Patents

Literature

62results about How to "Simplify process operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

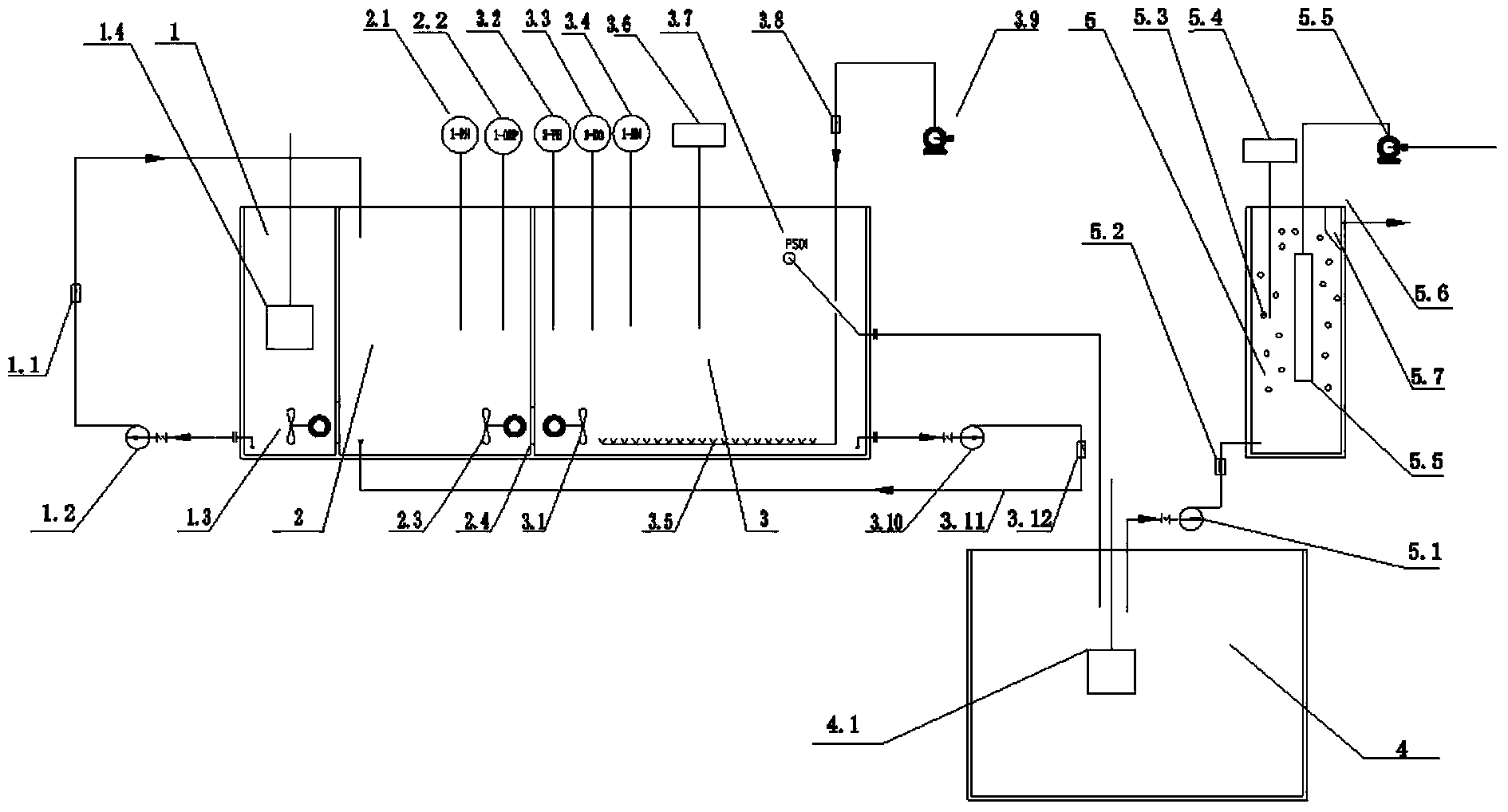

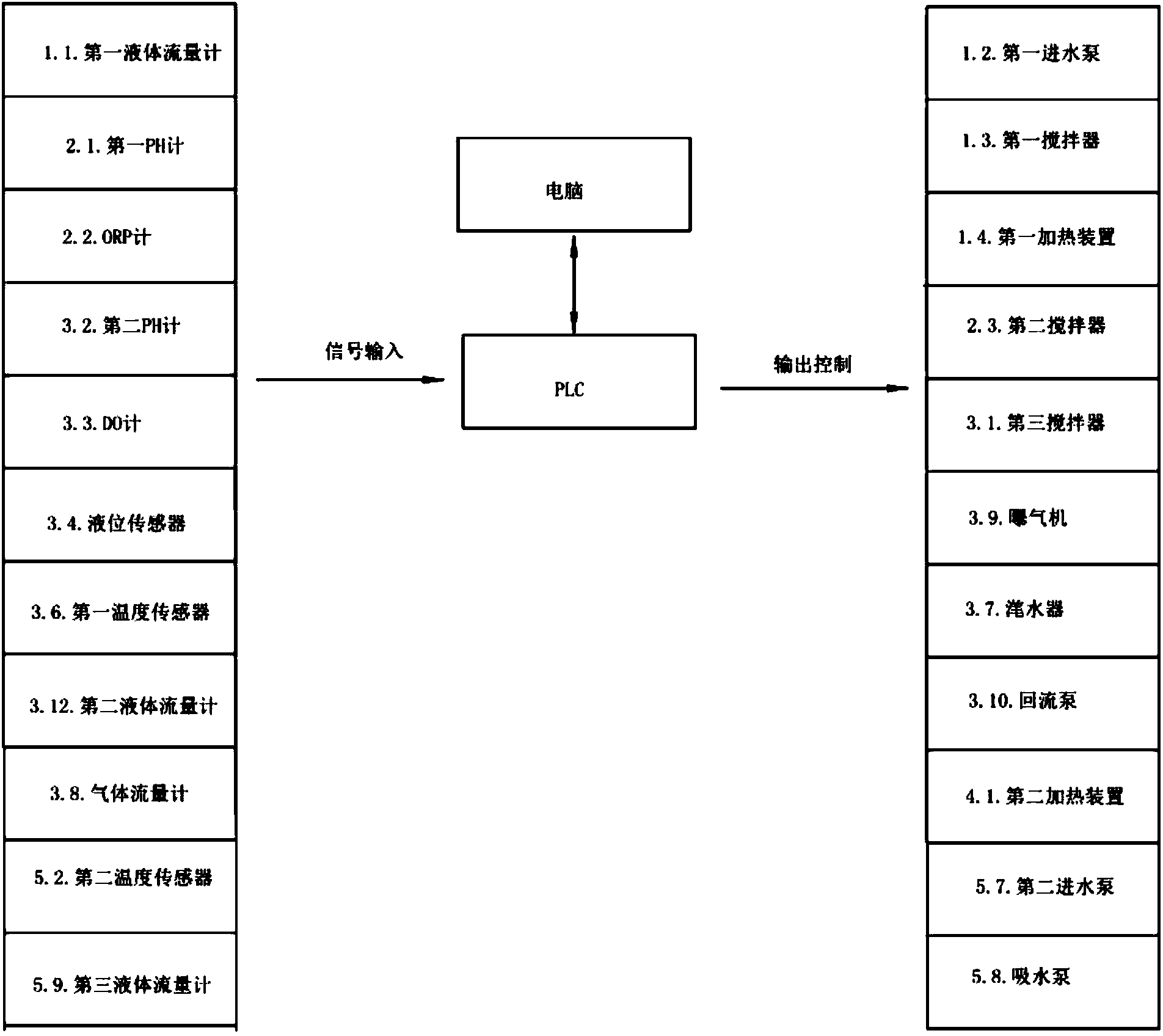

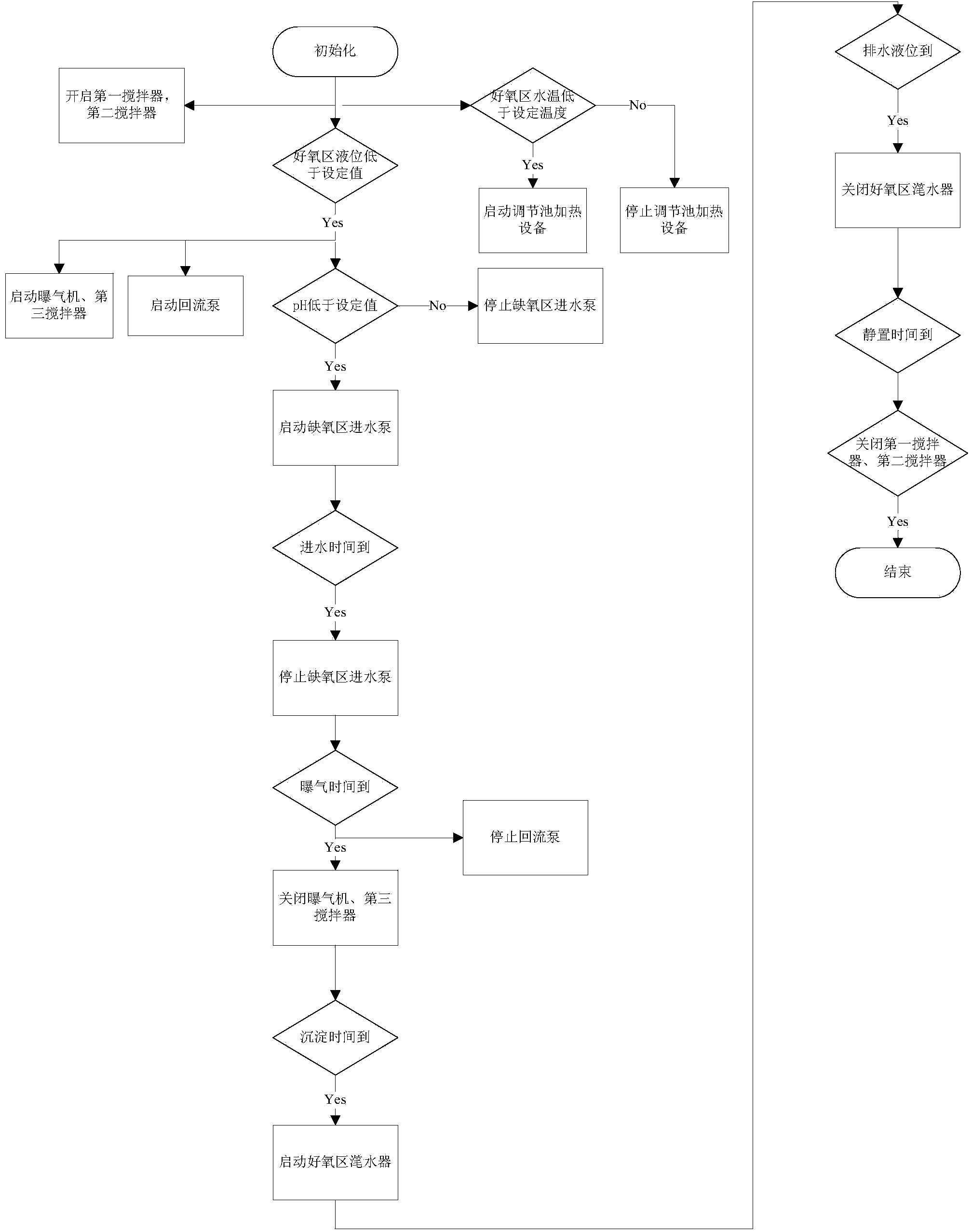

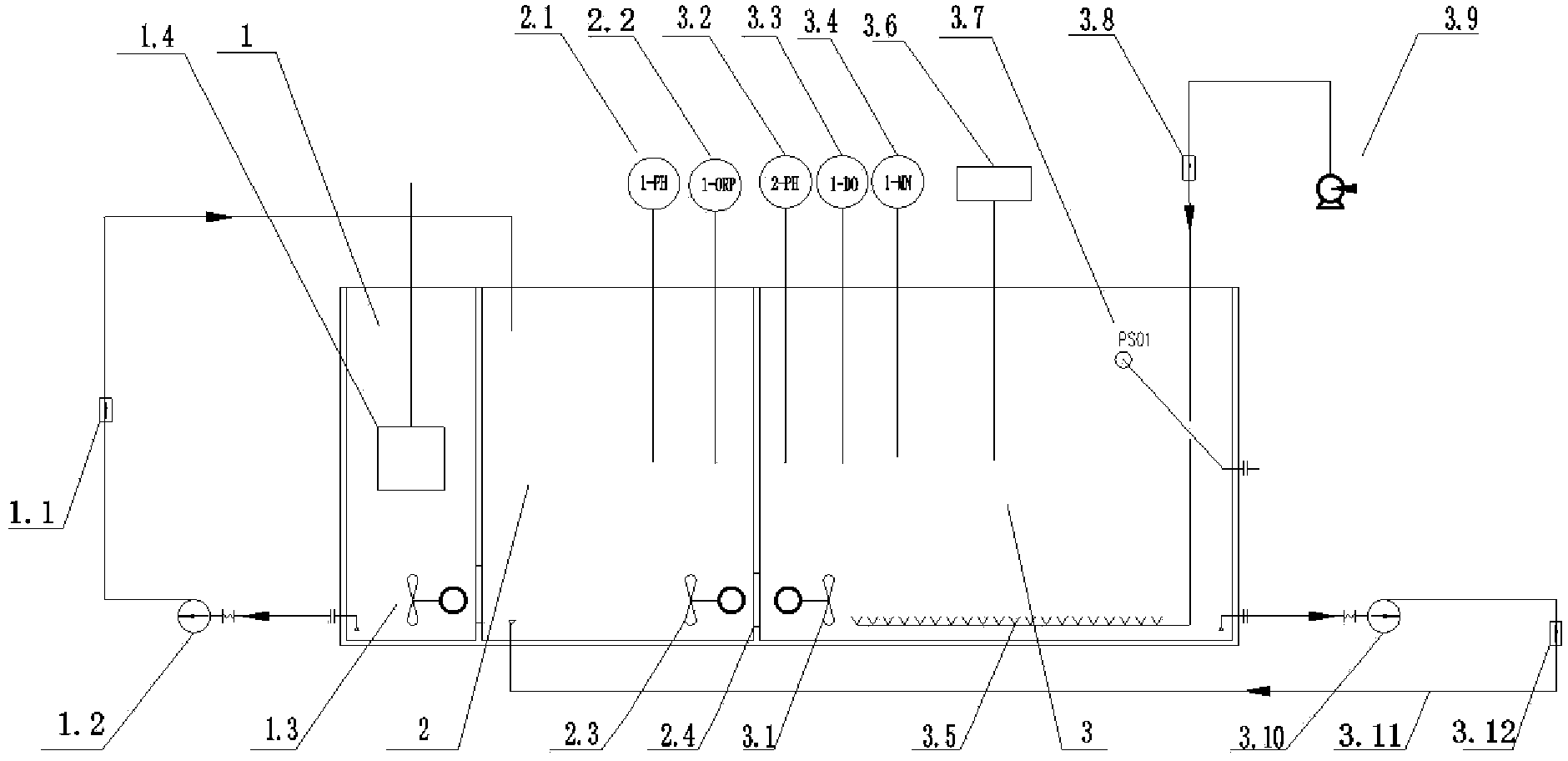

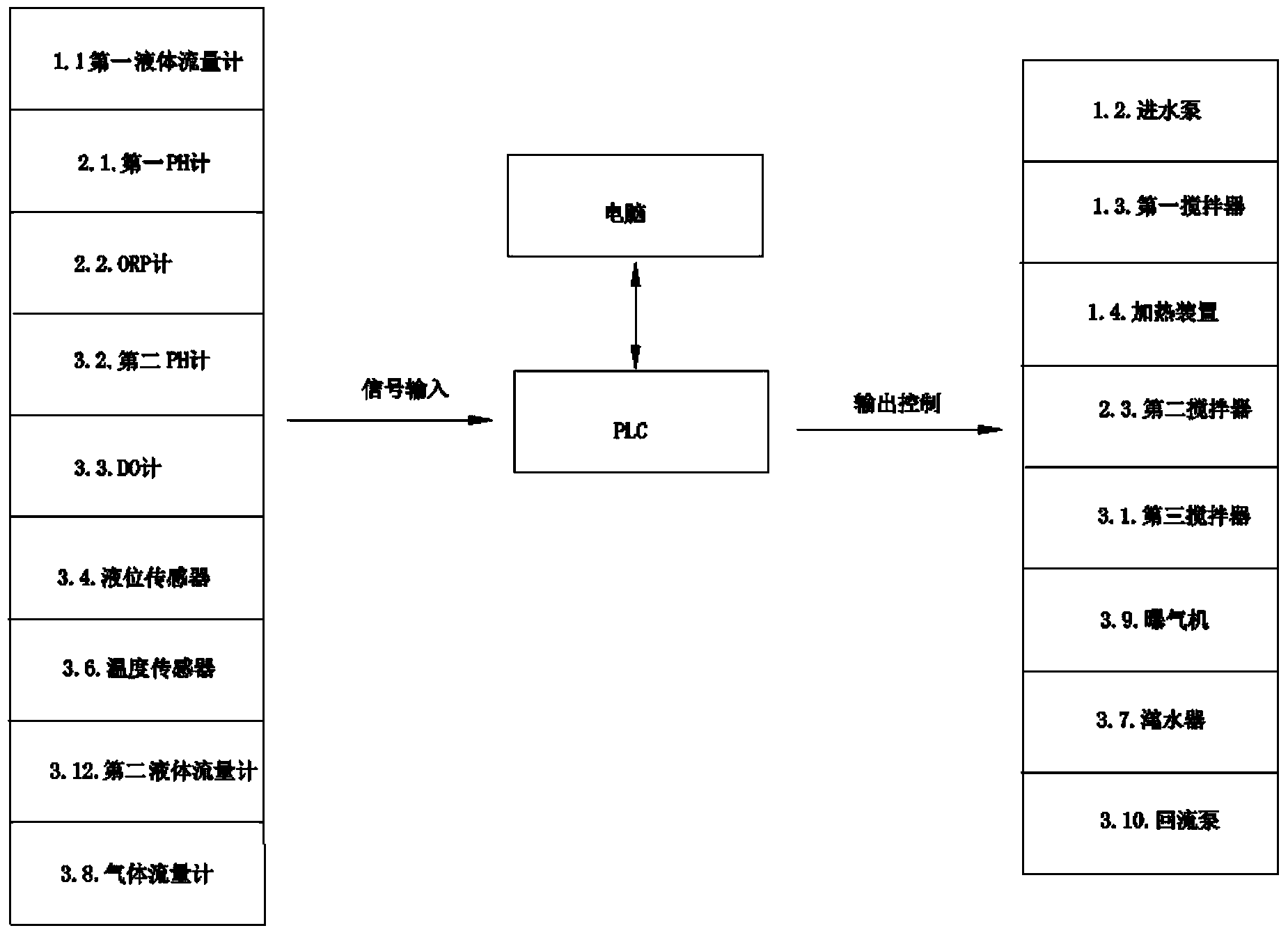

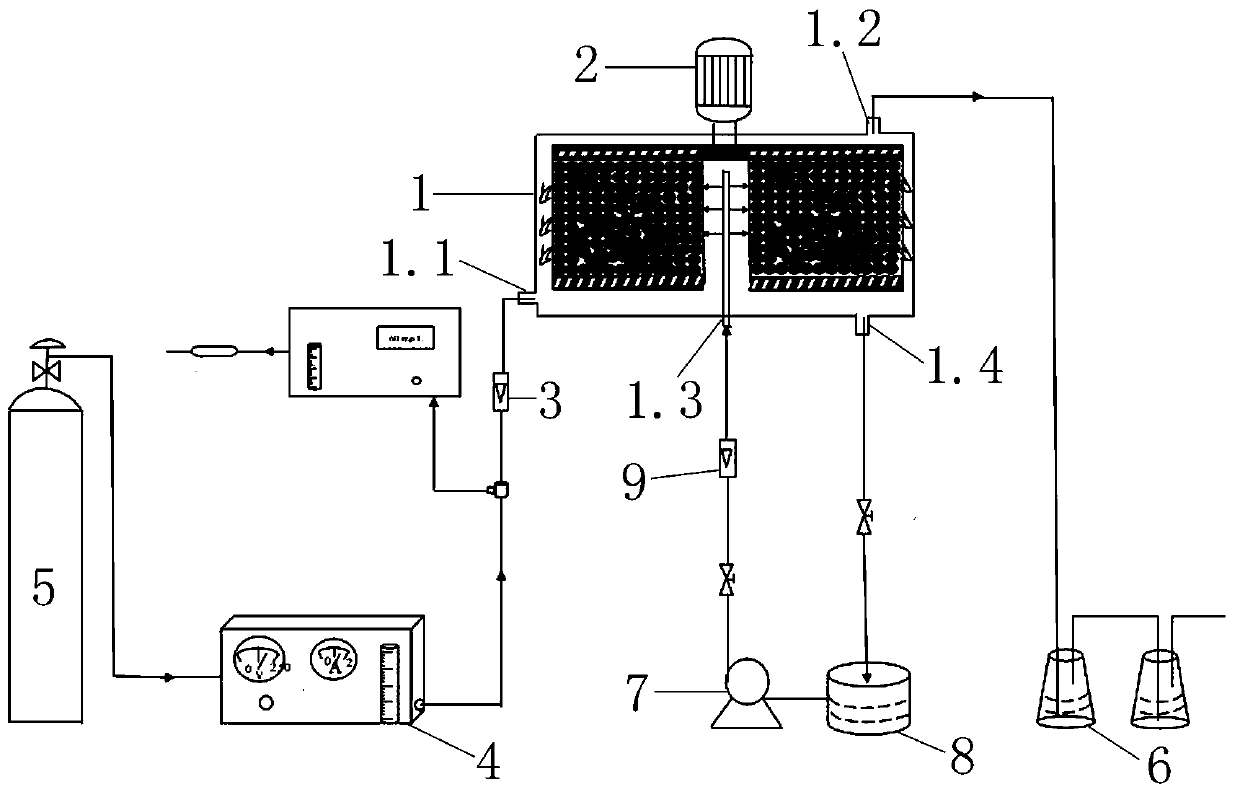

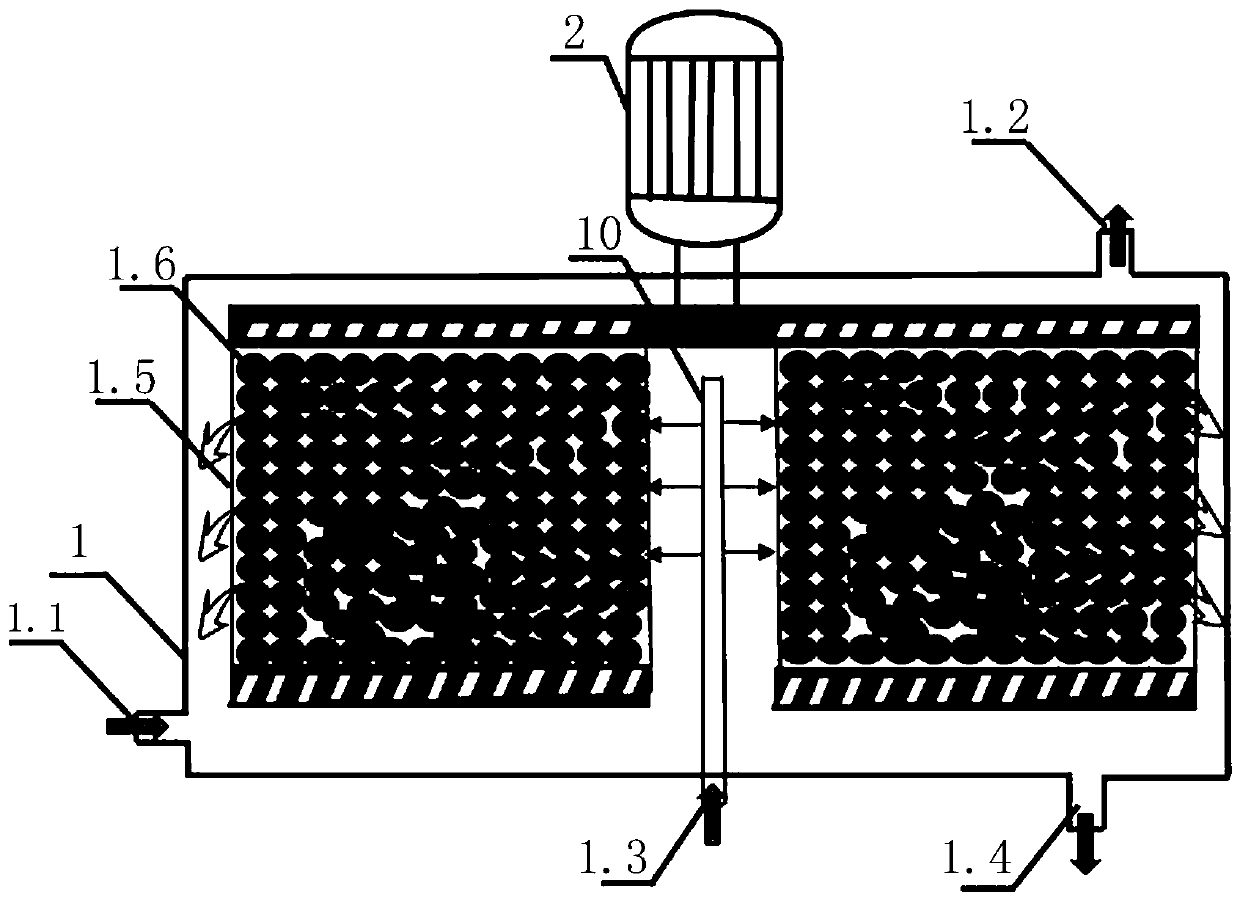

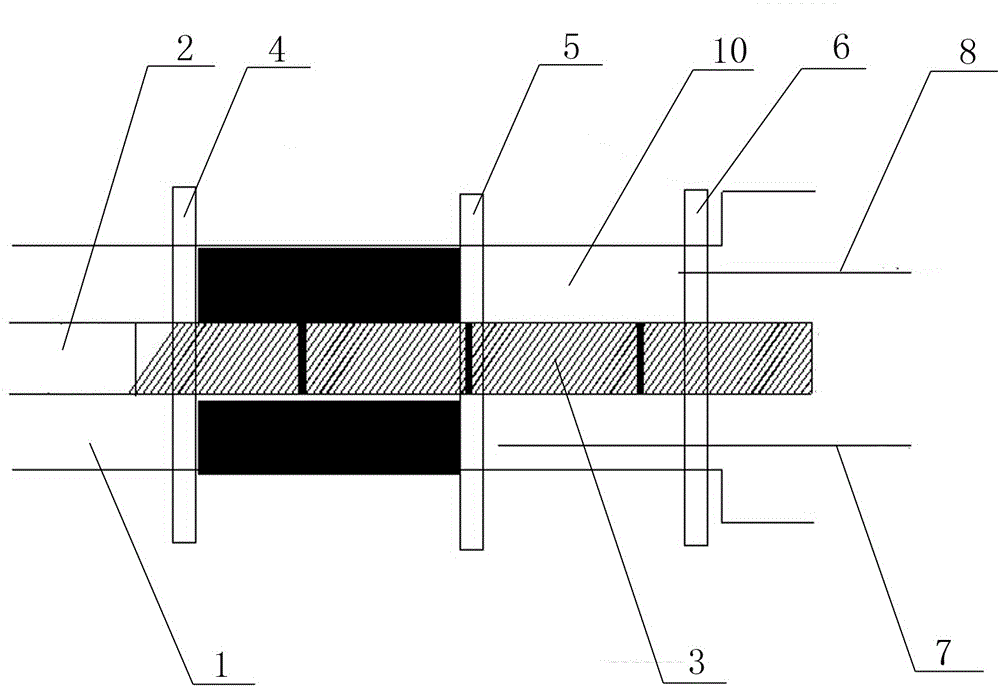

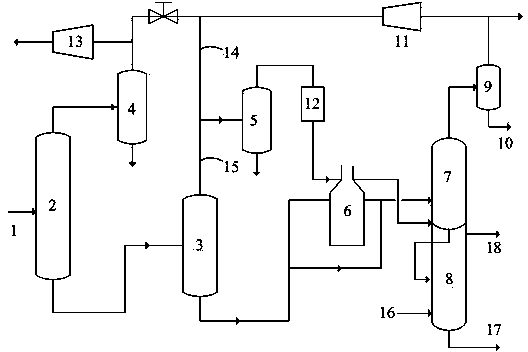

Wastewater treatment device and wastewater treatment method for realizing deep wastewater denitrification based on sequencing batch type A/O (Anoxic/Oxic) linkage system

InactiveCN104108841AEfficient retentionSimplify process operationMultistage water/sewage treatmentMoving bed biofilm reactorAmmonia

The invention relates to a wastewater treatment device and in particular relates to a wastewater treatment device and a wastewater treatment method for realizing deep wastewater denitrification based on a sequencing batch type A / O (Anoxic / Oxic) linkage system. The device comprises a regulating reservoir, an SBR (Styrene Butadiene Rubber) reaction tank, an intermediate reservoir and a membrane bio-reactor (MBR) / moving bed biofilm reactor (MBBR) reaction tank, wherein the SBR reaction tank comprises an SBR reaction tank anoxic zone and an SBR reaction tank aerobic zone. The method for treating wastewater by using the device comprises the following steps: starting the SBR reaction tank linkage water inlet to carry out a nitrosation reaction; starting the MBR / MBBR reaction tank to carry out an anaerobic ammonia oxidation reaction. The device and the method have the advantages that the ammonia nitrogen loading resistance is high, the nitrosation reaction and anaerobic ammonia oxidation reaction can be rapidly realized and stabilized, the process cost is saved and the like.

