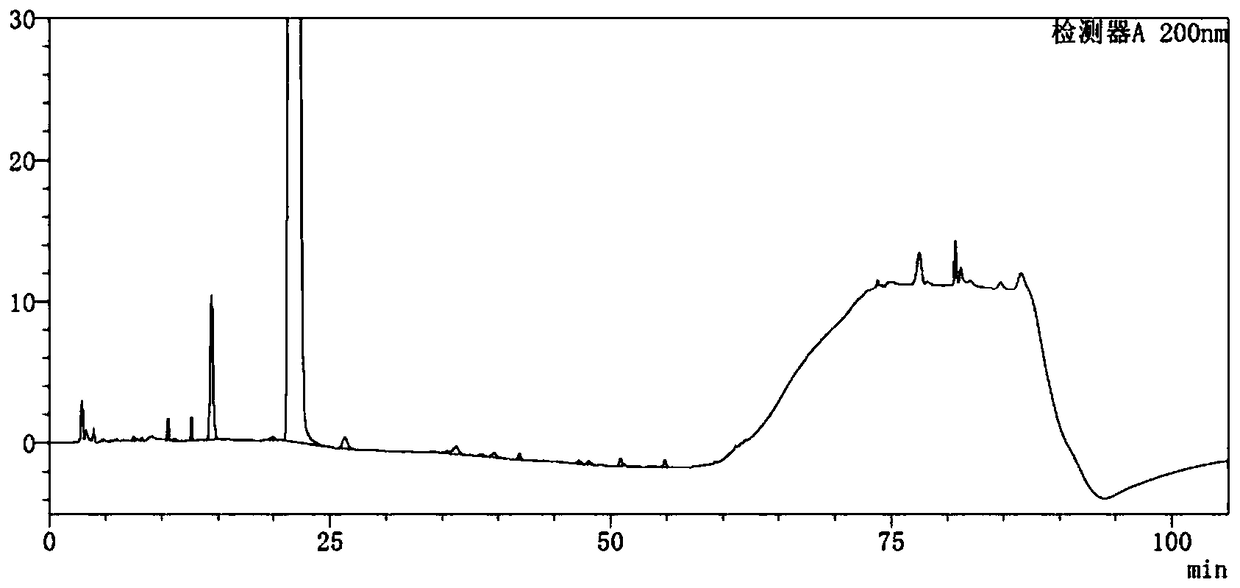

Method for producing 3-mercaptopropionic acid, and carbonic acid ester composition having mercapto group using same, and method for producing thiourethane-based optical materials

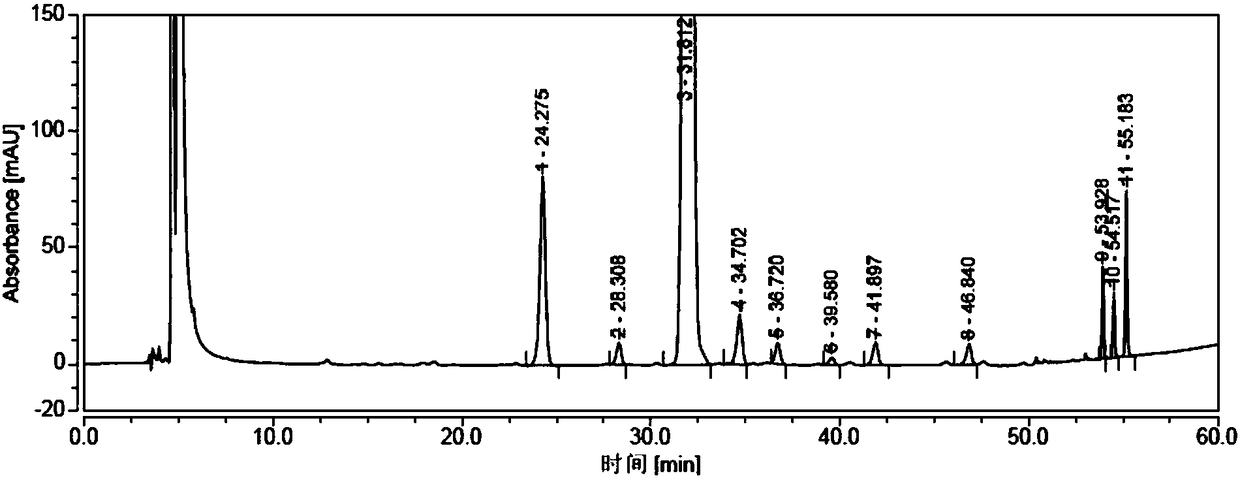

InactiveCN104053646AHigh purityGood hueOrganic compound preparationThiol preparationPhotochemistry3-Mercaptopropionic Acid

The present invention relates to a method for producing 3-mercaptopropionic acid and carbonic acid ester composition having mercapto group using same, and a method for producing thiourethane-based optical materials. The method for producing 3-mercaptopropionic acid according to the present invention does not include a post-processing treatment, which is necessitated by generation of a dimer such as thiodipropionitrile, thereby the process is simple and economical, and exhibits superior yield rate. Additionally, the carbonic acid ester composition produced with 3-mercaptopropionic acid produced using the method exhibit superior purity and coloring, and allows production at a low cost, and thus has the benefit of being usable as an inexpensive resin composition for urethane-based optical materials, and ptical materials thus produced exhibit excellent coloring. Thiourethane-based optical lenses having good coloring, obtained by means of the present invention, can replace existing lenses and be widely used in diverse fields.

