Patents

Literature

46 results about "Bis-triazine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

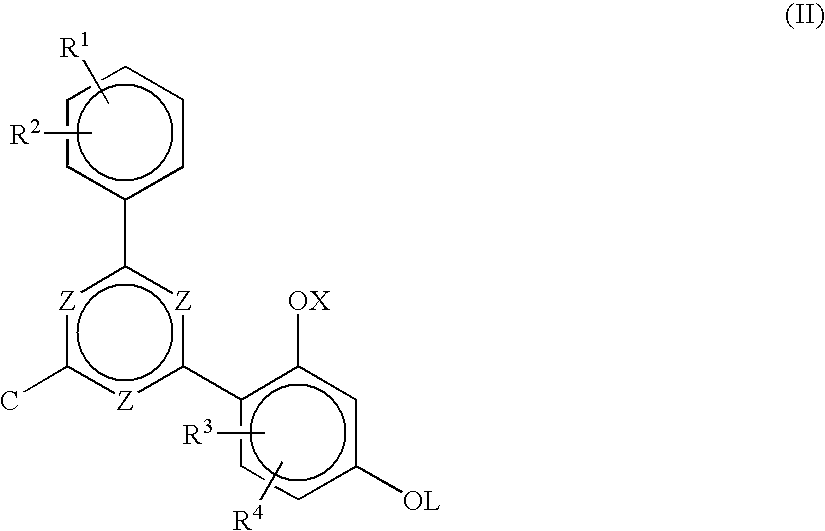

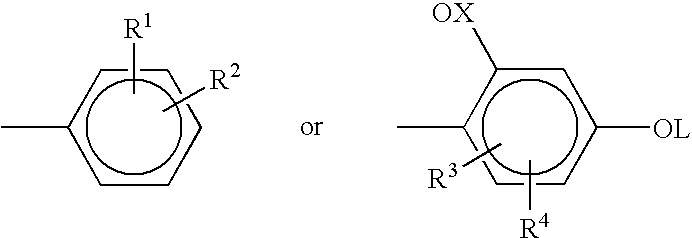

Non-yellowing ortho-dialkyl aryl substituted triazine ultraviolet light absorbers

The invention relates generally to pyrimidines and triazines ultraviolet light absorbers containing a phenolic aromatic group(s) and a non-phenolic aromatic group(s) and the use thereof to protect against degradation by environmental forces, inclusive of ultraviolet light, actinic radiation, oxidation, moisture, atmospheric pollutants, and combinations thereof. The new class of pyrimidines and triazines includes two (one) non-phenolic aromatic groups with hydrocarbyl groups that are ortho to each other and one (two) resorcinol or substituted resorcinol group attached to a triazine or pyrimidine ring. The pyrimidines and triazines may be included in a polymeric structure. A method for stabilizing a material by incorporating the novel pyrimidines and triazines is also disclosed.

Owner:CYTEC TECH CORP

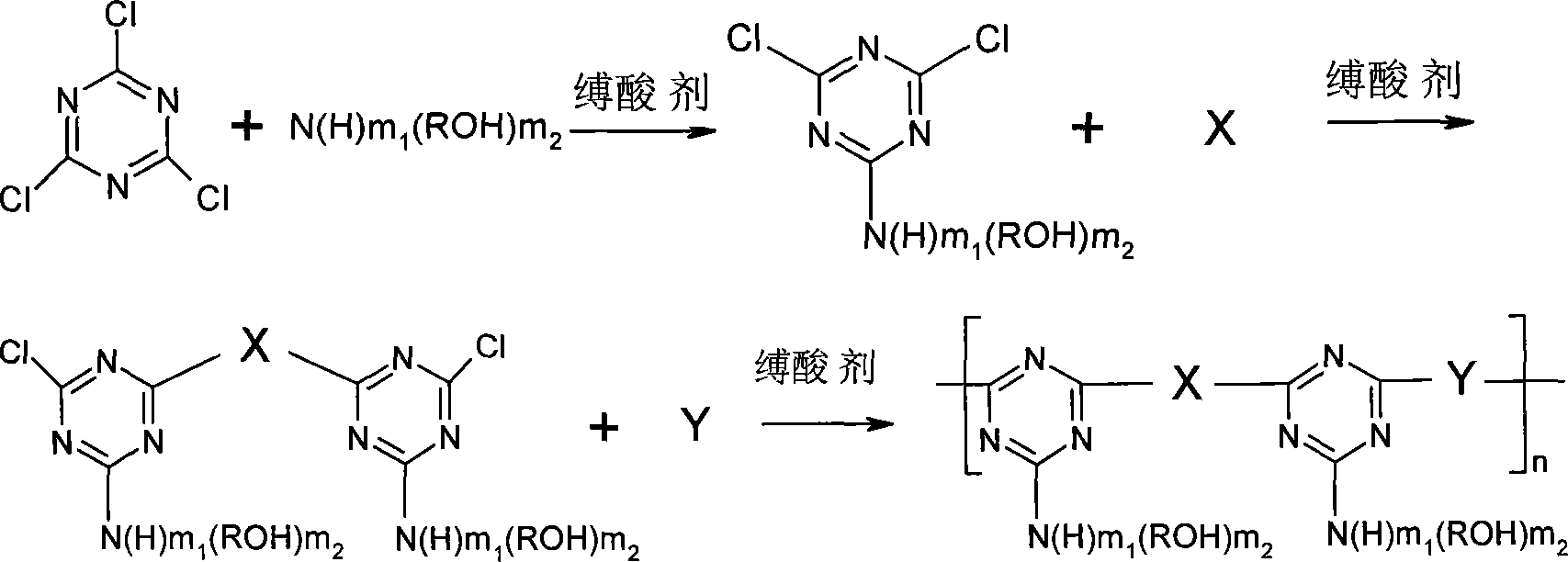

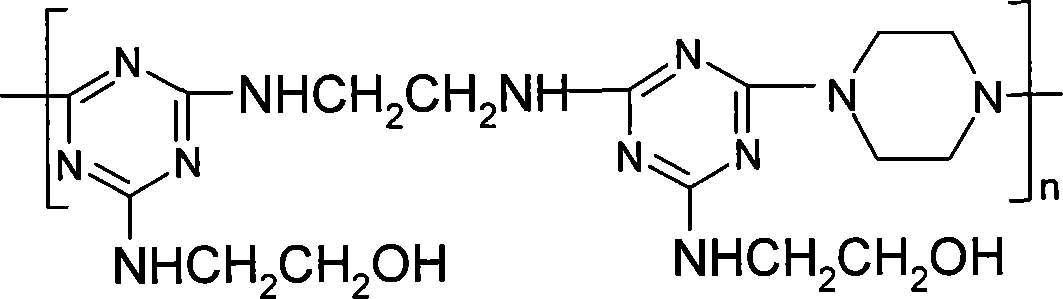

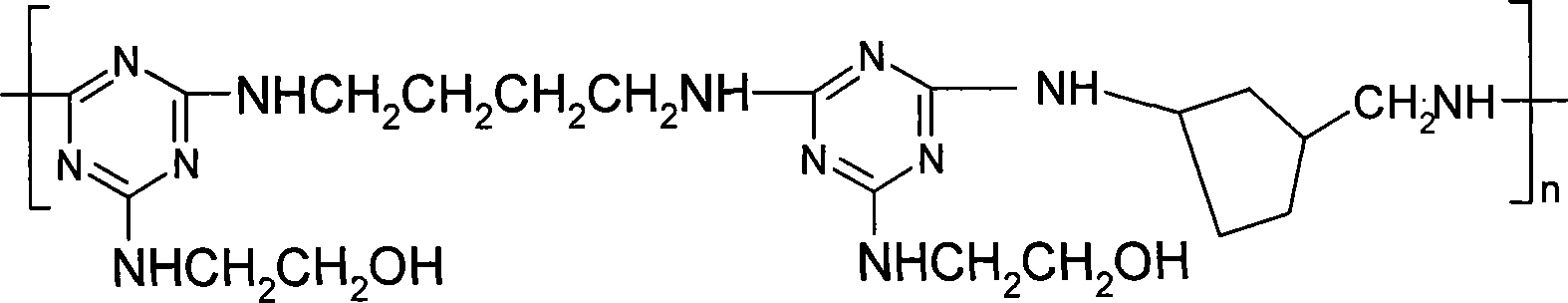

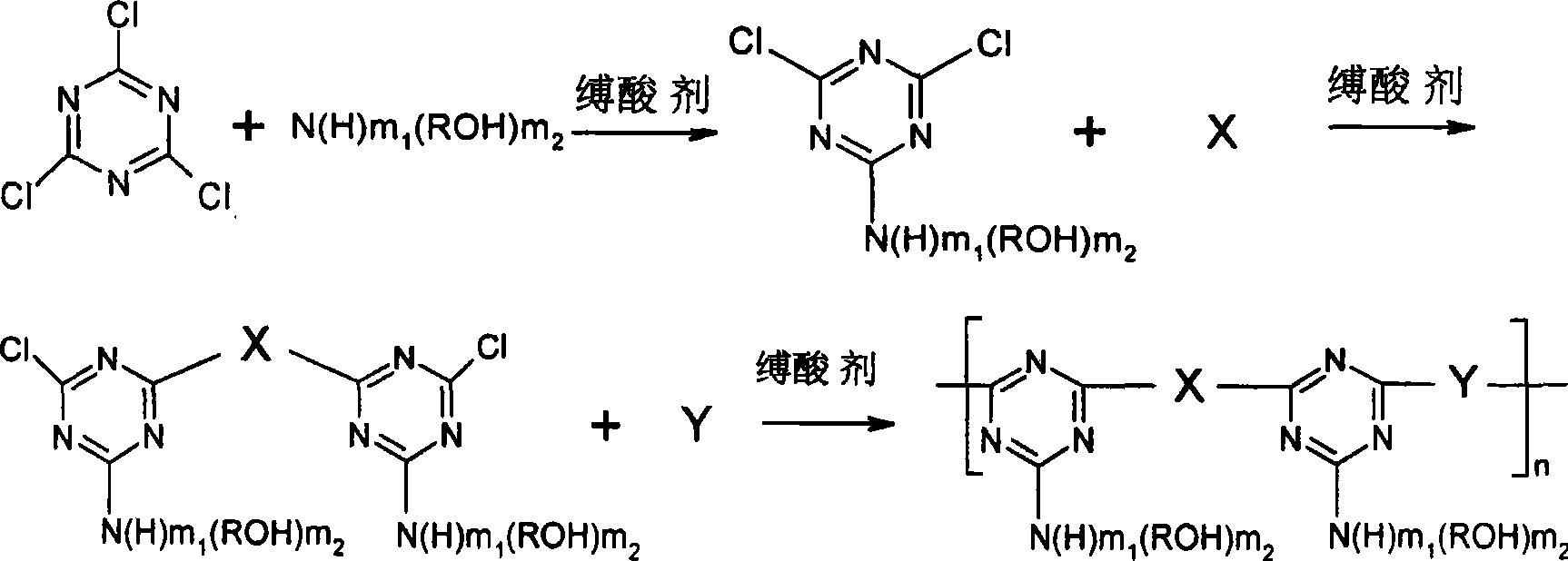

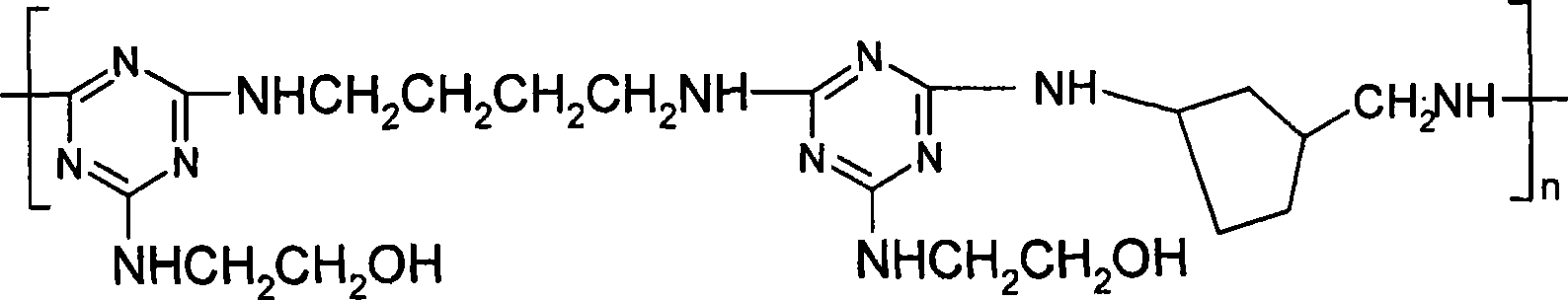

Triazine series oligomer and its synthesizing method

The invention relates to a triazine series oligomer and the compound method. The method has the following steps: adding solvent into cyanuric chloride, dropping alkylol amine and acid roping agent to gain substitute of cyanuric chloride; heating, dropping diamidogen and acid roping agent to gain the substitute of cyanuric chloride; adding diamidogen and acid roping agent into reaction solution, heating, pumping, washing, and drying to gain triazine series oligomer. The invention has strong charring and expanding ability, and good thermal stability. It has advantages of continuously reaction process, short reaction time, simple compounding technology, little organic solvent, and easy to recycle organic solvent.

Owner:NORTHEAST FORESTRY UNIVERSITY

Triazine exciplex material based on phosphine oxide and carbazole, and preparation method and application thereof

ActiveCN106883268AIncrease varietyImprove luminous efficiencyGroup 5/15 element organic compoundsSolid-state devicesDiphenyl phosphateCarbazole

The invention relates to a triazine exciplex material based on phosphine oxide and carbazole, and a preparation method and application thereof, which solve the technical problems of fewer existing blue light exciplex receptor materials. The structure of the triazine exciplex material based on the phosphine oxide and the carbazole is as follows (shown in the description). The preparation method comprises the following steps: adding monobromotrityl-based triazine, a carbazole compound, anhydrous K2CO3 and CuI into 1,3-dimethyl-2-imidazolone to react, and purifying to obtain an intermediate compound; and then enabling the intermediate compound to react with diphenyl phosphate and palladium acetate in anhydrous DMF, and then purifying to obtain the triazine-type exciplex material. The material can be applied to TADF (thermal activation delayed fluorescence) and phosphorescence organic electroluminescence devices.

Owner:HEILONGJIANG UNIV

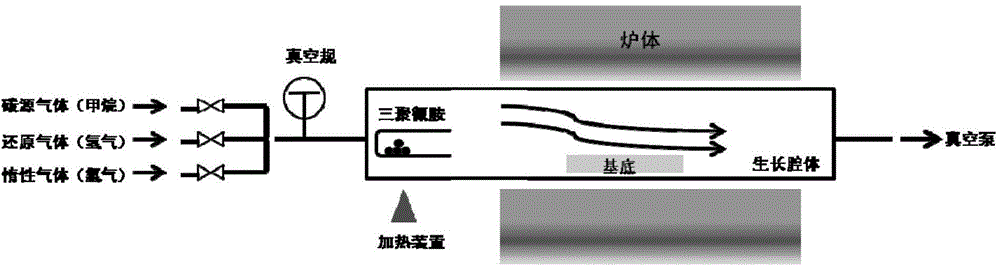

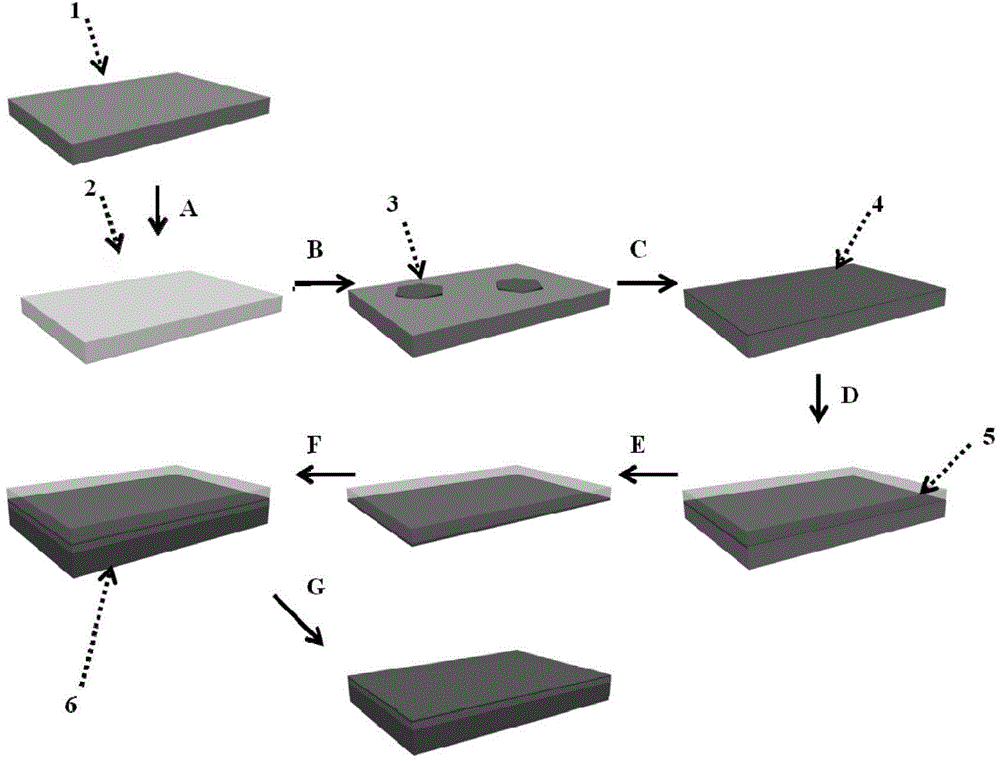

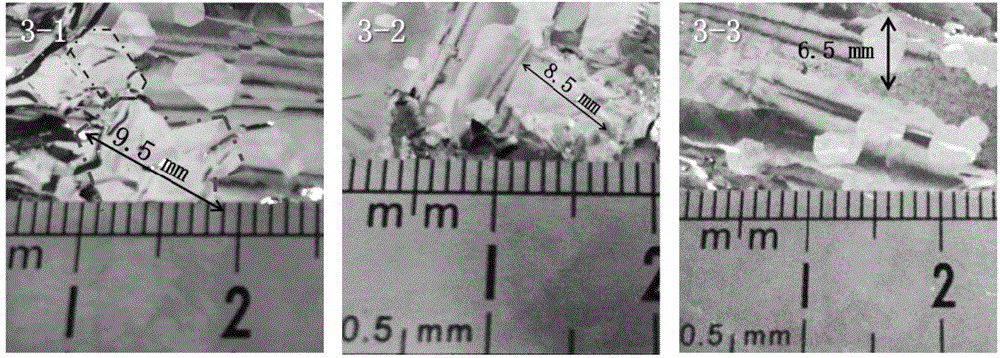

Large single crystal graphene and preparation method thereof

ActiveCN104674343AEasy to prepareReduce nucleation densityPolycrystalline material growthFrom chemically reactive gases1,3,5-TriazineSingle crystal

The invention relates to a large single crystal graphene and preparation method thereof. The preparation method comprises the following steps: 1) annealing a copper base under reducing atmosphere to obtain annealed copper base; 2) under triazine derivative steam atmosphere, treating the copper base annealed after the annealing treatment in the step 1) to obtain the copper base after the triazine derivative treatment, wherein the triazine derivative is selected from at least one of tripolycyanamide, 2,4-diamino-6-methyl-1,3,5-triazine, and 2-amino-4-methyl-6-methoxy-1,3,5-triazine; 3) depositing graphene on the surface of the copper base subjected to triazine derivative biological treatment by adopting a chemical vapor deposition method to obtain the large single crystal graphene. The preparation method is simple and suitable for large-scale production, the single crystal domain size achieves sub-centimeter level, and the single crystal quality is high and can be applied to the electronics.

