Silane polycarboxylate water-reducing agent and preparation method thereof

A silane type and polycarboxylic acid technology, which is applied in the preparation of silane type polycarboxylate water reducer, silane type polycarboxylate water reducer and water reducer field, can solve the problem of performance decline, poor cement adaptability, admixture mixing In order to achieve the effect of improving the force, good cement adaptability, and avoiding competitive adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

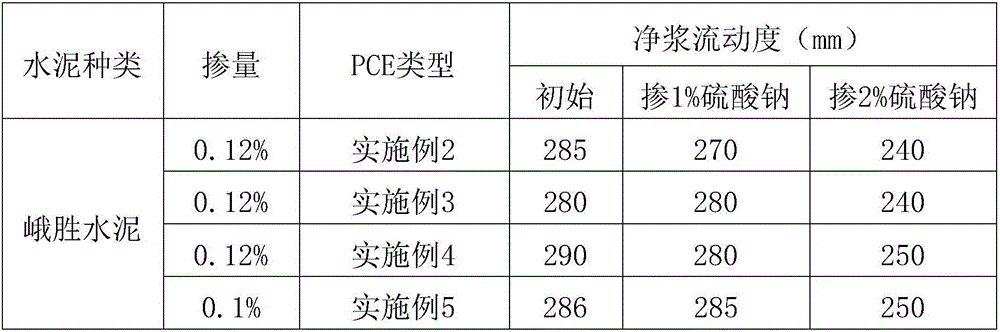

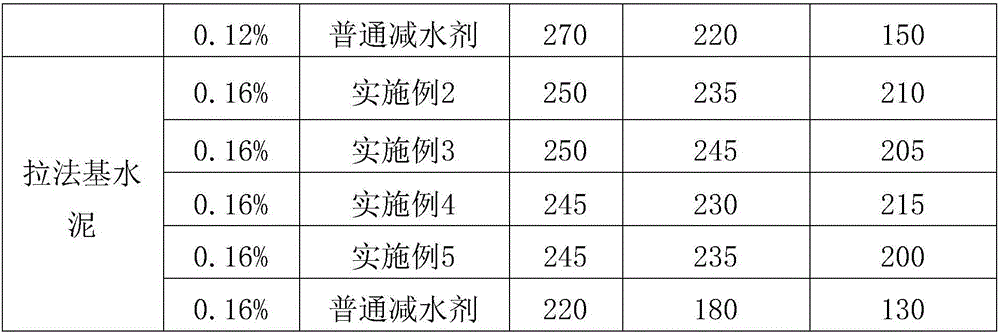

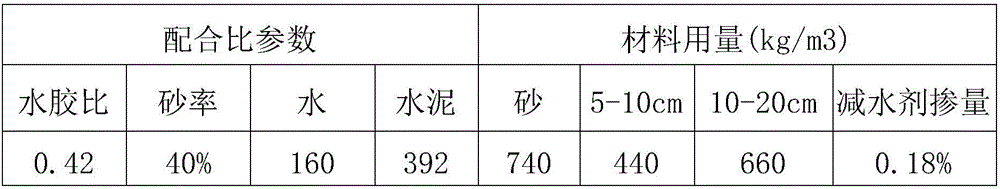

Examples

preparation example Construction

[0034] Among them, the preparation method includes the following steps:

[0035] (1) Add the above-mentioned polyoxyethylene ether macromonomer, 2-acrylamido-2-methyl-1-propanesulfonic acid and an appropriate amount of deionized water into a three-necked flask according to mass parts, heat and stir to dissolve;

[0036] (2) Dissolve the above-mentioned chain transfer agent and initiator in an appropriate amount of deionized water as part A by mass;

[0037] (3) Add the above-mentioned acrylic acid derivative monomers to an appropriate amount of deionized water to dissolve as B solution according to mass parts;

[0038] (4) Add the above-mentioned silane-based functional monomers to the remaining deionized water to dissolve as C solution according to mass parts;

[0039] (5) After step (1) is completed, heat the three-necked flask to 58-62°C or 78-82°C, and use a constant flow pump to add liquid A and liquid B dropwise in 1.8 to 2 hours; after 3 minutes of reaction Use a constant flow p...

Embodiment 1

[0042] The silane polycarboxylic acid water reducing agent is made of the following mass parts of raw materials:

[0043] Prenol polyoxyethylene ether TPEG-3000 or prenol polyoxyethylene ether TPEG-2400 82 parts, sodium acrylate 9.6 parts, sodium methallyl sulfonate 0.85 parts, sodium persulfate 1.3 parts, silane 6.5 parts of similar monomers, 5 parts of 2-acrylamido-2-methyl-1-propanesulfonic acid, and 145 parts of deionized water.

Embodiment 2

[0045] The silane polycarboxylic acid water reducing agent is made of the following mass parts of raw materials:

[0046] Prenol polyoxyethylene ether TPEG-3000 or prenol polyoxyethylene ether TPEG-2400 80 parts, 9.5 parts of sodium acrylate, 0.3 parts of mercaptopropionic acid, 1.0 part of sodium methallyl sulfonate, allyl 0.4 parts of sodium sulfonate, 1.3 parts of ammonium persulfate, 6.5 parts of silane monomers, and 150 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com