Owner:吕慧 +1

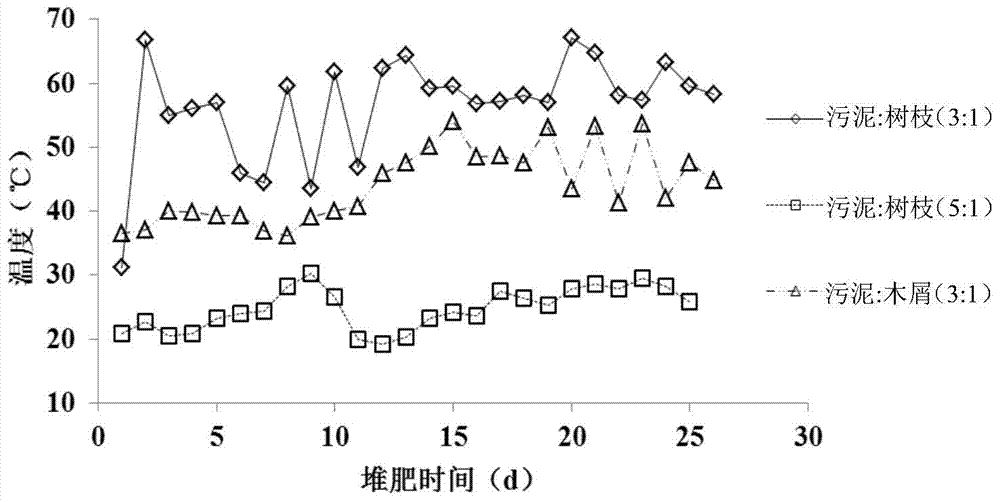

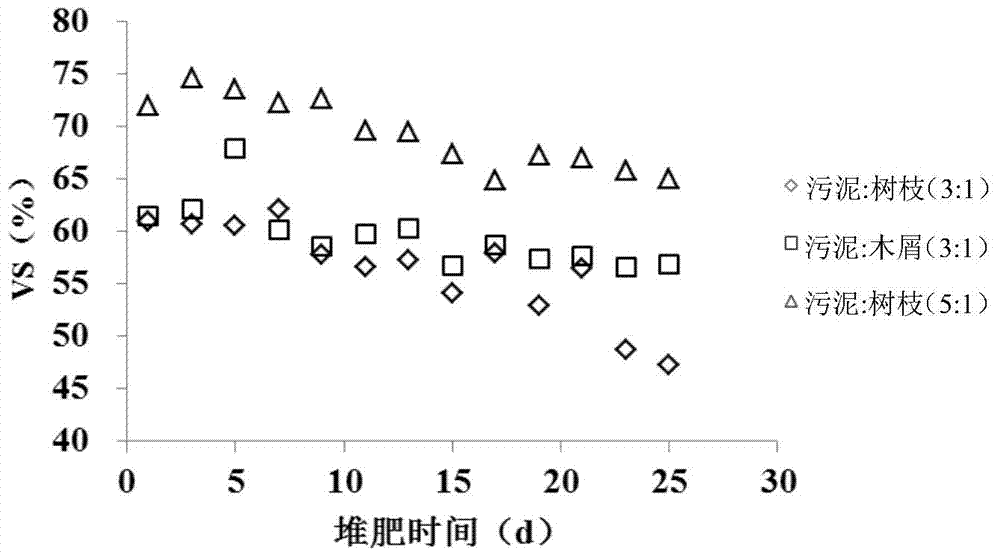

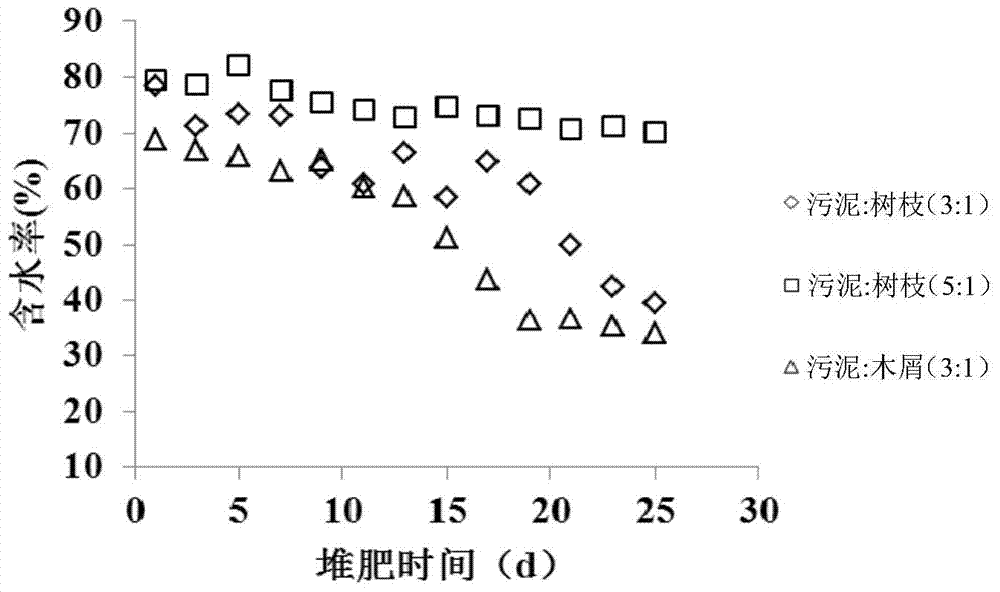

Sludge aerobic composting method

InactiveCN103613418ALower requirementLarge amount of processingBio-organic fraction processingOrganic fertiliser preparationMass ratioSludge

The invention discloses a sludge aerobic composting method. The method disclosed by the invention is a method for carrying out sludge aerobic composting by taking afforest wastes (such as branch sections) as a conditioner, and comprises the following steps: (1) mixing sludge and the afforest wastes according to a mass ratio of (2-4):1, specially 3:1, so as to obtain a mixture; and (2) composting the mixture obtained in the step (1) and monitoring the temperature of a pile body in the composting process; in the composting process, turning for one time when the temperature of the pile body is more than 60 DEG C; finishing the composting after a plurality of times of turning and when the temperature of the pile body is reduced to be lower than 30 DEG C and is not raised. According to the sludge aerobic composting method, the high-temperature aerobic composting of organic wastes is used as the basis and the afforest wastes are used as the conditioner to treat the municipal sludge so as to consume a large amount of the afforest wastes while the harmlessness and the reclamation of the sludge are realized, so that the two aims can be realized by one action. Visibly, the sludge aerobic composting method has a wide application prospect.