Owner:PEKING UNIV

Triazine series oligomer and its synthesizing method

The invention relates to a triazine series oligomer and the compound method. The method has the following steps: adding solvent into cyanuric chloride, dropping alkylol amine and acid roping agent to gain substitute of cyanuric chloride; heating, dropping diamidogen and acid roping agent to gain the substitute of cyanuric chloride; adding diamidogen and acid roping agent into reaction solution, heating, pumping, washing, and drying to gain triazine series oligomer. The invention has strong charring and expanding ability, and good thermal stability. It has advantages of continuously reaction process, short reaction time, simple compounding technology, little organic solvent, and easy to recycle organic solvent.

Owner:NORTHEAST FORESTRY UNIVERSITY

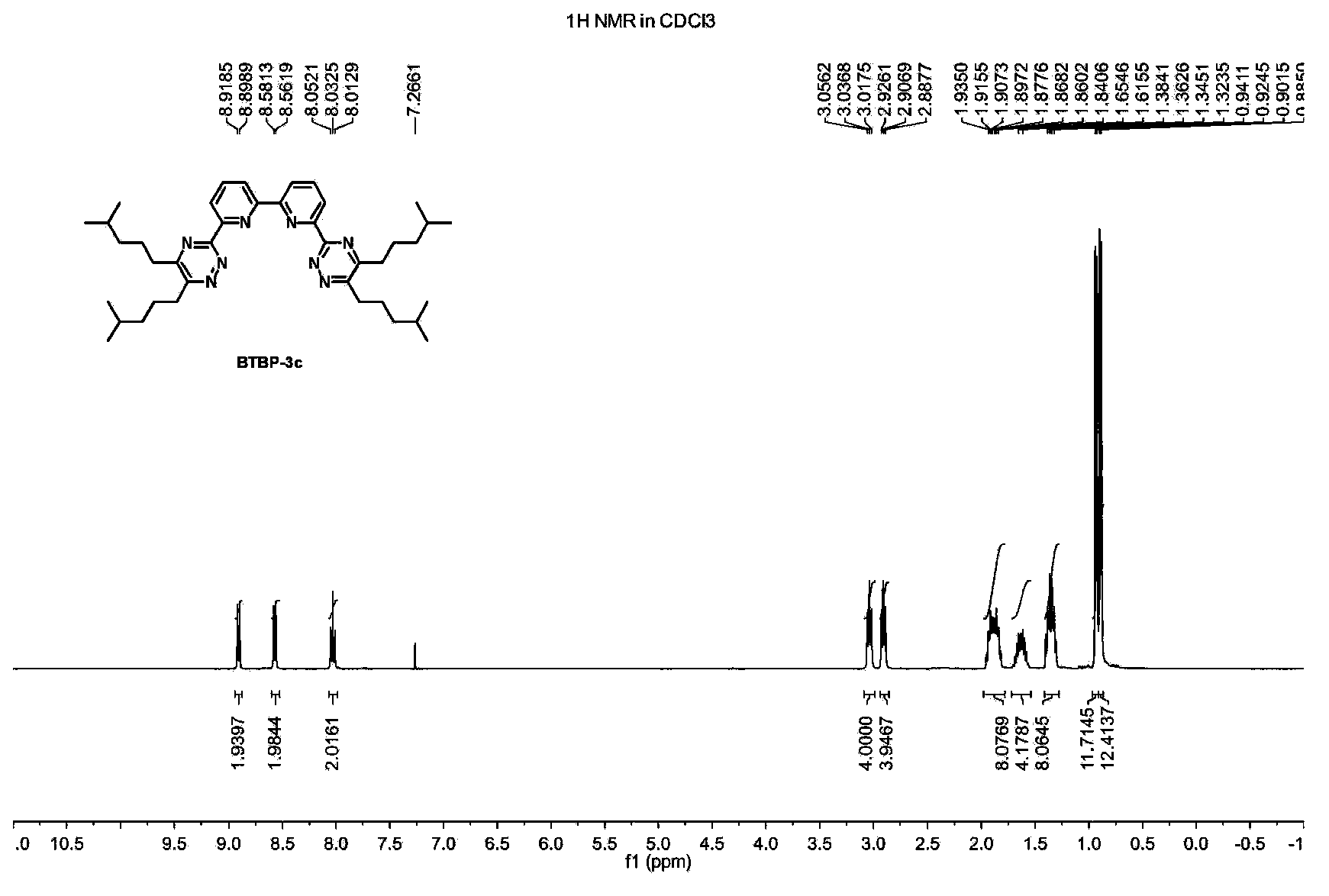

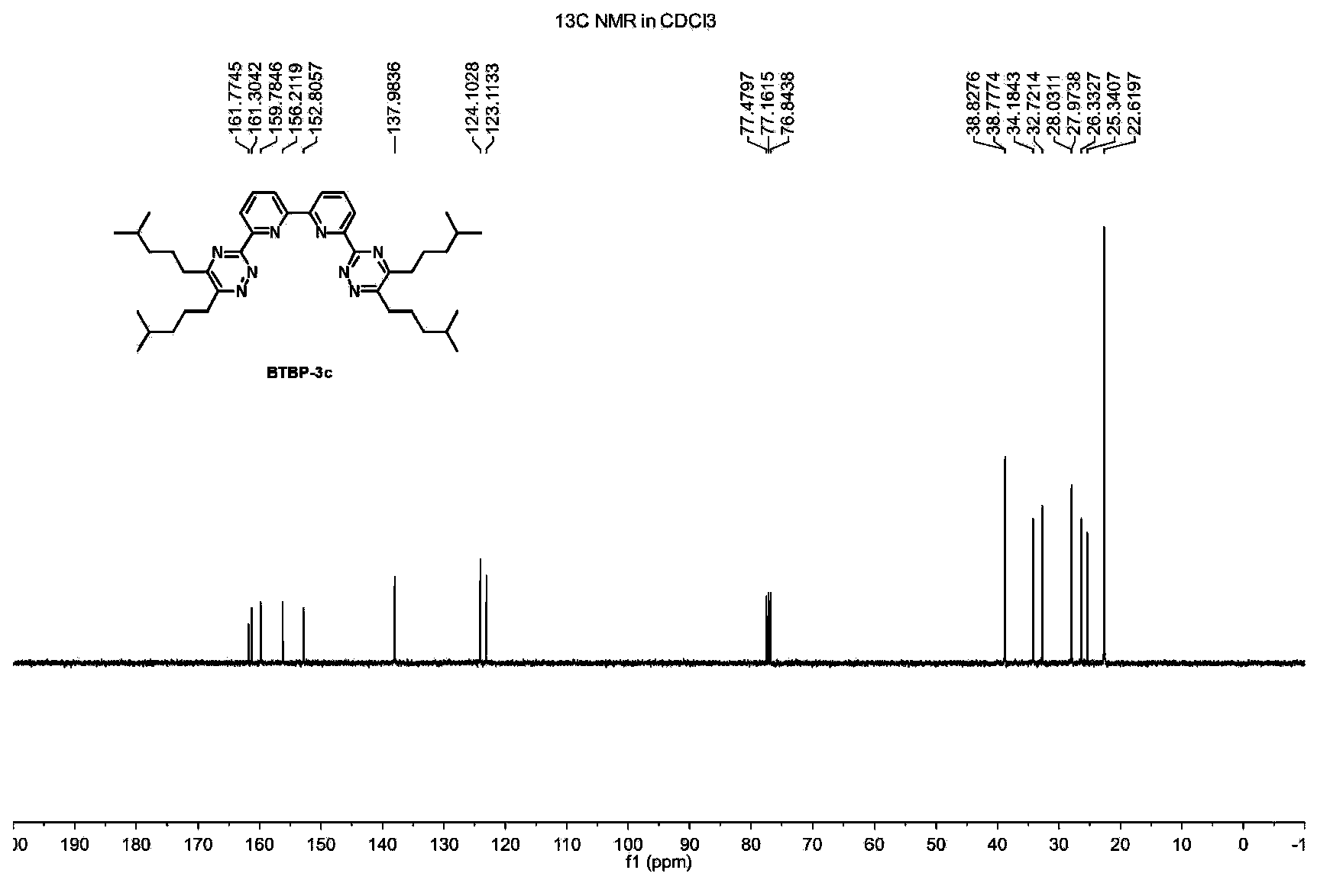

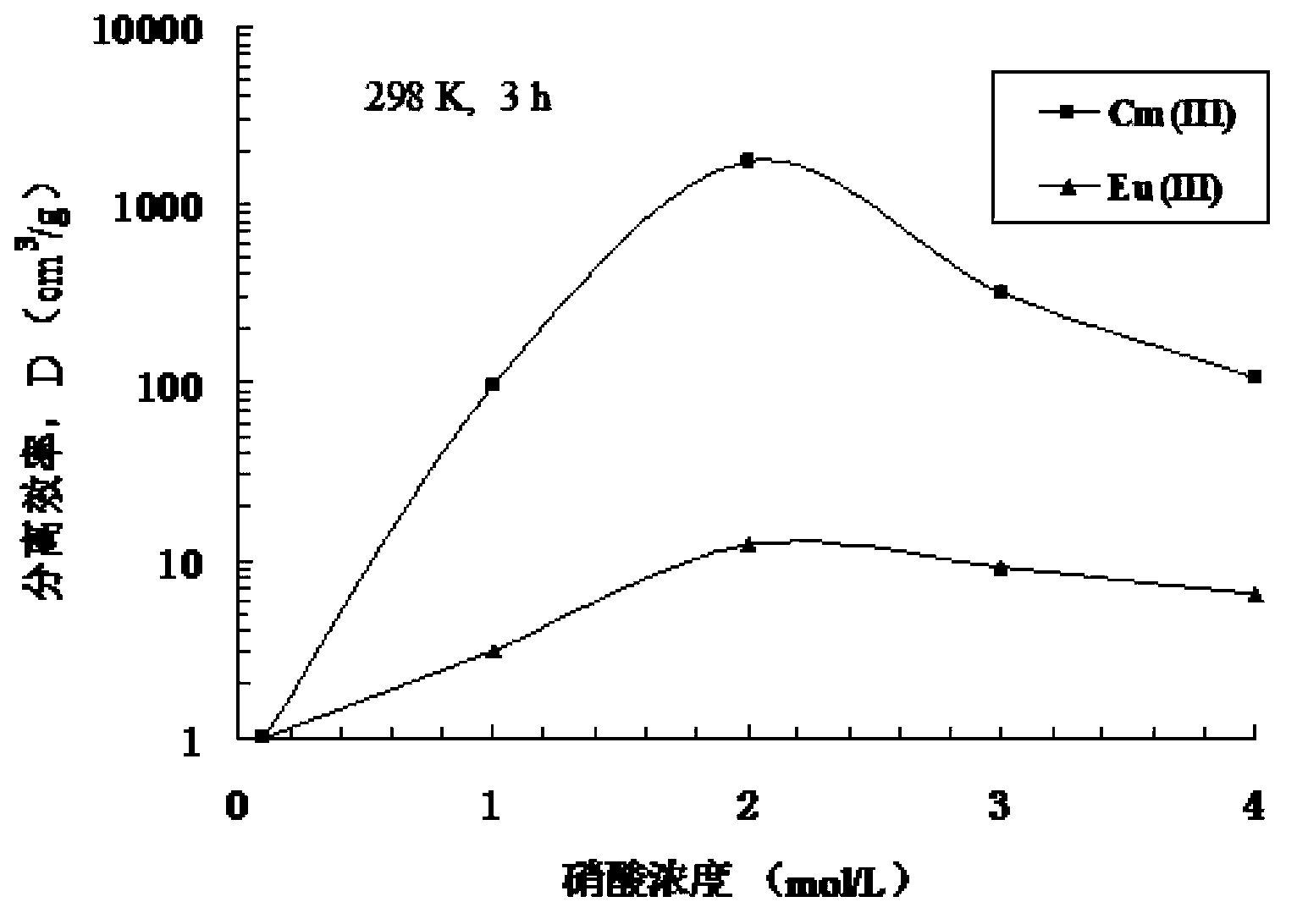

Dipyridine bridged bis-triazine compounds and preparation method thereof

The invention discloses seven novel 2,2'-dipyridine bridged bis-triazine compounds, particularly 6,6'-di(5,6-dialkyl-1,2,4-triazinyl-3-yl)-2,2'-dipyridine compounds with the side chain alkyl group of isobutyl, 3-methylbutyl, 4-methylamyl, 3-methylhexyl, 5-methylhexyl, 2-cyclopentylethyl or 2-cyclohexylethyl group and a preparation method thereof.2,2'-dipyridyl-6,6'-diiminohydrazide and alkyl substituted alpha-dione used as initial raw materials are heated to perform dehydration cyclization reaction for 5-24 hours by using tetrahydrofuran / triethylamine as a reaction solvent, thereby obtaining the seven 6,6'-di(5,6-dialkyl-1,2,4-triazinyl-3-yl)-2,2'-dipyridine compounds. The method has the characteristics of mild conditions, accessible raw materials, high target product yield and the like, and is simple to operate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

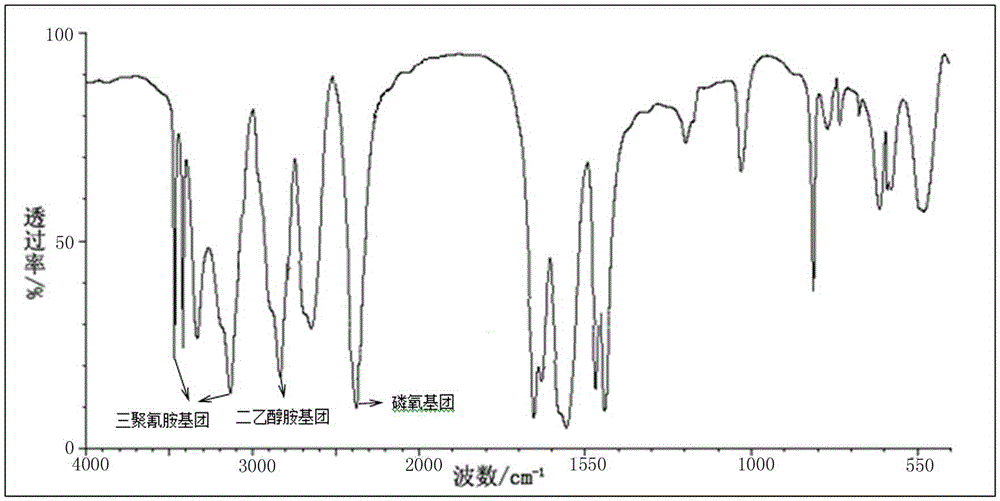

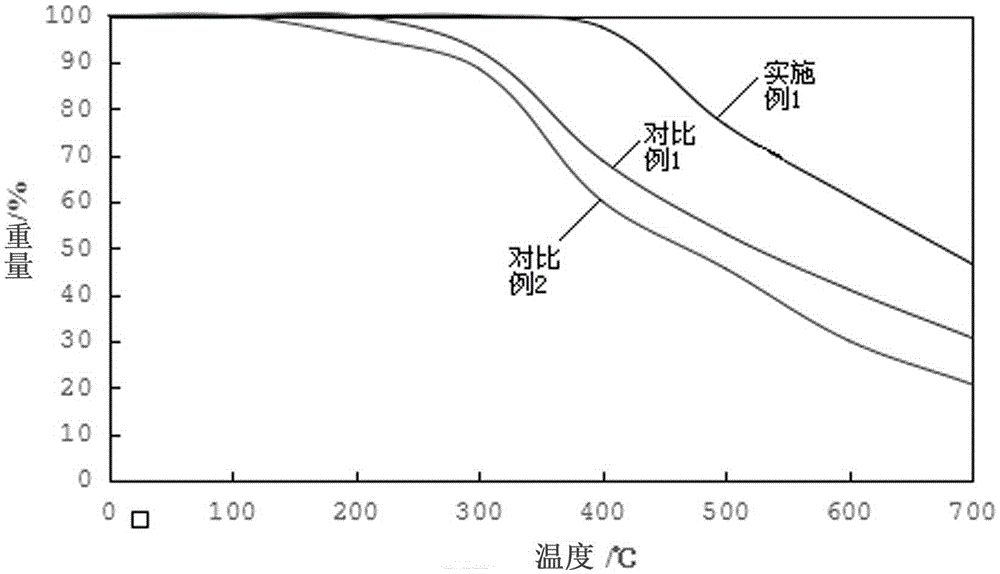

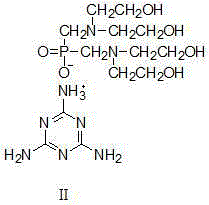

Triazine charring agent, preparation method therefor and application thereof

ActiveCN105418675AMild reaction conditionsSimplify process operationGroup 5/15 element organic compoundsBulk chemical productionPolymer scienceMannich reaction

The present invention discloses a triazine charring agent, a preparation method therefor and application thereof. The preparation method comprises the following steps: performing an Mannich reaction on hypophosphorous acid, diethanol amine, and formaldehyde catalyzed by hydrochloric acid in an aqueous phase; after the reaction, adding melamine to the reaction solution to react sequentially; and obtaining the triazine charring agent with the following structural formula. The present invention also provides application of the charring agent as a raw material of a flame retardant, as well as a preparation method of the flame retardant. According to the method disclosed by the present invention, reaction conditions are mild, a process flow of operations is simple, a reaction period is short, and post treatment is simple. The resulting charring agent has good expansibility, high thermal stability, a large amount of carbon residue, a good charring effect, and good compatibility with a polymer. The charring agent can be made into the flame retardant by mixing with ammonium polyphosphate, polypropylene, and the like, with excellent inflaming retarding performance and little influence on mechanical properties.