Owner:KOC SOLUTION

Process for preparation of sugammadex sodium

Owner:NEULAND LABORATORIES LTD

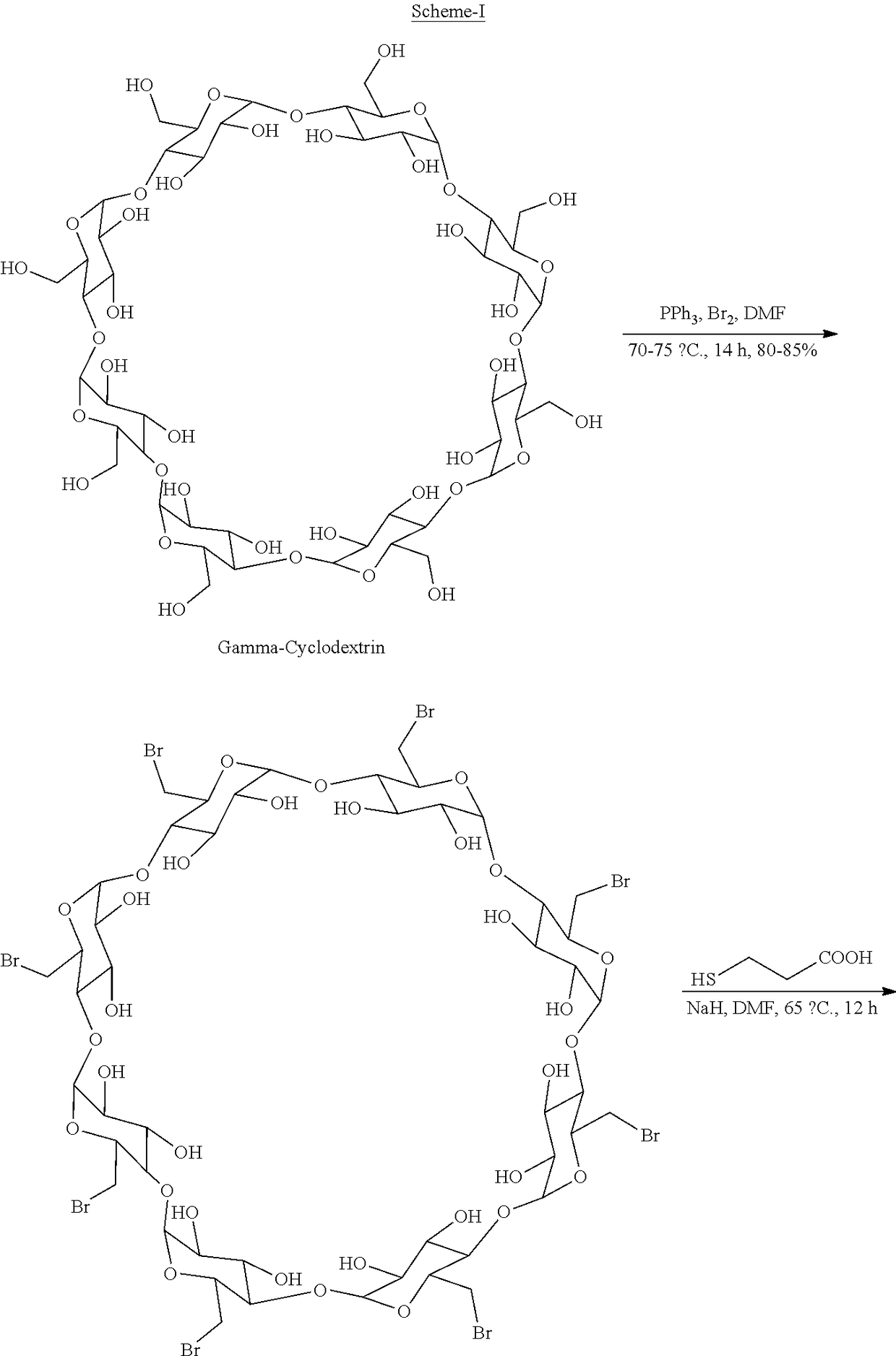

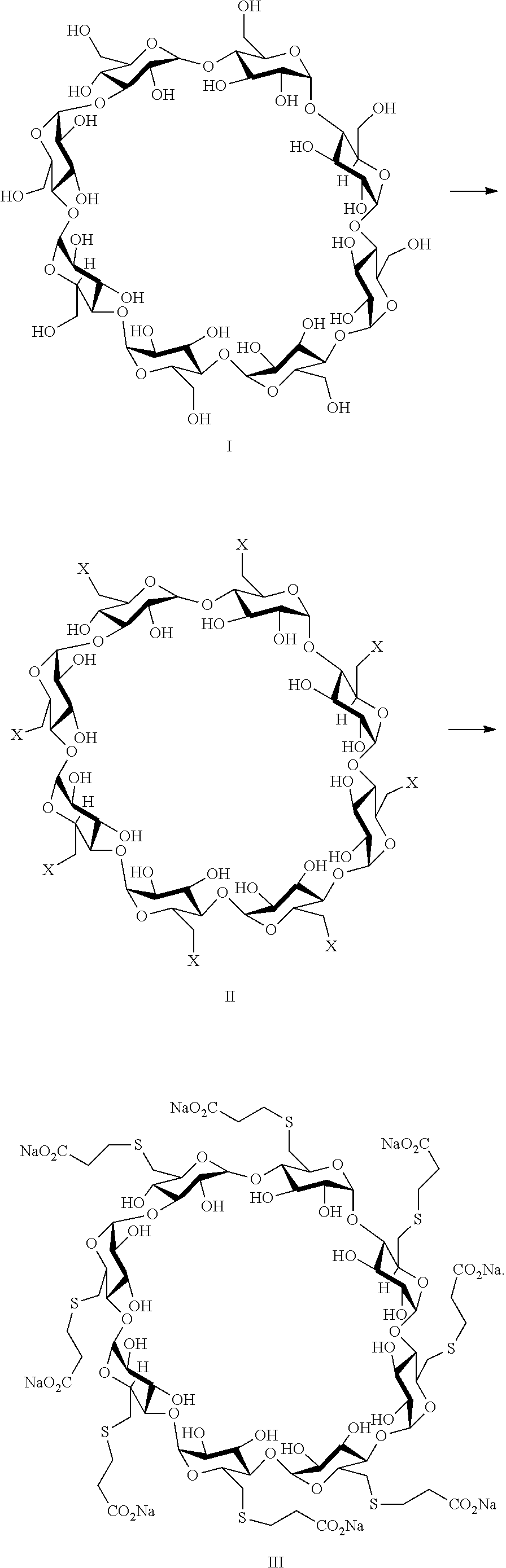

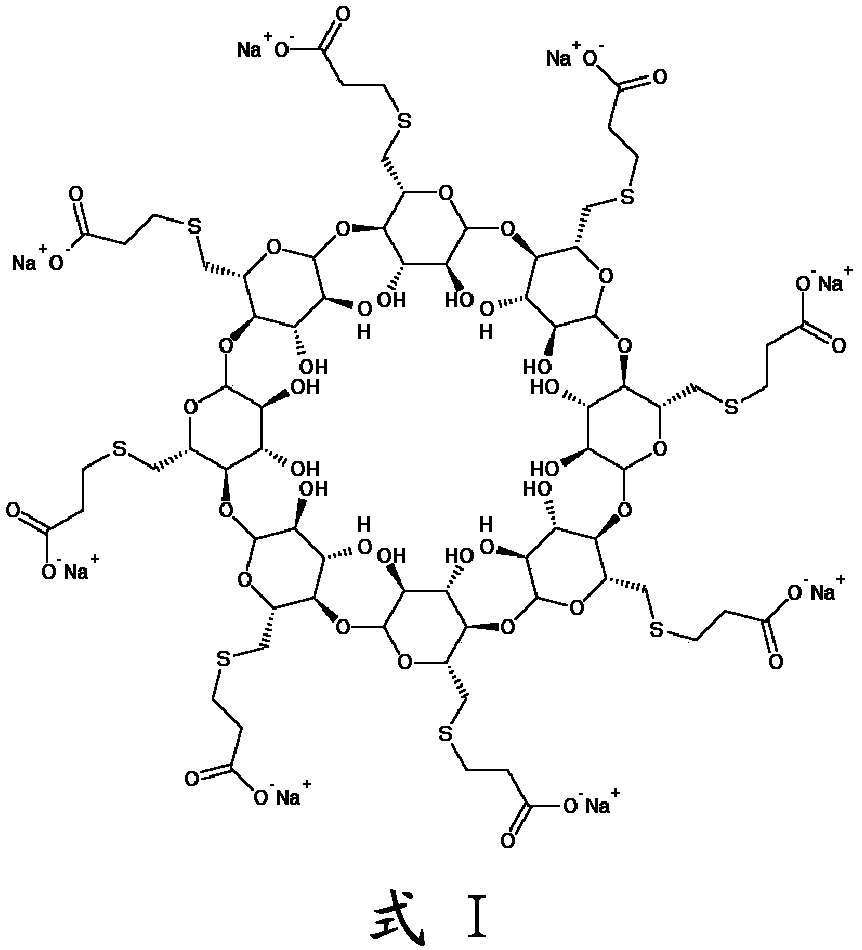

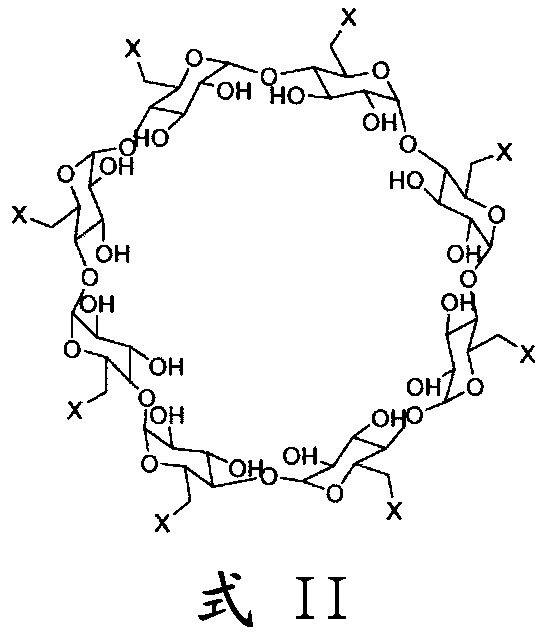

Method for preparing sugammadex sodium

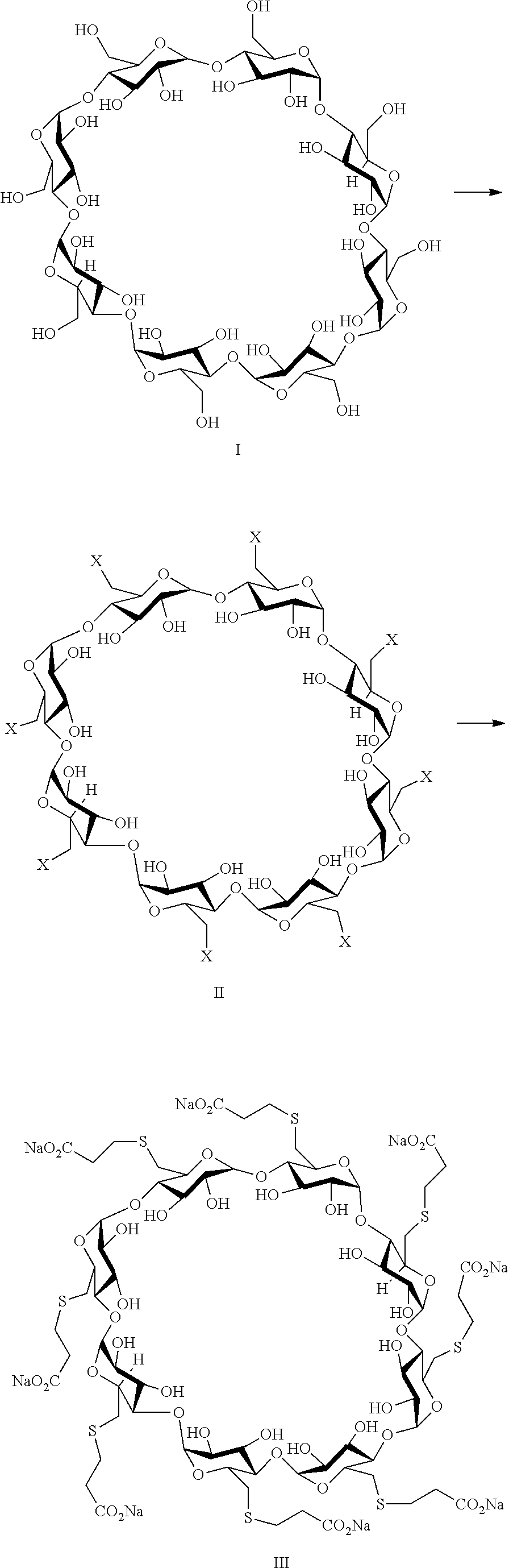

A process for preparing sugammadex sodium comprising:reacting a γ-cyclodextrin of formula I with a halogenating agent in the presence of N-methyl-2-pyrrolidone to provide a compound of formula II; andreacting the compound of formula II with 3-mercapto propionic acid in the presence of a sodium base and an organic solvent to provide sugammadex sodium formula III:

Owner:SCINOPHARM TAIWAN LTD

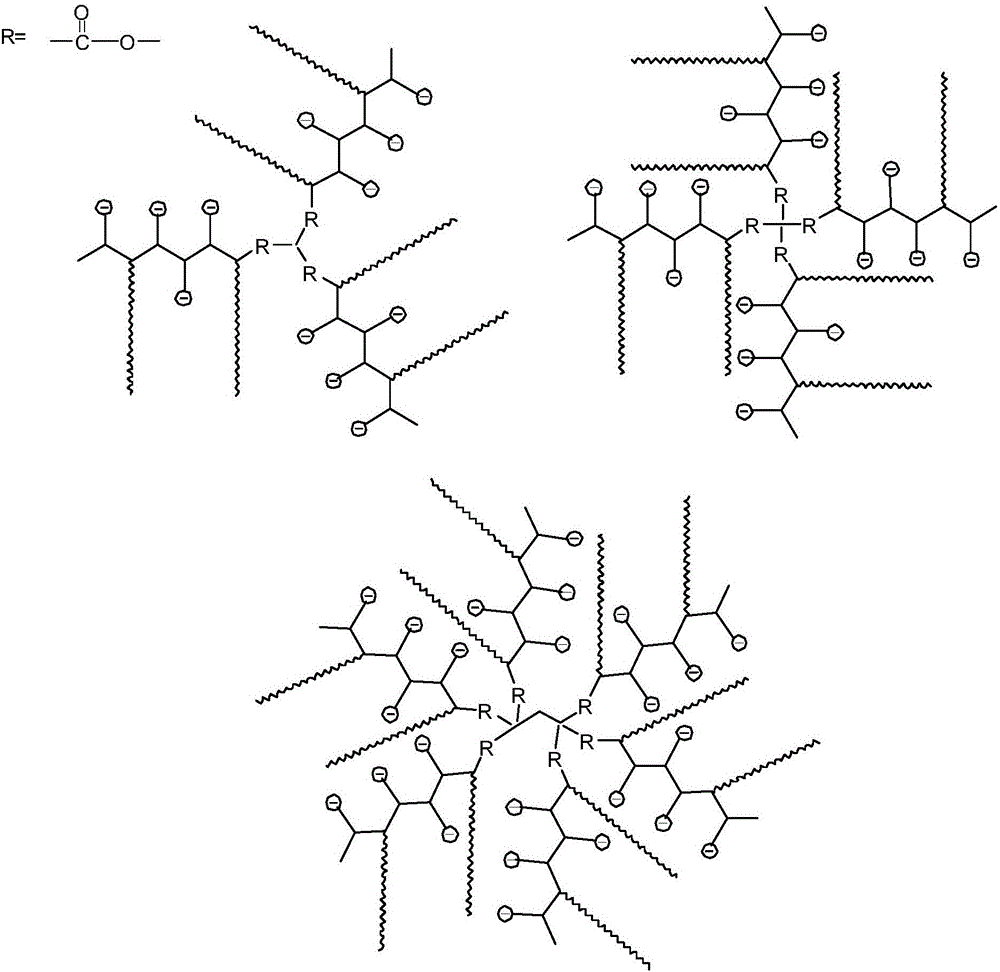

Low and slow coagulating hyperbranched polycarboxylic acid super-plasticizer, preparation method and application thereof

The invention belongs to the field of a super-plasticizer and discloses a low and slow coagulating hyperbranched polycarboxylic acid super-plasticizer, a preparation method and application thereof. The preparation method comprises the following steps: adding polyether macro-monomer, an initiator and water into a reactor; under the nitrogen protection, stirring and mixing uniformly, and meanwhile, heating to 10-100 DEG C; respectively dropwise adding a micro-molecule monomer, a reducing agent and an aqueous solution of a chain transfer agent; after the ending of the dropwise adding, keeping the temperature and reacting for 1-6h and neutralizing, thereby acquiring the low and slow coagulating hyperbranched polycarboxylic acid super-plasticizer. The chain transfer agent is selected from at least one of tri-mercaptoacetic trimethylolpropane ester, pentaerythritol tetrakis and dipentaerythritol hexakis(3-mercaptopropionate). According to the invention, a special chain transfer agent is used and three or more ester groups are introduced into the central position of a main chain, so that the acquired product has a hyperbranched structure. The super-plasticizer has the advantages of high hydration speed, short coagulating time and high initial strength when being applied.

