Preparation method for green and environmentally friendly sugammadex sodium

A technology of sugammadex sodium, green and environmental protection is applied in the field of preparation of sugammadex sodium, which can solve the problems of increasing the difficulty of industrial application, cumbersome processing process, etc., and achieves the effects of good application prospect, high product purity and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Synthesis of Crude Sugammadex Sodium

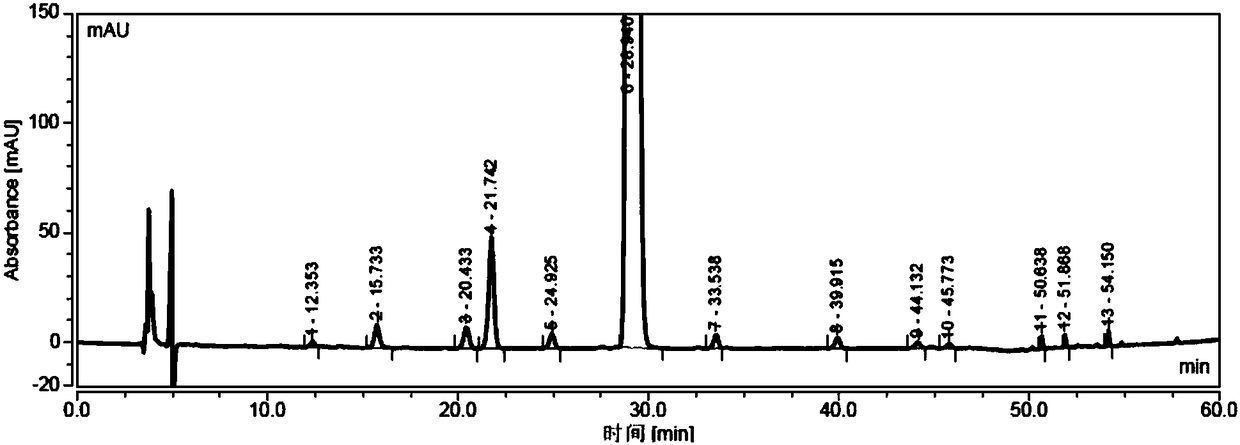

[0041] Add sodium hydroxide (23.5g, 588mmol) into the reaction flask, add 150ml water to dissolve completely; add dropwise 3-mercaptopropionic acid aqueous solution (39.0g, 368mmol, dissolve in 80ml water) to the flask under stirring, add 6-deoxy- 6-Periodo-γ-cyclodextrin (40g, 18.4mmol), after adding, raise the temperature to 100°C, and react for 4h; after the reaction, cool to room temperature, add 700mL DMF to crystallize while stirring, filter, collect the solid, and dry in vacuo Obtain off-white solid 45g, purity is 94.83% (see attached Figure 3-4 ).