Owner:TSINGHUA UNIV

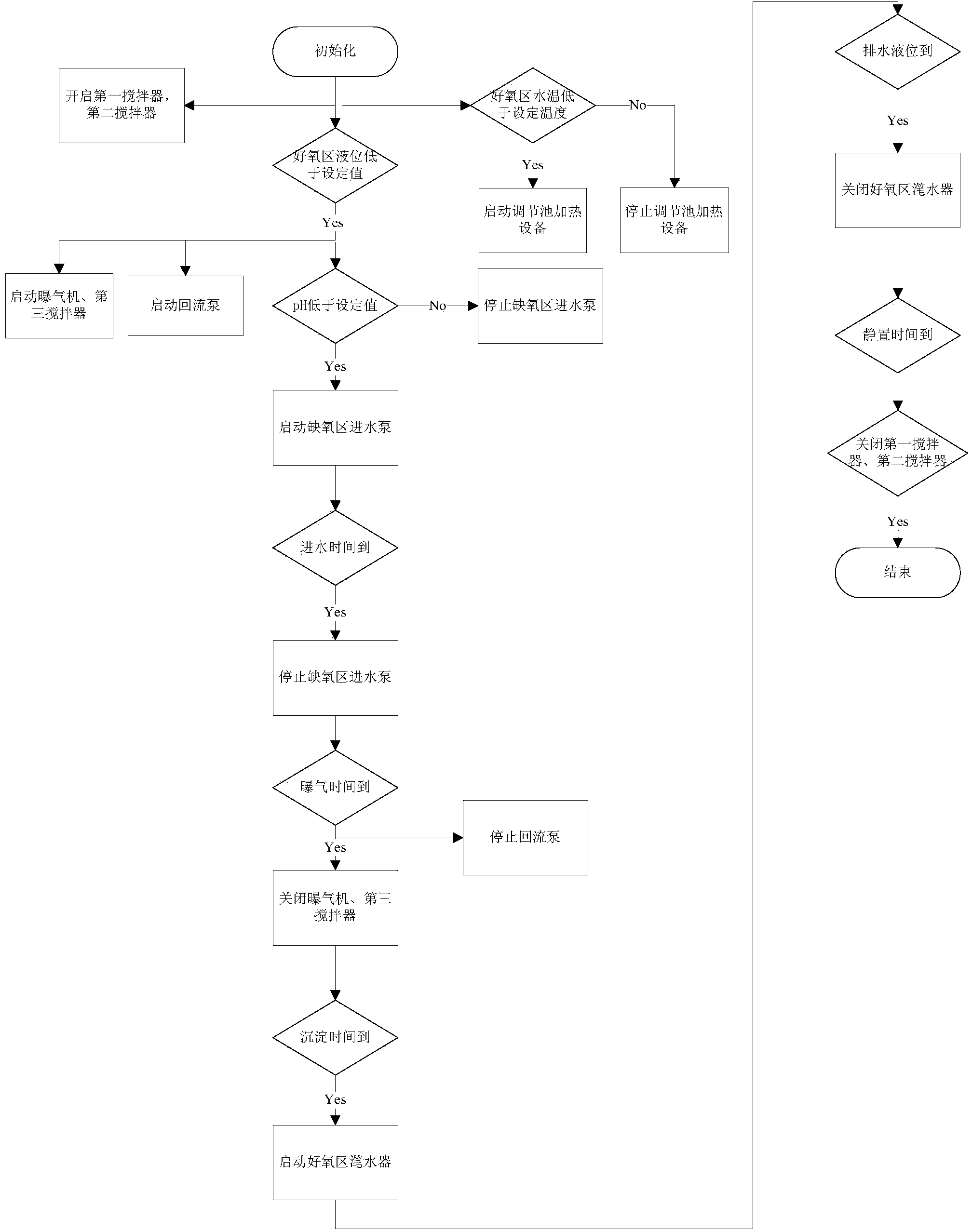

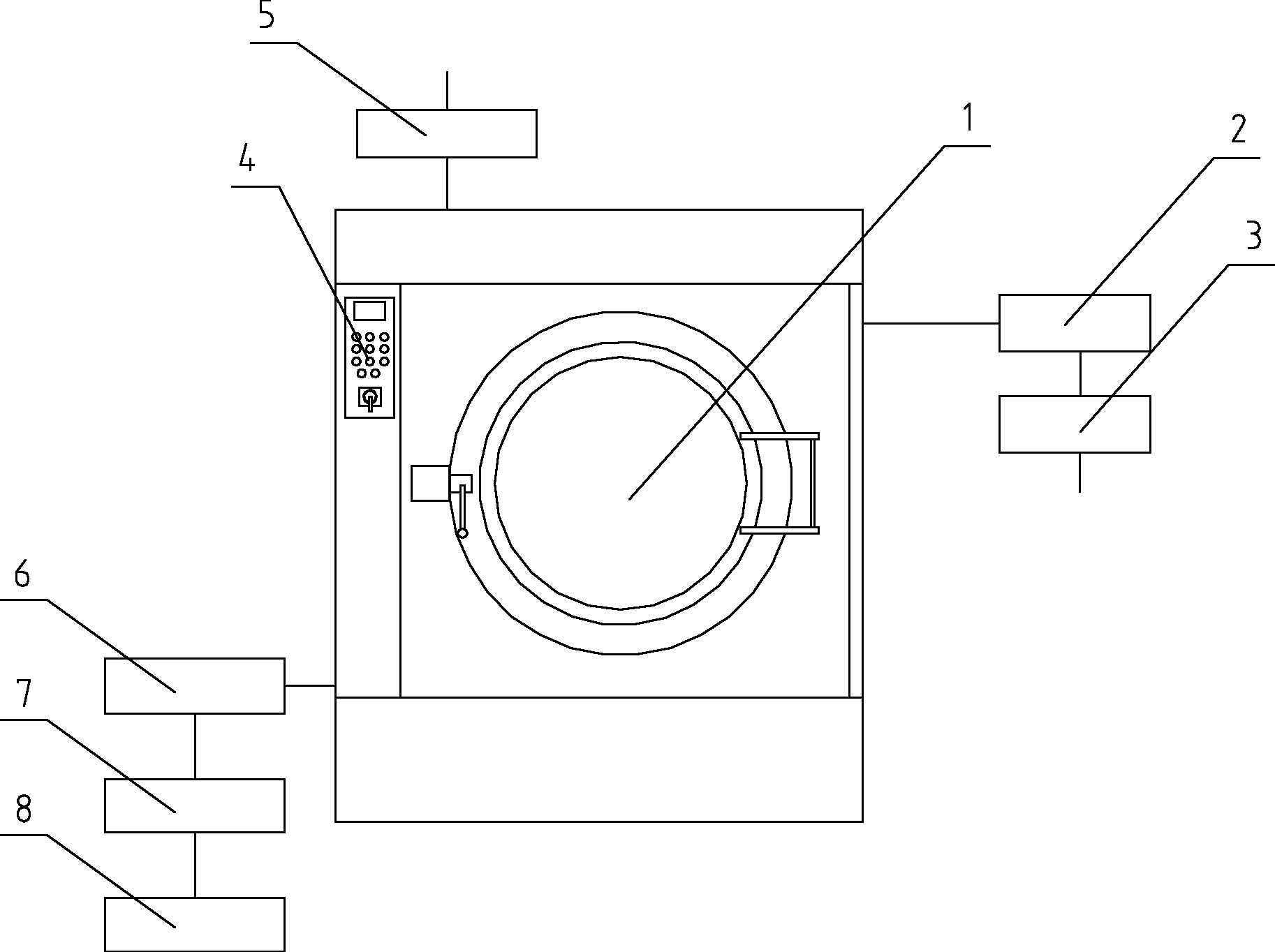

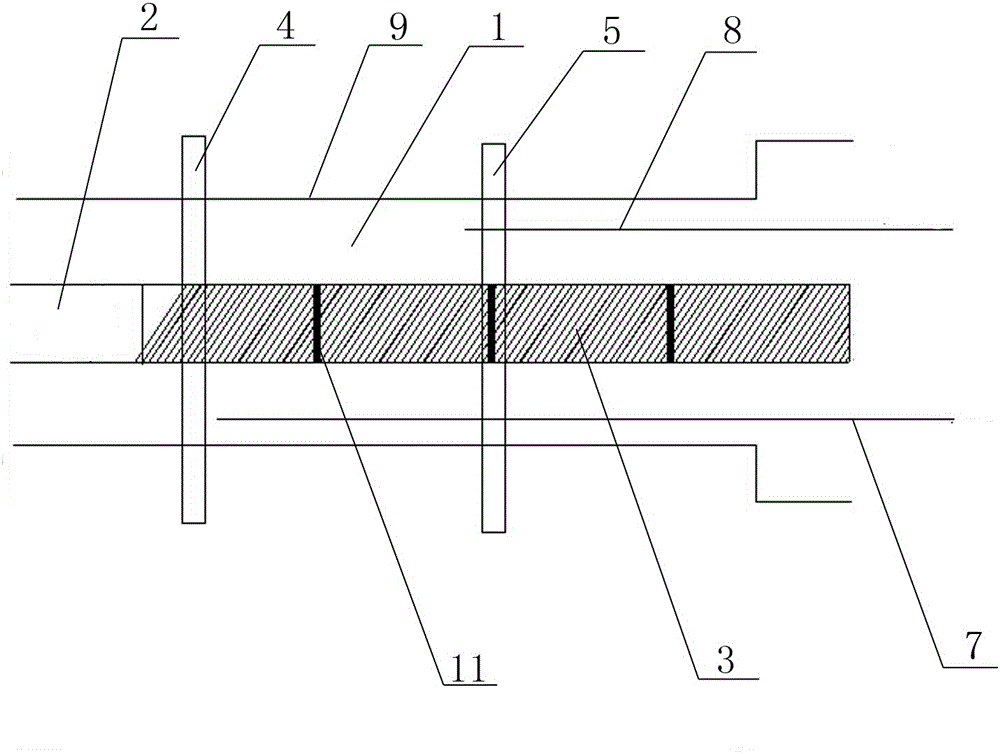

Wastewater treatment device and method of sequencing batch A/O (Anaerobic/Oxic) linked system for realizing partial nitrification of wastewater

InactiveCN104108794ASimplify process operationStrong resistance to ammonia nitrogen load impactTreatment with aerobic and anaerobic processesSequencing batch reactorBackflow

The invention particularly relates to a wastewater treatment device and method of a sequencing batch A / O (Anaerobic / Oxic) linked system for realizing partial nitrification of wastewater. The device is provided with an adjusting pool and an SBR (Sequencing Batch Reactor) reaction pool, wherein the SBR reaction pool is divided in an anaerobic region and an oxic region. The method for treating wastewater by using the wastewater treatment device specifically comprises the following steps that (1) wastewater enters into the adjusting pool; (2) wastewater in the adjusting pool is pumped into the anaerobic region of the SBR reaction pool through a water inlet pump for denitrification; and (3) a water flow in the anaerobic region of the SBR reaction pool overflows to the oxic region of the SBR reaction pool for linked water inlet; the oxic region of the SBR reaction pool adopts an operating mode of SBR for partial nitrification; in the water inlet stage of the oxic region of the SBR reaction pool, muddy water is simultaneously returned to the anaerobic region, backflow is stopped after water inflow in the oxic region is stopped, and effluent in the anaerobic region is overflowed to the oxic region, and the whole process is circulated like this. The carbon source in wastewater is fully used to denitrify in the anaerobic region of the SBR reaction pool.

Owner:吕慧 +1

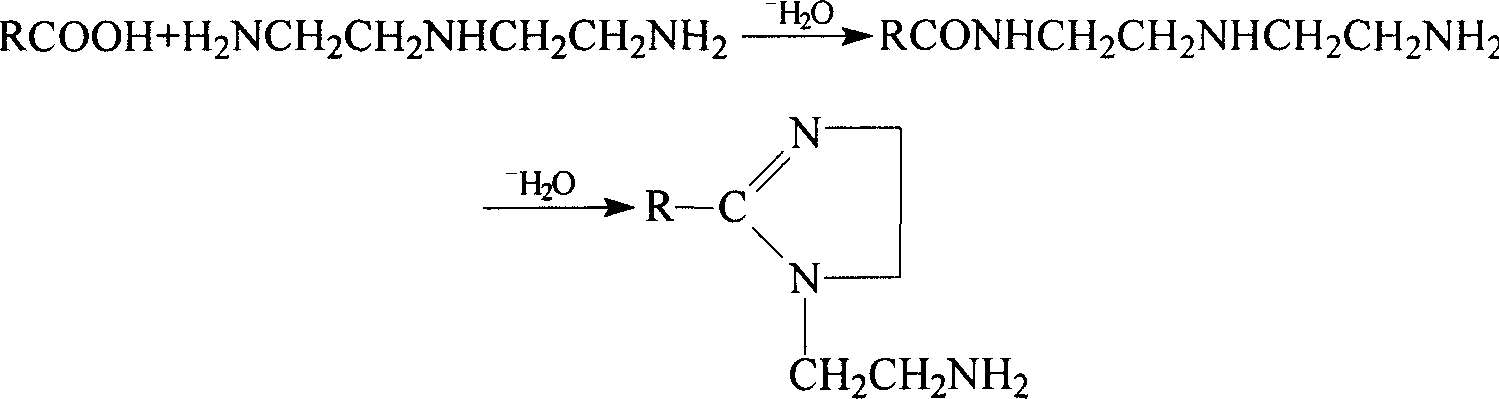

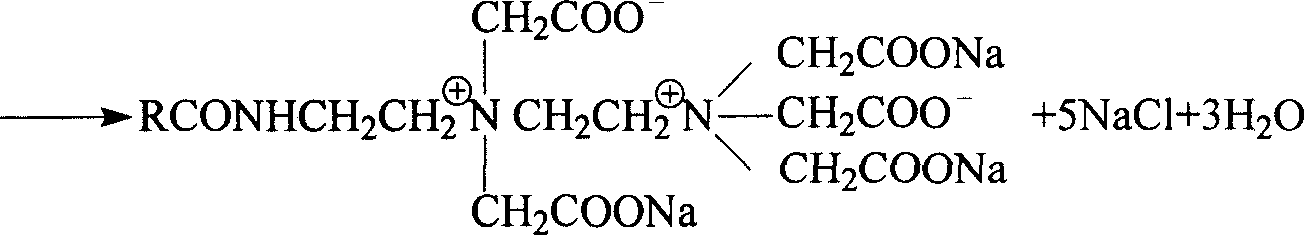

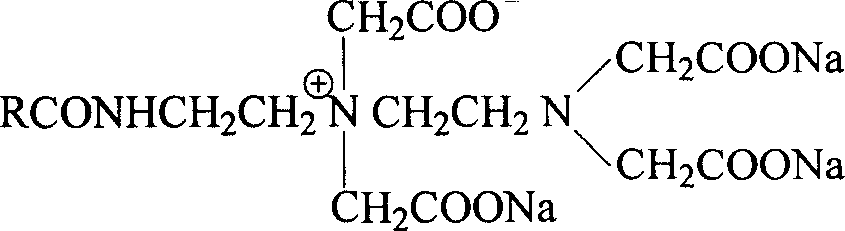

Process for preparing cycloalkanoimide betaine and use thereof

InactiveCN1884256AGood corrosion inhibitionImprove adsorption capacityDistillation corrosion inhibitionOrganic compound preparationBetaineWater soluble

The invention relates to a method for preparing naphthenic acid amide beet alkali and its application. Naphthenic acid amide or naphthenic acid imidazoline or mixture of them reacts with sodium monochloracetate, the molar proportion between naphthene base in naphthenic acid amide or imidazoline and sodium monochloracetate is 1.0: 4.8- 7.0, temperature is at 50-95 Deg. C, pH is about 10, and the reaction time is 8-18 hours. The product is used as water-soluble inhibitor for HCL-H2S-H2O system. The invention is characterized by low cost and simple process. The inhibiting property of said product is sound and compatibility with organic amine is good.

Owner:HUNAN UNIV OF SCI & TECH

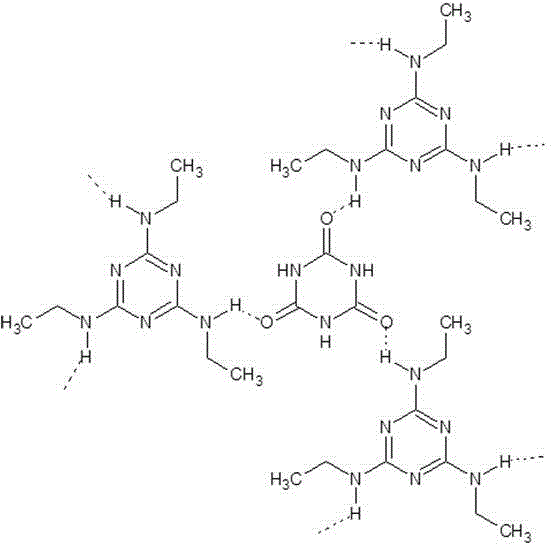

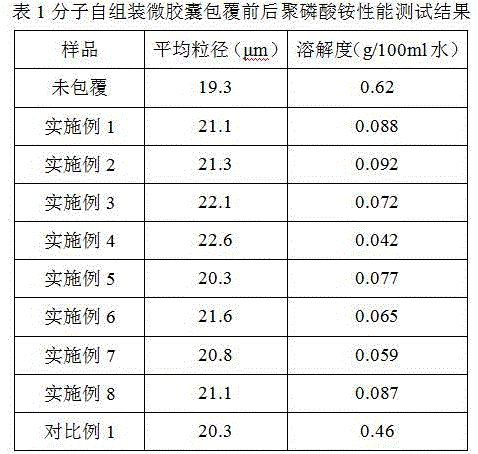

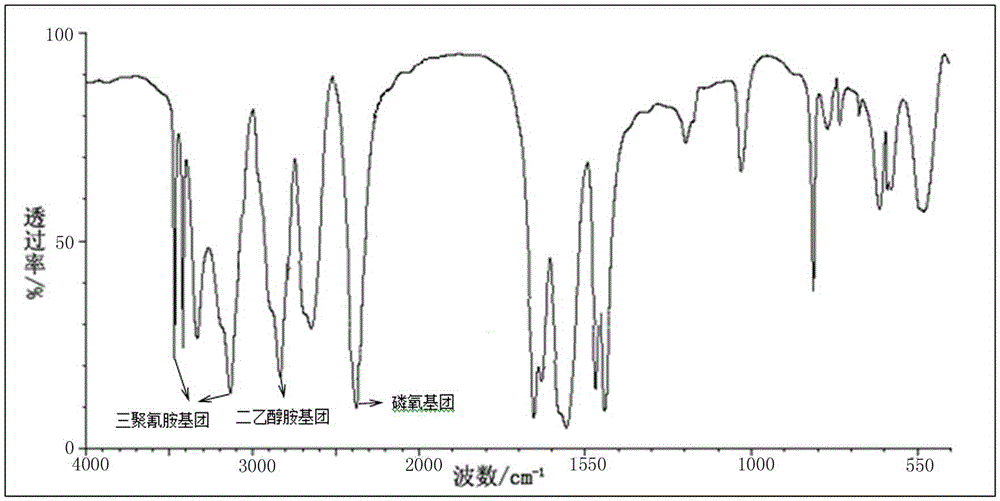

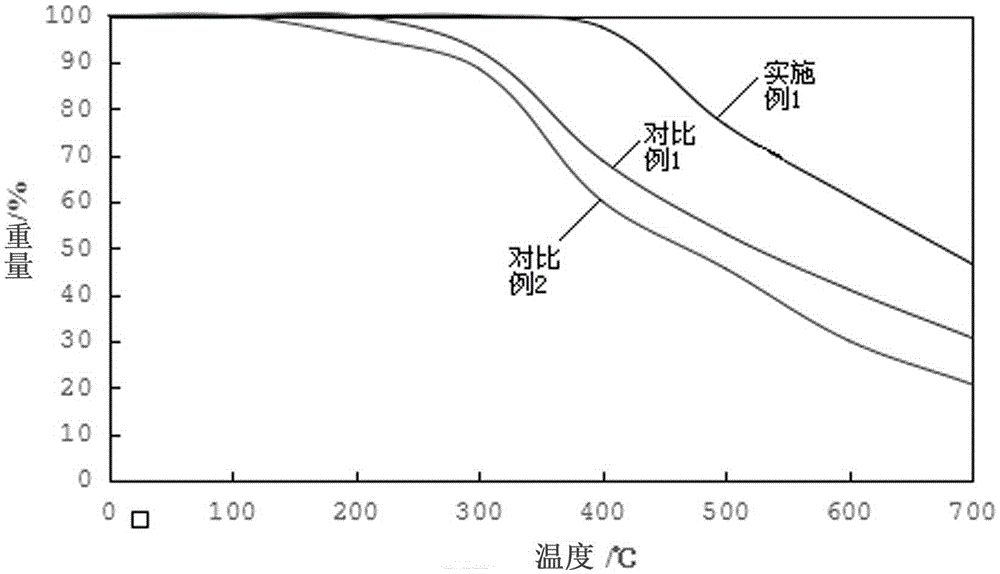

Method for preparing microcapsule-coated ammonium polyphosphate through in-situ polymerization molecular self-assembly

ActiveCN105566684ARaw material safetyRaw materials are easy to getIn situ polymerizationCyanuric acid

The invention discloses a method for preparing microcapsule-coated ammonium polyphosphate through in-situ polymerization molecular self-assembly. The method includes mixing formalin with melamine, increasing the temperature for condensation reaction after adjusting pH value of the mixture to 8-9, lowering the temperature after reaction, adding water and ammonium polyphosphate, stirring the mixture for 1-2 hours, adding cyanuric acid, increasing the temperature for in-situ polymerization reaction, coating the ammonium polyphosphate with a microcapsule, and performing filtering and drying after reaction to obtain the microcapsule-coated ammonium polyphosphate. The method has the advantages that the technological operation process is simple, ammonium polyphosphate coating rate is high, water solubility of the ammonium polyphosphate is reduced greatly, high dispersity and compatibility of the ammonium polyphosphate and polymer materials are achieved after coating, and flame retarding effect is remarkable; moreover, adhesion of the ammonium polyphosphate and resin to the inner wall of a reaction kettle is avoided during reaction, the reaction kettle is easy to clean, raw material utilization rate is increased and heat transfer efficiency of the reaction kettle is improved.

Owner:山东青科华创化工科技有限公司

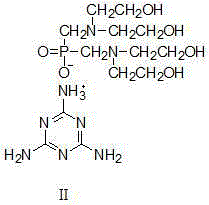

Triazine charring agent, preparation method therefor and application thereof

ActiveCN105418675AMild reaction conditionsSimplify process operationGroup 5/15 element organic compoundsBulk chemical productionPolymer scienceMannich reaction

The present invention discloses a triazine charring agent, a preparation method therefor and application thereof. The preparation method comprises the following steps: performing an Mannich reaction on hypophosphorous acid, diethanol amine, and formaldehyde catalyzed by hydrochloric acid in an aqueous phase; after the reaction, adding melamine to the reaction solution to react sequentially; and obtaining the triazine charring agent with the following structural formula. The present invention also provides application of the charring agent as a raw material of a flame retardant, as well as a preparation method of the flame retardant. According to the method disclosed by the present invention, reaction conditions are mild, a process flow of operations is simple, a reaction period is short, and post treatment is simple. The resulting charring agent has good expansibility, high thermal stability, a large amount of carbon residue, a good charring effect, and good compatibility with a polymer. The charring agent can be made into the flame retardant by mixing with ammonium polyphosphate, polypropylene, and the like, with excellent inflaming retarding performance and little influence on mechanical properties.