Owner:国科广化(南雄)新材料研究院有限公司 +1

Preparation method of high-performance solid polycarboxylic acid water reducer

The invention discloses a preparation method of a high-performance solid polycarboxylic acid water reducer. The preparation method comprises the following steps of: preparing materials: firstly, pumping acrylic acid and thiohydracrylic acid into a first metering tank through a pump as a material A for later use, and then pumping a vitamin C aqueous solution into a second metering tank as a material B for later use; adding water and methyl allyl polyethenoxy ether into a reaction kettle. And heating the mixture till the methyl allyl polyethenoxy ether is dissolved; a polymerization reaction: adding an active protecting agent, a viscosity modifier and an ammonium persulfate aqueous solution into the reaction kettle, and dropwise adding the materials A and B at the same time, and after dropwise addition, keeping the temperature and performing the polymerization reaction on the materials to obtain a liquid polycarboxylic acid water reducer; cooling and slicing: cooling and slicing the liquid polycarboxylic acid water reducer in a slicer; crushing: cooling and slicing the sliced polycarboxylic acid water reducer; and automatically packaging the crushed solid polycarboxylic acid water reducer in a packaging machine. By means of body polymerization-low-temperature slicing and crushing, reduction of performance due to damage of organic structures of active ingredients by high-temperature drying is effectively reduced; in the production process, the water consumption is small and the energy consumption is low.