Owner:山东艾孚特科技有限公司

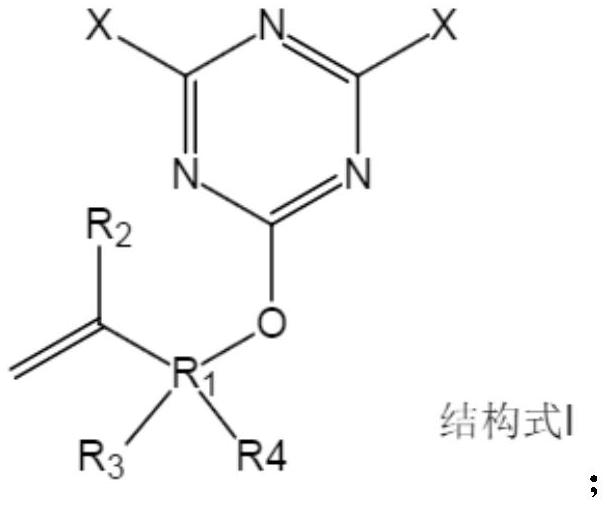

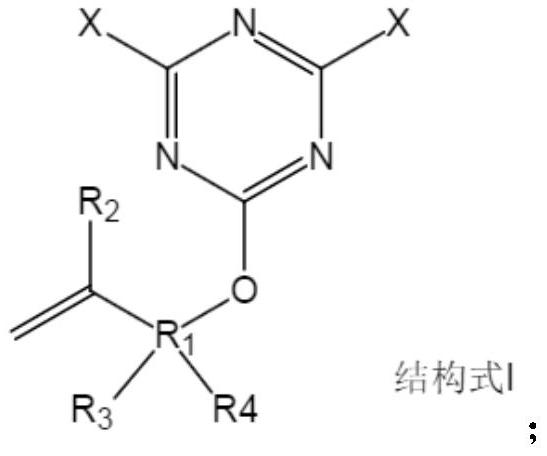

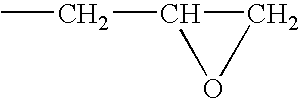

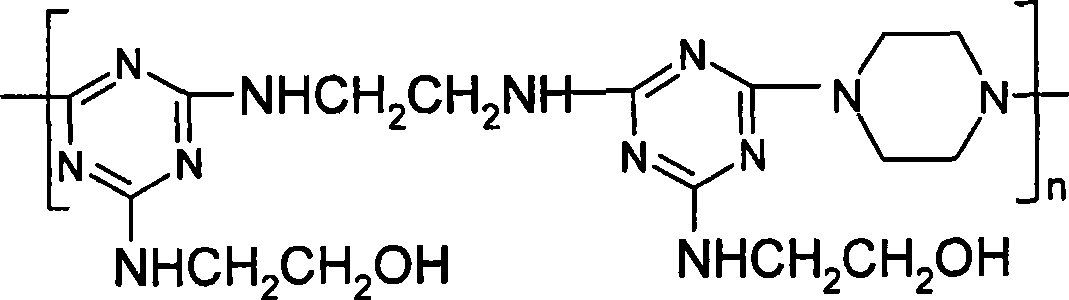

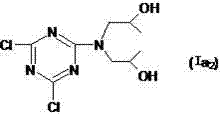

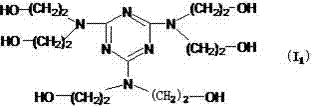

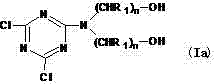

Triazine compound coordination crosslinking synergistic agent for elastomer and preparation method thereof

InactiveCN102181073AImprove chemical reactivityGood intrinsic foam flame retardant performanceOrganic chemistrySolventChemistry

The invention relates to a method for preparing a triazine compound coordination crosslinking synergistic agent for elastomers, and particularly for preparing a hydroxyalkyl chain substituted triazine compound. The method is characterized in that cyanuric chloride and dihydric alcohol are used as raw materials; the cyanuric chloride and the dihydric alcohol are allowed to react by a nucleophilic substitution reaction in an organic solvent medium; a few amount of a lewis base aqueous solution is added dropwisely to control the pH of the system; after the lewis base aqueous solution is added completely, an intermediate Ia is obtained; water is added into an Ia-containing reaction solution as a solvent; dihydric alcohol with a molar ratio to the intermediate of 2-2.2 is added at room temperature; the temperature is increased controllably; by-product hydrogen chloride is absorbed by the lewis base aqueous solution; the pH of the reaction system is controlled; and the triazine compound as the target product is obtained. The hydroxyalkyl chain substituted triazine compound obtained by the method of the invention comprises six hydroxyls and six nitrogen atoms, has strong chemical reactivity, is easy to participate in a coordination crosslinking reaction, and can be used as a crosslinking synergistic agent in an elastomer curing system.

Owner:FUJIAN NORMAL UNIV

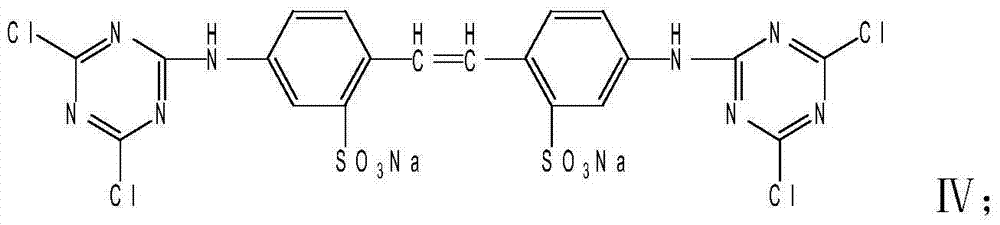

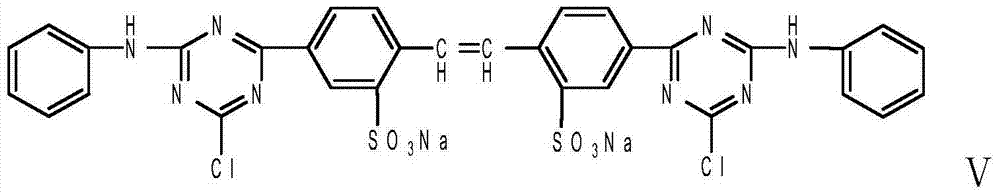

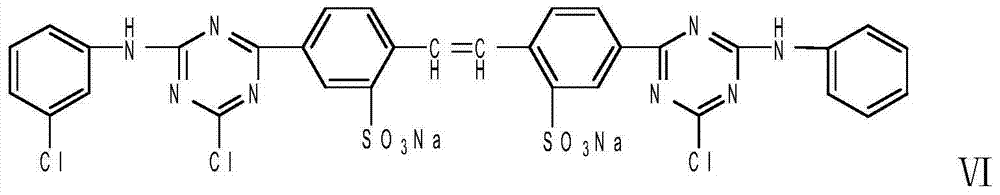

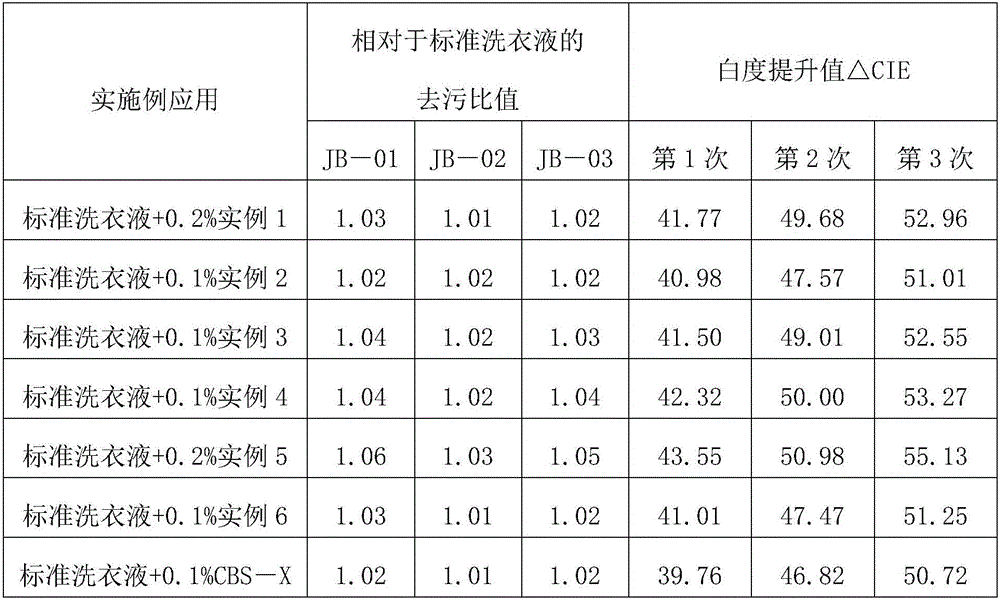

Stilbene triazine fluorescent whitening agent and preparation method thereof

ActiveCN104263011AHigh whitening strengthAdd lessStyryl dyesDetergent dyesBis-triazineMeta-chloroaniline

The invention belongs to the technical field of a fluorescent whitening agent and a preparation method thereof, and particularly relates to a special stilbene bis-triazine fluorescent whitening agent for detergents and a preparation method thereof. The special stilbene bis-triazine fluorescent whitening agent for detergents mainly solves the problems of poor whitening effect and high cost in the existing fluorescent whitening agent. The technical scheme is as follows: the preparation method of the stilbene triazine fluorescent whitening agent comprises the following steps: (1) weighing raw materials; (2) preparing a product IV; (4) uniformly mixing aniline and meta-chloroaniline, and adding the product IV in the step (3) to obtain products V, VI and VII; (5) preparing a composition of I, II and III; (6) carrying out acid precipitation; (7) drying; and (8) preparing the stilbene triazine fluorescent whitening agent. The stilbene triazine fluorescent whitening agent has the advantages of favorable whitening effect, low cost and the like.

Owner:山西青山化工有限公司

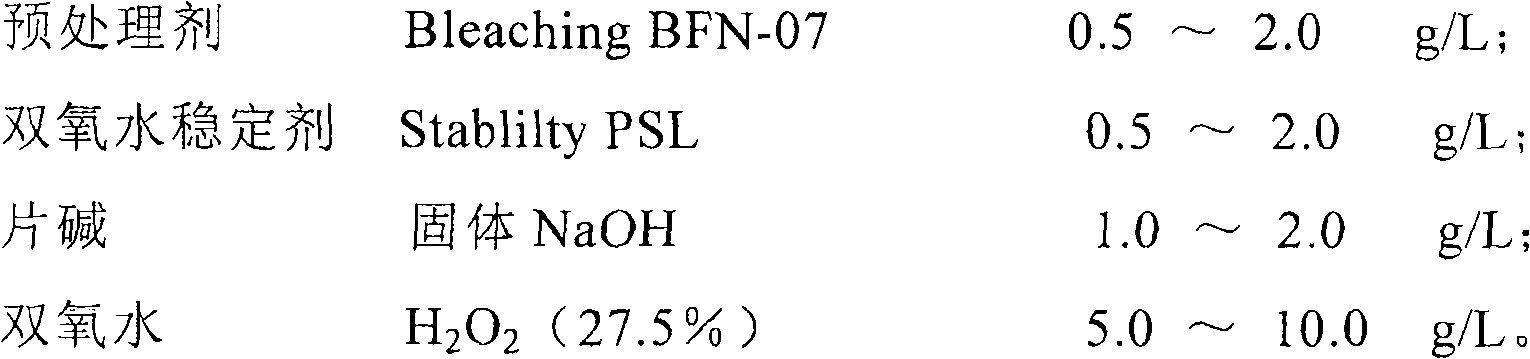

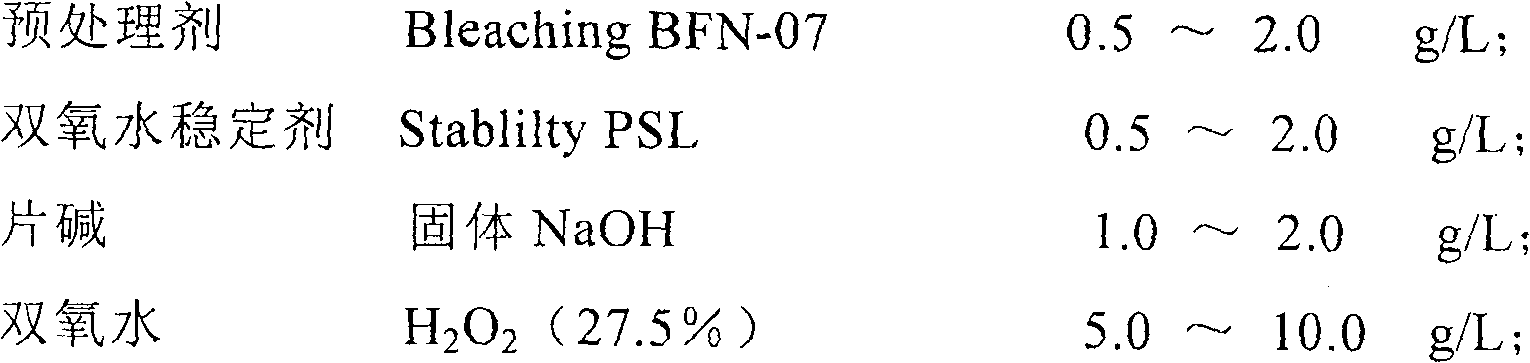

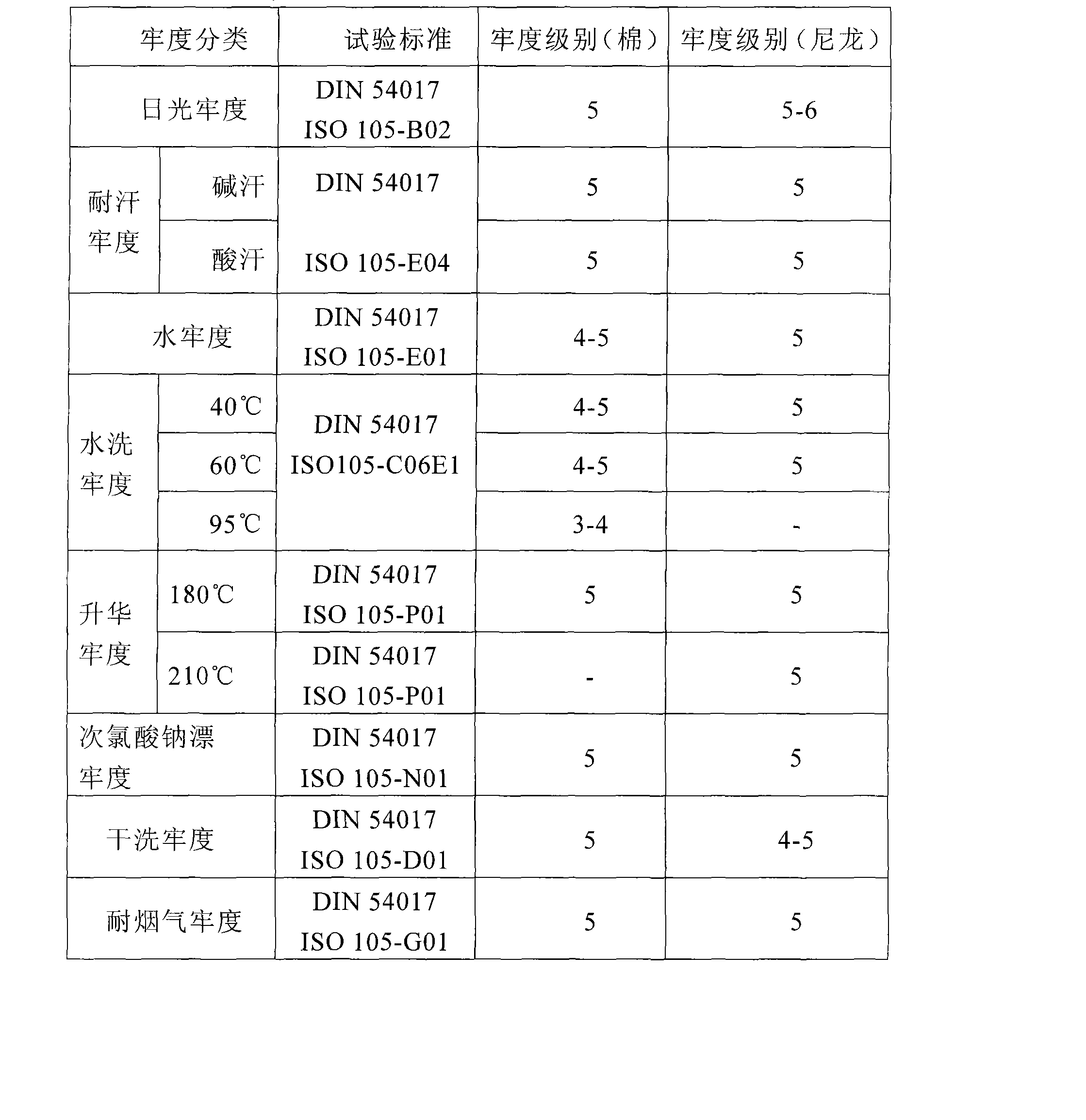

High solarization light fastness extra white fabric and manufacturing method thereof