Owner:山东艾孚特科技有限公司

Method and device for degrading phenol wastewater by heterogeneous catalysis of ozone in high gravity field

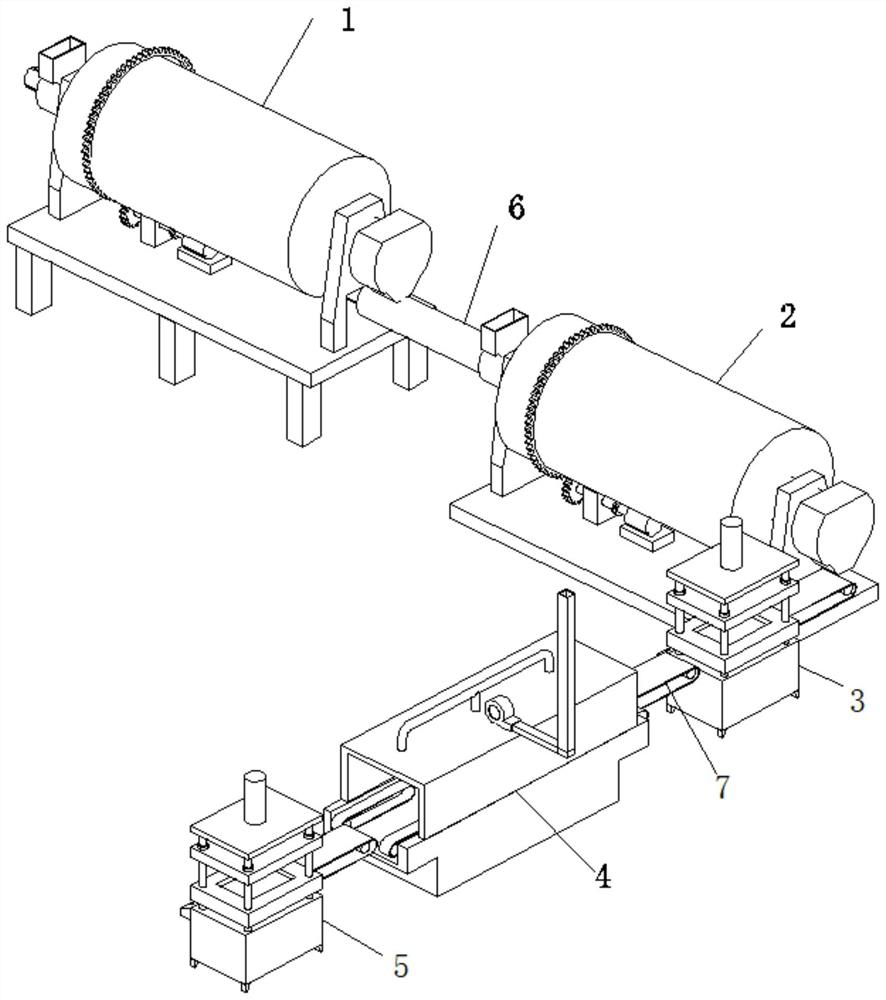

InactiveCN110436603ASolve the problem of reuse and recycling difficultiesIncrease mass transfer rateWater contaminantsWater/sewage treatment by oxidationPeristaltic pumpLiquid storage tank

The invention belongs to the technical field of phenol wastewater treatment, and provides a method and a device for degrading phenol wastewater by heterogeneous catalysis of ozone in a high gravity field in order to solve the problems of loss of metal ions, difficulty in separation, easiness in causing secondary pollution to the environment and low ozone mass transfer efficiency in a method for degrading phenol wastewater by homogeneous catalysis of ozone. The method comprises the following steps: with a supergravity rotating packed bed as a reactor and a heterogeneous solid catalyst as a filler, adding phenol wastewater into a liquid storage tank in a semi-intermittent feeding manner; under the action of a peristaltic pump, uniformly spraying the phenol wastewater on the inner side of theheterogeneous catalyst filler, and enabling the phenol wastewater to move outwards along the radial direction of the filler layer under the action of supergravity, at this time, the phenol wastewateris in cross-flow contact with ozone gas entering in the axial direction, and the heterogeneous catalyst catalyzes ozone and decomposes the ozone to generate hydroxyl radicals, so that the phenol wastewater is degraded. The process realizes repeated utilization of the catalyst, improves the degradation capability of organic matters, reduces post-treatment procedures, reduces the industrial cost, and has a wide application prospect in the field of treatment of degradation-resistant organic wastewater.

Owner:ZHONGBEI UNIV

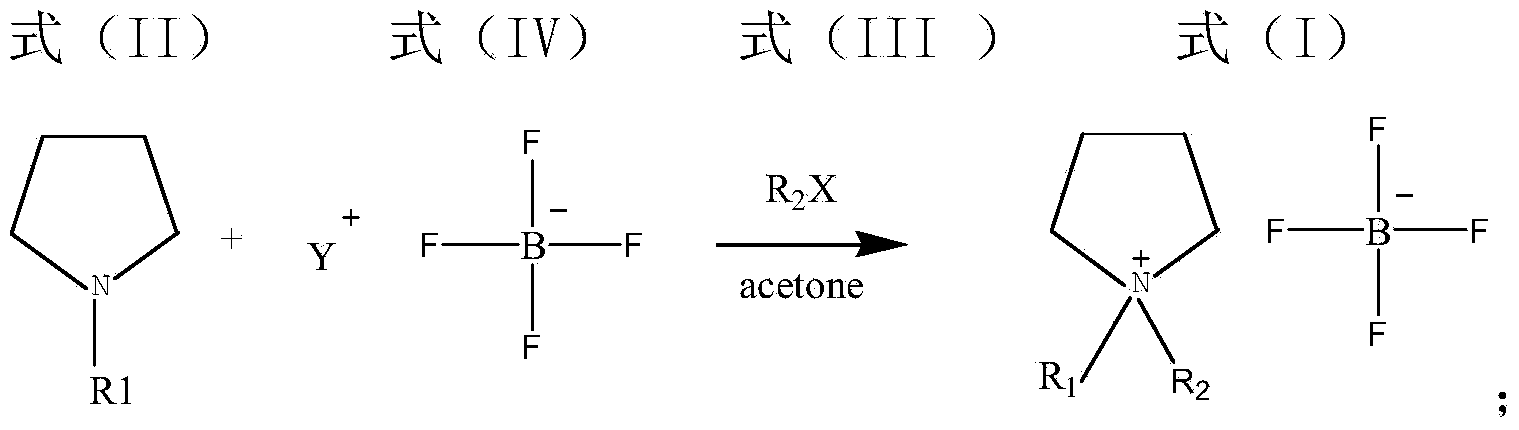

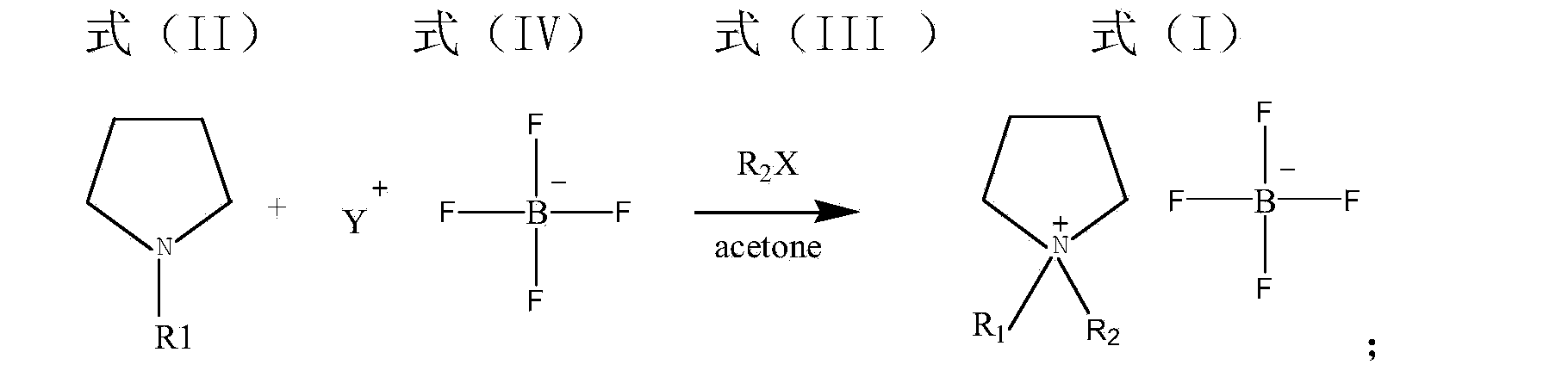

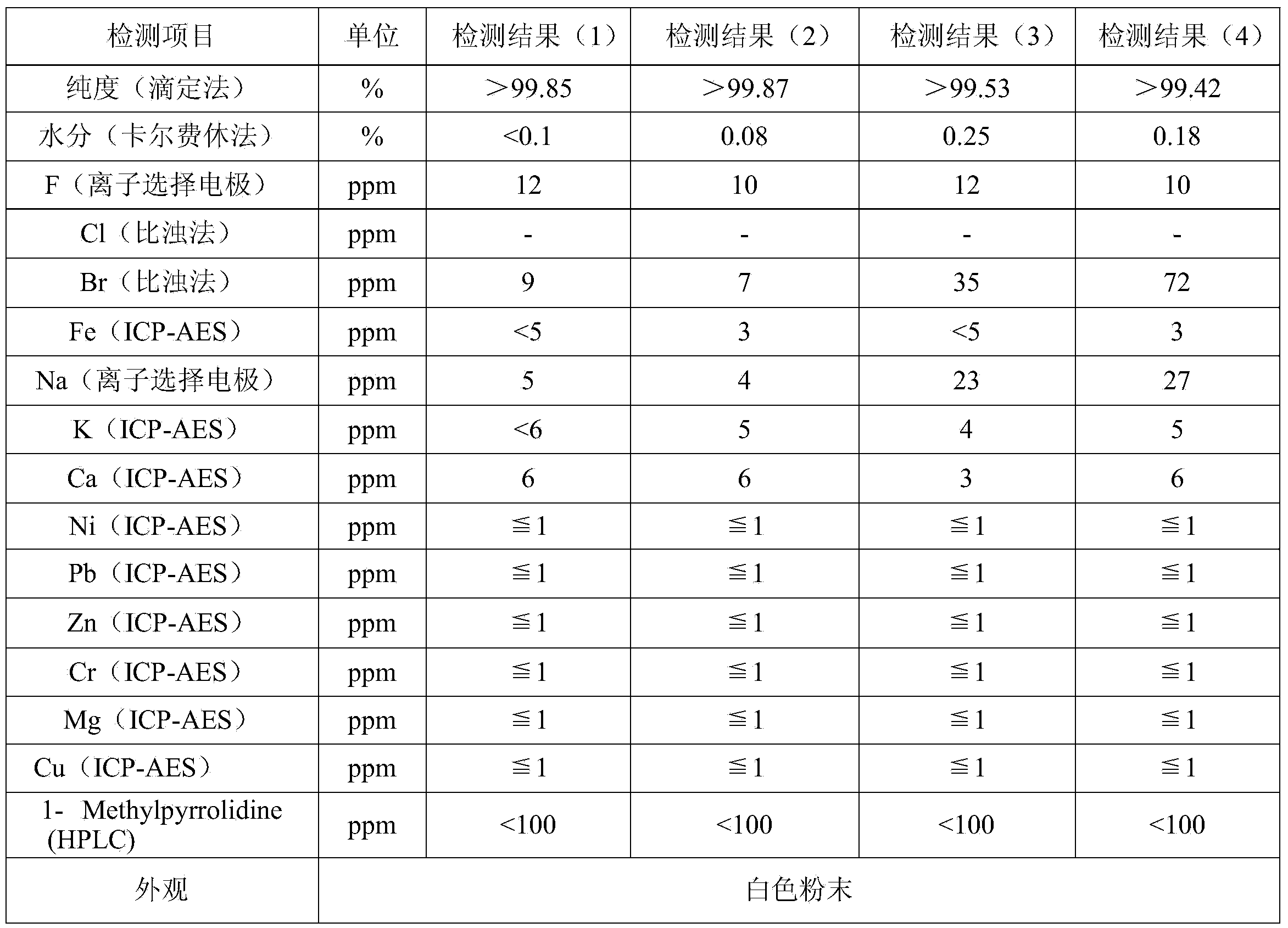

Preparation method and industrialized production method of pyrrolidinium with tetrafluoroborate anions

ActiveCN104262224ARaw materials are cheap and easy to getShort routeOrganic chemistryTetrafluoroborateDistillation

The invention provides a preparation method of pyrrolidinium with tetrafluoroborate anions, which comprises the following steps: (1) the one-step synthesis of a coarse product: by taking a non-proton organic solvent as a reaction medium, dropwise adding haloalkanes into a mixture consisting of N-alkyl pyrrolidine and tetrafluoroborate, reacting for obtaining a coarse product liquid, filtering the coarse product liquid by using a centrifuge, and carrying out reduced pressure distillation on filter liquor so as to obtain a coarse product solid; and (2) heating and stirring the coarse product solid so as to dissolve the coarse product solid into an alcohol organic solvent, and sequentially carrying out cooling crystallization, filtration, rinsing and vacuum drying on the obtained product, so that a refined finished product is obtained. The invention also discloses an industrialized production method of pyrrolidinium with tetrafluoroborate anions. The methods disclosed by the invention are implemented through one-step synthesis, cheap and easily-obtained in raw materials, short in synthetic route, mild in reaction conditions, short in reaction time, simple in operation, and relatively low in production cost; prepared products are high in product purity, good in crystal form and high in yield; and environmentally harmful substances are not produced in the production process, thereby facilitating industrialized continuous mass production.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

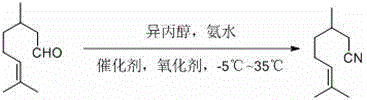

Production technology for preparing citronellyl nitrile from citronellal

ActiveCN104529822ASimplify process operationShorten the production cyclePreparation by hydrocarbon ammoxidationIodideSolvent

The invention relates to a production technology for preparing citronellyl nitrile from citronellal. The technology comprises the following steps: mixing citronellal with isopropanol in a same reaction kettle, controlling the reaction temperature in a range of -5-35DEG C, quickly adding a catalyst and 25% ammonia water, adding an oxidant in a dropwise manner under a controlled speed within 2-4h, neutralizing after the above reaction, carrying out solvent recovery, and purifying to obtain a citronitrile product with the yield of above 83%and the purity of above 97%, wherein the catalyst is chloride, iodide, nitrate or sulfate of copper, cobalt, silver or vanadium, and the oxidant is lead nitrate, manganese dioxide, hydrogen peroxide, ozone, oxygen or chromium trioxide. The technology for preparing citronellyl nitrile from citronellal adopts citronellal as a raw material and isopropanol as a solvent, utilizes a one-pot catalytic ammoxidation reaction technique and optimizes a ratio, so the technology provided by the invention has the advantages of simplified process operation flow, shortened production cycle, reduction of the labor intensity and the production cost, and environmental protection.

Owner:广州百花香料股份有限公司

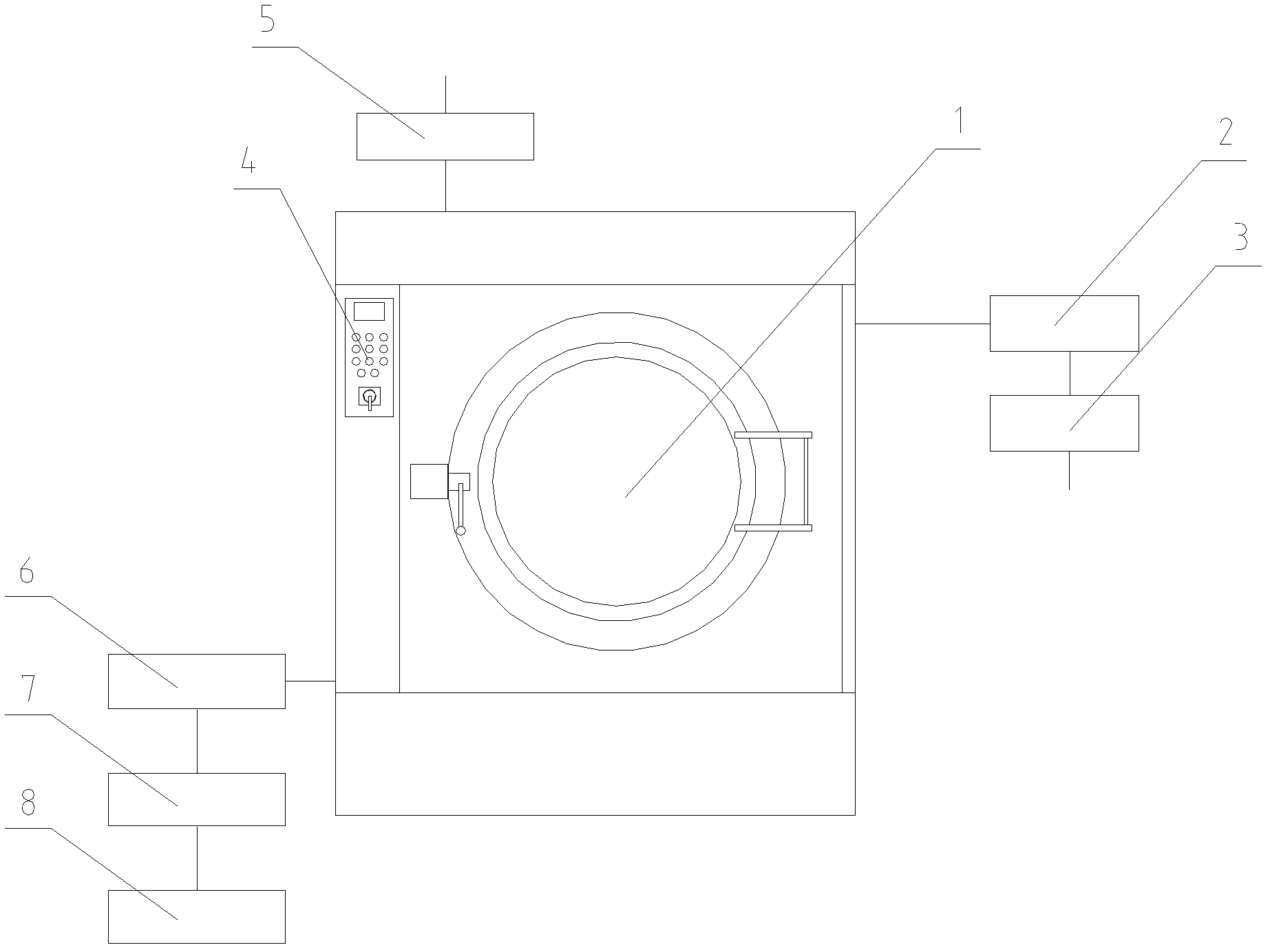

Method and device for cloth washing fading treatment by ozone gas

InactiveCN102587053ANo bleedingNo staining problemTextile treatment machine partsLiquid/gas/vapor textile treatmentWater savingAutomatic control

Disclosed are a method and a device for cloth washing fading treatment by ozone gas. The method for cloth washing fading treatment by ozone gas includes: without using water and any chemical agents, impregnating cloth into the gas environment with certain ozone concentration and keeping the same sufficiently contacting with the ozone gas for some time, finally completing fading by means of the principle of utilizing the ozone gas for clothes washing fading. The method for cloth washing fading treatment by ozone gas and the device realizing the same are environment-friendly, safe, water-saving, time-saving, lower in energy consumption and free of chemical agents and sewage treatment, fading effect is easy to control, and residual ozone gas can be replaced and reduced to meet the requirement of continuous production. The process is simple in operation procedures, convenient and fast, low in running cost and capable of realizing continuous production. In addition, by the aid of an ozone gas concentration monitoring device arranged additionally, concentration of the ozone gas and time can be controlled automatically according to different cloth and different fading requirements.