Owner:JIANGSU NIGAO SCI & TECH +1

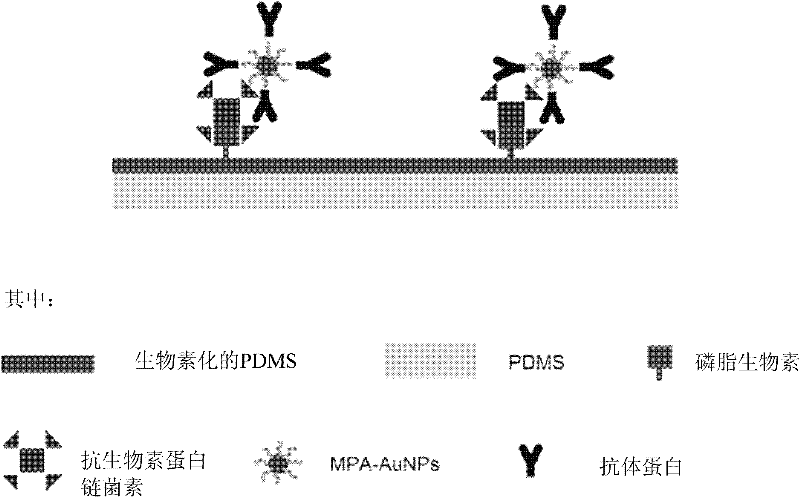

Method for fixing protein on surface of polydimethylsiloxane

The invention provides a method for fixing a protein on the surface of polydimethylsiloxane. The method is characterized in that a biotinylated polydimethylsiloxane film is prepared on the solidified surface of polydimethylsiloxane, a protein is fixed on the surface of polydimethylsiloxane by chemical technologies of biotin-avidin and water-soluble carbodiimide and a technology of 3-mercaptopropionic acid stabilized gold nano-particles, and beta-D-dodecyl-N-maltose and bovine serum albumin are utilized respectively for blockading the non-specific adsorption of a protein on the surface of polydimethylsiloxane and activated residual carboxylic groups on the surface of a 3-mercaptopropionic acid stabilized gold nano-particle. In the invention, the surface of a 3-mercaptopropionic acid stabilized gold nano-particle contains multiple carboxylic groups which can combine molecules of multiple proteins needing to be fixed thus multiple proteins needing to be fixed can be fixed on the surface of polydimethylsiloxane and a sensitivity of a subsequent enzyme-linked immuno sorbent assay (ELISA) is improved effectively.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

Preparation method of 3-mercaptopropionic acid

ActiveCN110372551AHigh yieldHigh purityThiol preparationOrganic compound preparationSodium bisulfideSulfur

