A kind of preparation method of petroleum waste phenol slag modified sulfamate high-efficiency water reducer

The technology of sulfamate and high-efficiency water-reducing agent is applied in the field of concrete materials, which can solve the problems that environmental pollution has not been effectively solved, the treatment of waste residue is complicated, and the treatment cost is high, and achieves significant social and economic benefits. Good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

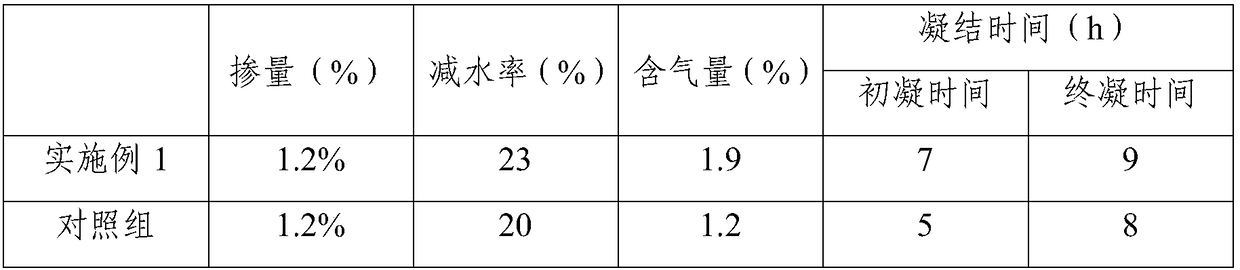

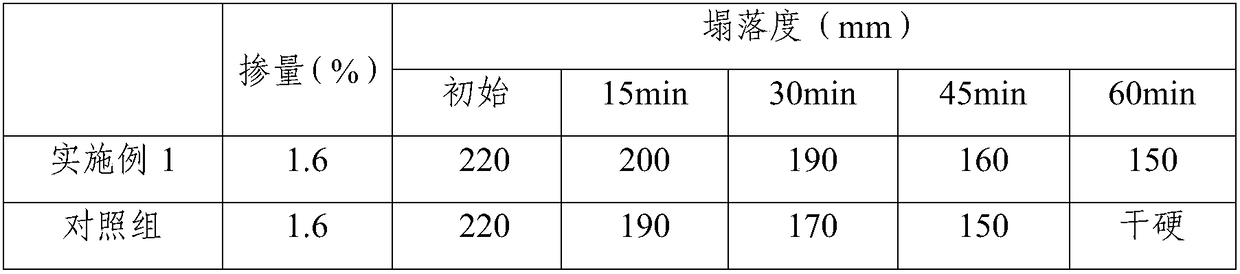

Examples

Embodiment 1

[0018] A high-efficiency sulfamate water reducer modified by petroleum waste phenol slag, which is prepared from the following components by weight: 136 parts of sodium p-aminobenzenesulfonate, 150 parts of 80% petroleum waste phenol residue, concentrated sulfuric acid 43 parts, 56 parts of phenol, 165 parts of formaldehyde, 24 parts of 30% liquid caustic soda, 7 parts of sodium dodecyl diphenyl ether disulfonate, 230 parts of water.

[0019] The preparation method of petroleum waste phenol slag modified sulfamate high-efficiency water reducer comprises the following steps:

[0020] 1) Heat the petroleum waste phenol residue to 85°C, slowly add concentrated sulfuric acid while stirring, sulfonate, keep warm for 1.5h, and obtain sulfonated petroleum waste phenol liquid;

[0021] 2) Heat the water in the reactor to 40°C, add sodium p-aminobenzenesulfonate and phenol in turn while stirring, and heat to 60°C while stirring;

[0022] 3) Add the sulfonated petroleum waste phenol so...

Embodiment 2

[0030] A high-efficiency sulfamate water reducer modified by petroleum waste phenol residue, which is prepared by the following components in proportion by weight: 132 parts of sodium p-aminobenzenesulfonate, 137 parts of 80% petroleum waste phenol residue, concentrated sulfuric acid 40 parts, 53 parts of phenol, 157 parts of formaldehyde, 221 parts of 30% liquid caustic soda, 5 parts of sodium dodecyl diphenyl ether disulfonate, 200 parts of water.

[0031] The preparation method of petroleum waste phenol slag modified sulfamate high-efficiency water reducer comprises the following steps:

[0032] 1) Heat the petroleum waste phenol residue to 83°C, slowly add concentrated sulfuric acid while stirring, sulfonate, keep warm for 1.5h, and obtain sulfonated petroleum waste phenol liquid;

[0033] 2) Heat the water in the reactor to 40°C, add sodium p-aminobenzenesulfonate and phenol in turn while stirring, and heat to 60°C while stirring;

[0034] 3) Add the sulfonated petroleum...

Embodiment 3

[0036] A high-efficiency sulfamate water reducer modified by petroleum waste phenol slag, which is prepared from the following components by weight: 130 parts of sodium p-aminobenzenesulfonate, 200 parts of 80% petroleum waste phenol residue, concentrated sulfuric acid 30 parts, 60 parts of phenol, 150 parts of formaldehyde, 30 parts of 30% liquid caustic soda, 1 part of sodium dodecyl diphenyl ether disulfonate, 200 parts of water.

[0037] The preparation method of petroleum waste phenol slag modified sulfamate high-efficiency water reducer comprises the following steps:

[0038] 1) Heat the petroleum waste phenol residue to 80°C, slowly add concentrated sulfuric acid while stirring, sulfonate, keep warm for 2 hours, and obtain sulfonated petroleum waste phenol liquid;

[0039] 2) Heat the water in the reactor to 40°C, add sodium p-aminobenzenesulfonate and phenol in turn while stirring, and heat to 60°C while stirring;

[0040] 3) Add the sulfonated petroleum waste phenol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com