InactiveCN101469508BResistant to high sunlightSolve dim lightBleaching apparatusBis-triazineWhitening Agents

The invention relates to a fabric in dyeing industry, especially relates to white fabric. A high light fastness ultra-white fabric includes fabric to be treated. The bleaching process of the high light fastness ultra-white fabric is obtained by fluorescent whitening agent treatment and reduction bleaching. The fluorescent whitening agent mainly comprises derivatives of bis-triazine diphenyl ethylene. Preparation of the high light fastness ultra-white fabric includes steps of: putting the fabric to be treated into a treatment bath, adding pre-treatment agents BFN-07, hydrogen peroxide stabilizer PSL, NaOH, H2O2 in sequence, direct heating to 98 DEG C., keeping temperature for 60 minutes, lowering temperature, discharging water, neutralizing and water washing, adding the fluorescent whitening agent for treatment, and reduction bleaching or the like. The ultra-white fabric has great light fastness, meets the requirement for high-grade clothes and sport clothing, is great in hand-feeling and comfortable for wearing.

Owner:上海德桑印染有限公司

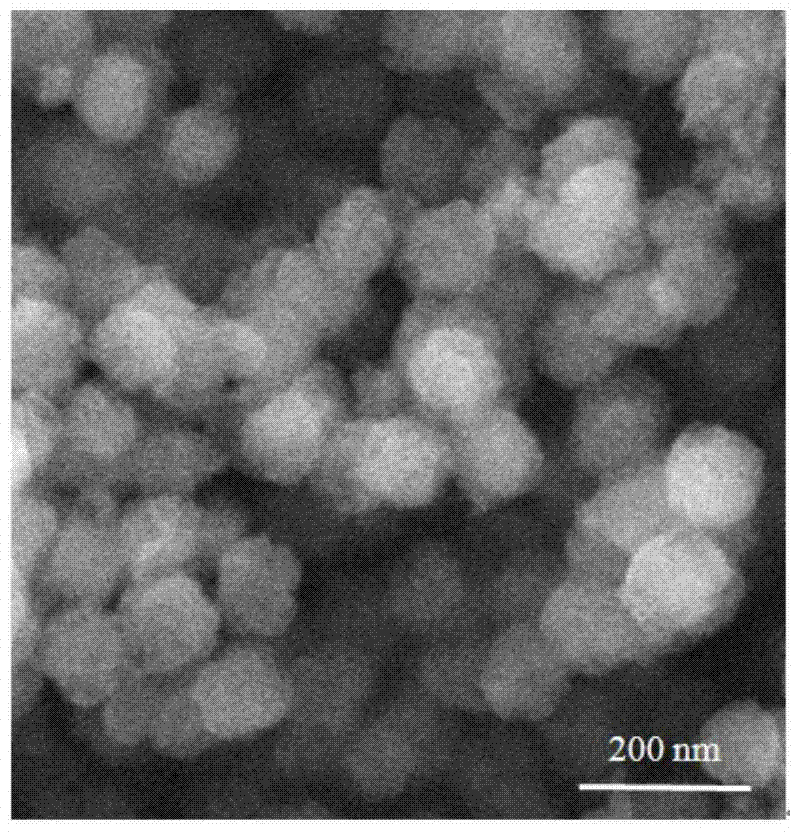

Preparation method and application of hydrostable nano complex

InactiveCN104774185ASimple methodReduce energy consumptionOrganic chemistryOther chemical processesN dimethylformamidePotassium hydroxide

The invention relates to a preparation method and application of a hydrostable nano complex. The preparation method comprises the following steps: dissolving zinc nitrate in water to obtain a zinc nitrate water solution, adding the solution into a dimethylformamide solution of triazinyl tribasic carboxylic acid, and blending by shaking; carefully adding anhydrous ethanol and a potassium hydroxide water solution into the supernatant of the mixed solution, blending by shaking to obtain a colloid homogeneous liquid, standing, carrying out centrifugal separation, and washing the obtained solid to obtain the nano triazinyl complex; and adding DMF (N,N-dimethylformamide) and hexamethyne diisocyanate into the prepared nano triazinyl complex under stirring conditions, keeping the temperature, cooling the solid, separating, washing and drying to obtain the hydrostable nano complex material. The nano complex material has the advantages of small particle size and high specific area, has abundant imino (-NH-) active sites in the structure, has higher capacity for adsorbing Hg (II) pollutants in water, and thus, has favorable industrial application prospects.

Owner:孙欣雨

Stilbene bis triazine liquid whitener and preparation method thereof

InactiveCN106349752AImprove decontamination abilityReduce pollutionDetergent dyesNon-surface-active detergent compositionsBis-triazinePreservative

The invention belongs to the technical field of liquid whiteners, and particularly relates to a stilbene bis triazine liquid whitener and a preparation method thereof. The liquid whitener composition is composed of a fluorescent whitening agent C.I.71, polylol, polyethyleneglycol, a non-polyethyleneglycol nonionic surfactant, a cosolvent, sodium citrate, a preservative and deionized water. The composition is a transparent liquid with lower viscosity, can be stably stored at -15-45 DEG C for 6 months without stratification, caking or precipitation, can be easily added into a laundry detergent, and has obvious effects on enhancing the comprehensive detergency of the laundry detergent and especially whitening the white textiles.

Owner:山西青山化工有限公司

High solarization light fastness extra white fabric and manufacturing method thereof

InactiveCN101469508AResistant to high sunlightSolve dim lightBleaching apparatusBis-triazineWhitening Agents

The invention relates to a fabric in dyeing industry, especially relates to white fabric. A high light fastness ultra-white fabric includes fabric to be treated. The bleaching process of the high light fastness ultra-white fabric is obtained by fluorescent whitening agent treatment and reduction bleaching. The fluorescent whitening agent mainly comprises derivatives of bis-triazine diphenyl ethylene. Preparation of the high light fastness ultra-white fabric includes steps of: putting the fabric to be treated into a treatment bath, adding pre-treatment agents BFN-07, hydrogen peroxide stabilizer PSL, NaOH, H2O2 in sequence, direct heating to 98 DEG C., keeping temperature for 60 minutes, lowering temperature, discharging water, neutralizing and water washing, adding the fluorescent whitening agent for treatment, and reduction bleaching or the like. The ultra-white fabric has great light fastness, meets the requirement for high-grade clothes and sport clothing, is great in hand-feeling and comfortable for wearing.

Owner:上海德桑印染有限公司

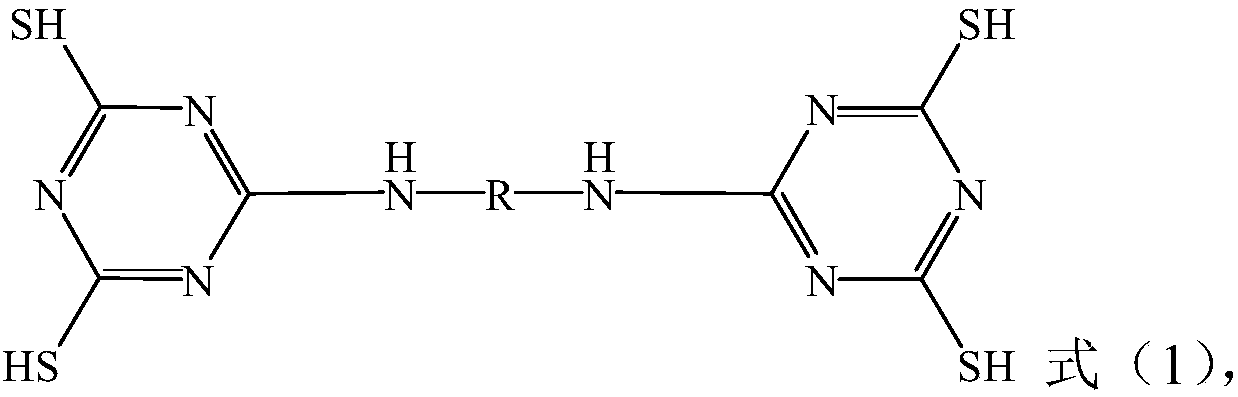

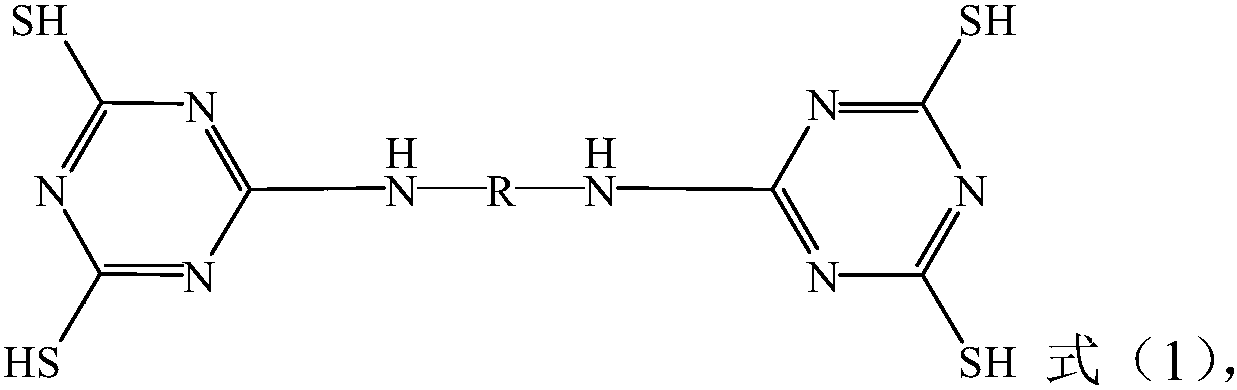

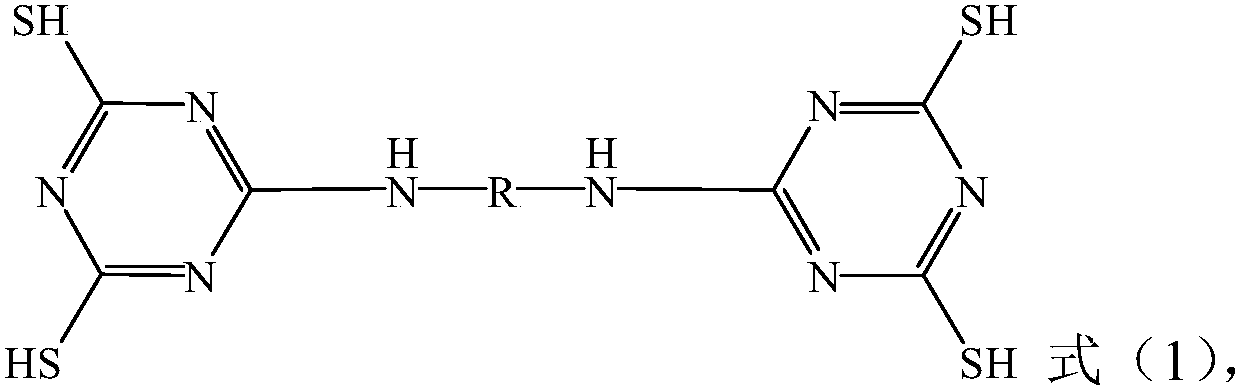

Binding agent, application of binding agent, composite product, and preparation method and application of composite product

The invention relates to the field of adhesives, and discloses a binding agent, an application of the binding agent, a composite product, and a preparation method and an application of the composite product. The binding agent contains a bis-triazine thiol compound having a structure represented as a formula (I), wherein R is at least one selected from a group consisting of straight-chain or branched alkylene of C1-C16 and arylene-containing chain segments of C6-C16. An organic thin film is formed between a metal layer and a plastic layer by using the binder containing the bis-triazine thiol compound which has the structure represented as the formula (I), wherein the bis-triazine thiol compound having the structure represented as the formula (I) contains a plurality of conjugated thiol functional groups, which can be combined with each other to form the compact organic film, and the excess thiol functional groups can be combined with metals and plastic through chemical bonds, so that the bonding effect is achieved.

Owner:BYD CO LTD

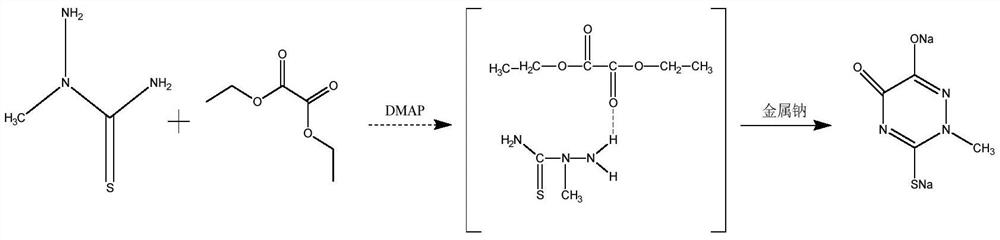

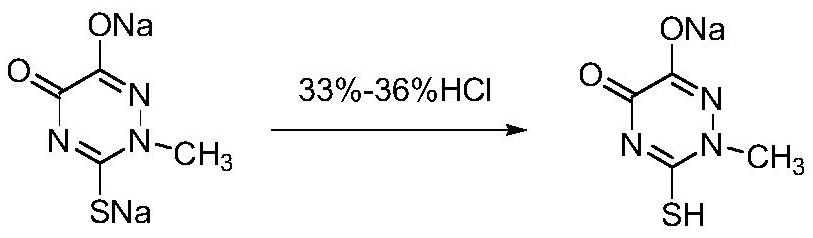

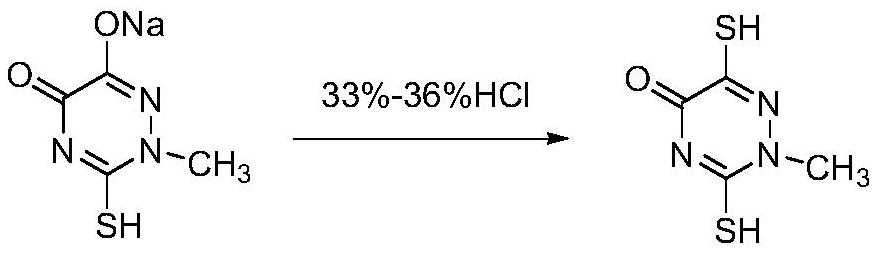

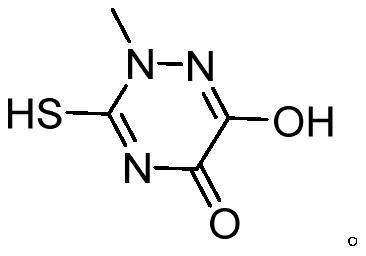

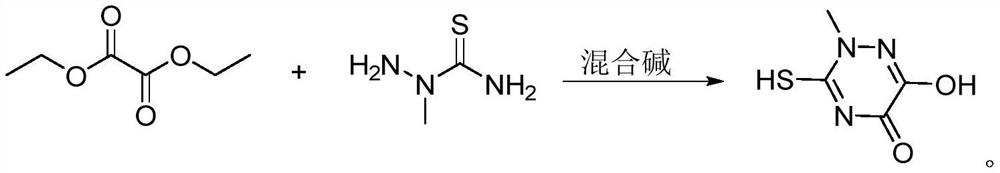

Preparation method of triazine ring

The invention belongs to the technical field of preparation of organic intermediates, and particularly relates to a preparation method of a triazine ring. The method comprises the following steps: adding 2-methyl thiosemicarbazide, diethyl oxalate and a mixed alcohol solvent into a reaction flask, dropwise adding a mixed base catalyst, carrying out cyclization reaction at 45-55 DEG C, performing acidifying with hydrochloric acid, performing cooling to 0-5 DEG C, and carrying out suction filtration to obtain a triazine ring crude product; dissolving the triazine ring crude product in distilled water at 65-70 DEG C, performing cooling to 10-15 DEG C, crystallizing to obtain a triazine ring wet product, and drying at 90-100 DEG C for 3-5 hours to obtain a triazine ring dry product. According to the preparation method, a new solvent system is not introduced, the reaction selectivity is high, side reactions are few, the solvent system is easy to recycle, and the product yield is high; the adopted raw materials are cheap, easy to obtain, low in cost and suitable for industrial amplification.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

