Modified aluminum-silicon particles and modifier thereof

A modifier, aluminum-silicon technology, applied in the field of cement additives, can solve the problems of poor chloride ion curing ability, poor adaptability, poor stability, etc., and achieve the effect of improving the curing rate, reducing the amount of cement, and increasing the range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

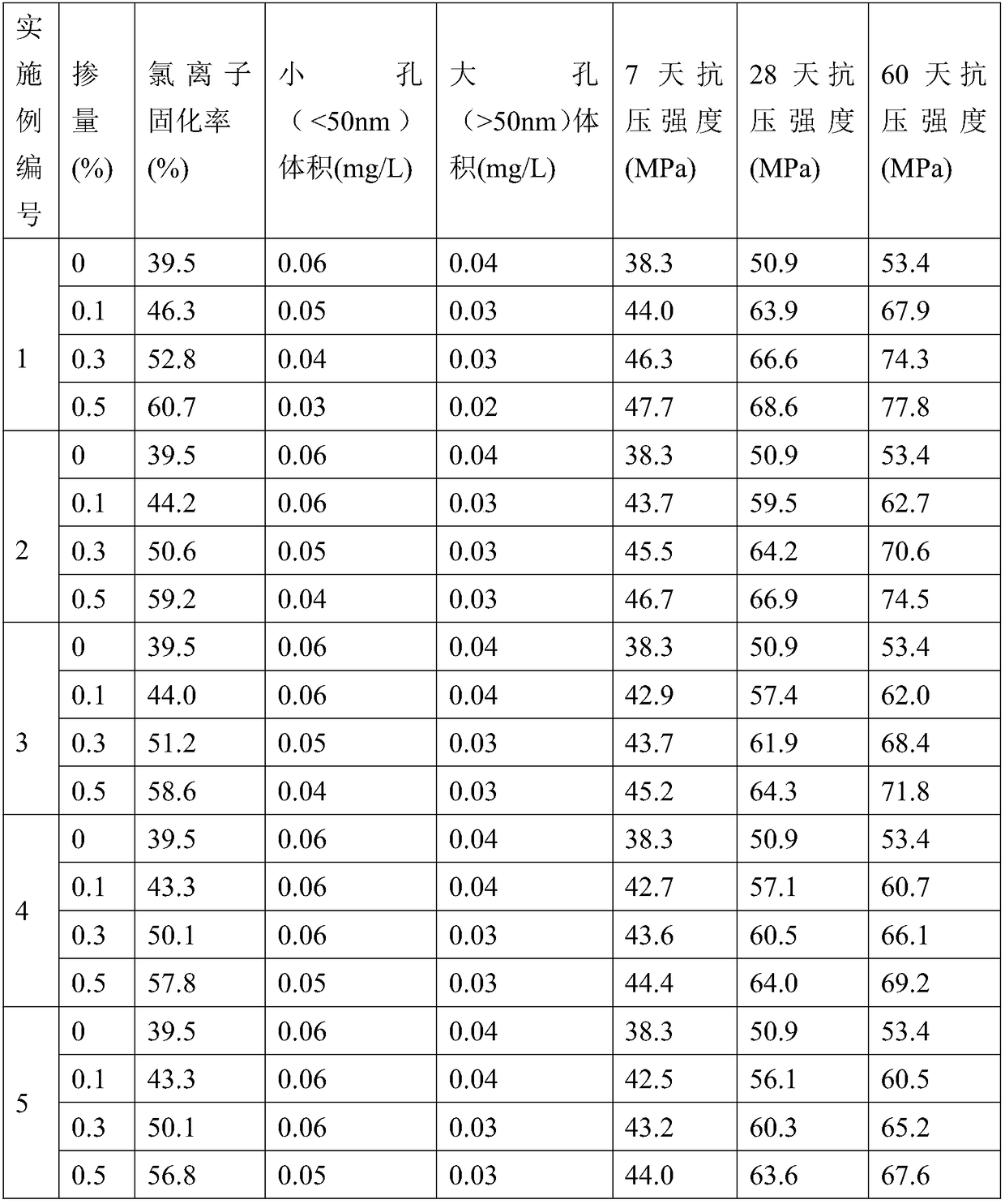

Embodiment 1

[0035] First add 10 parts of methoxypolyethylene glycol acrylate and 17 parts of water into the reaction kettle, raise the temperature to 40 degrees, heat for 30 minutes, and then add 0.5 parts of hydrogen peroxide at one time. Add 2 parts of acrylic acid to 2 parts of water to make material A; add 0.02 parts of mercaptopropionic acid and 0.02 parts of octyl mercaptan to 4 parts of water to make material B, and add A and B materials dropwise to the above reaction kettle to control material A After 3 hours of dripping, material B was dripped in 3.5 hours. After the addition was completed, the material was matured for 1 hour. Add sodium hydroxide to the reaction kettle to adjust its pH to 5-7. Add 4 parts of sodium sulfate and 4 parts of ethyl acetoacetate to the reaction kettle, and wait until it is completely dissolved, add 40 parts of triisopropanolamine, 10 parts of triethanolamine and 5 parts of water to prepare an aluminum silicate particle modifier solution .

[0036] A...

Embodiment 2

[0038] First add 9 parts of methoxypolyethylene glycol acrylate and 17 parts of water into the reaction kettle, raise the temperature to 40 degrees, heat for 30 minutes, and then add 0.5 parts of hydrogen peroxide at one time. Add 1.8 parts of acrylic acid to 2 parts of water to make material A; add 0.015 parts of mercaptopropionic acid and 0.015 parts of octyl mercaptan to 4 parts of water to make material B, and add materials A and B dropwise to the above reaction kettle to control material A After 3 hours of dripping, material B was dripped in 3.5 hours. After the addition was completed, the material was matured for 1 hour. Add sodium hydroxide to the reaction kettle to adjust its pH to 5-7. Add 4.2 parts of sodium sulfate and 4.2 parts of ethyl acetoacetate into the reaction kettle, and wait until they are completely dissolved, then add 39 parts of triisopropanolamine, 11 parts of triethanolamine and 7 parts of water to obtain a uniform solution.

[0039] At 40-60°C, the ...

Embodiment 3

[0041] First add 8.5 parts of methoxypolyethylene glycol acrylate and 16 parts of water into the reaction kettle, raise the temperature to 40 degrees, heat for 30 minutes, and then add 0.4 parts of hydrogen peroxide at one time. Add 1.5 parts of acrylic acid to 2 parts of water to make material A; add 0.016 parts of mercaptopropionic acid and 0.016 parts of octyl mercaptan to 4 parts of water to make material B, and add materials A and B dropwise to the above reaction kettle to control material A After 3 hours of dripping, material B was dripped in 3.5 hours. After the addition was completed, the material was matured for 1 hour. Add sodium hydroxide to the reaction kettle to adjust its pH to 5-7. Add 4.3 parts of sodium sulfate and 4.3 parts of ethyl acetoacetate to the reaction kettle, and wait until they are completely dissolved, then add 38 parts of triisopropanolamine, 11 parts of triethanolamine and 9 parts of water to obtain a uniform solution.

[0042] At 40-60°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com