Phosphoric-acid-base modified polycarboxylic-acid water reducer with high adaptability and preparation method thereof

A phosphoric acid-based, adaptable technology, applied in the preparation of the polycarboxylate superplasticizer, concrete admixtures, phosphoric acid-based modified polycarboxylate superplasticizer, and polycarboxylate superplasticizer fields, can solve the problem of unsatisfactory To improve the anti-sulfate ability and anti-mud ability, improve the adaptability, and improve the adaptability of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

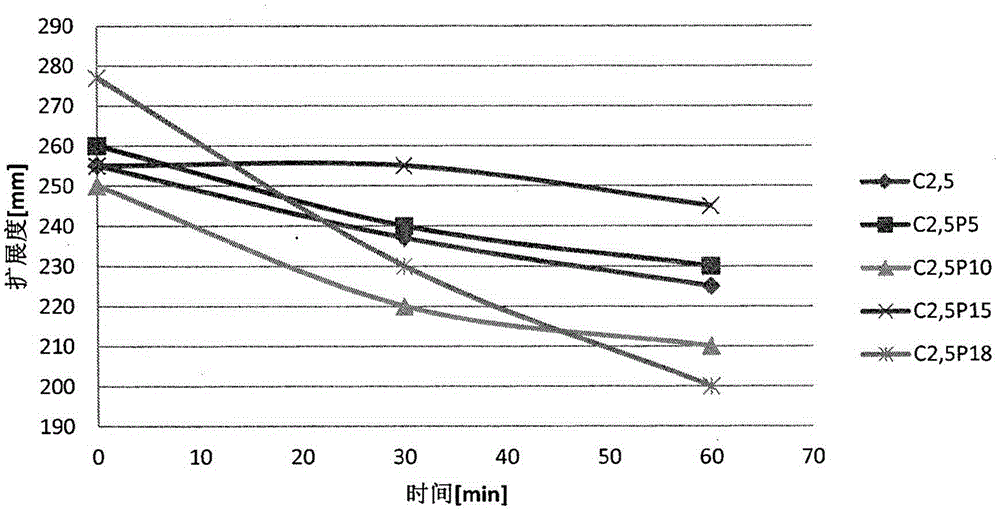

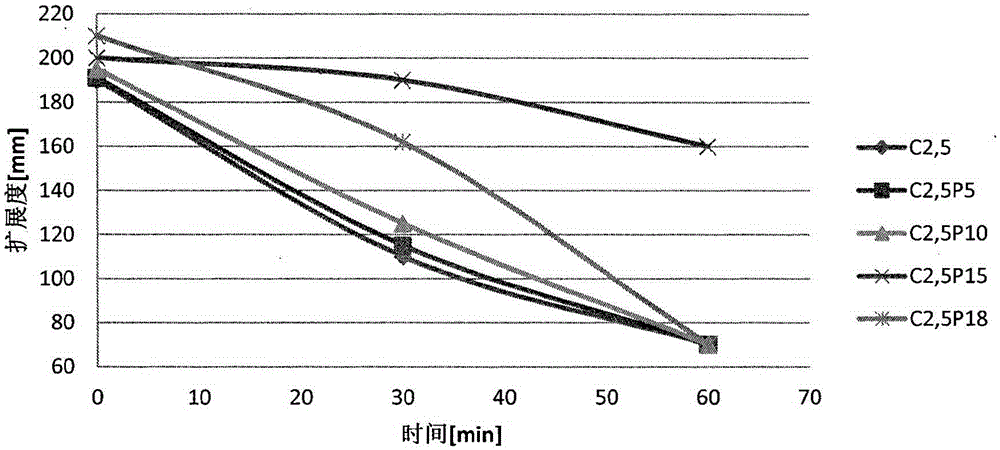

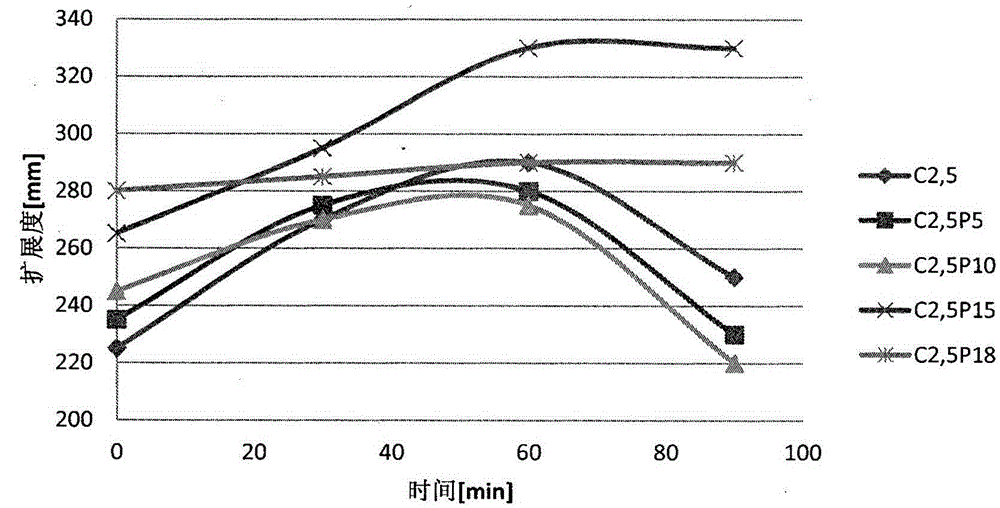

Embodiment 1

[0019]Example 1: In this example, no unsaturated phosphoric acid monomer C is used to synthesize a water reducer, and the product will be used as a base sample for comparison with a water reducer modified with phosphoric acid. The polycarboxylate water reducer described in this embodiment is made from the following raw materials in parts by weight: 72 parts of isopentenol polyoxyethylene ether (TPEG-2400), hydrogen peroxide (30 parts by mass percent can be used) % hydrogen peroxide solution) 2.5 parts, 5.4 parts of acrylic acid, 30 parts of deionized water X for preparing material liquid A, 1.02 parts of reducing agent, 0.4 part of chain transfer agent, 20 parts of deionized water Y for preparing material liquid B, used for dissolving Add 140 parts of deionized water Z of isopentenol polyoxyethylene ether. Among the 1.02 parts of reducing agent, L-ascorbic acid accounts for 0.85 parts, and phosphorous acid accounts for 0.17 parts. The above-mentioned chain transfer agent is o...

Embodiment 2

[0020] Example 2: The reaction conditions of this example are the same as those of Example 1, except that the unsaturated phosphoric acid monomer C is added in this example to modify the water reducing agent. The highly adaptable phosphoric acid-based modified polycarboxylate water reducer of the present invention is made of the following raw materials in parts by weight: 72 parts of isopentenol polyoxyethylene ether (TPEG-2400), hydrogen peroxide (can 2.5 parts, 5.4 parts of acrylic acid, 1.0 parts of unsaturated phosphoric acid monomer C, 30 parts of deionized water X for preparing material liquid A, 1.02 parts of reducing agent, 0.4 parts of chain transfer agent, 20 parts of deionized water Y for preparing material liquid B, and 140 parts of deionized water Z for dissolving prenol polyoxyethylene ether. Among the 1.02 parts of reducing agent, L-ascorbic acid accounts for 0.85 parts, and phosphorous acid accounts for 0.17 parts. The above-mentioned chain transfer agent is o...

Embodiment 3

[0021] Embodiment 3: This embodiment is similar to Embodiment 2, the difference is that the weight parts of unsaturated phosphoric acid monomer C in this embodiment is 2.0 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com