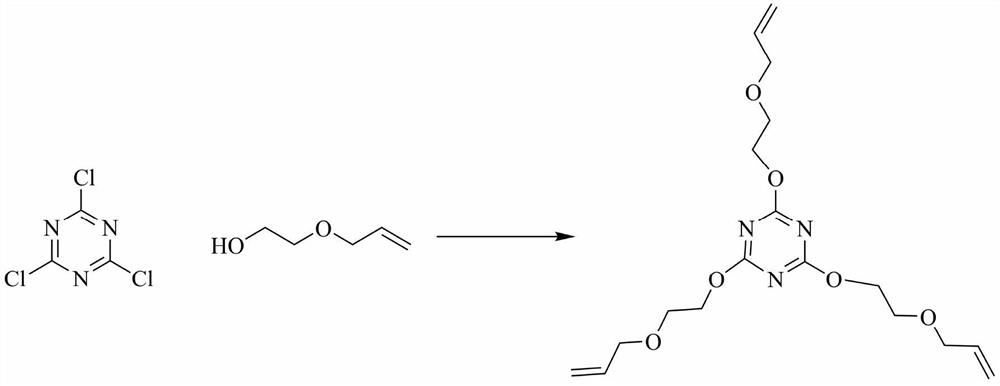

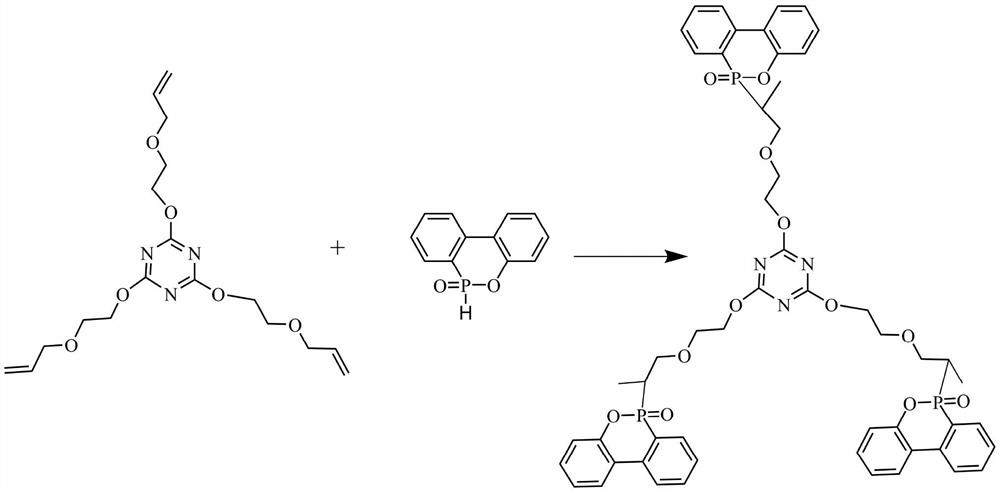

Triazinyl nitrogen-phosphorus flame retardant, preparation method and water-based acrylic coating

ActiveCN113354686AOvercome easy hydrolysisOvercome Migration DisadvantagesFireproof paintsGroup 5/15 element organic compoundsAcrylic coatingDouble bond

The invention relates to a triazinyl nitrogen-phosphorus flame retardant, a preparation method and a water-based acrylic coating, the triazinyl nitrogen-phosphorus flame retardant is prepared by the following steps: modifying cyanuric chloride by using allyl hydroxyethyl ether, introducing double bonds into triazinyl, and then carrying out addition reaction on 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and the double bonds, and finally, blending the prepared flame retardant with a water-based acrylic emulsion to prepare the flame-retardant coating with excellent performance. The water-based acrylic coating comprises the following components in parts by weight: 100 parts of water-based acrylic emulsion, 15-25 parts of a triazinyl nitrogen-phosphorus flame retardant, 0.5 part of a defoaming agent, 0.5 part of a flatting agent and 1.5 parts of a thickening agent. The prepared flame-retardant coating overcomes the defects that a common micromolecular triazinyl flame retardant is easy to hydrolyze and migrate; the modified triazinyl and DOPO construct a nitrogen-phosphorus synergistic flame-retardant system, so that the flame-retardant efficiency is greatly improved.

Owner:武汉海翎化学工业有限公司

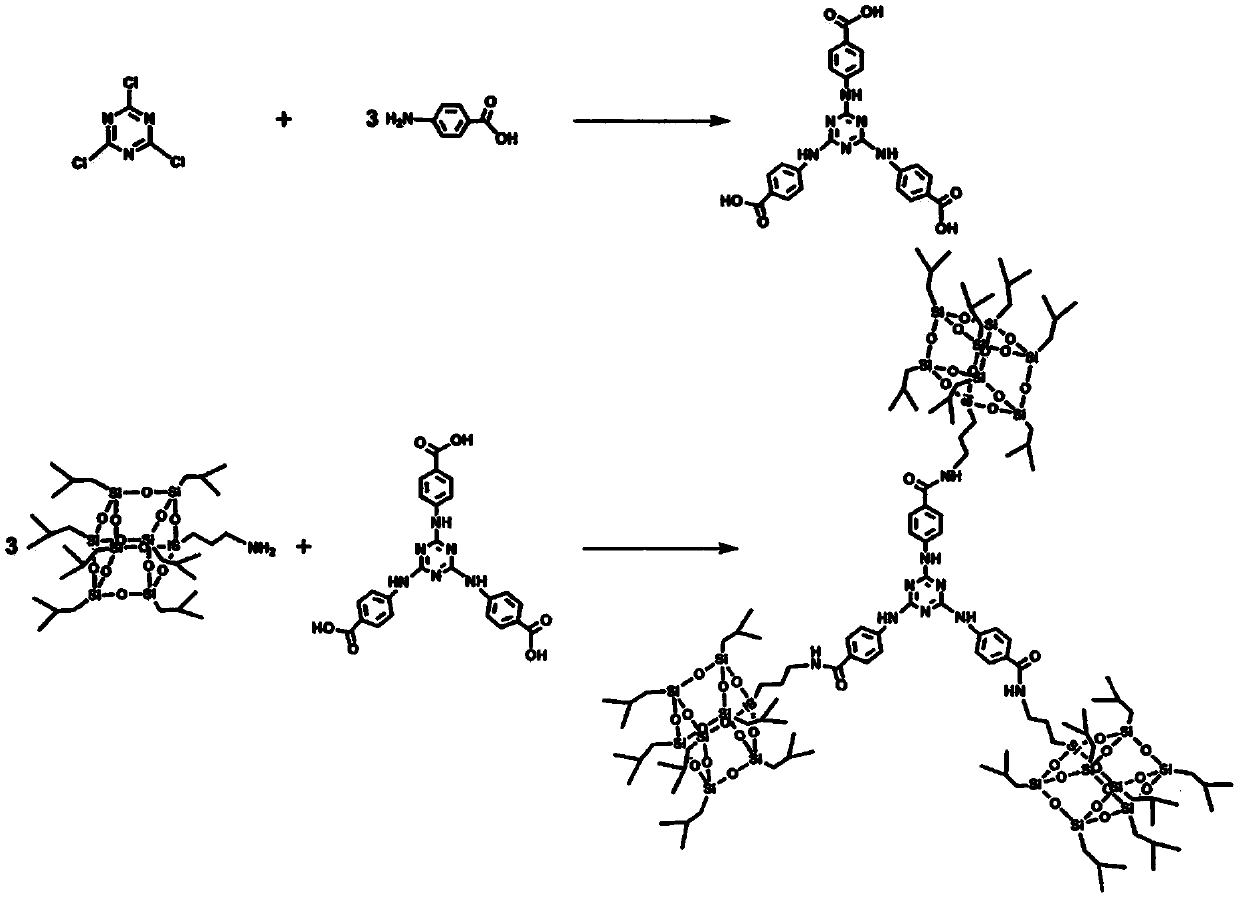

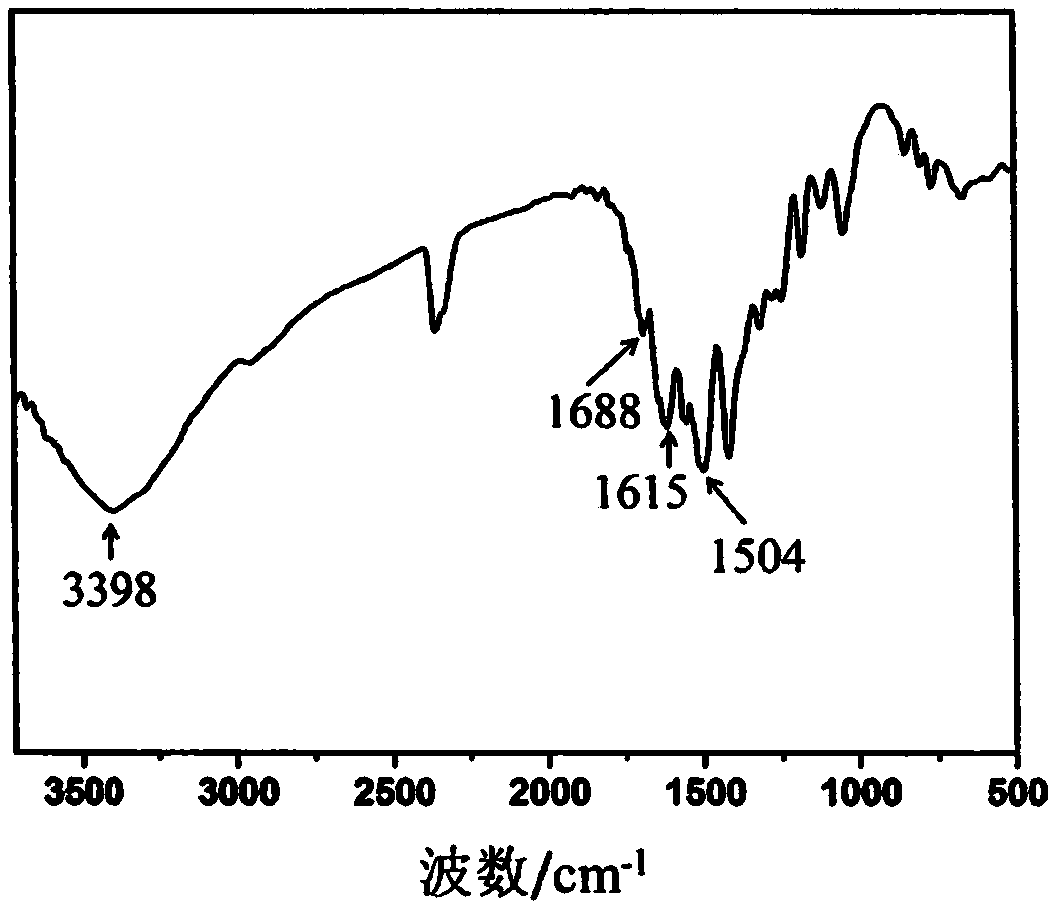

Silsesquioxane-modified melamine fire retardant and preparation method thereof

ActiveCN110408032AImprove heat resistanceImprove flame retardant performanceP-Aminobenzoic acidFire retardant

The invention discloses a silsesquioxane-modified melamine compound, and a preparation method and an application thereof. The method comprises the following steps: reacting raw materials which are cyanuric chloride, p-aminobenzoic acid and sodium hydroxide in an aqueous solvent system to prepare 4,4',4''-(1,3,5-triazine-2,4,6-trinitro)tribenzoic acid, and then reacting the 4,4',4''-(1,3,5-triazine-2,4,6-trinitro)tribenzoic acid with 2-ethoxy-1-ethoxycarbonyl-1,2-dihydroquinoline and monoaminosilsesquioxane in a dioxane and methanol mixed solvent system to prepare the target product. A result of test shows that the silsesquioxane-modified melamine compound prepared in the invention can significantly improve the compatibility with high-molecular materials in order to effectively improve thefire retardant efficiency. The preparation method of the compound has the advantages of simplicity, easy availability of the raw materials, low cost, realization of large-scale production, and very strong practical values.

Owner:ZHONGBEI UNIV

A kind of preparation method of triazinone

ActiveCN109293591BLow costAvoid it happening againOrganic chemistryChemical recyclingThiocarbohydrazidePtru catalyst

The invention relates to a triazinone preparation method, which comprises: carrying out a hydrolysis reaction on 1-chloropinacolone at a temperature of 80-140 DEG C under the actions of a solvent andan alkali to obtain a compound I, wherein the solvent is water; carrying out an oxidation reaction on the compound I in the presence of oxygen by using Pt as a catalyst under a neutral or weakly basiccondition to obtain a compound II; and carrying out a ring closure reaction on the compound II and thiocarbohydrazide under the catalysis of an acid to obtain triazinone, wherein the structure formula of the compound I is defined in the specification, and the structure formula of the compound II is defined in the specification. According to the present invention, 1-chloropinacolone is used as theraw material, and the water is used as the solvent, such that the generation of high salt wastewater can be avoided; Pt is used as the catalyst, and oxygen is used as the oxidant, such that the use of hydrogen peroxide can be avoided, and the catalyst can be recycled so as to reduce the raw material cost; and the production method is simple, meets the environmentally friendly requirement, and issuitable for industrial production, and the yield and the content of the final product are high.