Owner:JIANGSU KONER OZONE

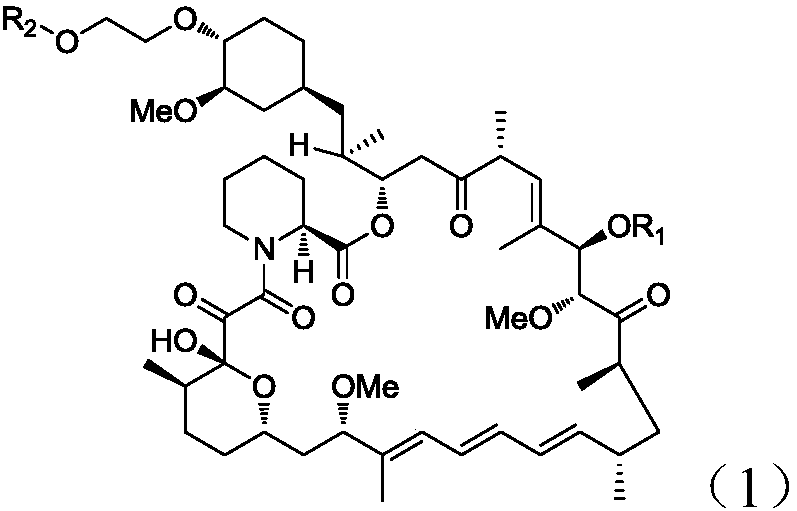

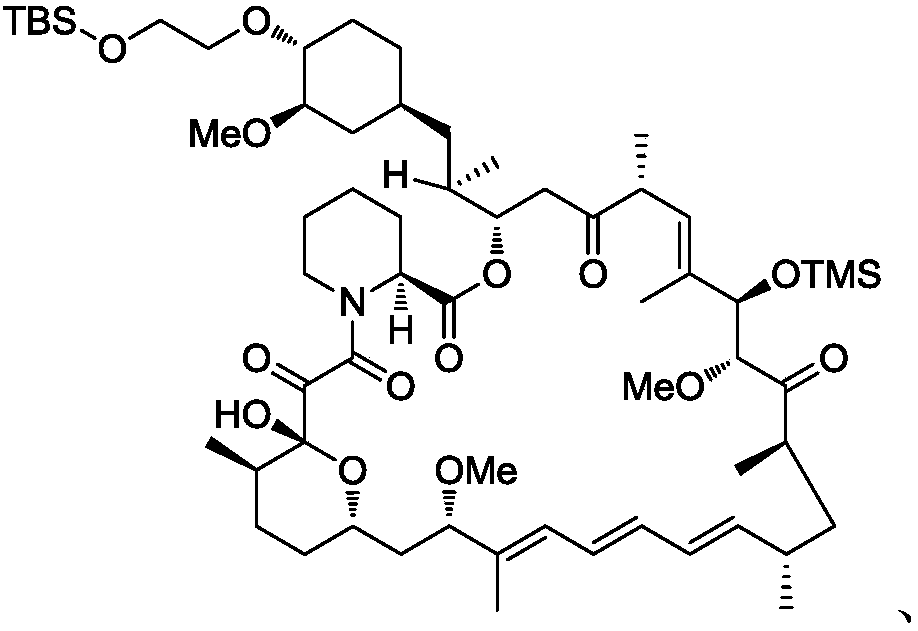

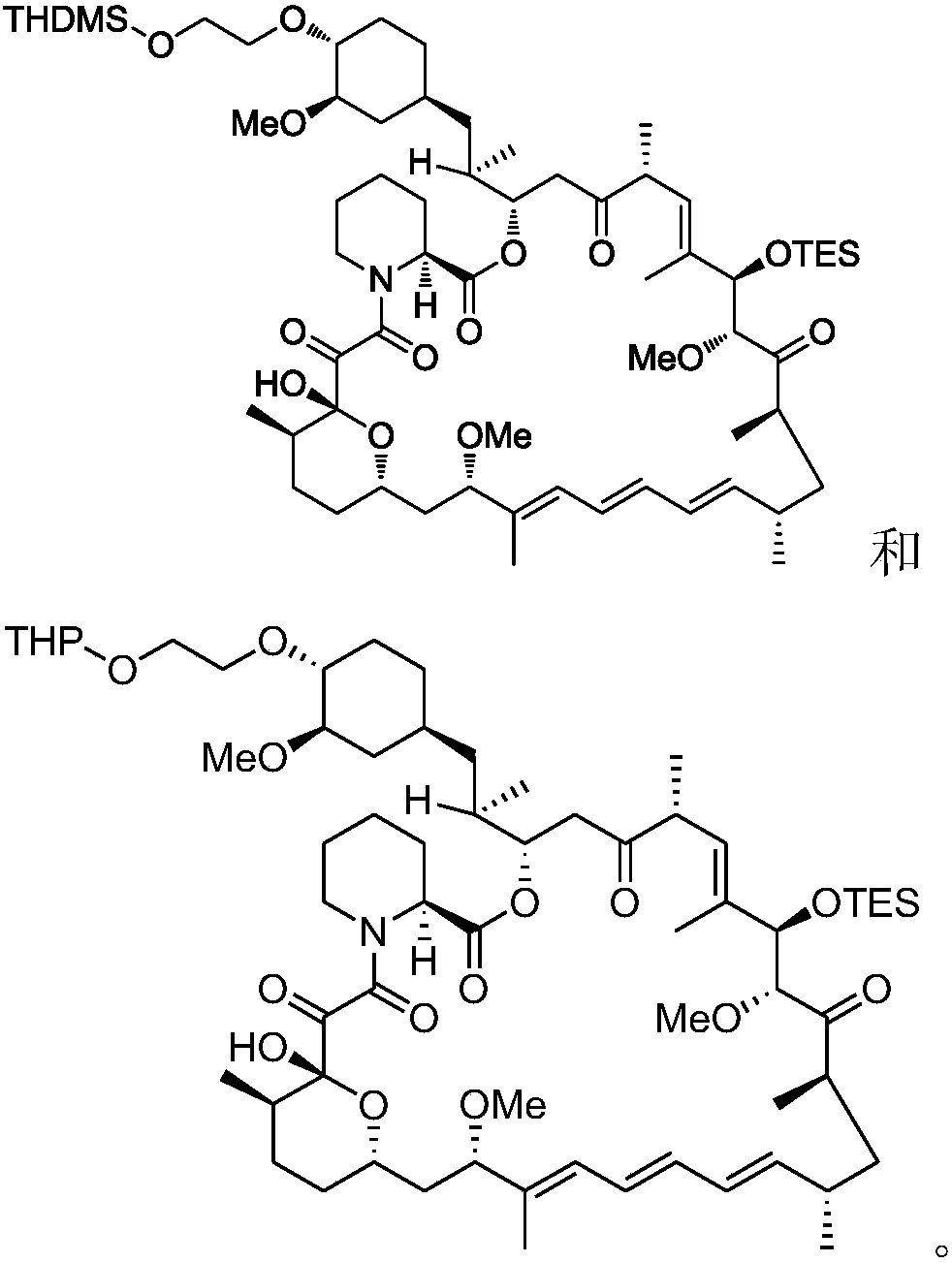

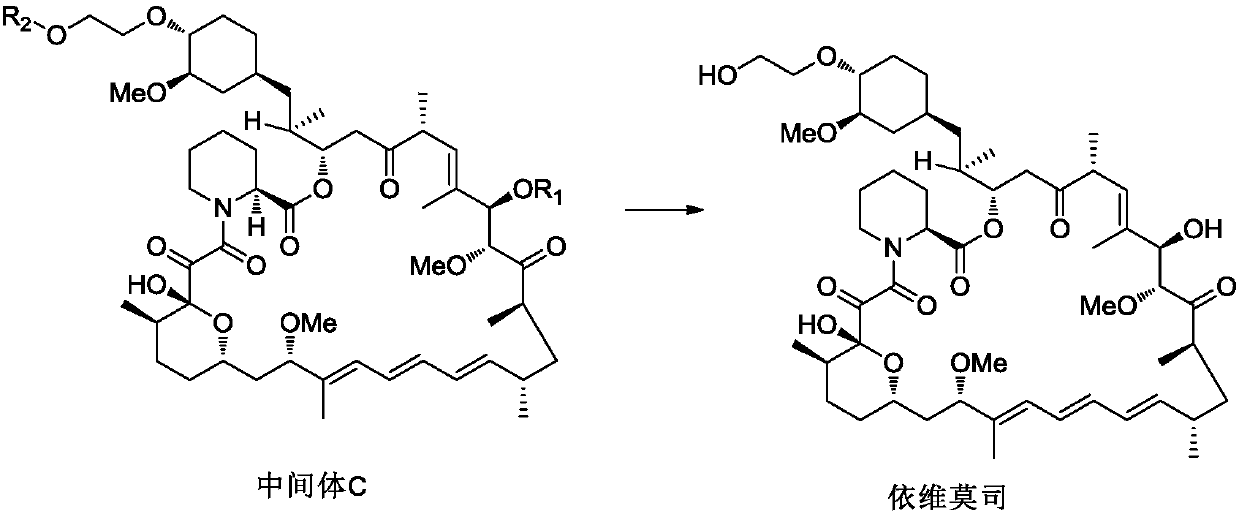

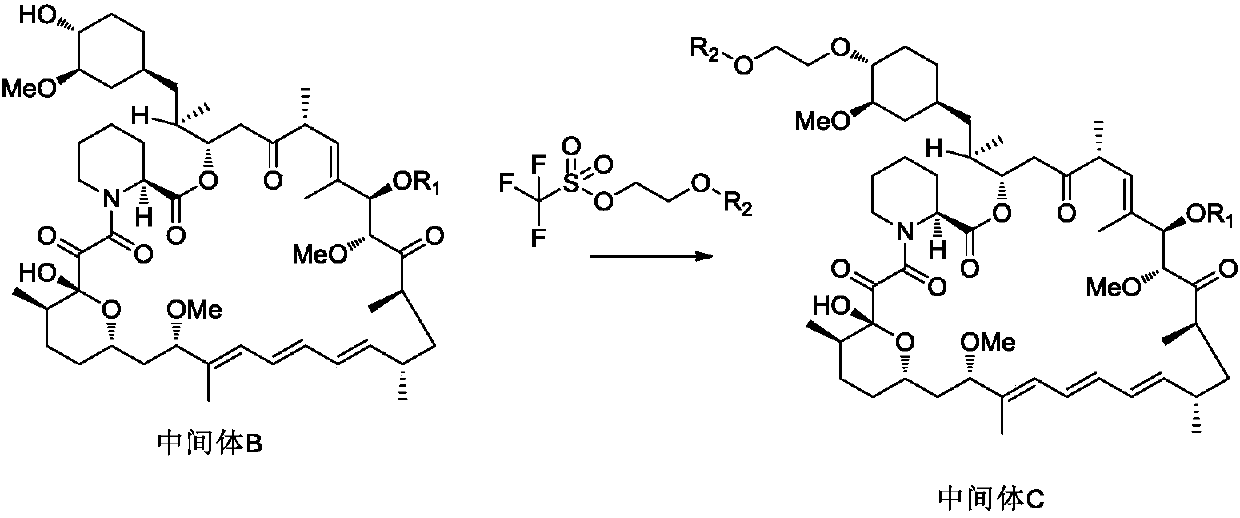

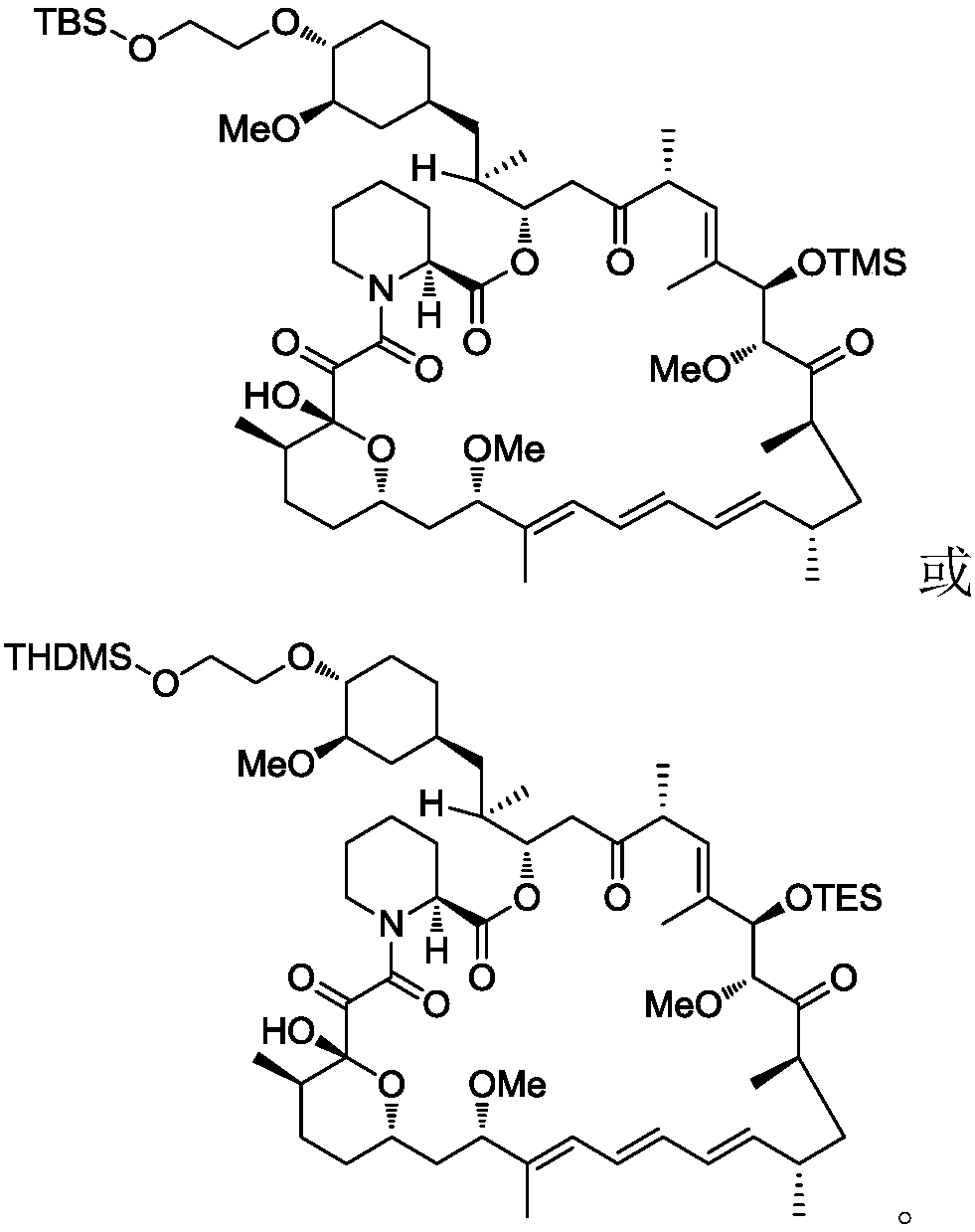

Everolimus intermediate, and preparation method and application thereof

InactiveCN109776570AEasy to prepareHigh yieldGroup 4/14 element organic compoundsComponent separationEverolimusOrganic base

The invention discloses an everolimus intermediate, and a preparation method and an application of the everolimus intermediate. A structure of the everolimus intermediate C is shown as formula (1) asshown in the specification. The preparation method comprises the following step: allowing 28-monosilicon protected rapamycin (an everolimus intermediate B) to react with trifluoromethanesulfonic acidsingle-protection glycol ester in the presence of organic base. The invention further discloses the application of the everolimus intermediate C. The preparation method of the everolimus intermediateis simple and high in yield; everolimus prepared from the intermediate can reduce side reactions; a technical operation procedure is simplified; the total yield is increased; the product quality is ensured; and therefore, the preparation method has better industrial application and popularization prospects.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

Three-blocking and two-injecting gas extraction hole sealing method

ActiveCN105134285AGuaranteed utilizationIncrease the concentration of pumpingGas removalSealing/packingEngineeringCoal mine methane

The invention relates to the field of underground coal mine gas extraction technologies, in particular to a three-blocking and two-injecting gas extraction hole sealing method. The hole sealing technology is more applied to the field of coal mine gas extraction, and a substantive improvement is achieved for the new technology and the new method compared with the original technology. The hole sealing technology includes the steps of hole flushing, floral tube plugging, pre-sealing, pressure measuring before grouting, pressurized grouting on a front half section, pressurized grouting on a rear half section and hole pasting. After a hole is formed, returned water in a drill rod is used for hole flushing, after the drill rod is pulled out, the drill hole can be fully plugged, a bag is used for pre-sealing, air is injected for a pressure bearing experiment, grouting is conducted on the front half section, grouting is conducted on the rear half section, and hole sealing cement is used for pasting the hole. The technology is simple in process and capable of saving cost, effectively overcoming the defects of two blocking and one injecting, reducing the scrap rate of drill holes and improving the extraction effect again.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

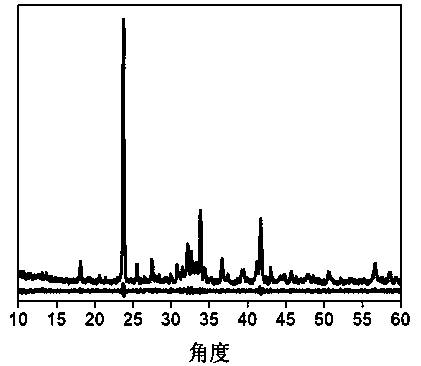

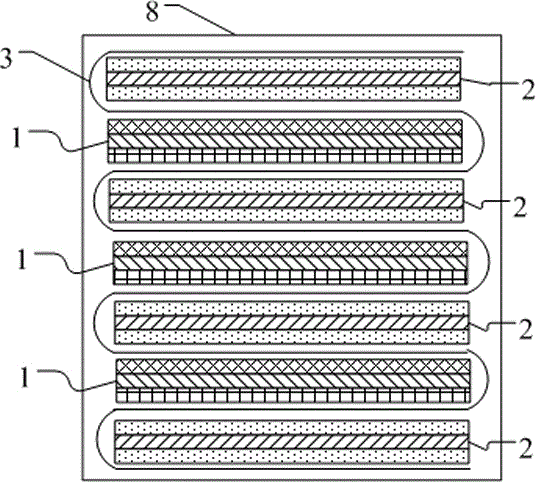

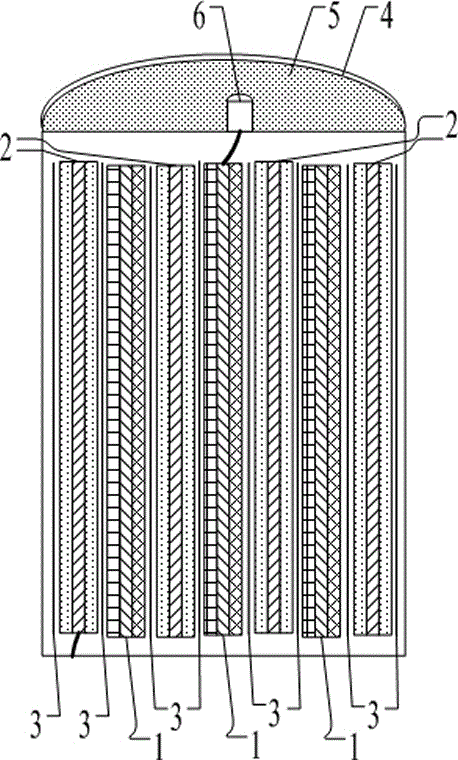

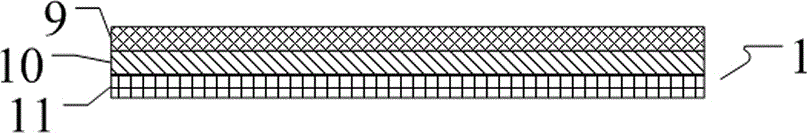

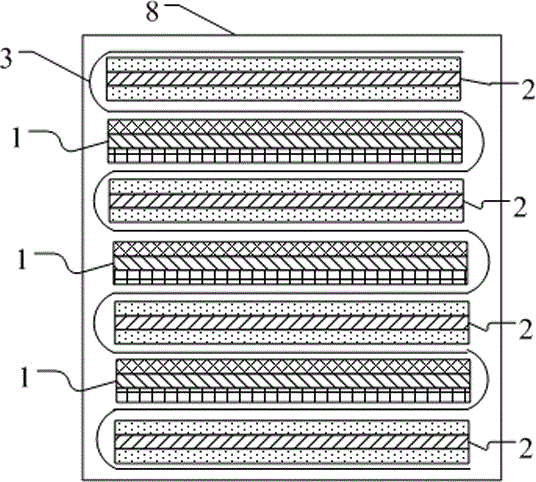

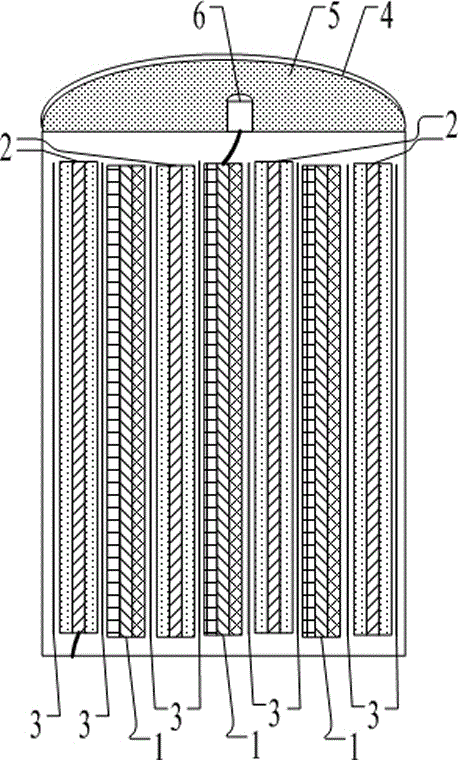

Composite positive electrode sheet lithium ion battery with high energy density

InactiveCN109698317AIncrease compaction densityIncrease energy densityFinal product manufactureNon-aqueous electrolyte accumulator electrodesHigh energyEngineering

The invention discloses a composite positive electrode sheet lithium ion battery with high energy density. A positive electrode sheet is a composite positive electrode sheet. The composite positive electrode sheet is of a multilayer composite structure. The positive electrode sheet includes a positive electrode current collector. The negative side of the positive electrode current collector is coated with a first positive electrode material layer. The positive side of the positive electrode current collector is coated with a second positive electrode material layer. The surface of the first positive electrode material layer is coated with a third positive electrode material layer. The surface of the second positive electrode material layer is coated with a fourth positive electrode material layer. A polydopamine material layer is sprayed between the first positive electrode material layer and the third positive electrode material layer. A polydopamine material layer is sprayed betweenthe second positive electrode material layer and the fourth positive electrode material layer. The lithium ion battery of the invention has the characteristics of high compaction density, excellent electrochemical performance, convenient processing, good quality stability and low cost.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

