Polycarboxylate water reducer with defoaming function and preparation method of water reducer

A technology of polycarboxylate and water reducer, applied in the field of polycarboxylate water reducer, concrete admixture, preparation of said polycarboxylate water reducer, polycarboxylate water reducer with defoaming function, can Solve problems such as no guidance plan, achieve the effect of reducing secondary construction treatment, avoiding damage to frost resistance, and eliminating air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

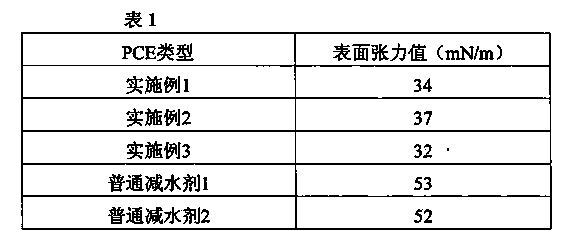

Examples

Embodiment 1

[0016] Example 1: The polycarboxylate water reducer with defoaming function is made from the following raw materials in parts by mass (mass ratio): 90 parts of polyoxyethylene ether macromonomer, 8.65 parts of acrylic acid, chain transfer 0.95 parts of agent, 0.53 parts of initiator, 0.9 parts of defoaming monomer, and 150 parts of deionized water. Wherein, the polyoxyethylene ether macromonomer is prenyl polyoxyethylene ether TPEG-3000 or prenyl polyoxyethylene ether TPEG-2400. The polyoxyethylene ether macromonomer can also be TPEG-1200, or HPEG-2400 (methallyl polyoxyethylene ether). Described chain transfer agent is sodium methallyl sulfonate; Described initiator is the combination of two kinds of hydrogen peroxide and ascorbic acid, and in 0.53 parts of initiator, hydrogen peroxide accounts for 0.38 part, and ascorbic acid accounts for 0.15 part; Described disinfectant The foam monomer is a block copolymer of polyoxyethylene-polyoxypropylene, and the block copolymer of p...

Embodiment 2

[0018] Example 2: The polycarboxylate water reducer with defoaming function is made of the following raw materials in parts by mass (mass ratio): 88 parts of polyoxyethylene ether macromers, acrylic acid (or its derivatives monomer) 8 parts, chain transfer agent 1.0 part, initiator 0.45 part, defoaming monomer 0.85 part, deionized water 148 parts. Wherein, the polyoxyethylene ether macromonomer is prenol polyoxyethylene ether TPEG-2400 or isopentenol polyoxyethylene ether TPEG-3000, and the polyoxyethylene ether macromonomer It can also be TPEG-1200, or HPEG-2400 (methallyl polyoxyethylene ether). The chain transfer agent is a combination of mercaptopropionic acid, sodium methallyl sulfonate and sodium allyl sulfonate. In 1.0 part of chain transfer agent, mercaptopropionic acid accounts for 0.15 part, methallyl Sodium sulfonate accounts for 0.30 part, and sodium allyl sulfonate accounts for 0.55 part; Described initiator is the combination of two kinds of ascorbic acid and am...

Embodiment 3

[0020] Example 3: The polycarboxylate water reducer with defoaming function is made from the following raw materials in parts by mass (mass ratio): 95 parts of polyoxyethylene ether macromonomers (or 85 parts or 90 parts ), 8 parts of acrylic acid or its derivative monomer (or 8.5 or 9 parts), 0.9 parts of chain transfer agent (or 0.95 or 1.0 parts), 0.5 parts of initiator (or 0.4 or 0.6 parts), defoaming type 1.0 parts (or 0.8 or 0.9 parts) of monomer, 155 parts of deionized water (or 145 parts or 151 parts). Wherein, the chain transfer agent is one or a combination of mercaptoacetic acid, mercaptopropionic acid, sodium methallylsulfonate, sodium allylsulfonate (the mass ratio of the combination is arbitrary ); the initiator is one or a combination of hydrogen peroxide, ascorbic acid, sodium persulfate, ammonium persulfate (the mass ratio of the combination is arbitrary); the defoaming monomer is poly Block copolymer of oxyethylene-polyoxypropylene. The above-mentioned poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com