Owner:JIANGSU SEVENCONTINENT GREEN CHEM CO LTD

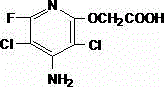

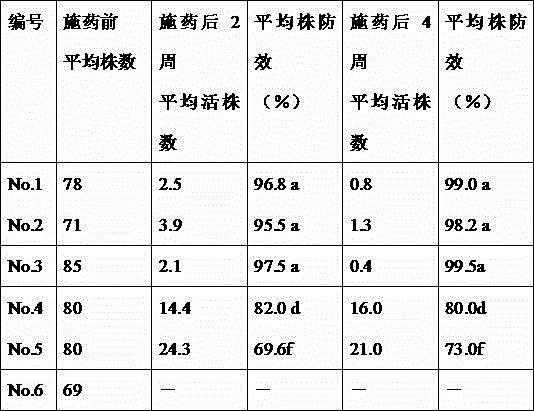

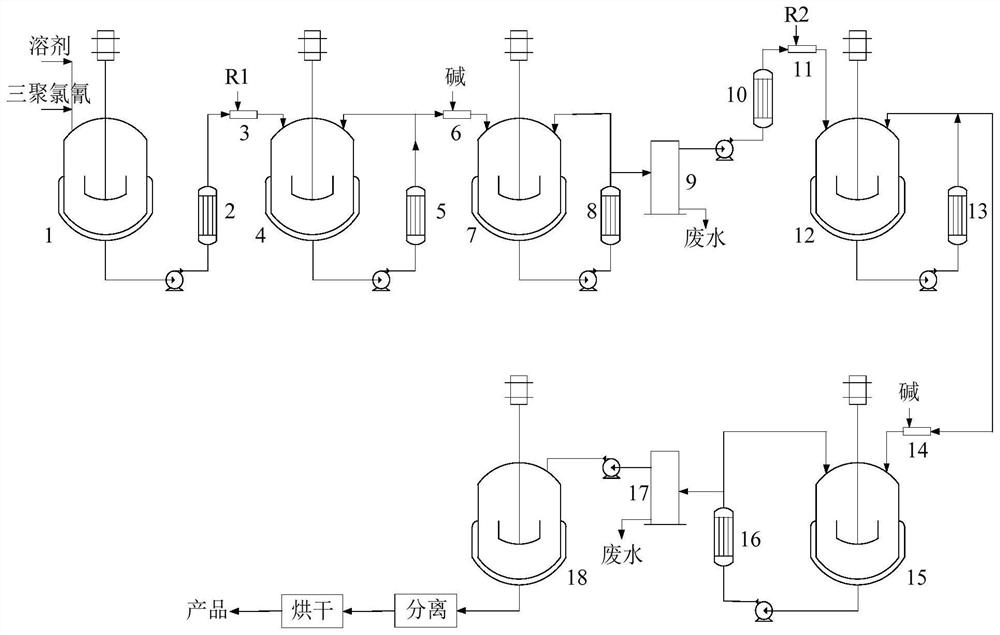

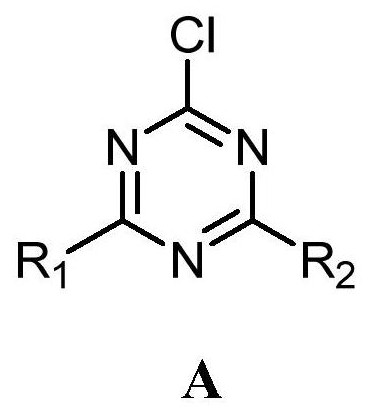

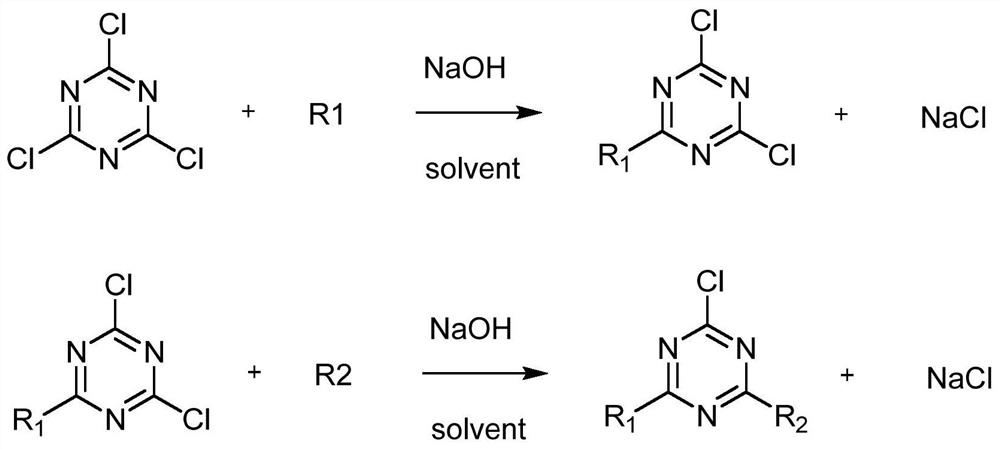

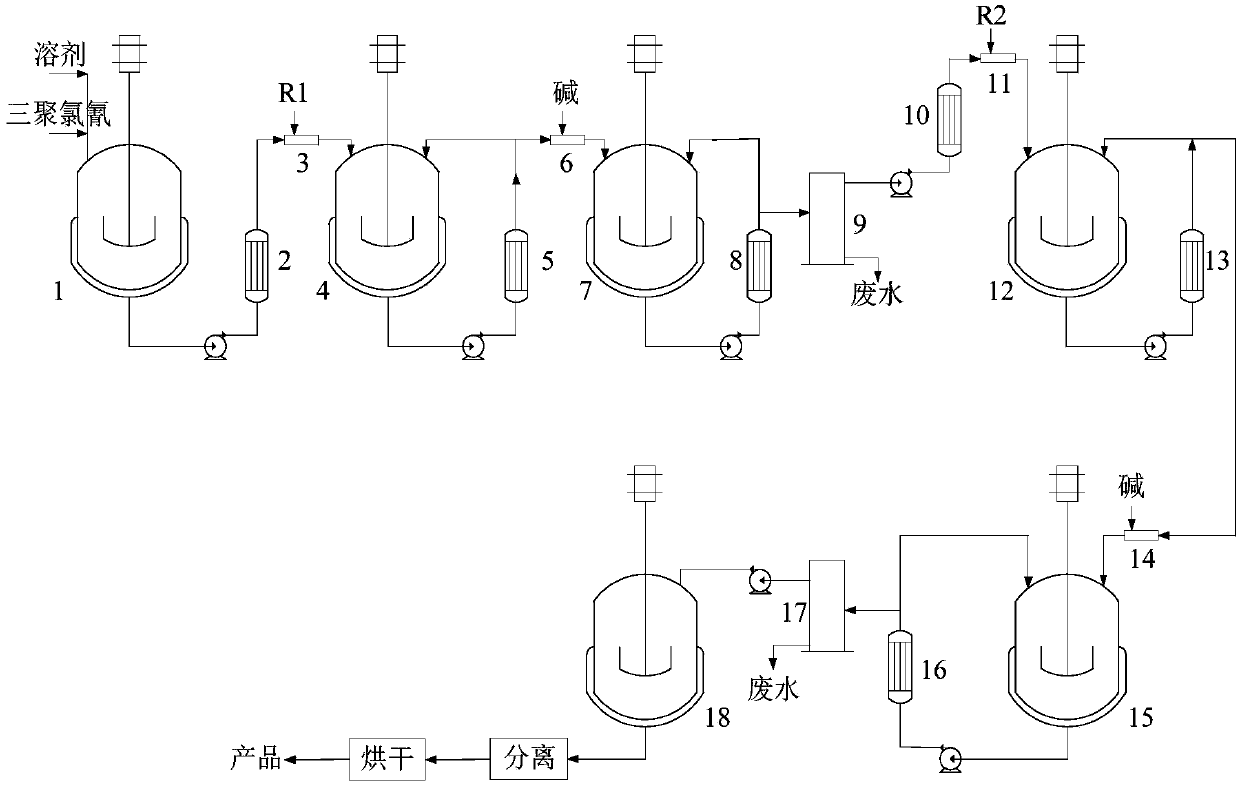

Continuous production method of multi-kettle serial triazine herbicide

InactiveCN109627225AStrong production process continuityIncrease production capacityOrganic chemistryTriazine herbicideSolvent

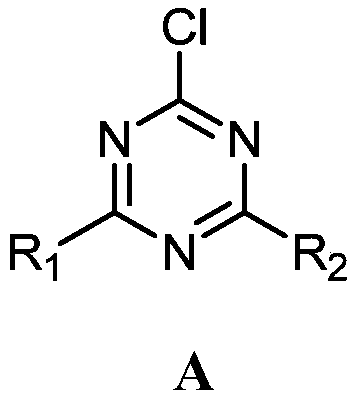

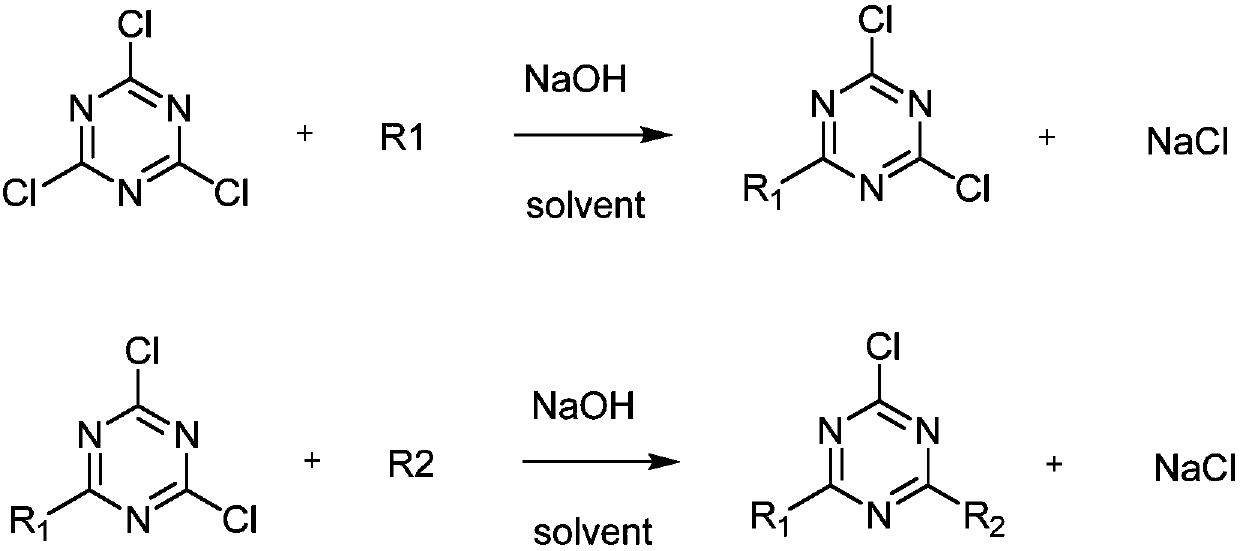

The invention relates to a continuous production method of a multi-kettle serial triazine herbicide. A metered cyanuric chloride solution is pre-cooled and mixed with alkylamine R1 in a mixer to entera first-stage reaction kettle, continuous discharging is conducted, after a heat exchanger is passed, the cyanuric chloride solution is neutralized with alkali in the mixer and enters a first-stage neutralization kettle, after a reaction is completed, the cyanuric chloride solution passes through a continuous water separator and the heat exchanger and is mixed with alkylamine R2 in the mixer to enter a second-stage reaction kettle, the continuous discharging is conducted, after the cyanuric chloride solution passes through the heat exchanger, the cyanuric chloride solution is mixed with the alkali in the mixer to enter a second-stage neutralization kettle, after the neutralization, a aqueous phase is separated by a continuous layerer, a solvent is removed, and drying is conducted to obtain a triazine product. The production method has the advantages of high productivity, good production stability, high efficiency, high product quality and the like, is particularly suitable for technical transformation of existing production enterprises, has a low transformation cost, basically does not add novel reaction equipment, and is easily mastered by existing enterprises.