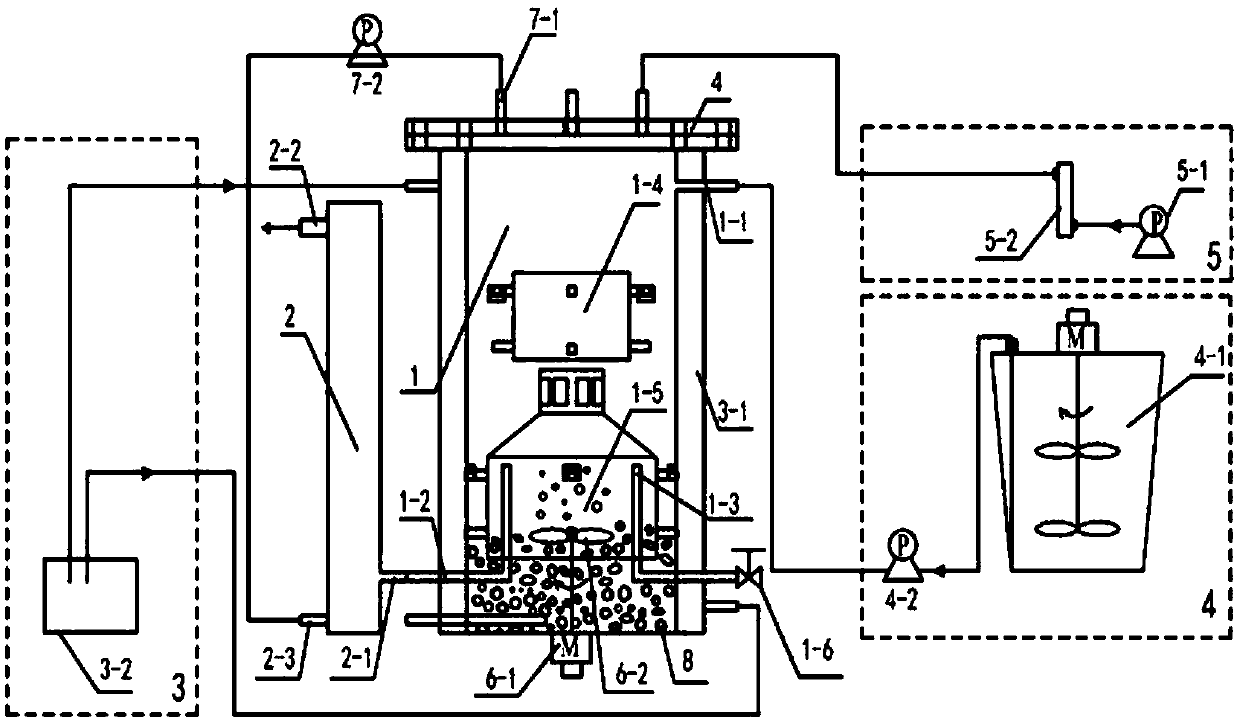

Biological membrane enhanced denitrifying treatment technology

ActiveCN107902850ANot easy to loseEasy to controlWater treatment parameter controlWater contaminantsMicroorganismEcological environment

The invention discloses a biological membrane enhanced denitrifying treatment technology. The biological membrane enhanced denitrifying treatment technology is mainly composed of a biological membraneenhanced denitrifying device, a constant-temperature system, a water inlet system, an aerating system, a stirring system and a slurry refluxing system, wherein the water inlet system pumps wastewatercontaining high ammonia-nitrogen in from a water inlet formed in the outer side of an outer barrel through the central position of the bottom of an inner cavity I, mixed liquid flows into a lower layer from the outer periphery of an inner cavity II after internal circulation in an upper layer, the treated mixed liquid flows into a sedimentation tank through a water outlet vertical pipe in the inner cavity II, and finally, the mixed liquid is drained out from a water outlet pipe at the upper end of the sedimentation tank. The biological membrane enhancing and denitrifying treatment technologydisclosed by the invention achieves layered internal circulation and zone control on dissolved oxygen and microorganism species and sludge concentration in the denitrifying device, is favorable for optimizing space distribution and accumulation of varieties of denitrifying functional microorganisms, utilizes biological packing to further optimize a micro-ecological environment to obtain a better denitrifying effect and has the advantages of short technological process, accurate zone partition, easiness in control small floor area, low operation cost, environmental friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

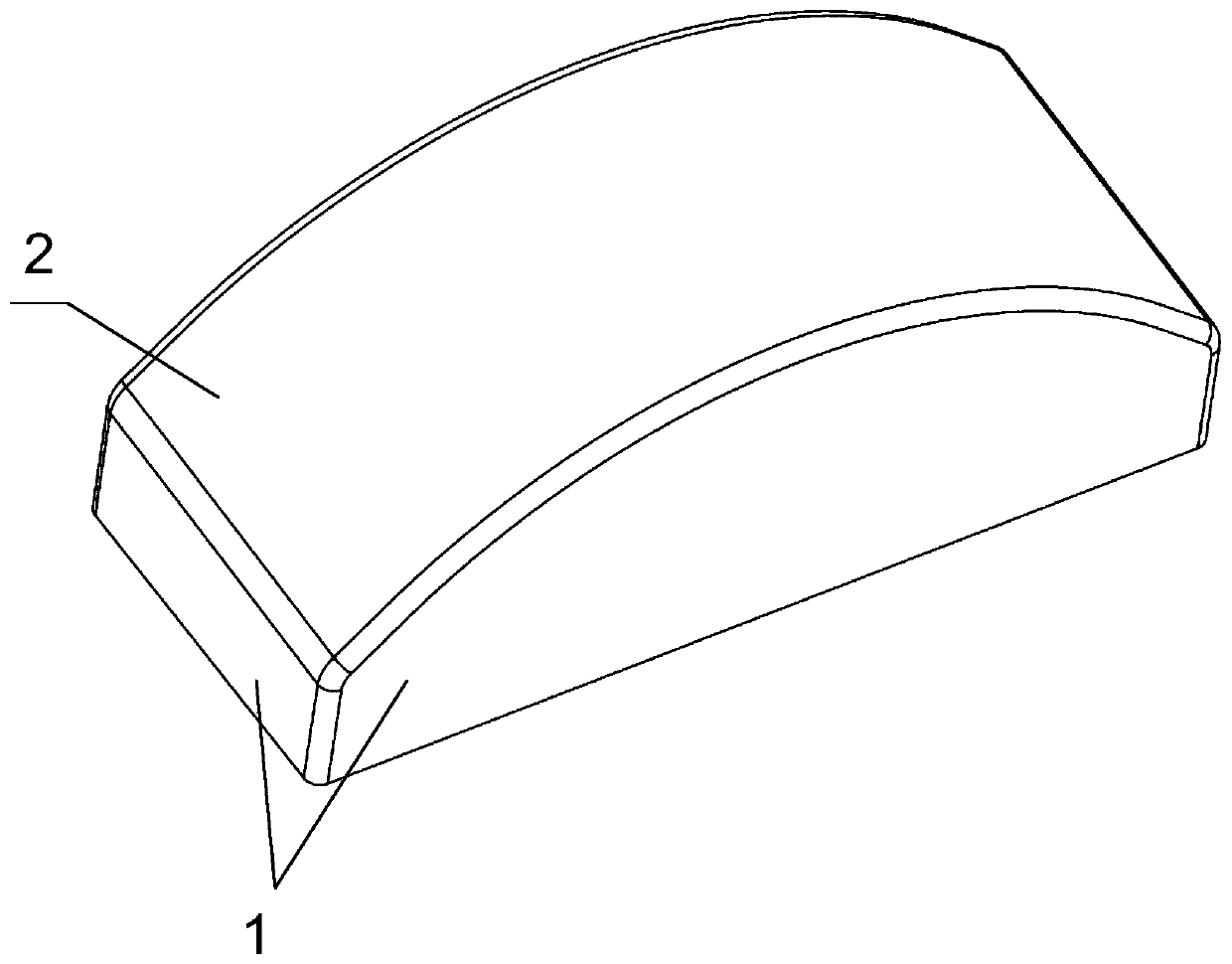

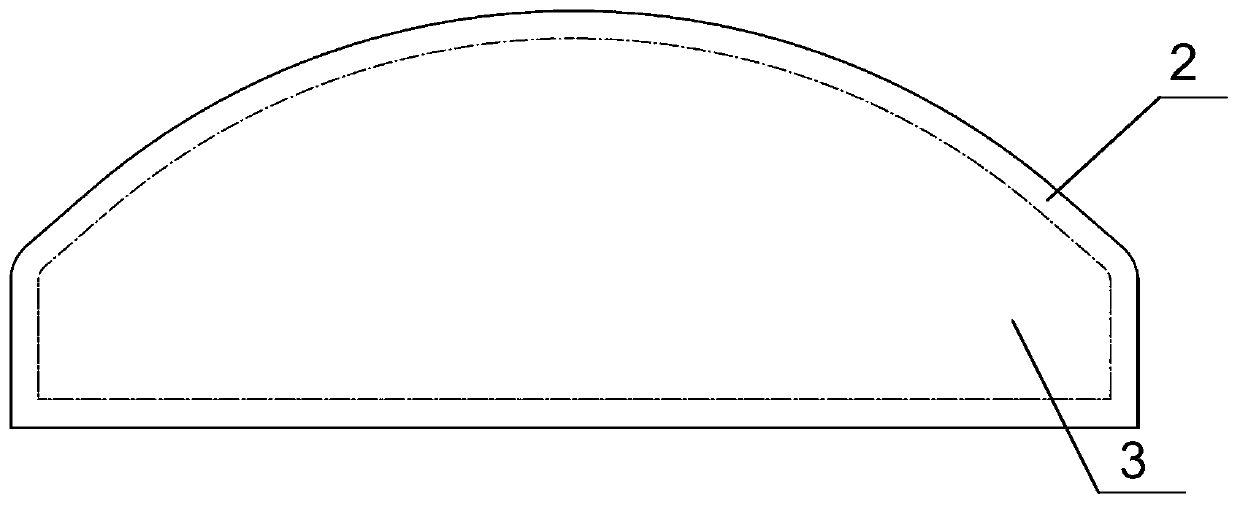

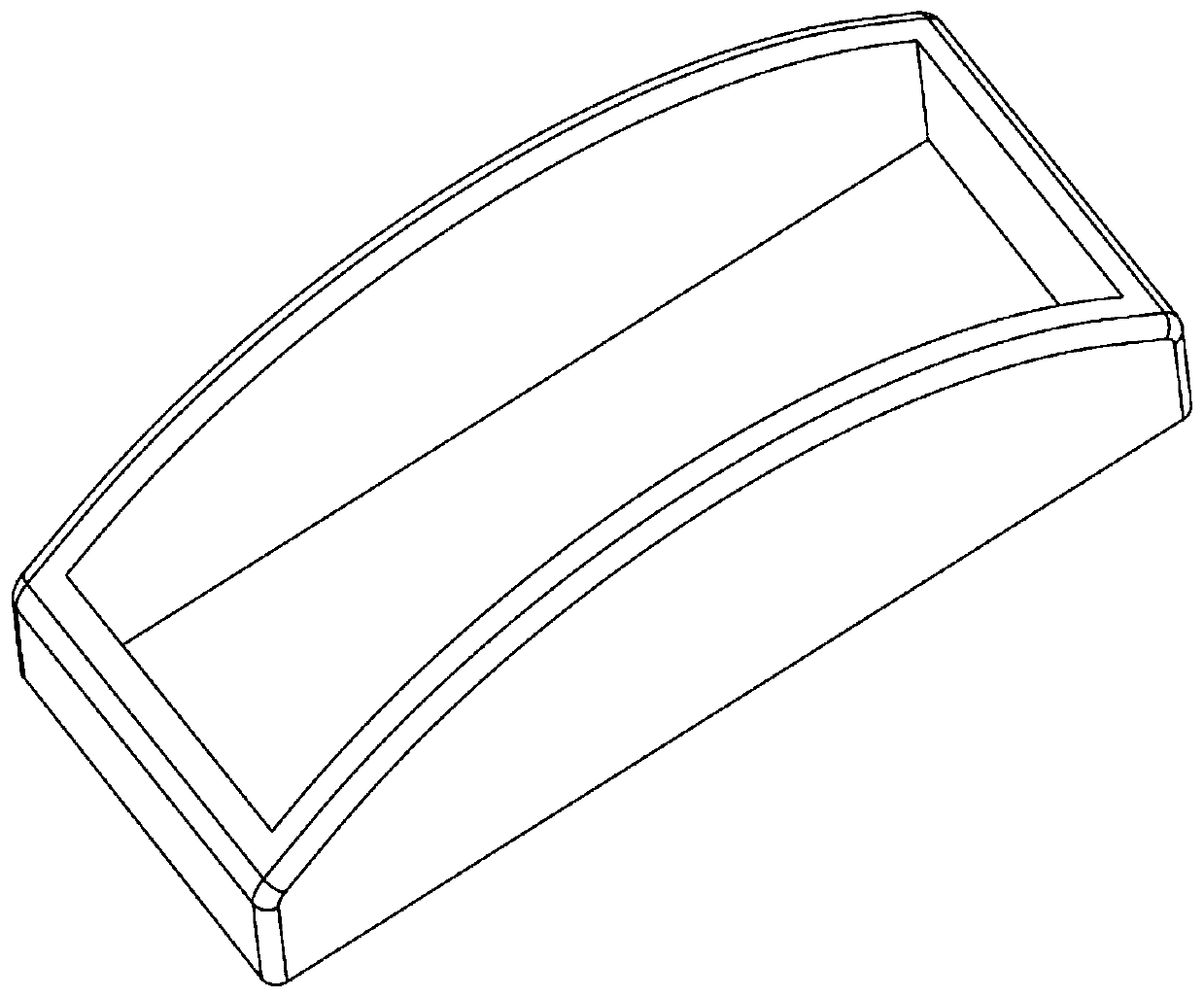

Skin stretch forming die and manufacturing method thereof

The invention belongs to the technical field of technological equipment designing and manufacturing, and particularly relates to a skin stretch forming die and a manufacturing method thereof. The skinstretch forming die comprises a wooden structure frame, an epoxy resin-talcum powder surface and an epoxy resin-glass bead filling body; and the wooden structure frame is arranged at the periphery and the bottom face of the skin stretch forming die, the epoxy resin-talcum powder surface is arranged on the top face of the skin stretch forming die, the wooden structure frame and the epoxy resin-talcum powder surface form a hollow space, and the hollow space is filled with the epoxy resin-glass bead filling body. According to the skin stretch forming die and a manufacturing method thereof, the technological operation processes are simple, filling material sources are wide, the relative cost is low, the relative weight is low, and machining and using are convenient in the skin part stretch forming process.

Owner:SHENYANG AIRCRAFT CORP

Paraffin hydrogenation post-treatment method

ActiveCN103789011AReduce dosageSave waterTreatment with plural serial refining stagesParaffin waxHigh energy

The invention provides a paraffin hydrogenation post-treatment method. According to the method, a post-treatment system for a paraffin hydrorefining reaction product employs a hydrogen stripping tower to replace an original steam stripping tower and a vacuum drying part, and the gas for stripping is changed from steam to hydrogen. Directed at the problems of large water consumption, high energy consumption and the like in the steam stripping tower and the vacuum drying part, the method adopts hydrogen as a stripping gas, not only makes full use of the purge gas of the device itself, the exhaust gas of a separator and other resources, saves the dosage of new hydrogen, but also saves the consumption of fresh water, saves valuable water resources, and reduces the energy consumption in the process of converting water into steam, so that the energy consumption of the whole device is reduced. The post-treatment system involved in the method omits the vacuum drying part, saves the equipment investment cost, and the economic benefit is also very significant.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing calcium sulfoaluminate-alite-belite-iron phase system cement clinker by phase separation combination

ActiveCN108101399AImprove performanceControllable clotting timeSulfur trioxideUltimate tensile strength

The invention discloses a method for preparing calcium sulfoaluminate-alite-belite-iron phase system cement clinker by a phase separation combination. The calcium sulfoaluminate-alite-belite-iron phase system cement clinker is prepared by uniformly mixing tricalcium silicate-dicalcium silicate-iron phase system clinker and calcium sulfoaluminate-belite-iron phase system clinker (namely, sulphate aluminium cement clinker) which are different in a calcination formation temperature interval according to a principle of preparing minerals with the same calcination formation temperature interval together and preparing minerals with different calcination formation temperature intervals separately. The difficult problems that the preparation of tricalcium silicate and calcium sulfoaluminate is difficult and sulfur trioxide in gypsum inhibits the formation of alite are solved, the preparation difficulty is reduced, the technological operation flow is simplified and the performance of the cementclinker is improved. The early strength and later strength of the obtained cement clinker are both high and the setting time is controllable. The early strength and the later strength are matched anddeveloped. In addition, no aluminate mineral exists in the cement clinker, thereby avoiding the occurrences of abnormal setting time, poor adaptability of an admixture and the like.

Owner:UNIV OF JINAN

Preparation method of everolimus

The invention discloses a preparation method of everolimus. The preparation method comprises the following step of performing deprotection reaction on an everolimus intermediate C. The preparation method of everolimus adopts a manner of regioselective protection of rapamycin 28-hydroxyl, so that the selectivity of a 40-hydroxyl alkylation reaction is improved; side reactions are reduced; a total yield of everolimus calculated from rapamycin can reach above 70%; compared with yields reported in available literatures, the yield is greatly increased; a technical operation procedure is simplified;the product quality is ensured; and the preparation method has better industrial application and popularization prospects.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +1