Embodiment 2

[0043] Purification of sugammadex sodium

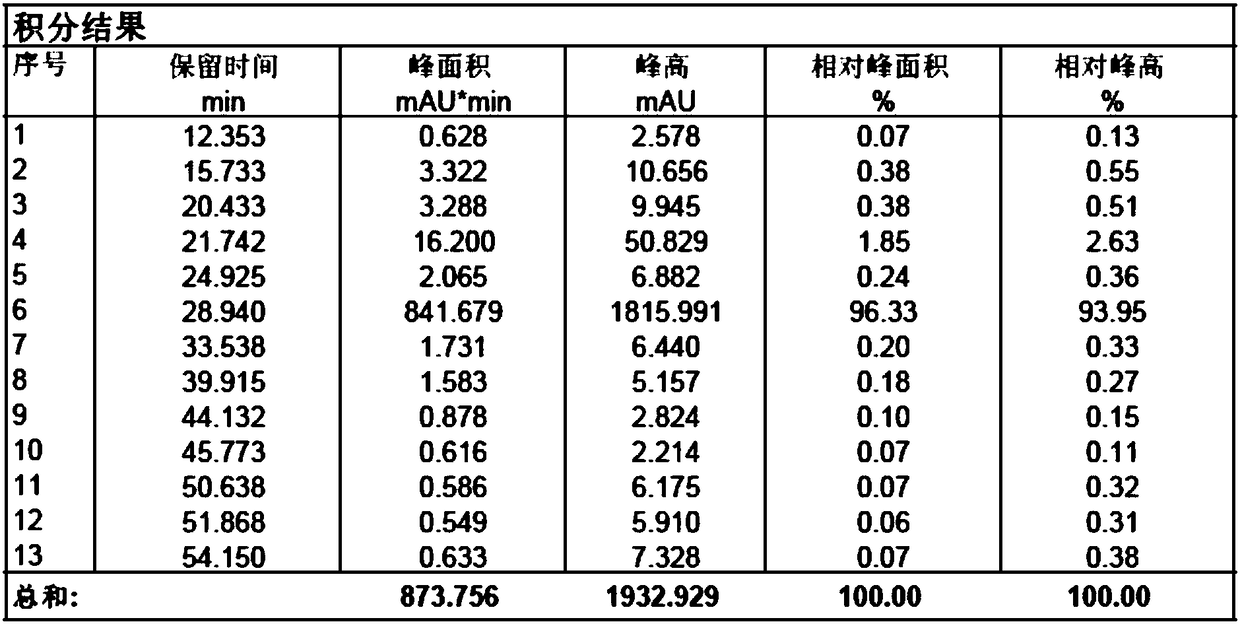

[0044] Under the protection of nitrogen, take 40g of crude sugammadex sodium, dissolve it in a mixed solution of 100ml of water and 600ml of ethanol, stir and raise the temperature to 40°C, then cool down to room temperature, a white solid precipitates out, and is filtered by suction to obtain 35g of a white solid; repeat the above During the recrystallization process, 32g of white solid was obtained; the solid was detected by HPLC, except that the impurity with retention time RRT=0.87 was relatively large, and all other impurities were less than 0.1% (see attached Figure 5-6 ).

[0045] Put 30 g of sugammadex sodium after recrystallization and purification into a beaker, add 100 ml of purified water into the beaker and stir to dissolve completely. 300g of neutral alumina was added to the glass chromatography column, and the crude sugammadex sodium solution was loaded into the chromatography column. The chromatographic column was e...

Embodiment 3

[0047] Purification of sugammadex sodium

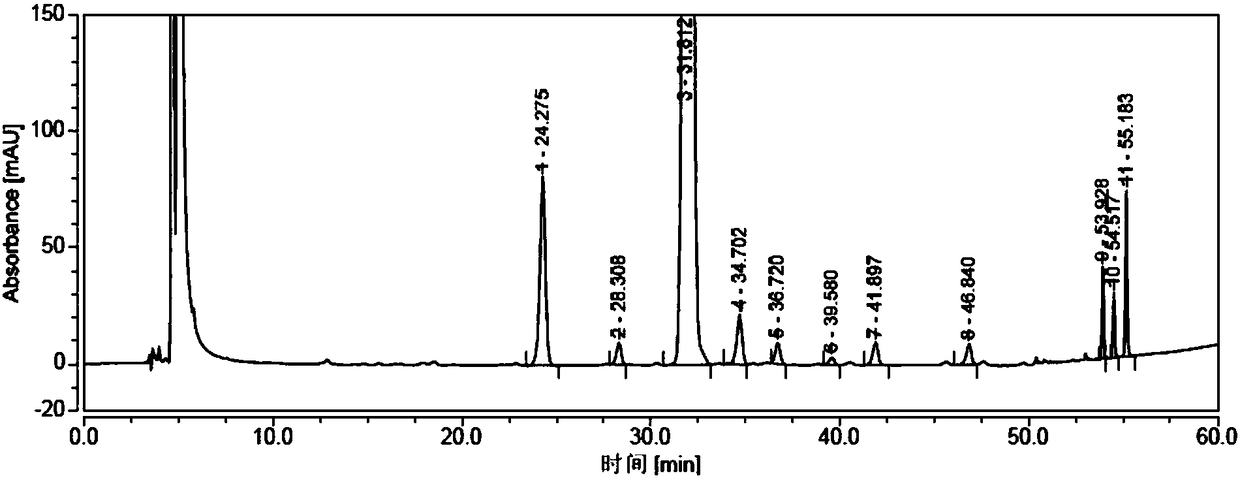

[0048]Put 35g of sugammadex sodium crude product into a beaker, add 120ml of purified water into the beaker and stir to dissolve completely; add 350g of neutral alumina to the glass chromatography column, and load the sugammadex sodium crude product solution onto the chromatography column Medium; the chromatography column was eluted with 2L of purified water, and the eluent was concentrated to dryness under reduced pressure to obtain 30 g of white solid; the solid was detected by HPLC, except for the impurity with retention time RRT=0.87 was removed, the rest of the impurities were relatively large (see attached Figure 9-10 ).

[0049] Under the protection of nitrogen, take 30 g of the above white solid, dissolve it in a mixed solution of 90 ml of water and 225 ml of DMF, stir to raise the temperature to 85 ° C, and then cool it down to room temperature, a white solid is precipitated, filtered by suction to obtain 28 g of a white so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com