Owner:HEBEI HOFMANN NEW MATERIAL TECH CO LTD

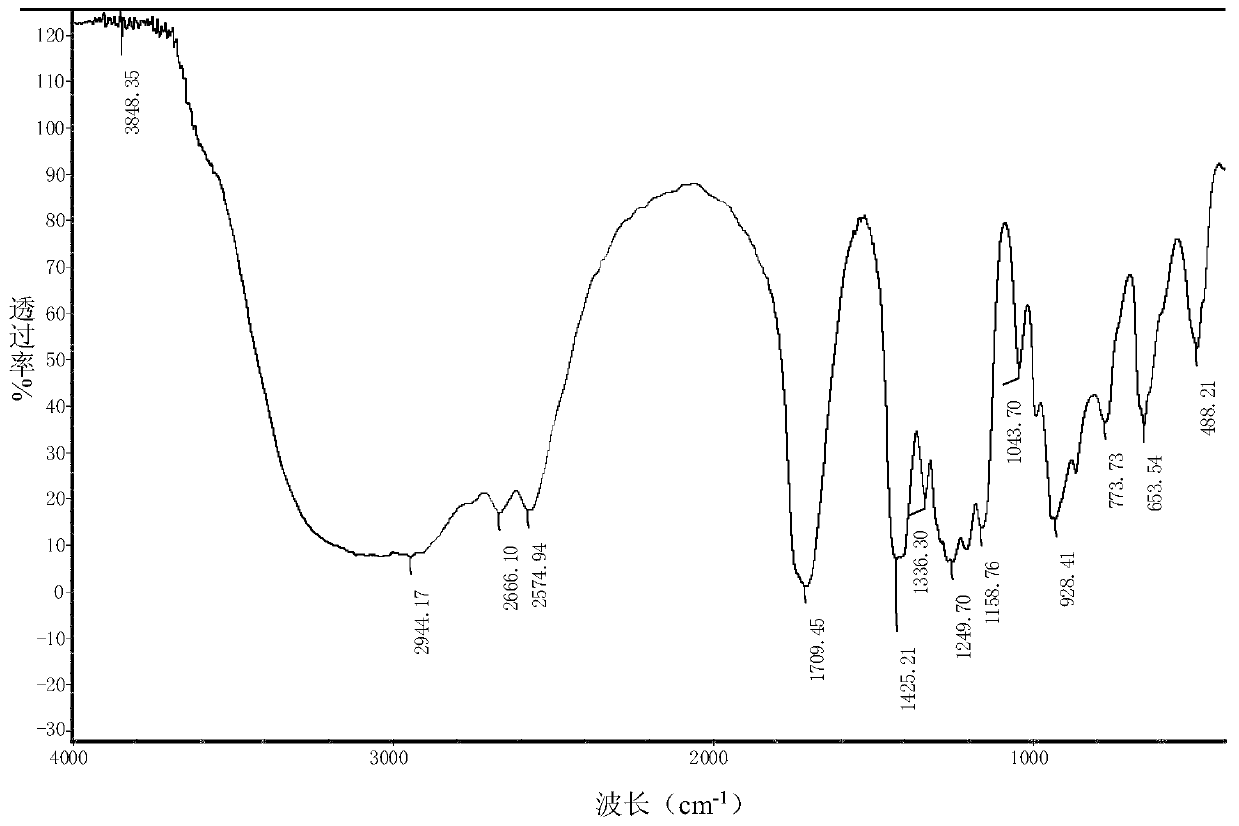

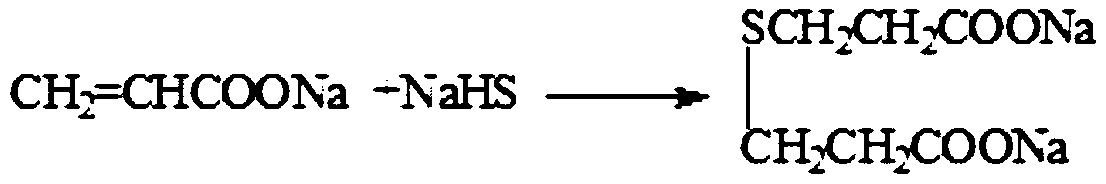

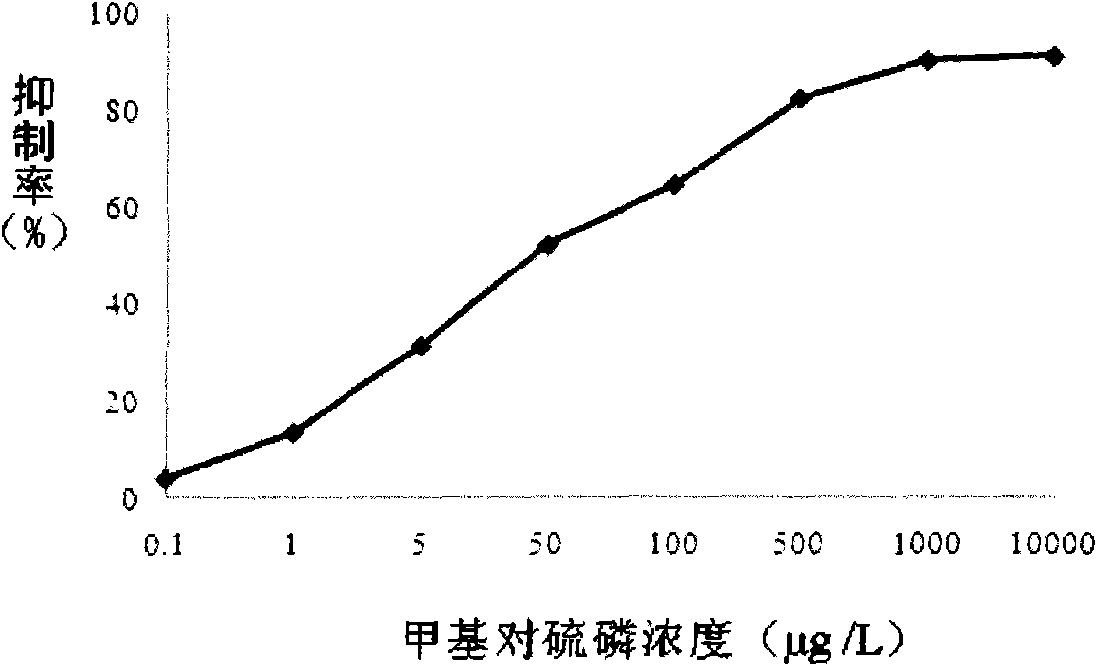

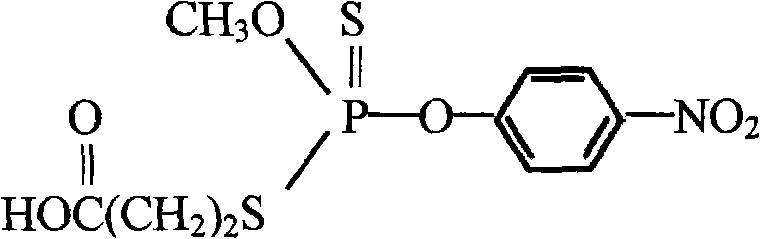

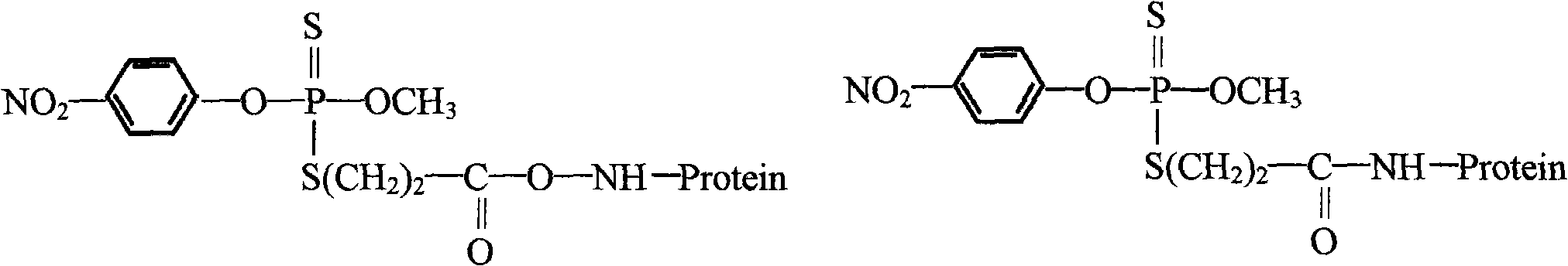

Preparation method and application of parathion-methyl artificial hapten, artificial antigen and specific antibody

The invention discloses a preparation method and application of a parathion-methyl artificial hapten, a parathion-methyl artificial antigen and a parathion-methyl specific antibody, and belongs to the technical field of pesticide immunologic chemistry. The method comprises the following steps of: introducing spacer arms and active groups into a methoxyl site of parathion-methyl by taking 3-mercaptopropionic acid as a functional group reagent to synthesize O-methyl-N-(2-carboxyethyl) sulfo-O-(4-nitrobenzophenone) phosphorothioate (MP for short) serving as the hapten; and coupling the hapten with protein in a mixed anhydride method and an active ester method to prepare the artificial antigen. In the method, the parathion-methyl antibody with high affinity and high specificity is prepared by immunizing an animal through an immunogen, and enzyme-linked immunosorbent assay (ELISA) established by the antibody can be used for detecting trace quantity of parathion-methyl residues in a sample quickly.

Owner:贾明宏 +1

Polyurethane photochromic lens and preparation method thereof

InactiveCN109369855AGood mechanical propertiesImprove mechanical propertiesOptical partsPolyesterPropanoic acid

The invention discloses a polyurethane photochromic lens and a preparation method thereof. The lens comprises the raw materials: polyester diol, isophorone diisocyanate, 2,2-dimethylol propionic acid,methyl methacrylate, styrene, an initiator, glycerol, 3-mercaptopropionic acid, methylbenzene, p-toluenesulfonic acid, a photochromic material and a UV adsorbent. The preparation method comprises thesteps: firstly, mixing glycerol, 3-mercaptopropionic acid, methylbenzene and p-toluenesulfonic acid to carry out a reaction to prepare a curing agent; then, adding polyester diol, isophorone diisocyanate and 2,2-dimethylol propionic acid into a mixed solution of methyl methacrylate and styrene, carrying out mixing, then, adding the curing agent, the photochromic material and the UV adsorbent, andcarrying out stirring to prepare mixed slurry; and pouring the mixed slurry into a die, and placing the die into an air curing furnace to carry out primary curing and secondary curing to obtain the polyurethane photochromic lens. The prepared lens has excellent photochromic and mechanical properties and can be widely applied.

Owner:苏新智能标签(江苏)有限公司

Sorbitol acrylate citric acid modified polycarboxylic acid water reducing agent and preparation method thereof

InactiveCN109593167AImprove collapse retentionGood retarding effectPotassium persulfateNuclear chemistry

The invention discloses a sorbitol acrylate citric acid modified polycarboxylic acid water reducing agent. The water reducing agent is a copolymer formed by polymerizing sorbitol acrylate citric acid,acrylic acid, an unsaturated polyether macromonomer, an initiator and a chain transfer agent through a free radical copolymerization reaction; the unsaturated polyether macromonomer is one or two ofallyl polyoxyethylene ether, methylallyl alcohol polyoxyethylene ether and isoamylene polyoxyethylene ether; the initiator is at least one of hydrogen peroxide, ammonium persulfate and potassium persulfate, or any one of hydrogen peroxide, ammonium persulfate and potassium persulfate in combination with at least one of ascorbic acid, sodium formaldehyde sulfoxylate and ferrous sulfate; the chain transfer agent is at least one of mercaptopropionic acid, thioglycolic acid, mercaptoethanol, mercaptoethylamine, sodium methallyl sulfonate, sodium hypophosphite and sodium allylsulfonate. According to the sorbitol acrylate citric acid modified polycarboxylic acid water reducing agent, a hydration film can be generated on the surface of cement particles, and the slump retaining capability of the water reducing agent and the adaptability to the mechanical sand of different flooring materials and the retarding effect on the concrete can be further improved.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

Preparation technology of sugammadex sodium

The invention provides a method for preparing sugammadex sodium, which is simple in technology, high in purity and high in yield. The method comprises the following step: enabling per(6-deoxy-6-iodo)gamma-cyclodextrin to react with 3-thiohydracrylic acid under the existence of sodium hydride and BHT (2,6-ditert butyl-4-methylphenol), thus obtaining per[6-deoxy-6-(2-carboxyl)sulfo]gamma-cyclodextrin sodium salt, thus the sugammadex sodium.

