Concrete with synergist and preparation method thereof

A synergist and concrete technology, applied in the field of concrete building materials, can solve the problems of high concrete cost, inability to guarantee concrete quality, and reduce the amount of cement, and achieve the advantages of improving collapse retention, strength and comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

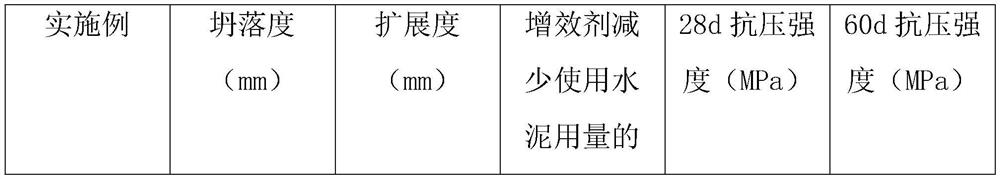

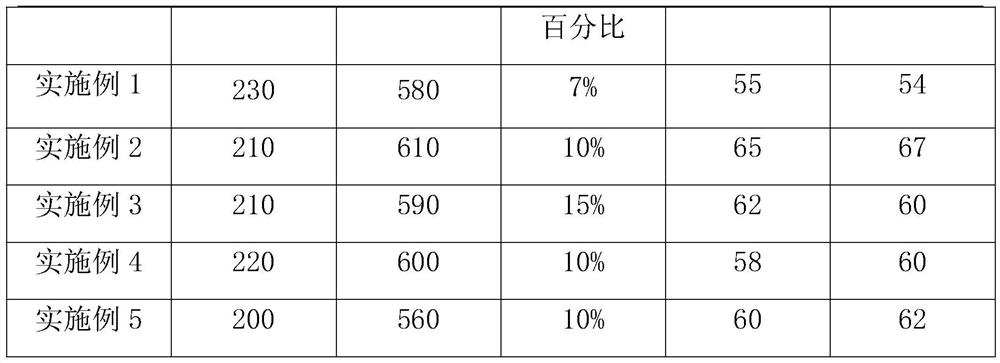

Examples

Embodiment 1

[0023] (1) Take by weighing 200g of triethanolamine, 10g of sodium tripolyphosphate, 20g of tetraethylenepentamine, 20g of sodium tungstate, 50g of sodium pyrophosphate, 50g of allylamine, and 200g of the second part of water;

[0024] (2) Add sodium tripolyphosphate, sodium tungstate, and sodium pyrophosphate to the second part of water, stir for 10 minutes at a temperature of 40°C and a rotation speed of 60r / min, then add triethanolamine, tetraethylenepentamine, allyl base amine, continue to stir for 5 minutes to obtain a synergist;

[0025] (3) Weigh 1.6 kg of melamine formaldehyde resin and 0.4 kg of sulfamic acid, and mix to obtain a water reducer. The melamine formaldehyde resin is a colorless and transparent liquid with a content of ≥98%;

[0026] (4) Weigh 10kg of cement, 25kg of fly ash, 6kg of silica fume, 0.1kg of synergist, 4kg of the first part of water, 10kg of pebbles with a particle size of 10-20mm, 10kg of river sand with a particle size of less than 5mm, and ...

Embodiment 2

[0029] (1) Take by weighing 300g of triethanolamine, 30g of sodium tripolyphosphate, 30g of tetraethylenepentamine, 25g of sodium tungstate, 70g of sodium pyrophosphate, 100g of allylamine, and 220g of the second part of water;

[0030] (2) Add sodium tripolyphosphate, sodium tungstate, and sodium pyrophosphate to the second part of water, stir for 12 minutes at a temperature of 45°C and a rotation speed of 80r / min, then add triethanolamine, tetraethylenepentamine, allyl base amine, continue to stir for 7 minutes to obtain a synergist;

[0031] (3) Weigh 2.2 kg of melamine-formaldehyde resin and 0.8 kg of sulfamic acid, and mix to obtain the water-reducing agent. The melamine-formaldehyde resin is a colorless and transparent liquid with a content ≥ 98%;

[0032] (4) Take by weighing 15kg of cement, 28kg of fly ash, 7kg of silica fume, 0.15kg of synergist, 5kg of the first part of water, 20kg of fly ash ceramsite with a particle size of 10-20mm, and 20kg of quartz sand with a p...

Embodiment 3

[0035] (1) Take by weighing 350g of triethanolamine, 50g of sodium tripolyphosphate, 40g of tetraethylenepentamine, 30g of sodium tungstate, 100g of sodium pyrophosphate, 150g of allylamine, and 250g of the second part of water;

[0036] (2) Add sodium tripolyphosphate, sodium tungstate, and sodium pyrophosphate to the second part of water and stir for 15 minutes at a temperature of 50°C and a rotation speed of 100r / min, then add triethanolamine, tetraethylenepentamine, allyl base amine, continue to stir for 10min to obtain a synergist;

[0037] (3) Weigh 3 kg of melamine-formaldehyde resin and 1 kg of sulfamic acid, and mix to obtain a water-reducing agent. The melamine-formaldehyde resin is a colorless and transparent liquid with a content ≥ 98%;

[0038] (4) Take by weighing 20kg of cement, 30kg of fly ash, 9kg of silica fume, 0.2kg of synergist, 6kg of the first part of water, 25kg of concrete recycled coarse aggregate with a particle size of 10-20mm, and 25kg of steel sla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com