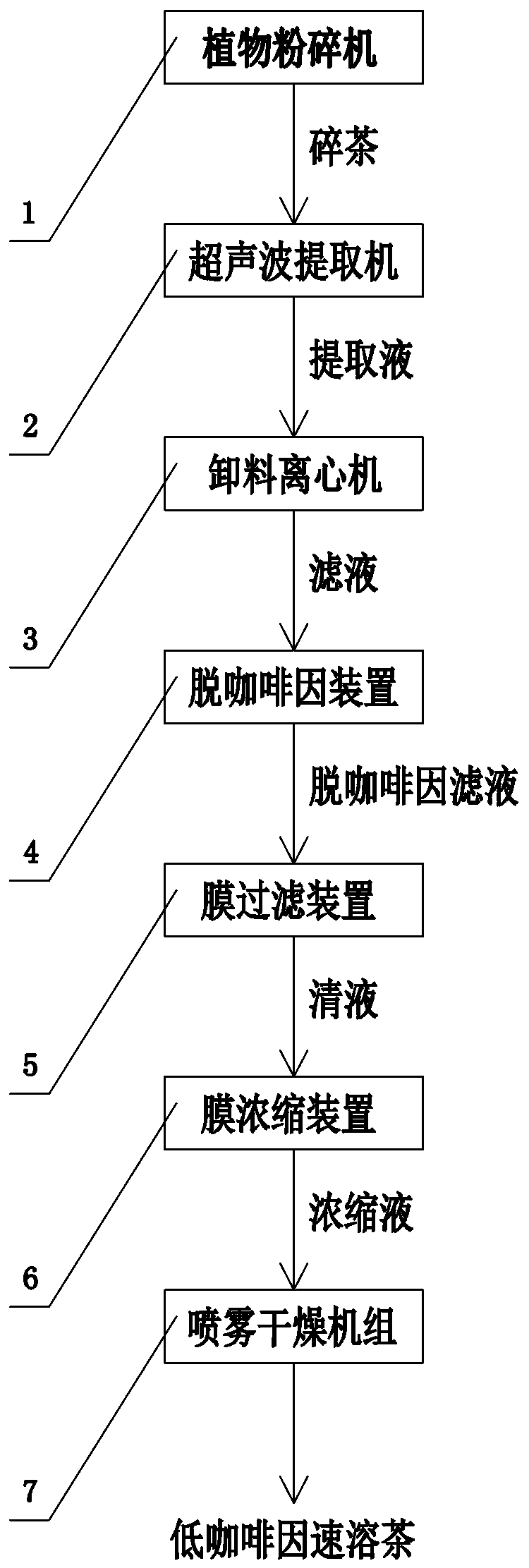

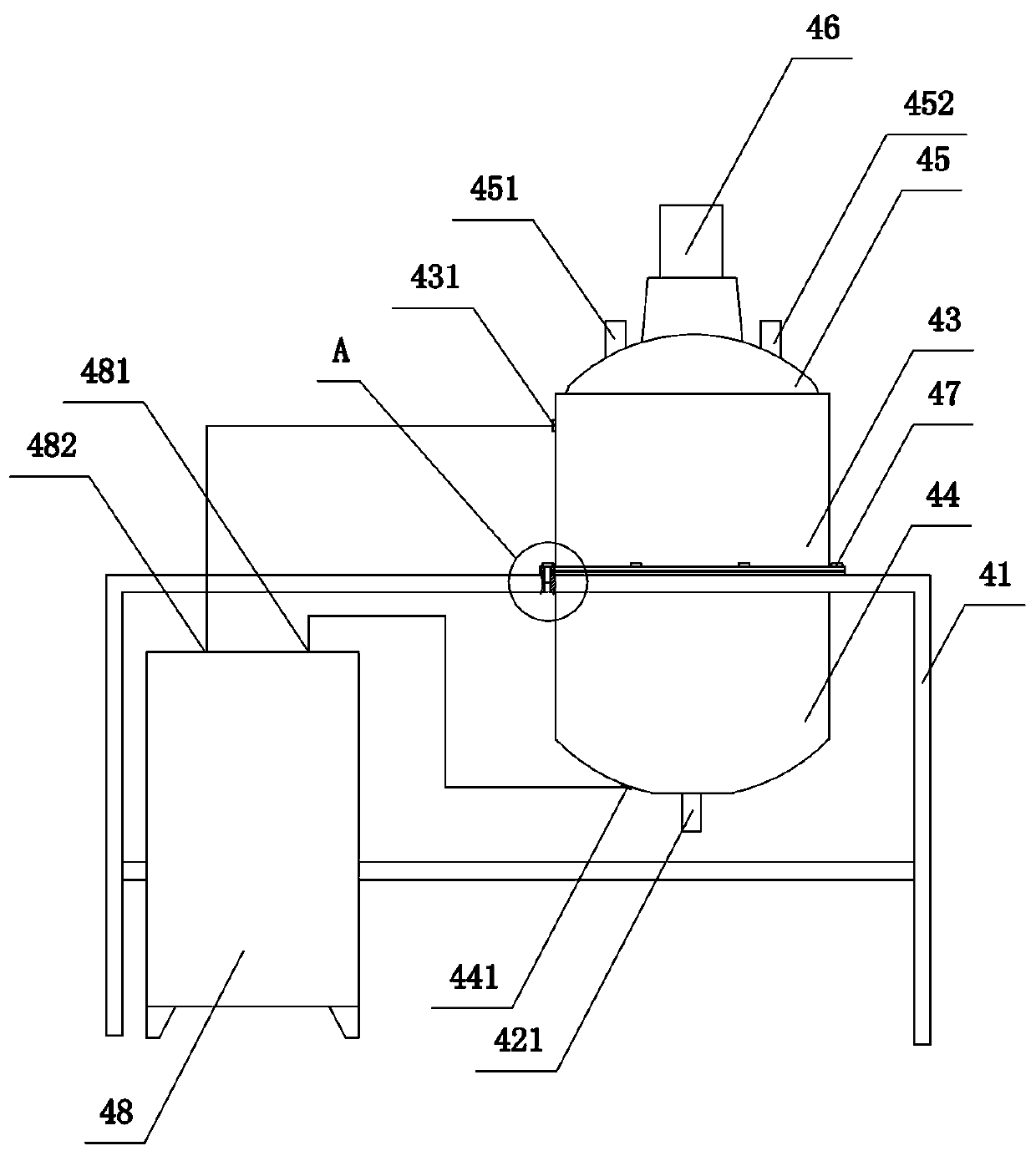

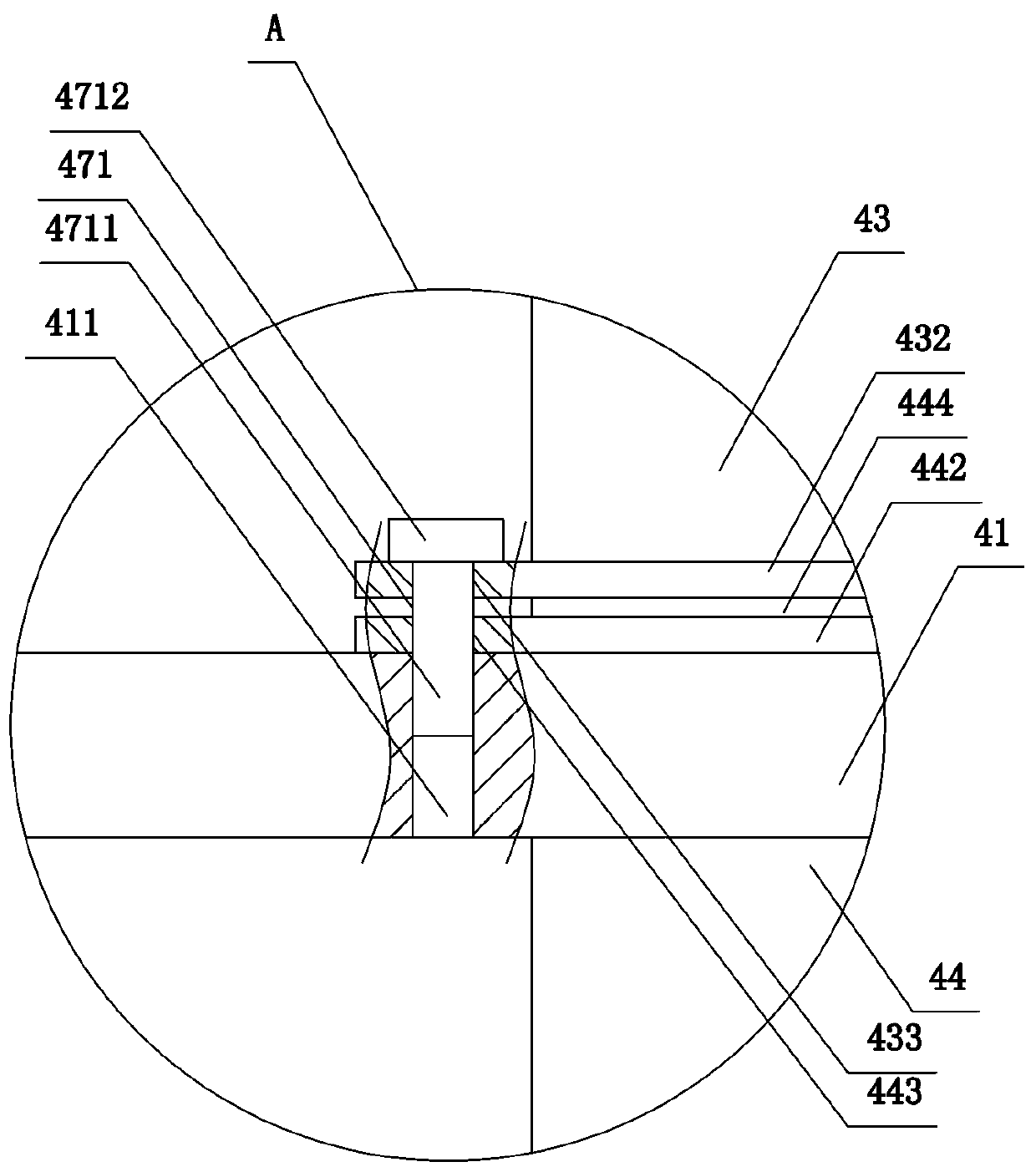

Preparation process and production line of low caffeine instant tea

PendingCN110651863AReduce caffeine contentHarm reductionTea extractionTea alkaloid content reductionDecaffeinationInstant tea

The invention relates to a preparation process and a production line of low caffeine instant tea. The preparation process comprises the steps of crushing, water extraction, filtration, decaffeination,ultrafiltration, concentration and spray drying. The process is simple and the decaffeination effect is remarkable, so that the caffeine content in the instant tea product is less than 1%, thus reducing the harm of excessive intake of caffeine to human body, expanding the application surface of the instant tea, and being suitable for men, women and children. In addition, through the improvement of the traditional decaffeination device, the cooling water can exchange heat with the liquid in the kettle more quickly, thus improving the heat release efficiency of the caffeine adsorbent, further improving the caffeine adsorption effect, and facilitating transportation and subsequent maintenance.

Owner:福建安溪铁观音集团股份有限公司

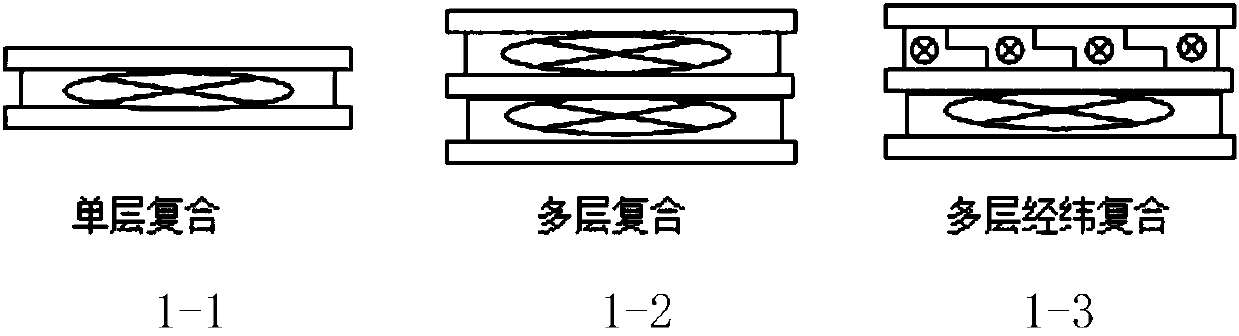

Lightweight aluminum bamboo/carbon compound material, and preparation method and application thereof

ActiveCN107761017ASimple methodSimplify process operationMetal layered productsAluminum matrix compositesInteraction forces

The invention relates to the technical field of novel compound materials, and relates to an aluminum bamboo compound material and a preparation method. The compound material adopts the technical scheme of a lightweight aluminum bamboo / carbon composite material, and is characterized by comprising an aluminum plate layer and a bamboo sheet layer, wherein the aluminum plate layer and the bamboo sheetlayer are compounded in a single layer way, a multi-layer way or a multi-layer longitude and latitude compounding way, and is formed through vacuum sintering. The preparation method is characterizedby comprising the following steps: processing the bamboo sheet layer and the aluminum plate layer; compounding in a single layer way, a multi-layer way or a multi-layer longitude and latitude compounding way; performing vacuum sintering. The compound material effectively reduces the weight of an aluminum matrix composite material, and is good in mechanical interaction force and wide in application; the preparation method is simple, the technical operation flow is simple, investment capital for equipment is less, and the cost is low.

Owner:QINGHAI UNIVERSITY

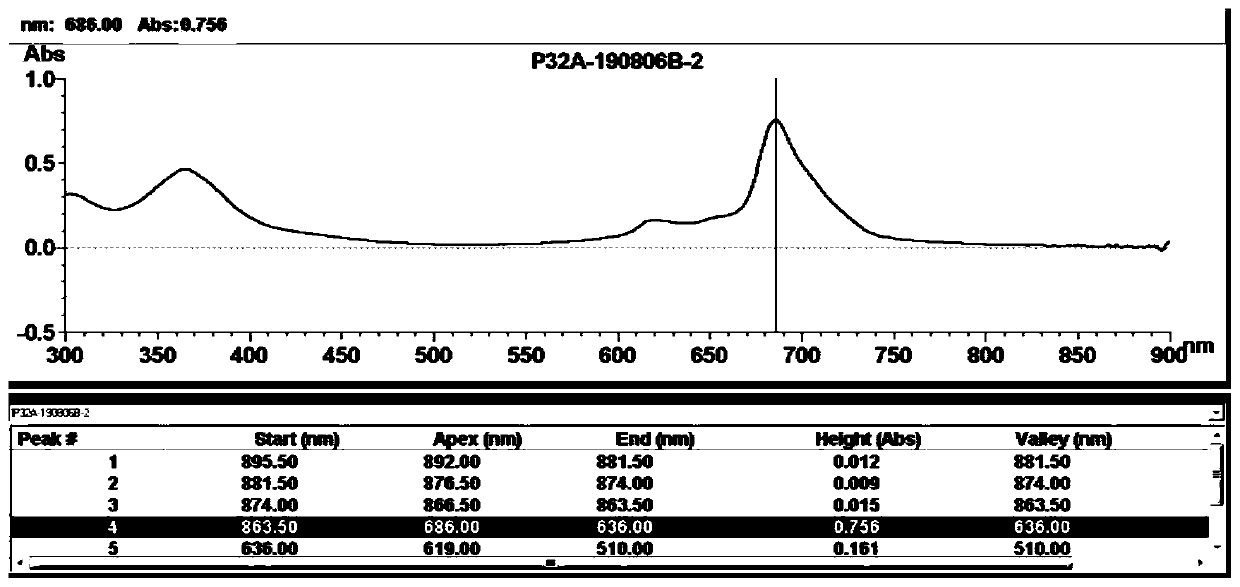

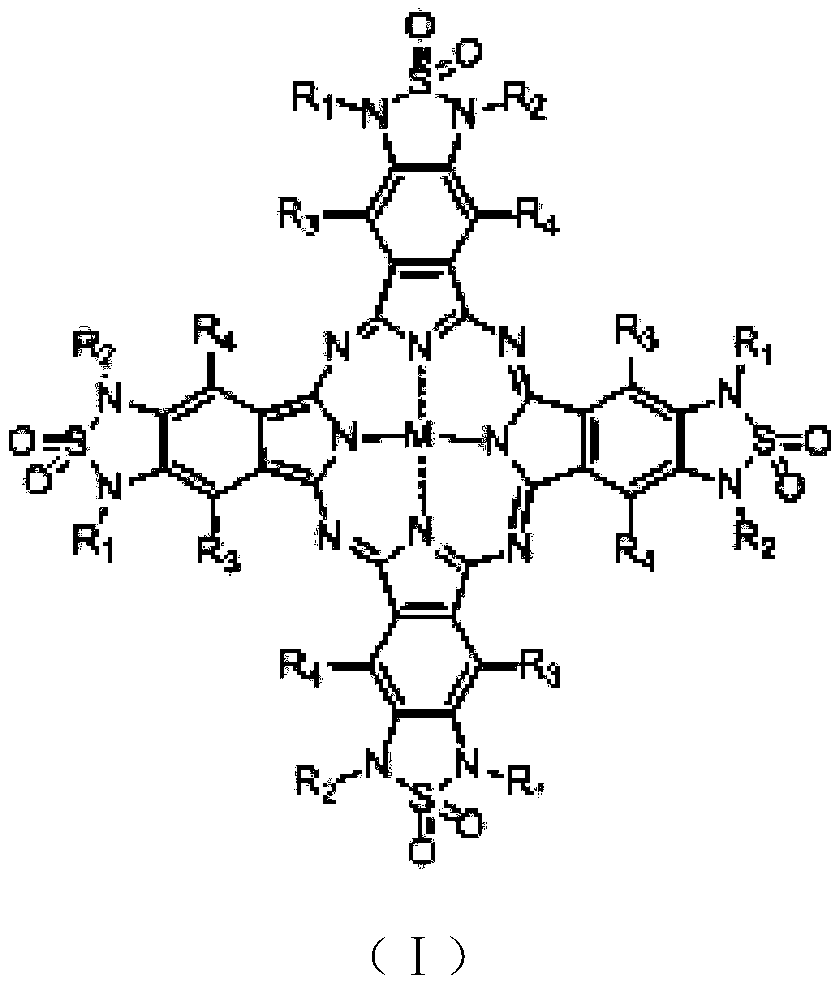

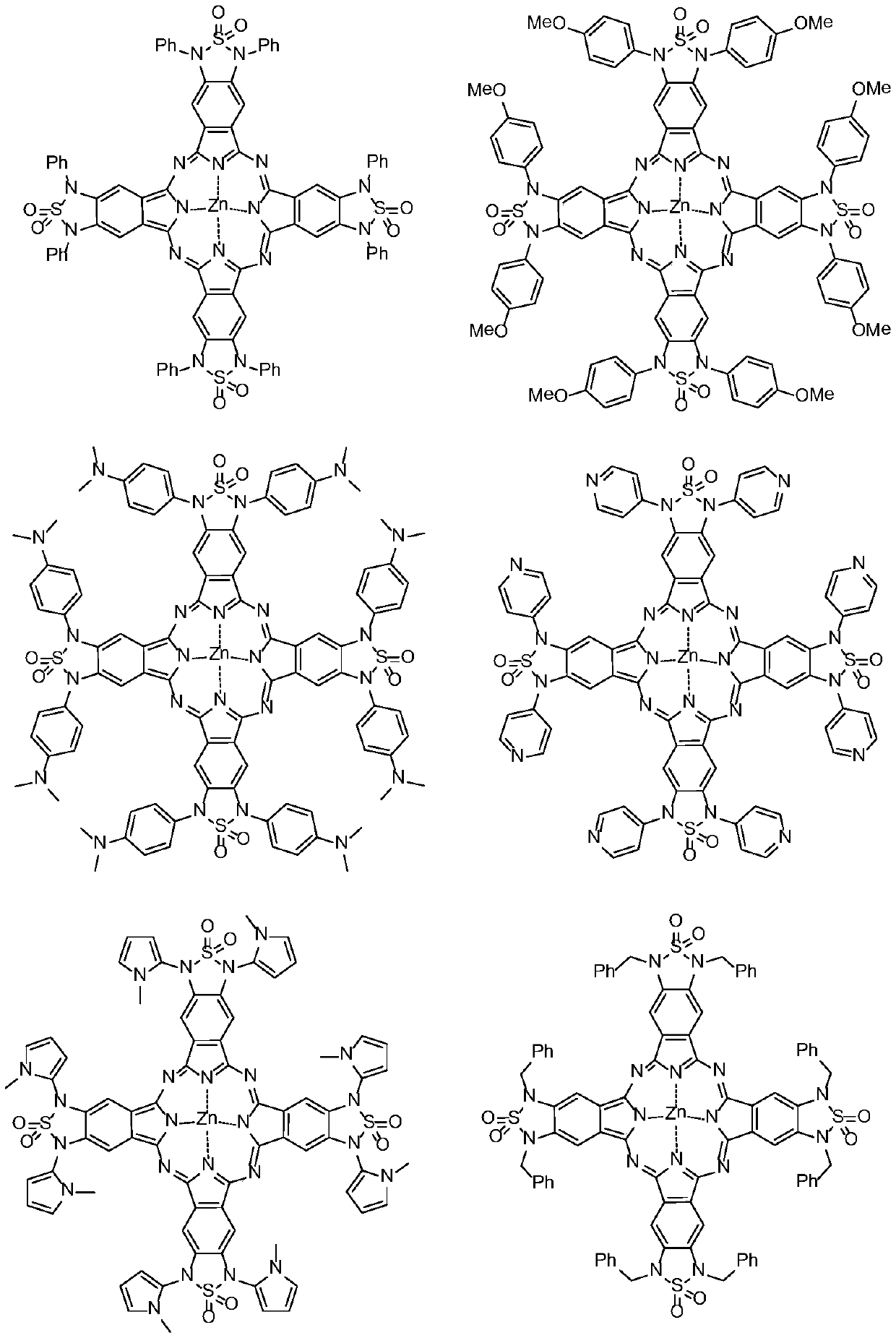

Green phthalocyanine compound and preparation method thereof

ActiveCN110845519AImprove solubilityImprove securityOrganic chemistryPorphines/azaporphinesPtru catalystPhthalocyanine

The invention discloses a green phthalocyanine compound having a structure represented by a formula (I). The structure of the precursor of the green phthalocyanine compound is represented by a formula(II). Under the protection of nitrogen, the precursor represented by the formula (II), metal salts, and a solvent are added into a dry reaction bottle, the dry reaction bottle is vacuumized, then nitrogen is filled into the dry reaction bottle; under the protection of nitrogen, a catalyst is added, and the reaction bottle is heated to a temperature of 100 to 190 DEG C to carry out reactions for 1to 20 hours under the protection of nitrogen to prepare the phthalocyanine compound represented by the formula (I). During the synthesis process, no halogenation reaction is needed, thus the safety of the synthesis process is high, and the environmental load is low. Moreover, the solubility of the green phthalocyanine compound is high, can be used as a novel soluble dye, and is capable of being dissolved in a molecule form. The technical process is largely simplified. At the same time, the dye can be made into a uniform solution, the light scattering caused by insoluble pigment particles is avoided, and high resolution and high contrast are realized.