Owner:BRIGHTGENE PHARMA

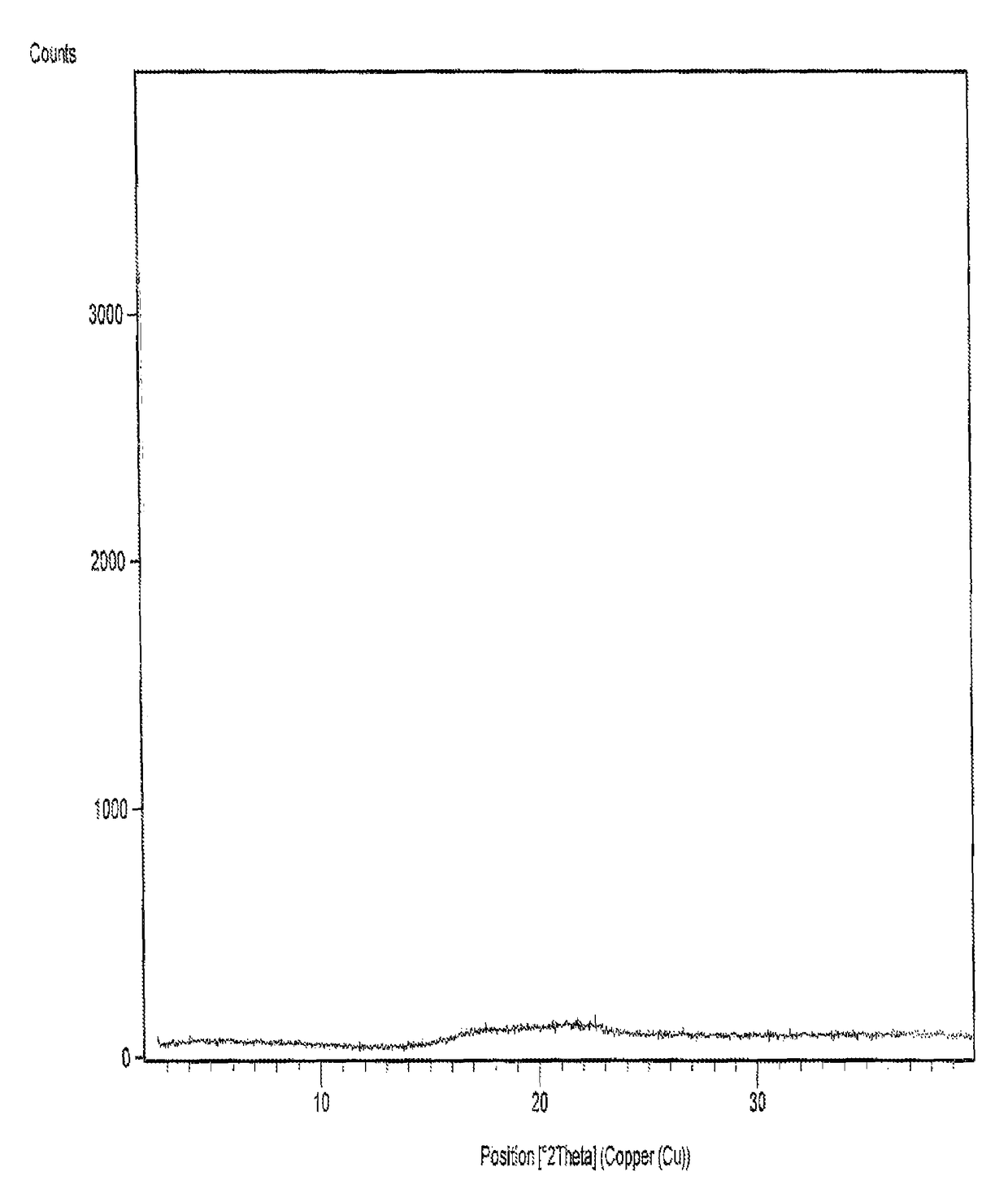

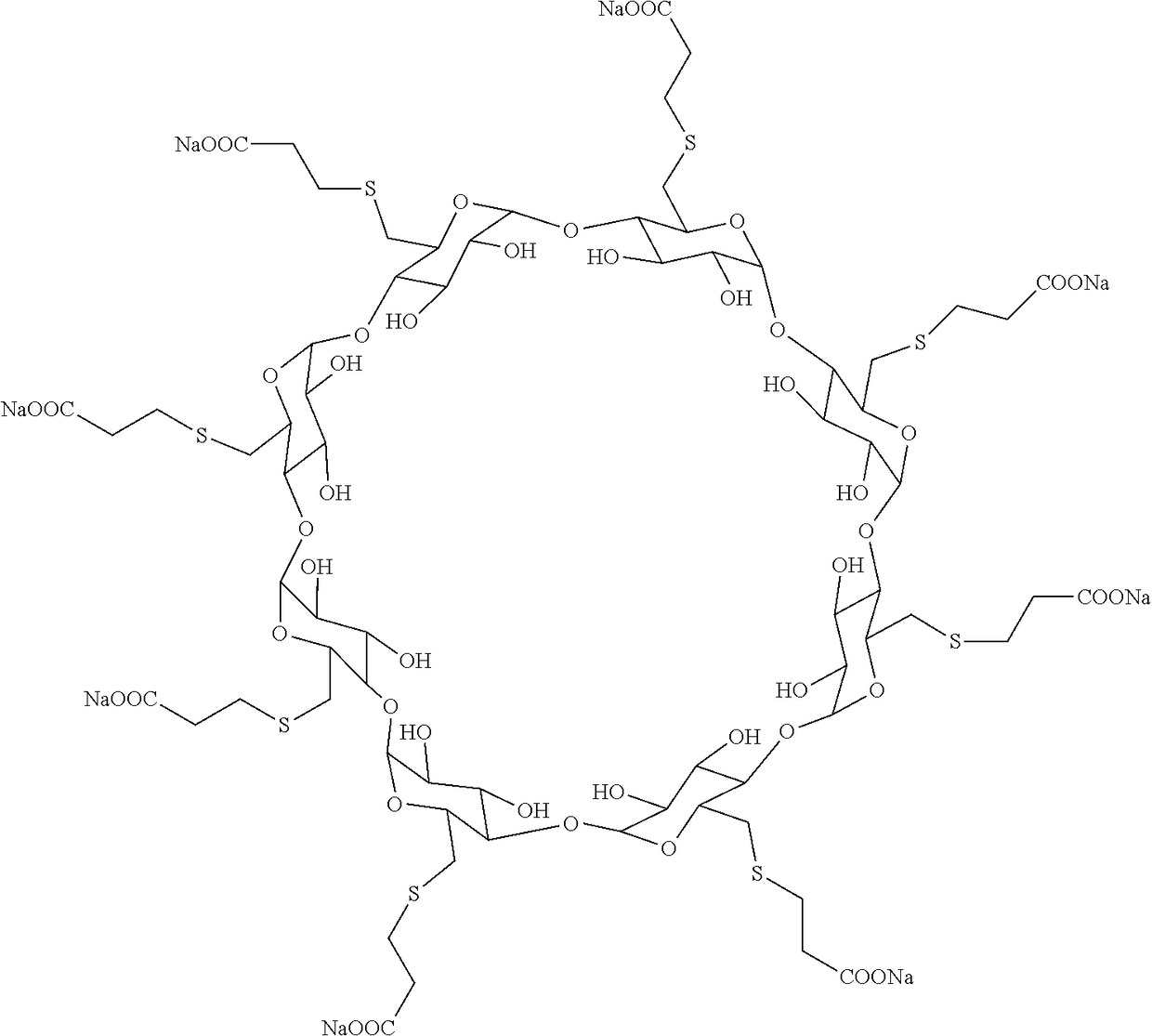

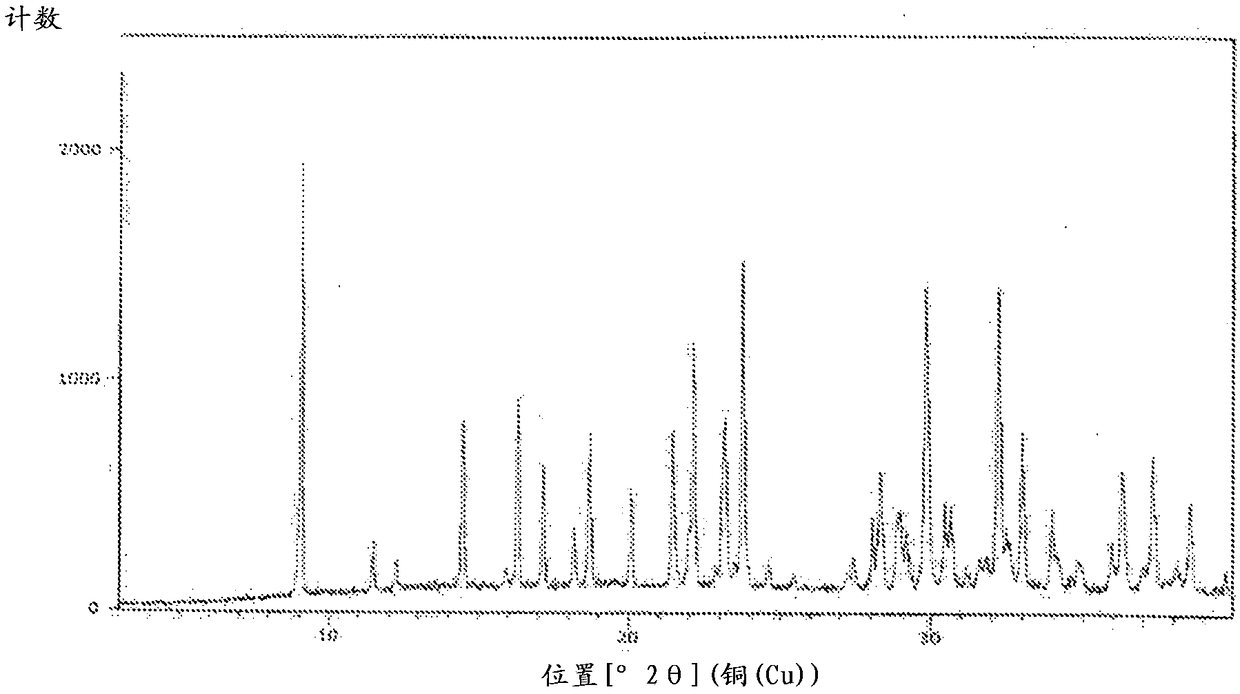

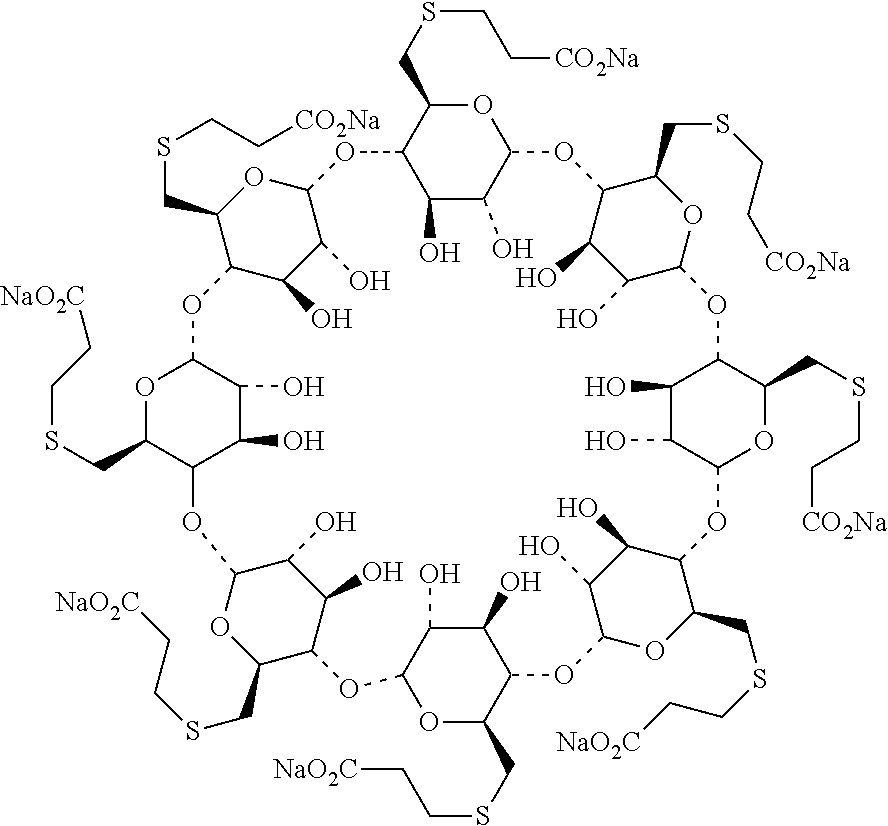

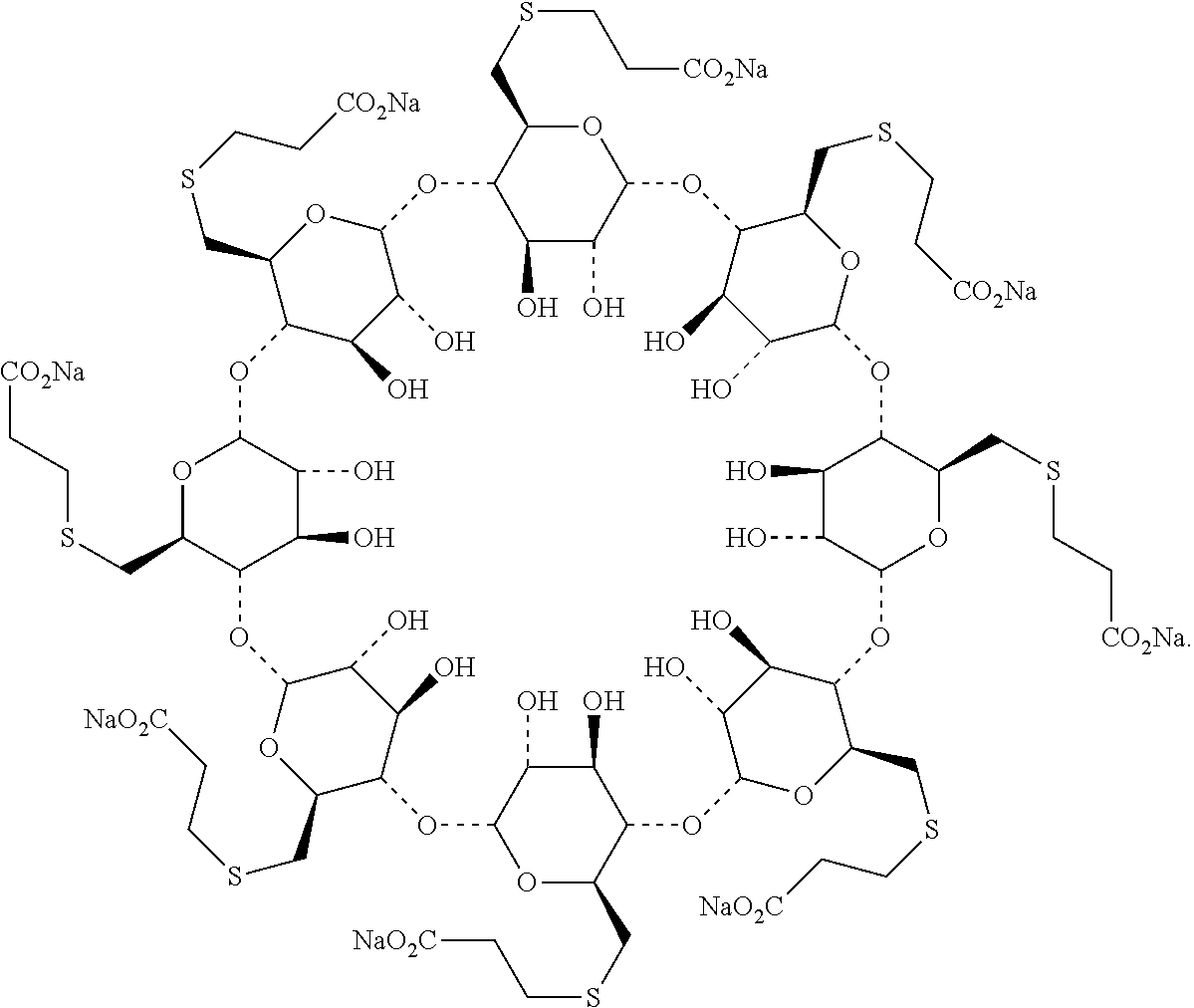

An improved process for the preparation of sugammadex

The present application provides an improved process for the preparation of sugammadex by reacting a salt of 3-mercapto propionic acid with 6-per-deoxy-6- per-halo-[gamma]-cyclodextrin in a suitable organic solvent. This application also provides crystalline form of a salt of 3-mercapto propionic acid, preferably di sodium salt of 3-mercapto propionic acid and its use for the preparation of sugammadex, whereas formula (I) shows the sodium salt of sugammadex.

