A low-foaming high-adhesion photosensitive dry film resist

A resist and sensitive technology, applied in the field of low-foaming high-adhesion photosensitive dry film resist, can solve the problem that the chemical properties of the viscosity enhancer are not stable enough, the degree of improvement is limited, and the storage stability of the dry film resist is damaged. problem, to achieve the effect of improving production efficiency and yield rate, enhancing the combination ability, and avoiding the risk of spillover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

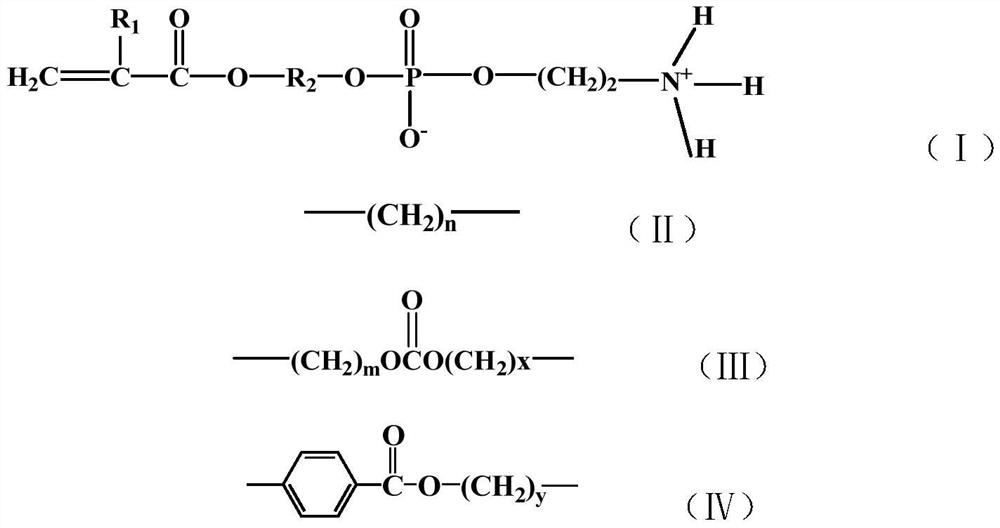

[0020] Ethylenic photopolymerizable unsaturated monomer is one of the core components of photosensitive dry film resist. Targeted modification of its molecular formula can significantly improve the adhesion, developing speed and storage stability of dry film resist , thermal stability and other comprehensive properties.

[0021] The invention discloses a high-adhesion fast-developing photosensitive dry film resist, which is described in more detail below.

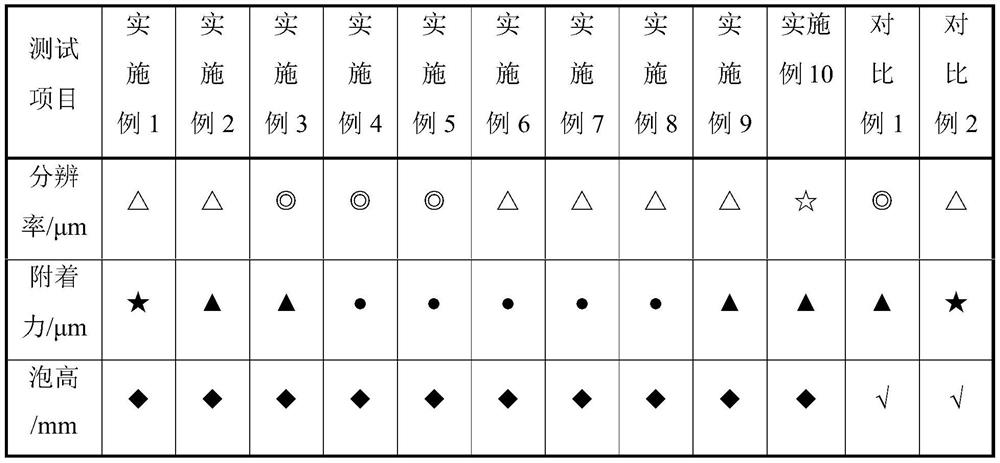

[0022] The present invention is also characterized in that by applying the ethylenic photopolymerizable unsaturated monomer modified at the molecular level to the photosensitive resin composition, it provides a metal plate that has excellent adhesion to PCBs and is highly efficient. Low-foaming photosensitive dry film resist with developing speed and good resolution after developing.

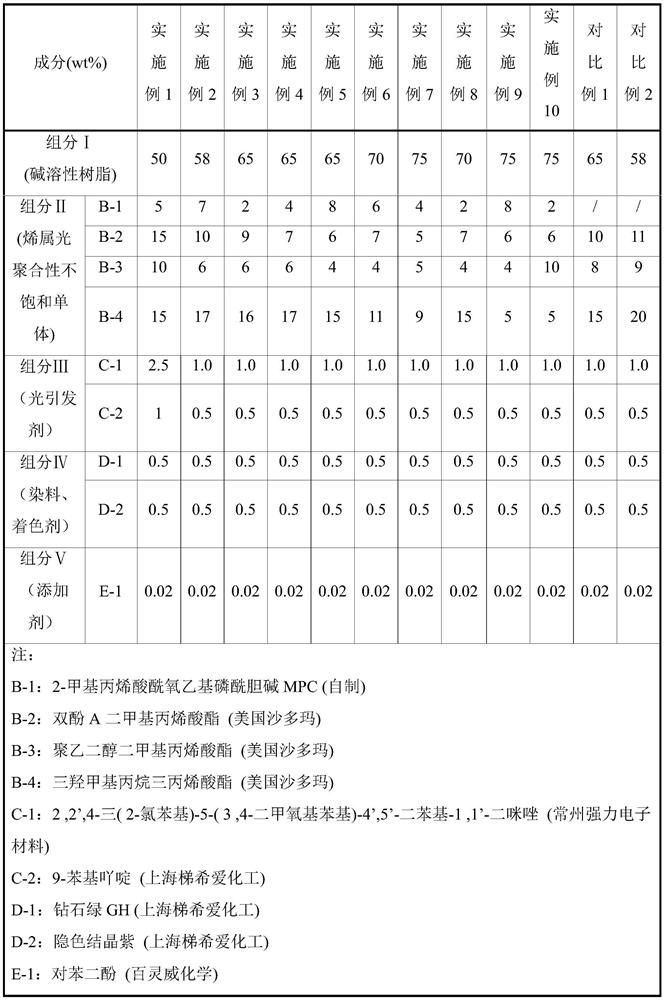

[0023] Preferred embodiments and comparative examples of the present invention will be described below. However, the following embodiments...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com