Sorbitol acrylate citric acid modified polycarboxylic acid water reducing agent and preparation method thereof

A technology of sorbitol acrylate and citric acid, which is applied in the field of building materials, can solve the problems of poor adaptability, poor segregation and bleeding workability, insufficient slump retention performance of concrete, etc., and achieves the effects of reasonable design, improved slump retention capability and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

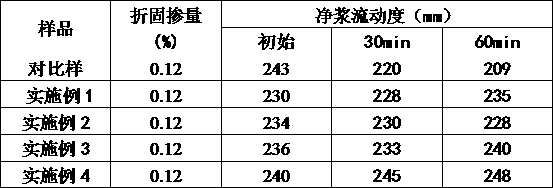

Examples

Embodiment 1

[0019] A citric acid modified polycarboxylate water reducer of sorbitol acrylate is prepared according to the following preparation method, including the synthesis of citric acid of sorbitol acrylate and the process of ternary copolymerization of each unit, the specific steps are as follows:

[0020] (1) Add 124g of ethylene glycol, 316.8g of acrylic acid, 364g of sorbitol, 3.17g of p-toluenesulfonic acid and 2.52g of p-hydroxyanisole into a three-necked round bottom flask equipped with a thermometer and an electric stirrer, stir well and heat To 100°C, react for 8 hours, then cool down to 50°C, add 576g of citric acid, then continue to stir and raise the temperature to 100°C, react for 10 hours, and finally obtain a yellow viscous liquid that is citric acid of sorbitol acrylate.

[0021] (2) Add 250g of water and 320g of polyether macromonomer APEG into a 1000mL four-neck round bottom flask equipped with a thermometer, electric stirrer, constant temperature electric heating ma...

Embodiment 2

[0023] A preparation method of a citric acid-modified polycarboxylate water-reducer of sorbitol acrylate, comprising the synthesis of citric acid of sorbitol acrylate and each unit process of ternary copolymerization, the specific steps are as follows:

[0024] (1) Add 124g of ethylene glycol, 316.8g of acrylic acid, 364g of sorbitol, 3.17g of p-toluenesulfonic acid and 2.52g of p-hydroxyanisole into a three-necked round bottom flask equipped with a thermometer and an electric stirrer, stir well and heat To 100°C, react for 8 hours, then lower the temperature to 50°C, add 576g of citric acid, then continue to heat up to 100°C, react for 10 hours, and finally obtain a yellow viscous liquid that is citric acid of sorbitol acrylate.

[0025] (2) Add 280g of water and 320g of polyether macromonomer HPEG into a 1000mL four-necked round-bottomed flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle and a peristaltic pump. The molecular...

Embodiment 3

[0027] A preparation method of a citric acid-modified polycarboxylate water-reducer of sorbitol acrylate, comprising the synthesis of citric acid of sorbitol acrylate and each unit process of ternary copolymerization, the specific steps are as follows:

[0028] (1) Add 124g of ethylene glycol, 316.8g of acrylic acid, 364g of sorbitol, 3.17g of p-toluenesulfonic acid and 2.52g of p-hydroxyanisole into a three-necked round bottom flask equipped with a thermometer and an electric stirrer, stir well and heat To 100°C, react for 8 hours, then lower the temperature to 50°C, add 576g of citric acid, then continue to heat up to 100°C, react for 10 hours, and finally obtain a yellow viscous liquid that is citric acid of sorbitol acrylate.

[0029] (2) Add 270g of water and 300g of polyether macromonomer TPEG to a 1000mL four-necked round-bottomed flask equipped with a thermometer, an electric stirrer, a constant temperature electric heating mantle, and a peristaltic pump. The molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com