Owner:FRESENIUS KABI IPSUM SRL

Modified aluminum-silicon particles and modifier thereof

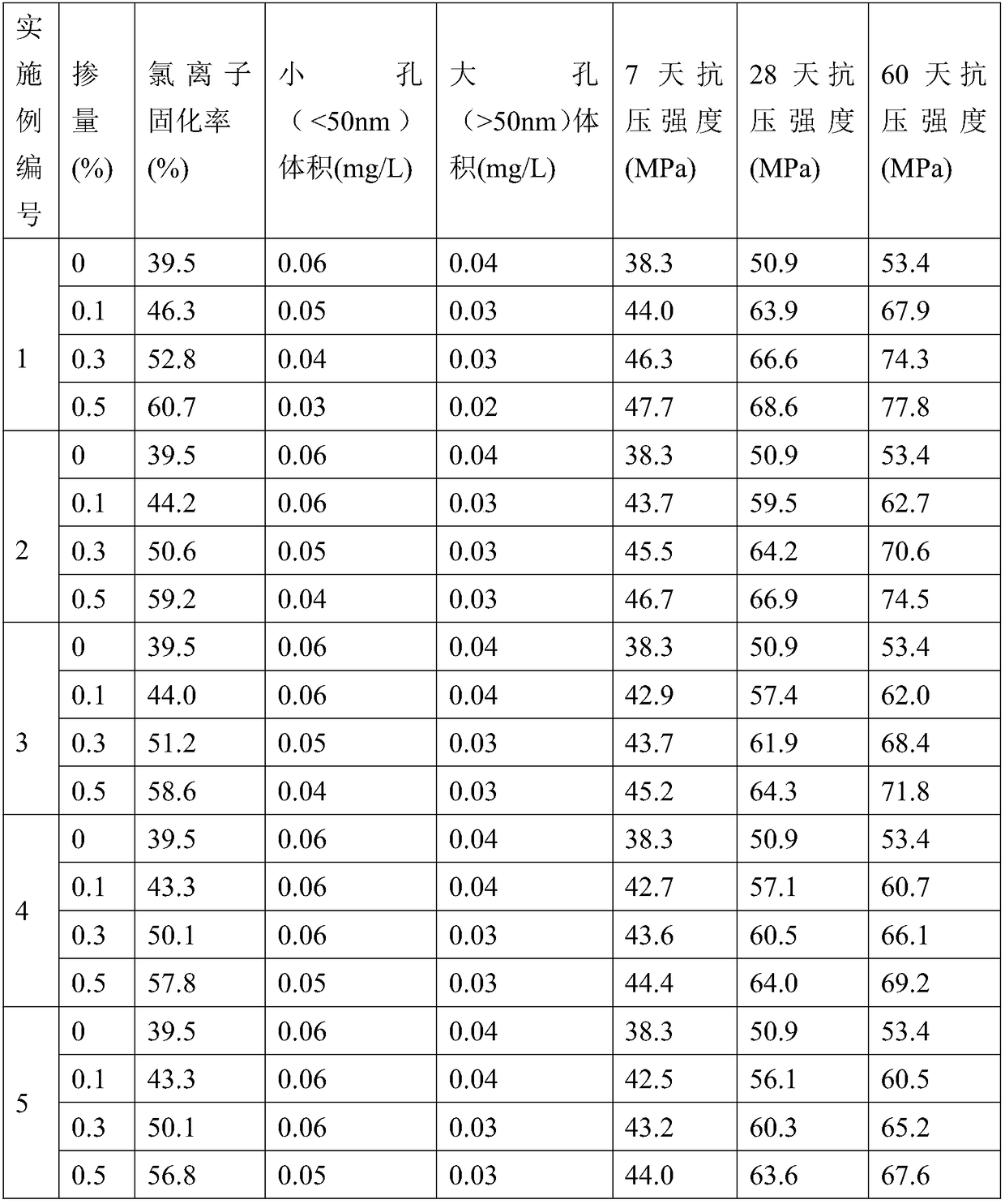

The invention discloses modified aluminum-silicon particles and a modifier thereof. The modified is sprayed to the surface of aluminum-silicon particles by means of vapor deposition at 40-60 DEG C toprepare the modified aluminum-silicon particles. The modifier is prepared by: adding methoxy polyethylene glycol acrylate and water into a reactor, heating to 30-50 DEG C, and adding hydrogen peroxide; dropwise adding acrylic acid, thiohydracrylic acid and n-octyl mercaptan into the reactor, and curing after dropping; adding sodium hydroxide into the reactor, and adjusting pH to 5-7; continuing toadd sodium sulfate and ethyl acetoacetate, and adding triisopropanolamine, triethanolamine and water after full dissolution to obtain a modifier solution. The modified aluminum-silicon particles thatare superfine can be used in cement-based materials to significantly increase the curing rate of chloride ions, up to 50%, with less damage caused to reinforcement by the chloride ions; cement can bereplaced, so that early and later strengths are significantly improved, and the pore structure is optimized.

Owner:WUHAN UNIV OF TECH

Process for preparation and purification of sugammades sodium

ActiveUS20180251575A1Quality improvementSimple processOrganic chemistry methodsSodium methoxideFiltration

The present invention provides a process for the preparation of (6-per-deoxy-6-per-(2-carboxyethyl)thio-γ-cyclodextrin) sodium salt, comprising the steps of:reacting γ-cyclodextrin (SM1) with iodine in the presence of triphenylphosphine in an organic solvent to afford an intermediate, 6-per-deoxy-6-iodo-γ-cyclodextrin (abbreviated as SGMD-1);adding methanol solution of sodium methoxide into the reaction system followed by the addition of acetone without removal of the solvent under reduced pressure to obtain the crude SGMD-1 as a solid after filtration;purifying the crude SGMD-1 by recrystallization;reacting a obtained recrystallized intermediate (SGMD-1) with 3-mercaptopropionic acid in basic medium e.g., sodium hydride, to obtain the crude 6-per-deoxy-6-per-(2-carboxyethyl)thio-γ-cyclodextrin sodium salt (abbreviated as SGMD);purifying the crude SGMD by passing through adsorbents followed by recrystallization.

Owner:BEIJING CREATRON INST OF PHARMA RES CO LTD

Method for preparing sugammadex sodium

A process for preparing sugammadex sodium comprising:reacting a γ-cyclodextrin of formula I with a halogenating agent in the presence of N-methyl-2-pyrrolidone to provide a compound of formula II; andreacting the compound of formula II with 3-mercapto propionic acid in the presence of a sodium base and an organic solvent to provide sugammadex sodium formula III:wherein X in formula II is halo.

Owner:SCINOPHARM TAIWAN LTD

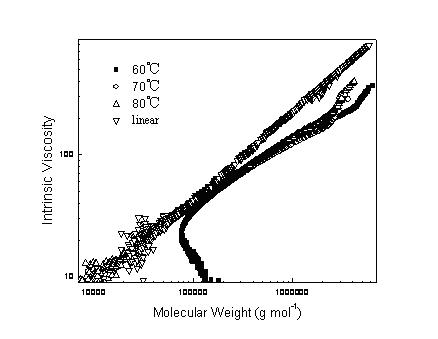

Method for synthesizing branched polymer by using vinyl benzyl sulfydryl propionate as a functional monomer

The invention belongs to the field of macromoleclar polymerization and relates to a method for preparing a branched polymer by using a vinyl benzene monomer containing polymerizable double bonds and chain transfer sulfydryl. In the method, vinyl benzyl sulfydryl propionate serving as a functional monomer and a vinyl monomer such as vinyl benzene undergo polymerization at 60 to 135 DEG C in methylbenzene, benzene or dimethylbenzene serving as a solvent in the presence of azodiisobutyronitrile (AIBN) serving as an initiator to form the branched polymer successfully. The branch degree of the branched polymer can be regulated by regulating the molar ratio of the branched monomer and the polymer monomer, polymerization temperature and polymerization time. In the method, the vinyl benzyl sulfydryl propionate with high storage stability is used as the branched monomer to form the branched polymer under a conventional free radical polymerization condition successfully, the polymerization conditions are mild, the operation is simple and easy to implement, the monomer conversion rate is high, and the degree of branching of the polymer is controllable; and the method has high adaptability for synthesizing branched polymers by using various monomers.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com