Method for synthesizing branched polymer by using vinyl benzyl sulfydryl propionate as a functional monomer

A technology of vinylbenzyl mercaptopropionate and branched polymers, which is applied in the field of branched polymers prepared from styrene monomers, and can solve the problems of extremely unstable storage of monomers, poor stability of polymers, and low branching efficiency. problems, to achieve the effect of simple and easy operation, mild polymerization reaction conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

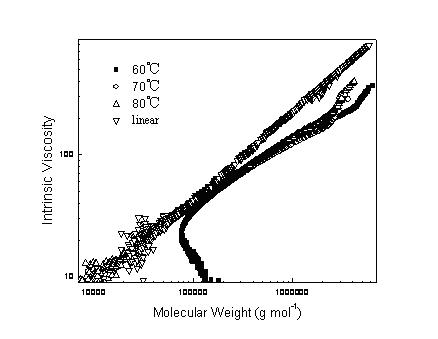

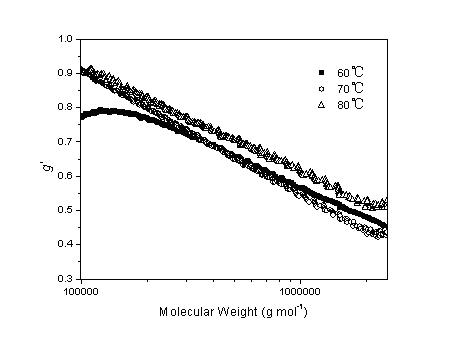

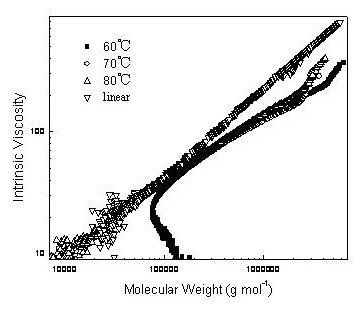

[0018] Vinylbenzyl mercaptopropionate (0.0215g, 0.1mmol), styrene (10.4067g, 0.1mol), initiator AIBN (0.0823g, 0.5mmol) and solvent toluene (5.2051g) were added to the flask, and the flask Put it into an oil bath at 60° C. and react for 45 hours, and the conversion rate of styrene is measured to be 91.50%. The polymer was analyzed by three-detection gel permeation chromatography, and the results were as follows: light scattering weight average molecular weight M w.MALLS =606900, molecular weight distribution PDI=4.81, Mark-Houwink index α=0.585, branching factor g '=0.47, confirming that the obtained polymer has a branched structure.

Embodiment 2

[0020] Vinylbenzyl mercaptopropionate (0.0227g, 0.1mmol), styrene (10.4096g, 0.1mol), initiator AIBN (0.0818g, 0.5mmol) and solvent toluene (5.2096g) were added to the flask, and the flask Put it into an oil bath at 70° C. for 44 hours to react, and the measured conversion rate of styrene reaches 97.40%. The polymer was analyzed by three-detection gel permeation chromatography, and the results were as follows: light scattering weight average molecular weight M w.MALLS =235700, molecular weight distribution PDI=3.74, Mark-Houwink index α=0.546, branching factor g ' = 0.62, confirming that the obtained polymer has a branched structure.

Embodiment 3

[0022] Vinyl benzyl mercaptopropionate (0.0231 g, 0.1 mmol), styrene (10.4102 g, 0.1 mol), initiator AIBN (0.0825 g, 0.5 mmol) and solvent toluene (5.2170 g) were added to the flask, and the flask Put it into an 80° C. oil bath and react for 18 hours, and the measured conversion rate of styrene reaches 92.10%. The polymer was analyzed by three-detection gel permeation chromatography, and the results were as follows: light scattering weight average molecular weight M w.MALLS =233900, molecular weight distribution PDI=4.07, Mark-Houwink index α=0.517, branching factor g '=0.65, confirming that the obtained polymer has a branched structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

| Branching factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com