Owner:SHANDONG NORMAL UNIV

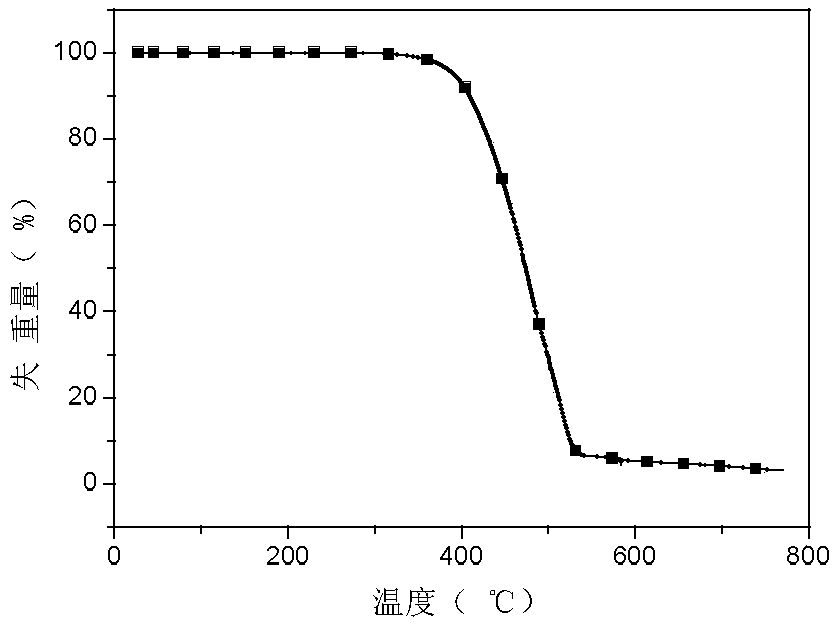

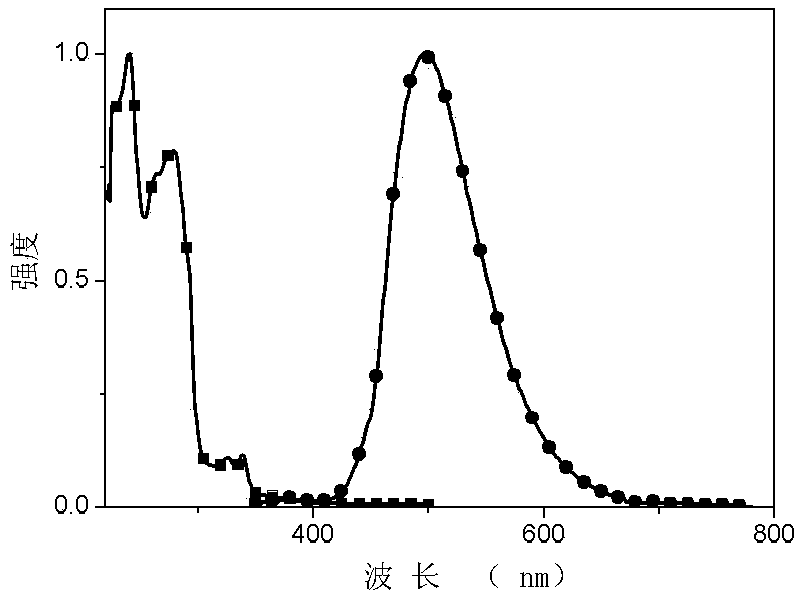

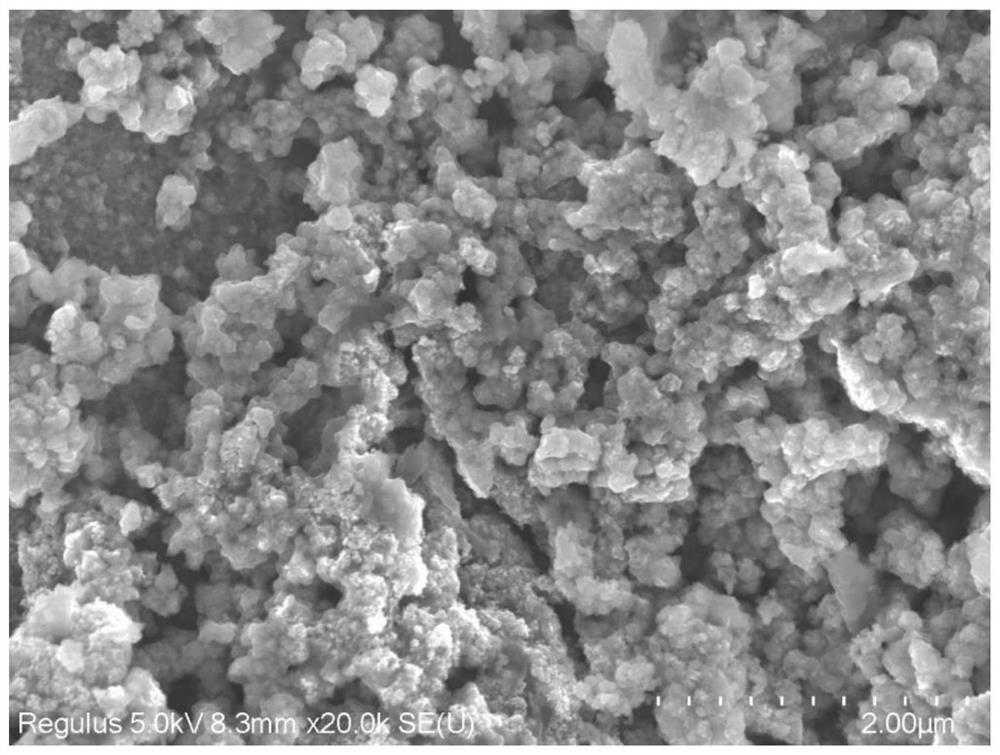

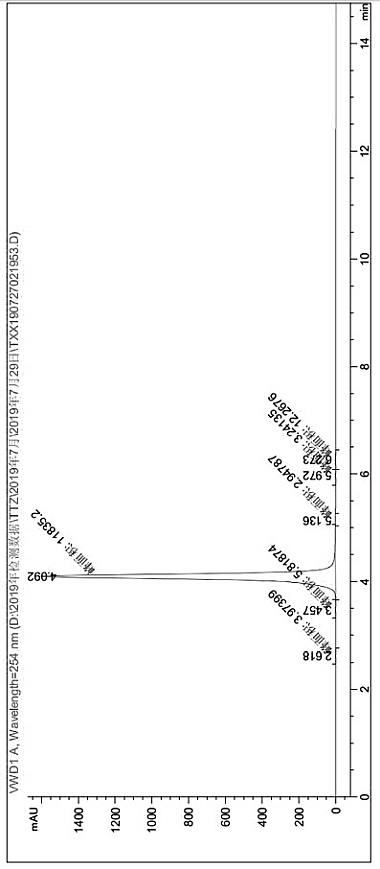

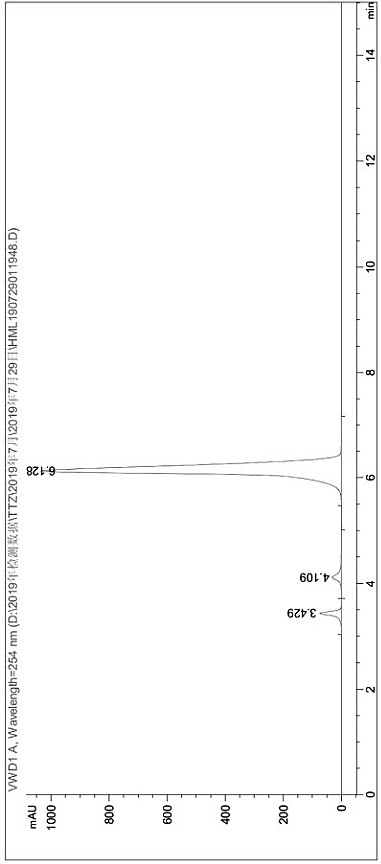

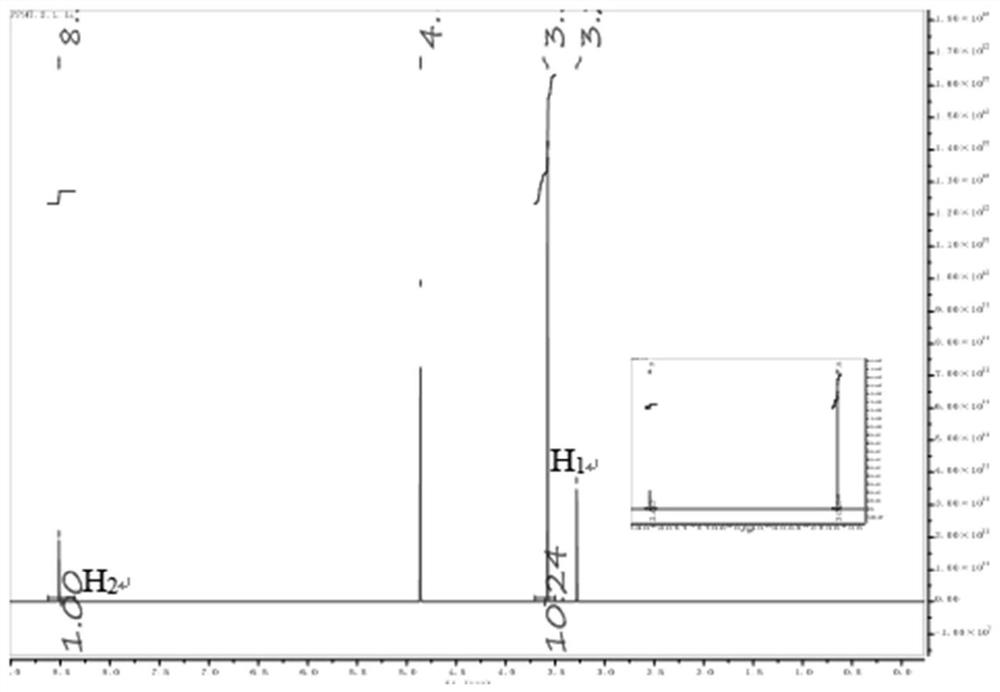

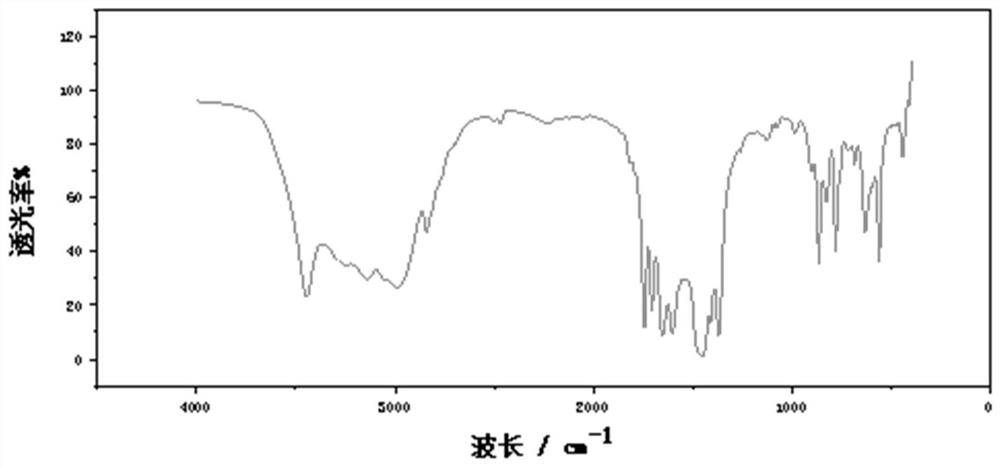

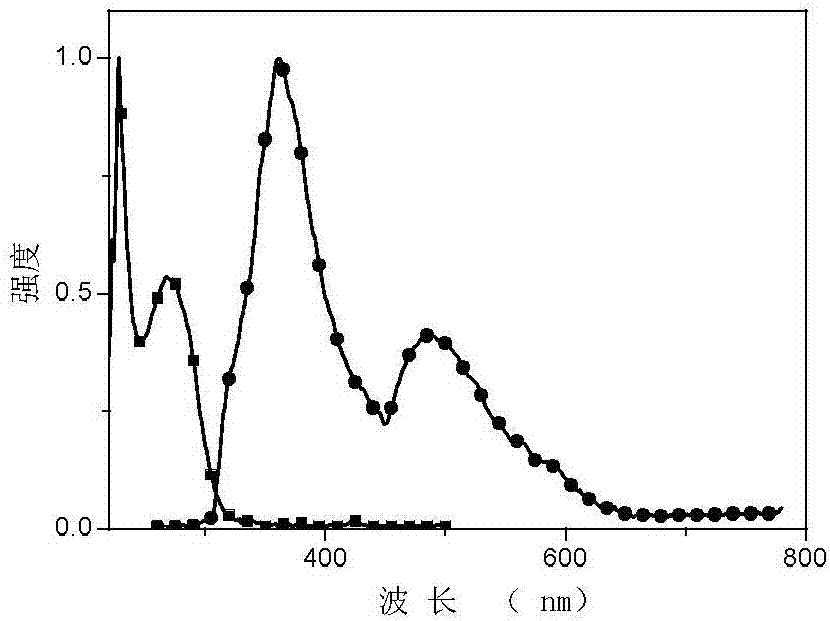

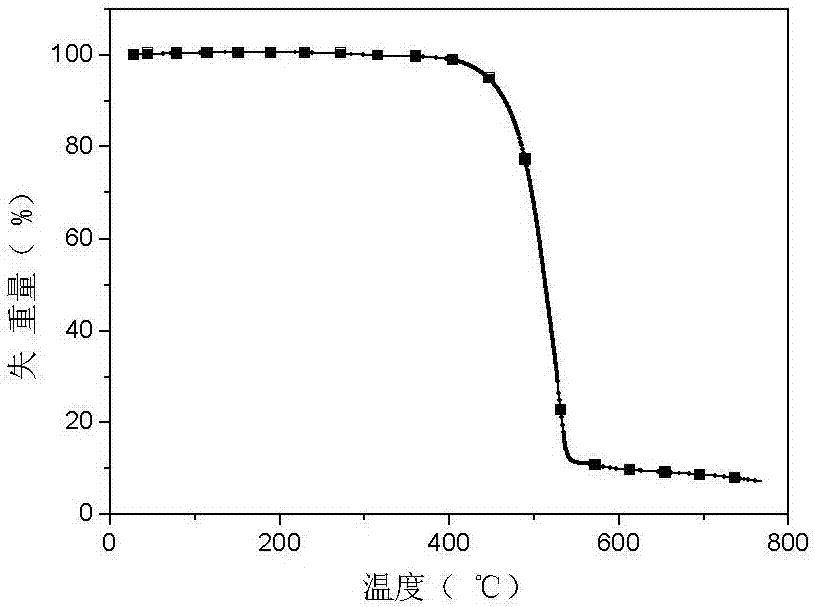

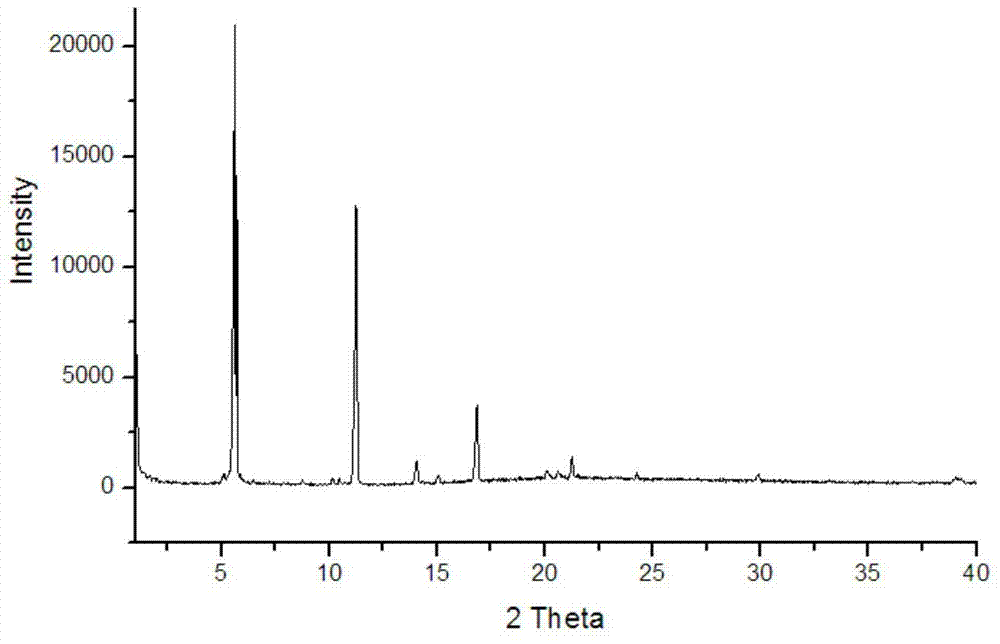

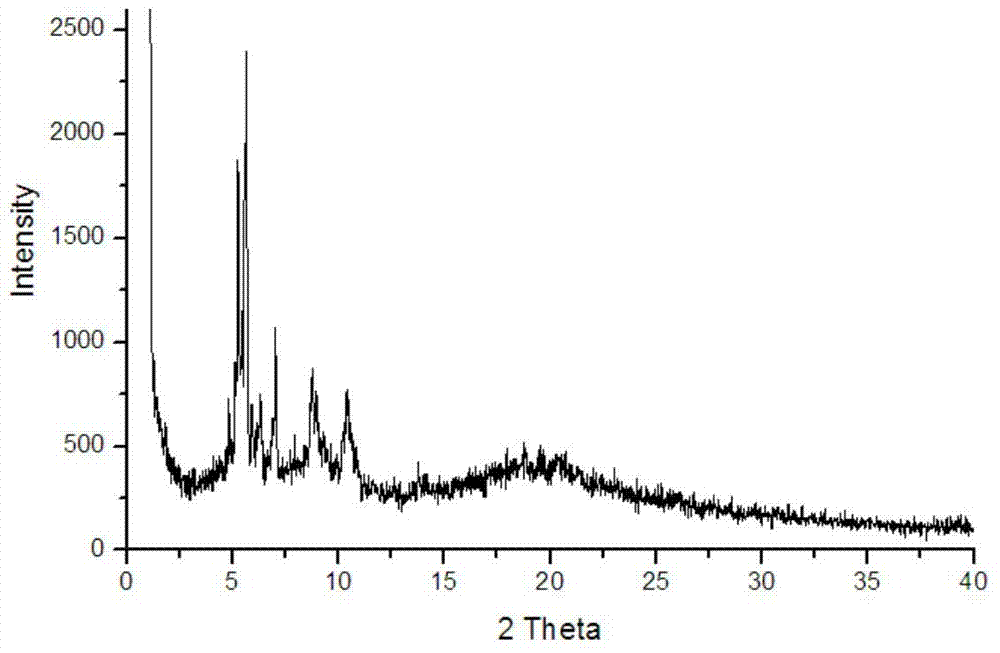

Three-dimensional covalent triazinyl calix[4]arene polymer and preparation method and application thereof

ActiveCN111363160AHigh nitrogen contentImprove thermal stabilityOther chemical processesWater contaminantsBenzeneAminocalix

The invention relates to a three-dimensional covalent triazinyl calix[4]arene polymer and a preparation method and application thereof. The preparation method comprises the steps that 4-amino calix[4]arene and s-triazine react under the ice bath condition so that an intermediate is obtained, and performing functional polymerization on the intermediate and 1, 3, 5-(4-aminophenyl)benzene under an alkaline condition to obtain a triazinyl calix[4]arene polymer, wherein the triazinyl calix[4]arene polymer can be used for adsorbing and treating organic micropollutants in water. Compared with the prior art, the triazinyl calix[4]arene polymer prepared by the method has good stability to humidity and water, has the advantages of high adsorption efficiency, large adsorption capacity per unit mass,good desorption effect, long cycle life, good heat resistance of the polymer and the like, and has a wide application prospect in the aspect of rapid treatment of wastewater.

Owner:SHANGHAI INST OF TECH

Preparation method of triazine ring

The invention belongs to the technical field of medicines, and particularly relates to a preparation method of a triazine ring. The method comprises the following steps: performing cyclization reaction on 2-methylthiosemicarbazide, diethyl oxalate, dimethylaminopyridine and metal sodium, adding hydrochloric acid for crystal transformation reaction after the cyclization reaction is finished to obtain a triazine ring sodium salt crude product, and adding hydrochloric acid into the triazine ring sodium salt crude product for refining reaction to obtain the triazine ring. The method has the advantages of simple raw materials, high yield, easy treatment and low cost.

Owner:SHANDONG JINCHENG KERUI CHEMICAL CO LTD

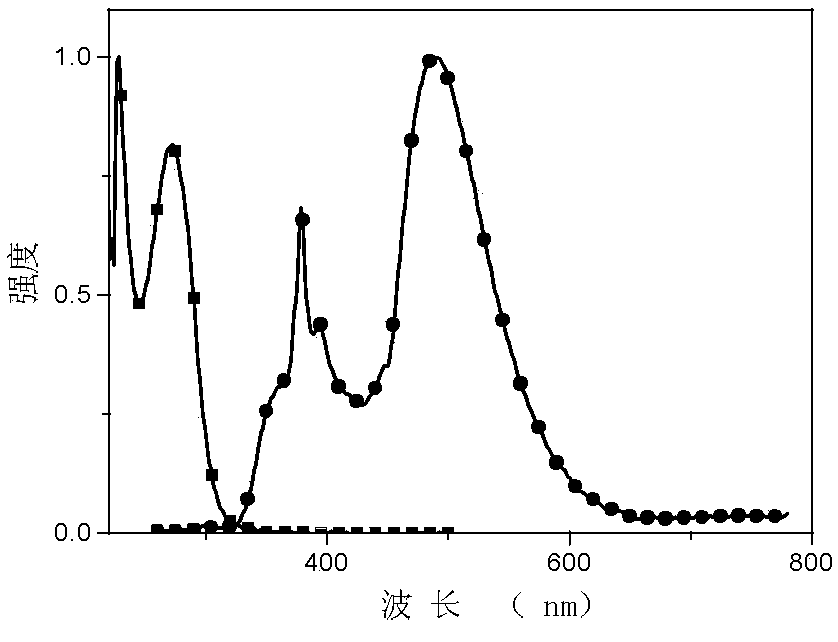

Triazine exciplex material based on phosphine oxide and carbazole and its preparation method and application

ActiveCN106699811BRealize regulationImprove power efficiencyGroup 5/15 element organic compoundsSolid-state devicesCarbazoleBis-triazine

The triazine exciplex material based on phosphine oxide and carbazole and its preparation method and application are to solve the technical problem that the existing blue light exciplex acceptor materials are few. The structure of the triazine exciplex material based on phosphine oxide and carbazole of the present invention is as follows: preparation method: monobromotriphenyltriazine, carbazole compound, anhydrous K 2 CO 3 After adding CuI to 1,3-dimethyl-2-imidazolinone for reaction, the intermediate compound is purified; then the intermediate compound is reacted with diphenylphosphine and palladium acetate in anhydrous DMF, and then purified to obtain the triazine exciplex-like materials. The material can be used in TADF and phosphorescent organic electroluminescent devices.

Owner:HEILONGJIANG UNIV

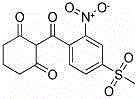

A kind of herbicidal composition containing mesotrione and amenzazone

The present invention relates to a herbicidal composition containing mesotrione and amenzazone, which uses mesotrione and amenzazone as active ingredients, and the weight ratio of the active ingredients is mesotrione: amfenflumele =1~90:90~1, the active ingredient accounts for 1%~99% by weight of the herbicidal composition. The herbicidal composition of the present invention can be used for soil sealing and post-emergence stem and leaf treatment by compounding mesotrione and amenzazone. The application period is long, the weeding effect is good, and the dosage is less than 1% of triazine agents. / 3-1 / 5, and can solve the problems of safety and water pollution after cropping, so the combination of the two has good economic and social benefits.

Owner:ZIBO NAB AGROCHEM

A kind of method for continuous production of triazine herbicides in series with multiple reactors

InactiveCN109627225BStrong production process continuityIncrease production capacityOrganic chemistryTriazine herbicideBis-triazine

The invention relates to a continuous production method of a multi-kettle serial triazine herbicide. A metered cyanuric chloride solution is pre-cooled and mixed with alkylamine R1 in a mixer to entera first-stage reaction kettle, continuous discharging is conducted, after a heat exchanger is passed, the cyanuric chloride solution is neutralized with alkali in the mixer and enters a first-stage neutralization kettle, after a reaction is completed, the cyanuric chloride solution passes through a continuous water separator and the heat exchanger and is mixed with alkylamine R2 in the mixer to enter a second-stage reaction kettle, the continuous discharging is conducted, after the cyanuric chloride solution passes through the heat exchanger, the cyanuric chloride solution is mixed with the alkali in the mixer to enter a second-stage neutralization kettle, after the neutralization, a aqueous phase is separated by a continuous layerer, a solvent is removed, and drying is conducted to obtain a triazine product. The production method has the advantages of high productivity, good production stability, high efficiency, high product quality and the like, is particularly suitable for technical transformation of existing production enterprises, has a low transformation cost, basically does not add novel reaction equipment, and is easily mastered by existing enterprises.

Owner:SHANDONG NORMAL UNIV

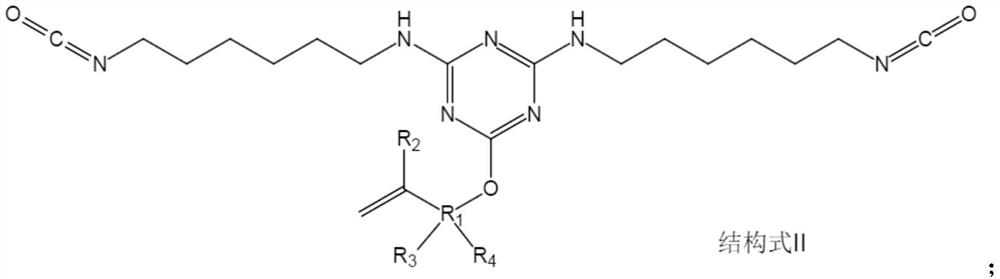

Engine sound insulation pad and preparation method thereof

PendingCN114057952AImprove flame retardant performanceImprove heat resistanceLamination ancillary operationsSynthetic resin layered productsPolymer sciencePtru catalyst

The invention discloses a preparation method of an engine sound insulation pad, the preparation method comprises the following steps: S1, under the protection of inert gas, carrying out reflux reaction on halogenated s-triazine and unsaturated olefin alcohol under the action of a catalyst to obtain a triazine derivative; s2, continuously carrying out heating reflux reaction on the triazine derivative and 6-isocyanato hexane-1-amine to obtain a triazine intermediate; s3, enabling the oligomer dihydric alcohol and diisocyanate to be subjected to a reaction, and obtaining a hydroxyl-terminated polyurethane prepolymer; s4, adding the triazine intermediate into the polyurethane prepolymer, and carrying out chain extension reaction to obtain a polyurethane elastomer with a main chain containing triazine; and S5, adding vinyl ferrocene into the polyurethane elastomer, and then adding an initiator and a foaming agent for foaming reaction to obtain the engine sound insulation pad. The engine sound insulation pad not only has a good sound insulation effect, but also has excellent flame retardance and heat resistance, and meets the performance requirements of long-term use of the sound insulation pad under harsh conditions of the engine.

