Method for recovering polyether from waste metal processing liquid and application of polyether in concrete slump retaining agent

A technology for metal processing and processing waste liquid, applied in recycling technology, plastic recycling, chemical instruments and methods, etc., can solve problems such as poor safety, gas corrosion, large one-time investment, etc., to reduce equipment requirements and production costs , Improve production safety, the effect of a small one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

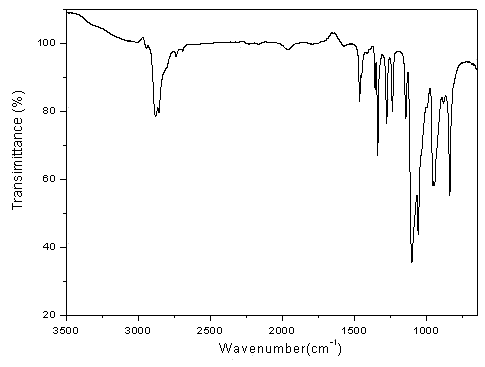

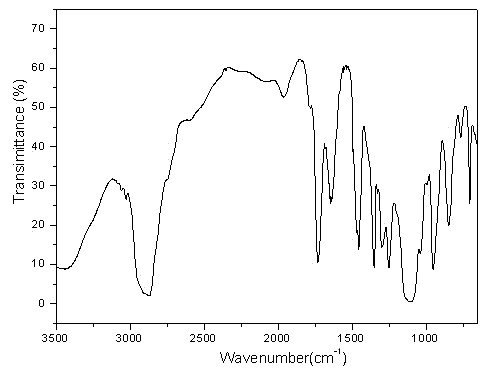

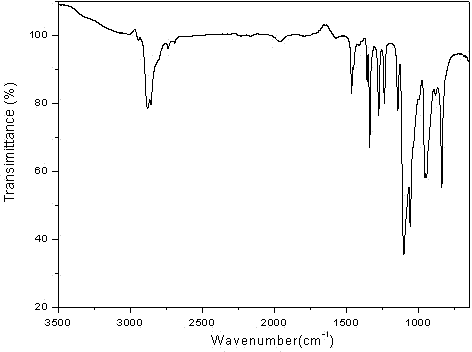

Image

Examples

Embodiment 1

[0039] (1) Polyether recovery process

[0040] 1000L of water-based metal processing waste liquid with a polyether (polyethylene glycol ether) content of 9% was added to the reactor, sodium hydroxide was added to adjust the pH to 10, the reaction was left to stand for 1 hour, filtered, and the filtrate was taken. Add 1kg of activated carbon, add sulfuric acid to adjust the pH to 4-5, add 5kg of sodium sulfate, heat to about 5-10°C above the cloud point temperature of polyether, until the solution starts to separate, and stand at constant temperature for 1h; take the upper polyether phase, add 0.5% hydroquinone and other antioxidants, heated to 105 ° C, fully dried to remove water, and obtained 83 kg of polyether products with a recovery rate of 92% and a purity of 94%.

[0041] (2) Synthesis process of concrete slump retaining agent

[0042] 10kg of polyether, 50g of p-toluenesulfonic acid, and 1.2kg of maleic anhydride were esterified at 107°C for 4 hours. After cooling down...

Embodiment 2

[0044] (1) Polyether recovery process

[0045] It is to add 1000L water-based metal processing waste liquid with a content of 5% polyether (polyethylene glycol ether) in the reaction kettle. The polyether is polyethylene glycol ether or polyoxyethylene oxypropylene ether, and its molecular weight is 800-4000, add potassium hydroxide to adjust the pH value to 11, let it stand for 1 hour, filter, take the filtrate, add 1 kg of activated carbon, add sulfuric acid to adjust the pH to 4-5, heat to the temperature above the cloud point of polyether, that is, about 5-10°C, until the solution starts to separate, keep it at constant temperature for 1h; take the upper polyether phase, add 0.05% benzoquinone antioxidant, heat to 105°C, fully dry and remove water, and obtain 45kg of polyether product, the recovery rate is 90% , 95% purity.

[0046] (2) Synthesis process of concrete slump retaining agent

[0047] 10kg of polyether, 10g of sodium bisulfate, and 1kg of maleic anhydride wer...

Embodiment 3

[0049] (1) Polyether recovery process

[0050] 1000L of water-based metal processing waste liquid with a content of 50% of polyether (polyoxyethylene oxypropylene ether) is added to the reactor, and potassium hydroxide and 25-28% wt of concentrated ammonia water are added to adjust the pH value to 12. Stand to react for 1.5h, filter, take the filtrate, add 5kg of activated carbon, add nitric acid and phosphoric acid to adjust the pH to 4-5, add 25kg of potassium nitrate, heat to about 5-10°C above the cloud point temperature of polyether, until the solution starts to separate , standing at constant temperature for 2 hours; take the upper polyether phase, add 0.8% of hydroquinone and other antioxidants, heat to 105 ° C, fully dry and remove water, and obtain 460 kg of polyether product with a recovery rate of 92% and a purity of 92%.

[0051] (2) Synthesis process of concrete slump retaining agent

[0052] 10kg of polyether, 30g of sulfuric acid, nano-montmorillonite, 1.96kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com