Method for preparing polycarboxylic acid water reducing agent by using sodium methyl acryl sulfonate as chain transfer agent

A technology of sodium methacrylate and chain transfer agent, which is applied in the field of concrete water reducing agent, can solve the problems of not conforming to the concept of green environmental protection, high toxicity, and polluting the construction environment, so as to avoid the poisonous effect on the human body and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

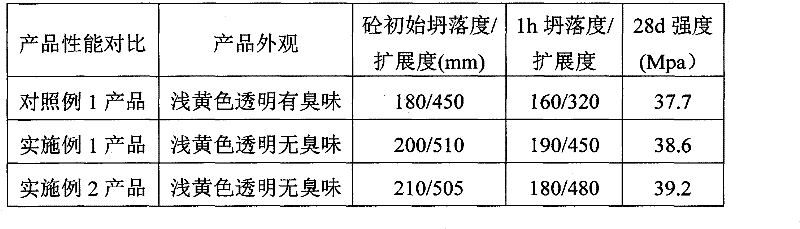

Examples

Embodiment 1

[0017] First add 930g of tap water, 1800g of modified polyether methylbutenol polyoxyethylene ether, and 20g of sodium methacrylic acid sulfonate to the reaction kettle (four-necked flask), heat up and dissolve, and start to prepare liquid A and liquid B at the same time. Liquid A is made by mixing 22g ammonium persulfate and 580g water, i.e. ammonium persulfate solution; liquid B is made by mixing 193g acrylic acid, 16g sodium methacrylic acid sulfonate and 180g water, i.e. acrylic acid solution; (The mixture of water, sodium methacrylate and modified polyether) starts to add liquid A and liquid B dropwise when it reaches 58°C~62°C, liquid A drops 3.5 hours after dropping, and drops 1 / 3 1.5 hours before dropping B, After the last 1.5h, drop 2 / 3, when the liquids A and B are dropped, keep warm for 1 hour. The temperature of the heat preservation reaction is controlled at 60°C to 65°C. When the temperature drops below 45°C, 1100g of make-up water and 220g of 32% liquid caustic ...

Embodiment 2

[0019] First add 930g of tap water, 1800g of modified polyether methylbutenol polyoxyethylene ether, 16g of sodium methacrylic acid sulfonate to the four-neck flask, heat up and dissolve, and start to prepare liquid A and liquid B at the same time, that is, ammonium persulfate solution And acrylic acid solution, wherein A liquid is formed by mixing 22g of ammonium persulfate and 580g of water, and B liquid is formed by mixing 193g of acrylic acid, 16g of sodium methacrylate sulfonate and 185g of water.

[0020] When the four-neck flask (mixture of water, sodium methacrylate and modified polyether) reaches 58°C-62°C, start to add liquid A and liquid B dropwise, liquid A drops 3.5h, and B drops 1.5h Drop 1 / 3, then drop 2 / 3 in the last 1.5 hours. After A and B drops, keep warm for 1 hour, control the reaction temperature at 60°C to 65°C, and add supplementary water 1100g and 32% solution when the temperature drops below 45°C Neutralize with 220g of alkali to finally obtain a poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com