Owner:宁波尚唯汽车饰件有限公司

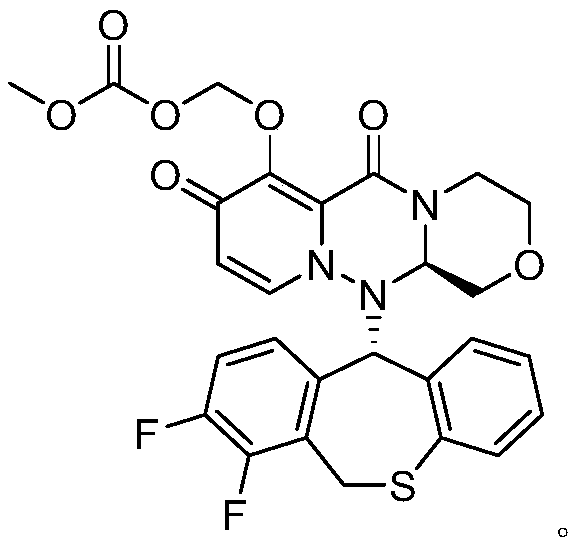

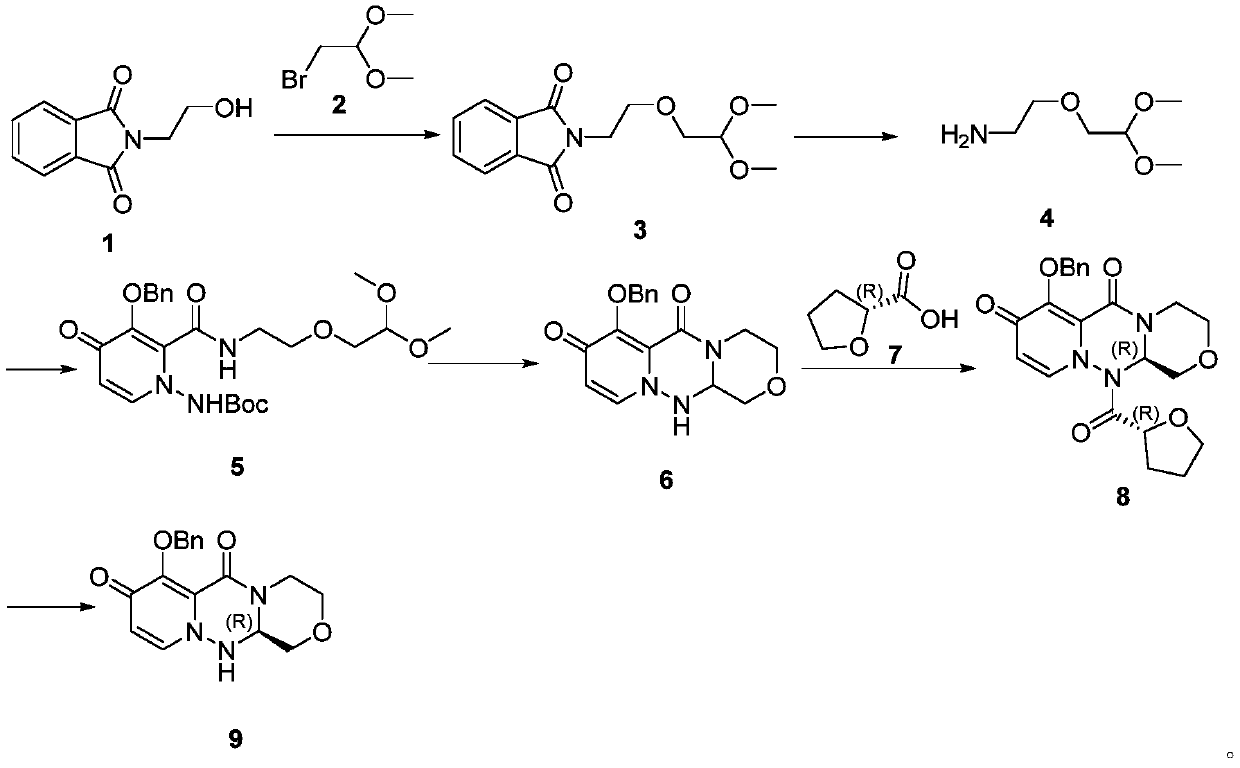

A kind of preparation method of cyclopyridone compound

The invention provides a preparation method of a fused-ring pyridone compound, and belongs to the field of pharmaceutical chemicals. The method comprises the following steps: performing a reaction ona morpholine ring compound with an activating reagent to obtain a morpholine ring compound with a leaving group; then adding a pyridone compound and performing a reaction under certain conditions to obtain a triazine compound; and adding a reducing agent, and performing a reaction under different conditions to respectively obtain a racemic fused-ring pyridone compound or a chiral fused-ring pyridone compound. The method has the characteristics of high product purity, high yield, low cost, simplicity in operation and the like.

Owner:SUNSHINE LAKE PHARM CO LTD

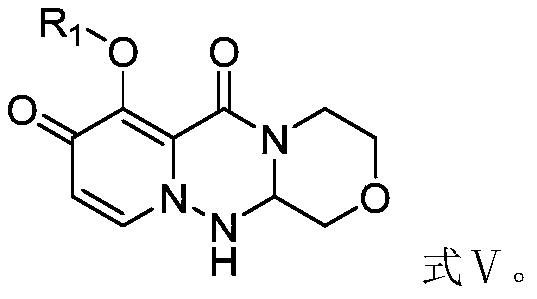

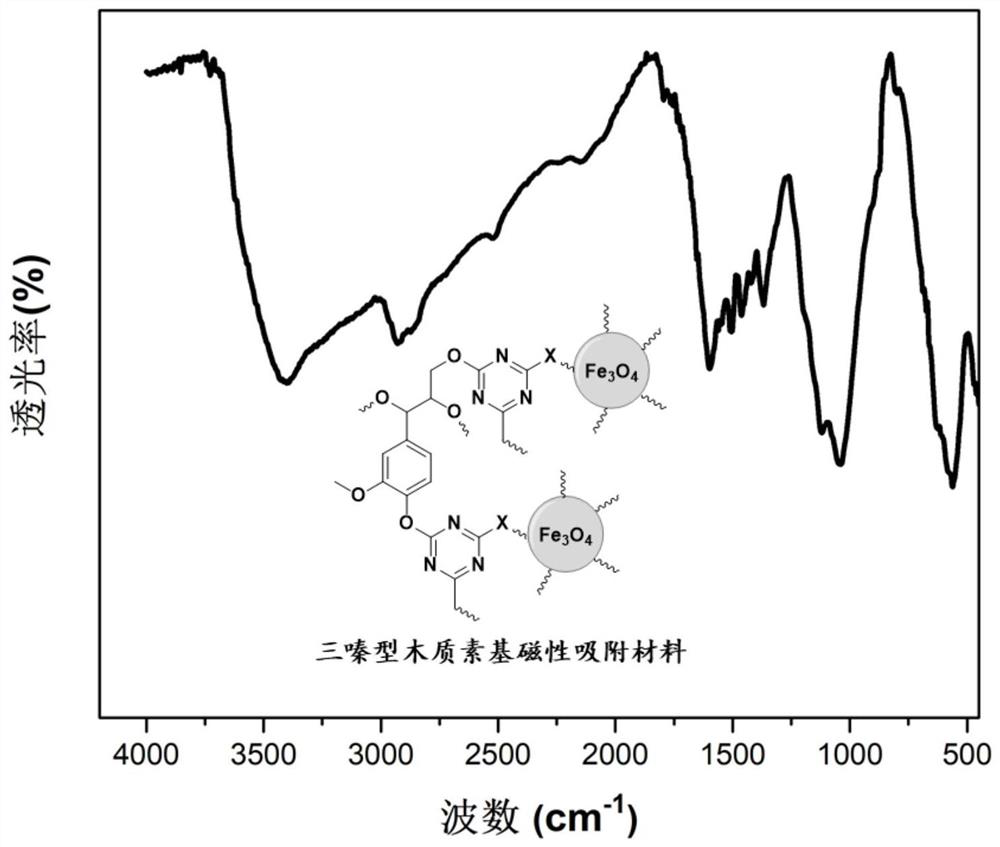

Triazine lignin-based magnetic adsorption material and preparation method thereof

ActiveCN111744460ASimple preparation processLess equipmentOther chemical processesWater contaminantsElectrolysisOrganic dye

The invention discloses a triazine lignin-based magnetic adsorption material and a preparation method thereof. The preparation method comprises the following steps of: dispersing lignin and magnetic Fe3O4 in a solvent medium; reacting a mixed liquid in the previous step with cyanuric chloride at 0-120 DEG C for 2-48 hours under the catalytic action of alkali; and performing separation and purification to obtain the triazine lignin-based magnetic adsorption material. The preparation method is simple and convenient in preparation process, high in yield and low in cost. The molecular structure ofthe prepared magnetic adsorption material contains rich heteroatom adsorption sites such as nitrogen and oxygen, so that the magnetic adsorption material can quickly adsorb heavy metal ions and organic pollutants in a water body with high capacity, has excellent magnetic response performance, has the advantages of easiness in magnetic separation, recycling performance and the like, and can be applied to the fields of heavy metal ion and organic dye-containing wastewater treatment, water body purification and the like in mining, electrolysis, printing and dyeing and other industries.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Modified preparation method of cotton woven grey cloth

InactiveCN109989261AHigh whitenessImprove washing resistanceTextile storage in superimposed formSingeingOligomerBis-triazine

The invention provides a modified preparation method of cotton woven grey cloth. Grey cloth prepared herein has very high whiteness; after the grey cloth is washed with water, the whiteness has very little decline; the whiteness of the grey cloth can last long. Cold pad-batch bleaching and washing are performed on the cotton woven grey cloth via a complex of sodium hydroxide, hydrogen peroxide solution, a negative non-ionic surfactant and an oligomer ester; bleaching is then performed via a complex of sodium hydroxide, hydrogen peroxide solution, a negative non-ionic surfactant and an oligomerester; the grey cloth is additionally brightened with stilbene bis-triazine brightener RSB. The grey cloth prepared via the modified preparation method herein has high whiteness, with the final whiteness reaching 155 and above, and has good washing fastness, the whiteness has a very low decline after 20 times of common domestic washing, and the decline value is less than 5.

Owner:TIANJIN TIANGE TEXTILE

A method for preparing 3-mercapto-5-methyl-1,2,4-triazole from triazine ring

The invention discloses a method for preparing 3-mercapto-5-methyl-1,2,4-triazole from a triazine ring, comprising the following steps in sequence: (1) dissolving the triazine ring in water to obtain the triazine ring solution; (2) adding acid to the triazine ring solution to adjust the pH value of the solution to 2-3; (3) heating up and refluxing; (4) after refluxing, cooling and solid-liquid separation to obtain a filtrate; (5) decompressing the filtrate Distill until a white solid appears; (6) Cool the temperature for solid-liquid separation to obtain a solid material; (7) Dry to obtain 3-mercapto-5-methyl-1,2,4-triazole. The present invention uses triazine ring as raw material to prepare 3-mercapto-5-methyl-1,2,4-triazole through transformation, the process is simple, the yield is high, the generated three wastes are few, the environmental pollution is small, and the A new efficient and safe preparation method.

Owner:SHANDONG HUIHAI PHARMA & CHEM

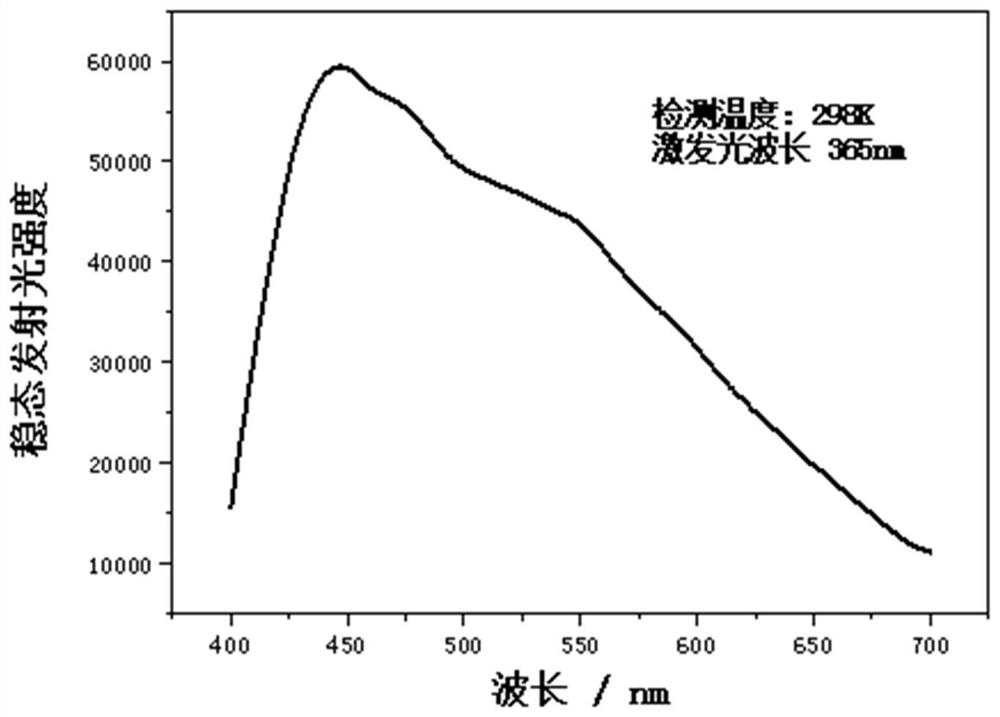

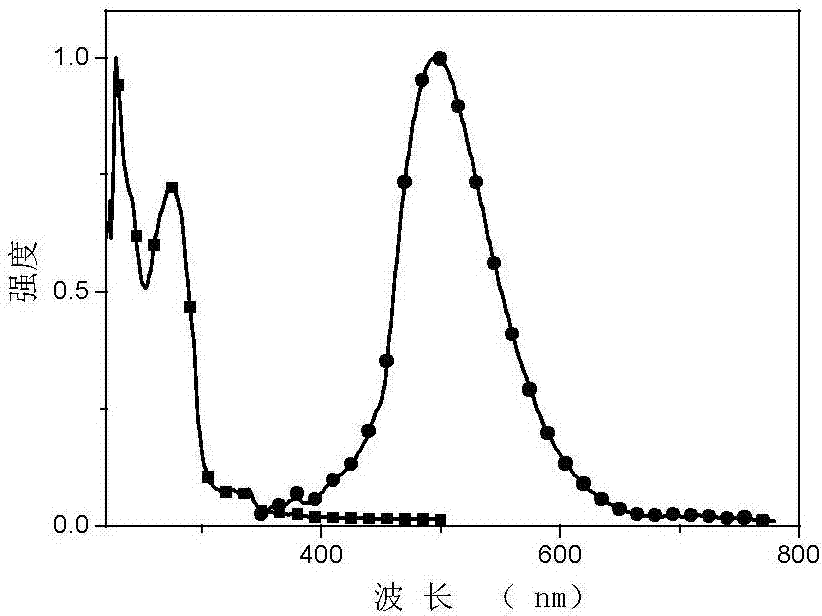

Triazine polymer and preparation method thereof

PendingCN112940241AExcellent phosphorescent quantum yieldWide operating temperature rangeLuminescent compositionsPolyolBis-triazine

The invention belongs to the technical field of triazine polymers, and relates to a triazine polymer and a preparation method thereof. The triazine polymer is obtained by mixing a compound containing a triazine ring with polyhydric alcohol sodium salt, conducting condensation polymerization through a Williamson ether synthesis method and conducting washing; the compound containing the triazine ring comprises a halogenated s-triazine compound, and the halogenated s-triazine compound comprises tripolychloroazine or 2-hydroxy-4, 6-dichloro s-triazine; the prepared triazine polymer has excellent phosphorescence quantum yield, long phosphorescence lifetime and unique luminescence characteristic, still has good long afterglow characteristic in a high-temperature environment, and utilizes the limitation of a special long-chain entanglement structure of the polymer on a non-radiation process to improve the luminous efficiency of the triazine polymer. The attenuation speed of the afterglow life along with the environment temperature is greatly slowed down; and the obtained triazine polymer not only can be used for photoelectric functional materials, but also can be used as an organic chemical intermediate, and has wide application in the fields of multiple encryption, anti-counterfeiting and the like.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Three-dimensional covalent triazinyl calix[4]arene polymer and preparation method and application thereof Three-dimensional covalent triazinyl calix[4]arene polymer and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/f6061e17-3f7b-419e-8a66-3a4b2fe30f6e/HDA0002422490320000011.png)

![Three-dimensional covalent triazinyl calix[4]arene polymer and preparation method and application thereof Three-dimensional covalent triazinyl calix[4]arene polymer and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/f6061e17-3f7b-419e-8a66-3a4b2fe30f6e/HDA0002422490320000012.png)

![Three-dimensional covalent triazinyl calix[4]arene polymer and preparation method and application thereof Three-dimensional covalent triazinyl calix[4]arene polymer and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/f6061e17-3f7b-419e-8a66-3a4b2fe30f6e/HDA0002422490320000021.png)