Owner:CINIC CHEM SHANGHAI

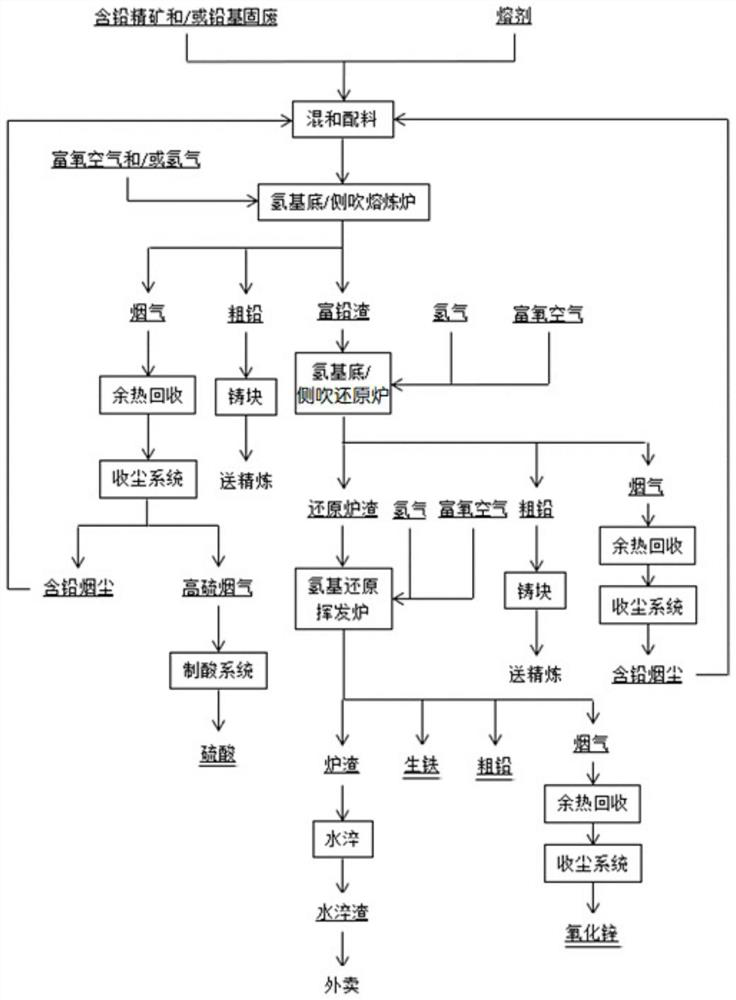

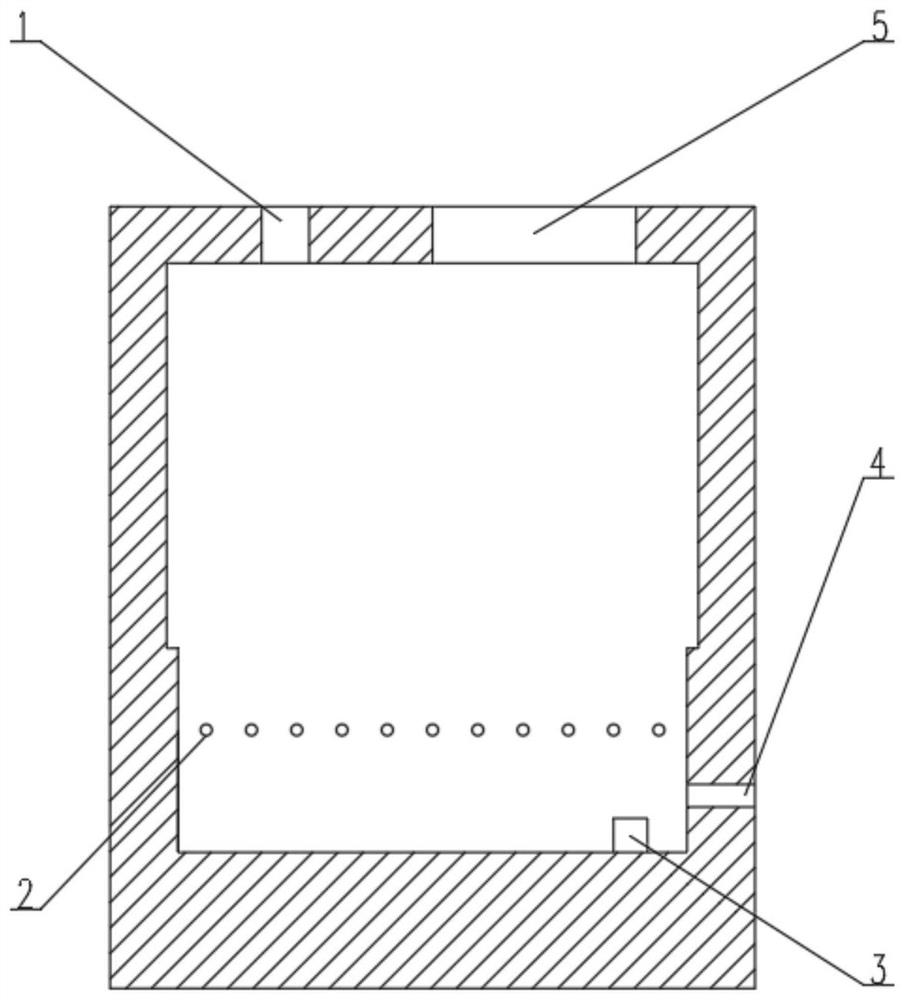

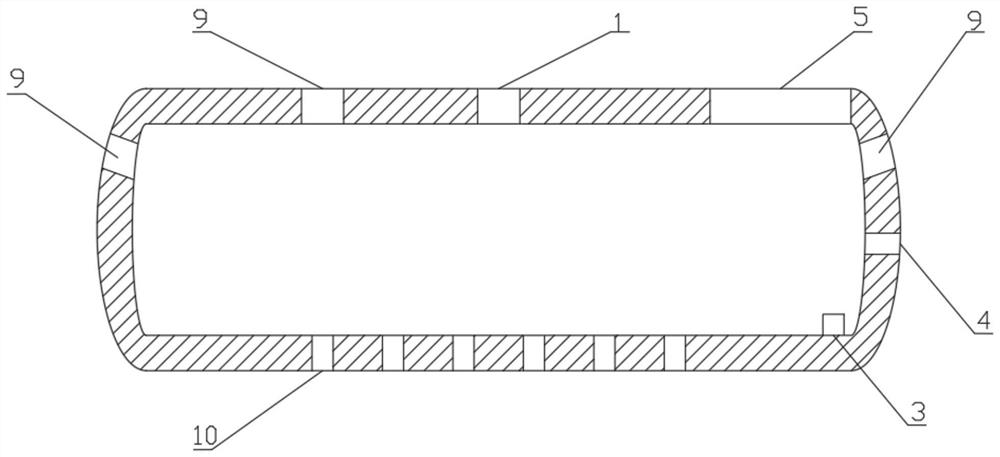

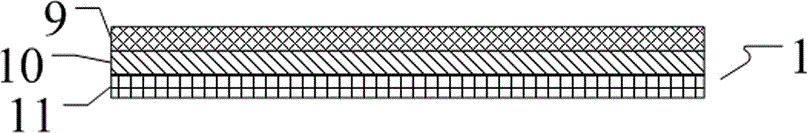

Method for hydrogen-based smelting of lead-containing concentrate and treatment of lead-based solid waste

PendingCN114854995ASimple preparationIncrease energy densityMaintainance of heating chambersExhaust gas handlingLead smeltingFlue gas

According to the method for hydrogen-based smelting of the lead-containing concentrate and treatment of the lead-based solid waste, lead smelting or treatment of the lead-based solid waste is conducted through the method, and carbon emission is avoided. Hydrogen is high in energy density and heat efficiency, and low energy consumption and high heat efficiency in the lead-based solid waste smelting or treatment process can be achieved; hydrogen serves as a reducing agent to replace a carbonaceous reducing agent, and carbon emission in the reduction smelting process is greatly reduced. By adopting the process, zero emission of greenhouse gas carbon dioxide can be realized; the treatment capacity can be improved, the lead recovery rate is increased, and the lead content of tailings is reduced. Meanwhile, valuable metals such as iron, zinc, tin, indium, germanium and the like are recovered, and a relatively high recovery rate is ensured; water vapor in the produced flue gas can be used for producing hydrogen and oxygen by an industrial hydrogen production system after being washed and purified, so that cyclic utilization is realized; the existing pyrogenic process lead smelting process and equipment can be utilized for simple transformation, so that the investment cost is low; the equipment is easy to operate and high in metal recovery rate, and the single-series productivity adapts to various scales.

Owner:CHINA ENFI ENGINEERING CORPORATION

Capacitive type lithium cobalt oxide power battery

InactiveCN105406135ASimple structureImprove applicabilityHybrid capacitor electrodesFinal product manufacturePower batterySupercapacitor

The invention discloses a capacitive type lithium cobalt oxide power battery. The lithium cobalt oxide power battery comprises a positive plate, a negative plate and a diaphragm; the positive plate, the negative plate and the diaphragm are coiled or laminated at intervals; the diaphragm is arranged between the positive plate and the negative plate; the positive plate is a capacitive type positive plate; the capacitive type positive plate adopts a three-layer composite structure; the positive electrode pole piece comprises a supercapacitor positive electrode layer, a lithium ion battery positive electrode layer and a positive electrode current collector layer; the negative electrode surface and the positive electrode surface of the positive electrode current collector are coated with the supercapacitor positive electrode layer and the lithium ion battery positive electrode layer respectively; the supercapacitor positive electrode layer is an active carbon electrode material layer; the lithium ion battery positive electrode layer is a lithium cobalt oxide positive electrode material layer; the negative electrode material layer is a mixture of natural graphite, synthetic graphite, soft carbon and hard carbon, wherein the soft carbon and the hard carbon account for 50-95% of the mixture in percentage by mass. The capacitive type lithium cobalt oxide power battery has the characteristics of high applicability, excellent performance, good quality, convenient processing, high production efficiency and low cost.

Owner:李朝

Porous aluminum-carbon composite material and preparation method thereof

The invention relates to a porous aluminium carbon composite material and a preparation method thereof. The preparation method comprises the following steps: sintering bamboo chips in vacuum for carbonization to obtain a carbon material; machining aluminium alloy into aluminium scraps; mixing the carbon material of certain proportion with the aluminium scraps to obtain a mixed material, and carrying out pressure molding on the mixed material to obtain an aluminium carbon composite material; and sintering the aluminium carbon composite material after pressure molding in vacuum to obtain the porous aluminium carbon composite material. The preparation method is simple to operate and low in cost, and has the advantages of effectively reducing weight of aluminum matrix composite material and prolonging the service life. And in addition, the porous aluminium carbon composite material has the advantages of being high in thermal insulating performance, silencing effect and comfort level.

Owner:QINGHAI UNIVERSITY

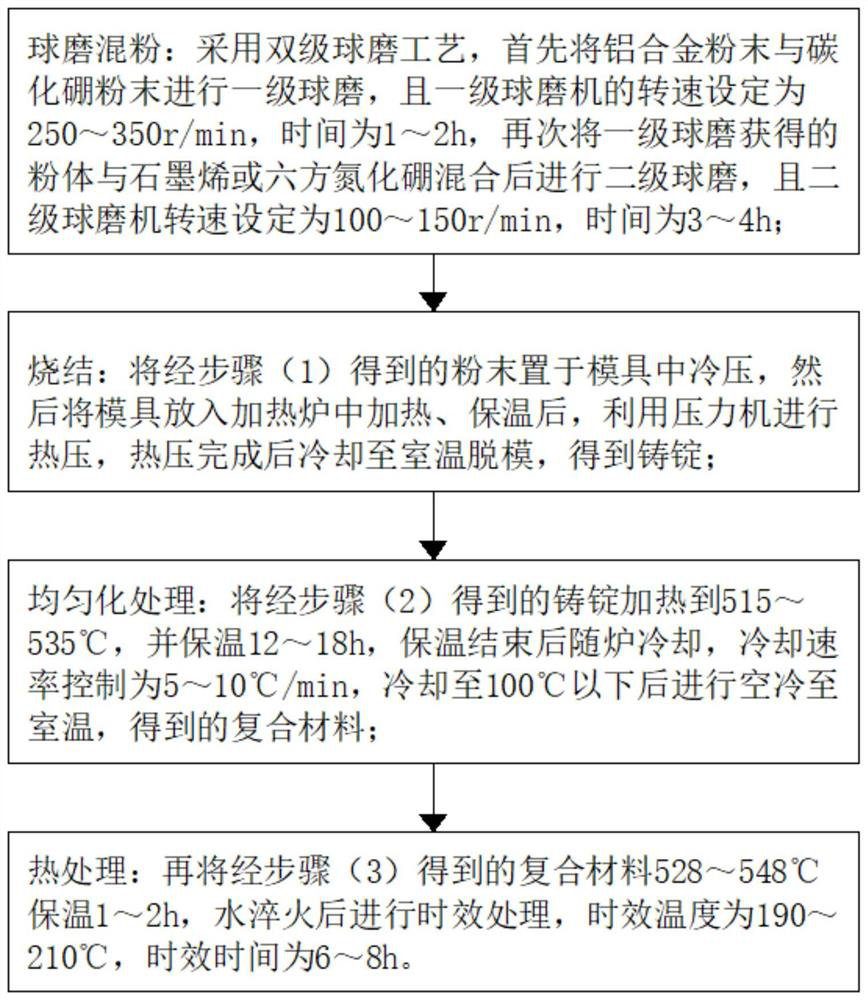

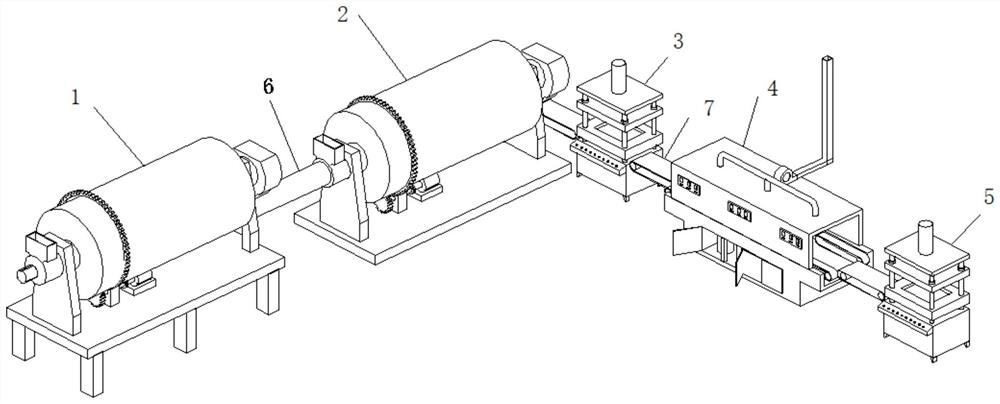

Aluminum-based composite material and preparation method thereof

ActiveCN113684410AImprove wear resistanceHas self-lubricating propertiesIncreasing energy efficiencyHexagonal boron nitrideBoron nitride

The invention discloses an aluminum-based composite material and a preparation method thereof, and relates to the technical field of metal-based composite materials. The aluminum-based composite material comprises the following raw materials by volume percentage: 15-25% of boron carbide, 3-5% of graphene or hexagonal boron nitride, and 70-82% of an aluminum alloy. The preparation method of the aluminum-based composite material comprises the following steps of ball milling and powder mixing, sintering, homogenization treatment and heat treatment. A preparation device comprises a first-stage ball mill, a second-stage ball mill, a cold pressing forming machine, a heating furnace and a hot pressing forming machine which are sequentially connected, a powder conveyor is connected between the first-stage ball mill and the second-stage ball mill, and the cold pressing forming machine, the heating furnace and the hot pressing forming machine are conveyed through a conveying line. The density of the prepared aluminum-based composite material is 2.5-2.6g / cm<3>, the boron carbide reinforcement in the composite material is the third hard ceramic particles in the nature, so that the wear resistance is excellent; and meanwhile, the aluminum-based composite material has the self-lubricating characteristic, graphene and hexagonal boron nitride are both of a layered structure, and the composite material can be effectively spread on the surface to form a self-lubricating film in the working state.

Owner:福建祥鑫轻合金制造有限公司

Waterborne polyurethane for base cloth printing impregnation and preparation method thereof

InactiveCN110903460AReduce pollutionFulfil requirementsLight resistant fibresPolymer sciencePropanoic acid

Belonging to the technical field of environment-friendly waterborne polyurethane, the invention discloses a waterborne polyurethane for base cloth printing impregnation and a preparation method thereof. The waterborne polyurethane for base cloth printing impregnation comprises the following substances by weight: 700-742 parts of polypropylene glycol, 135-200 parts of a diisocyanate compound, 5-11parts of a plasticizer, 38-42 parts of dimethylolpropionic acid, 0.05-0.07 part of a catalyst stannous octoate, 30-40 parts of acetone, 2.5-7 parts of a chain extender, 27-30 parts of a neutralizer and 1200-1500 parts of deionized water. The product provided by the invention has the advantages of small environmental pollution, simple technological operation flow, low VOC and the like. The printedand impregnated base cloth generally requires peel strength of greater than 6kg / 3cm, normal-temperature folding resistance of greater than 80,000 times and low-temperature folding resistance (-20DEG C) of greater than 20,000 times, the hydrolysis resistance requires that after 12h of soaking in a 10% sodium hydroxide solution, 75% or more of the physical properties are retained, and higher-end products need to meet the jungle experiment requirements. After the waterborne polyurethane resin for printing impregnation prepared according to the invention is applied to leather-imitation factories and microfiber-imitation factories, base materials can meet the industrial leather requirements.

Owner:SHANDONG TIANQING TECH DEV

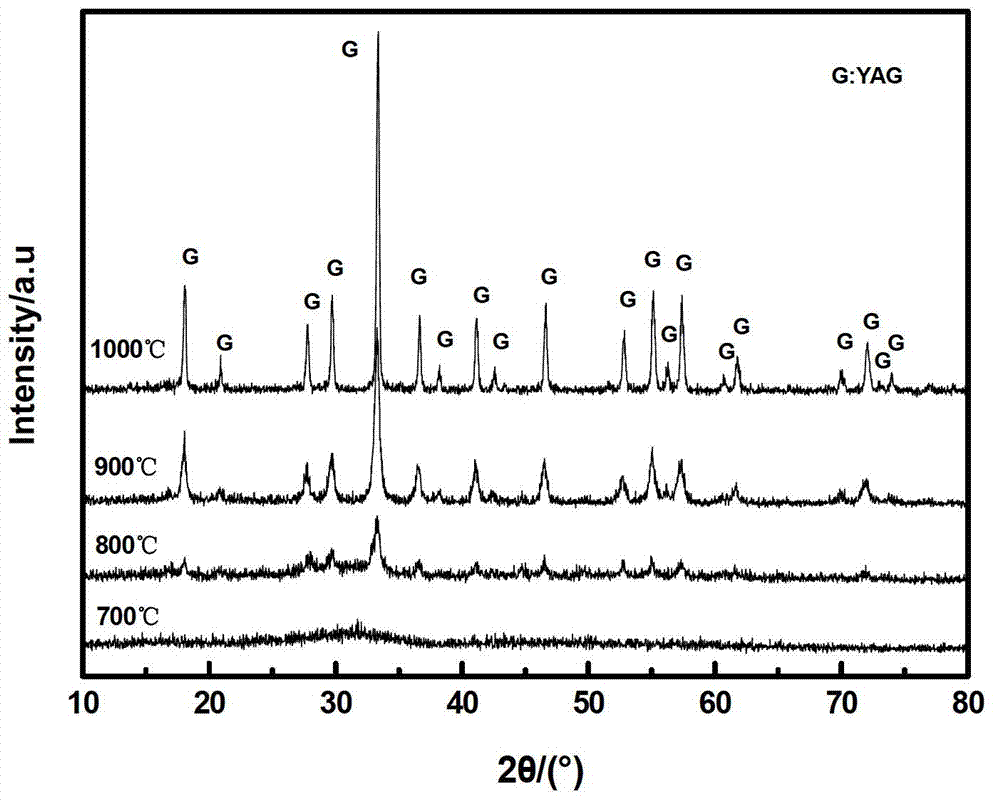

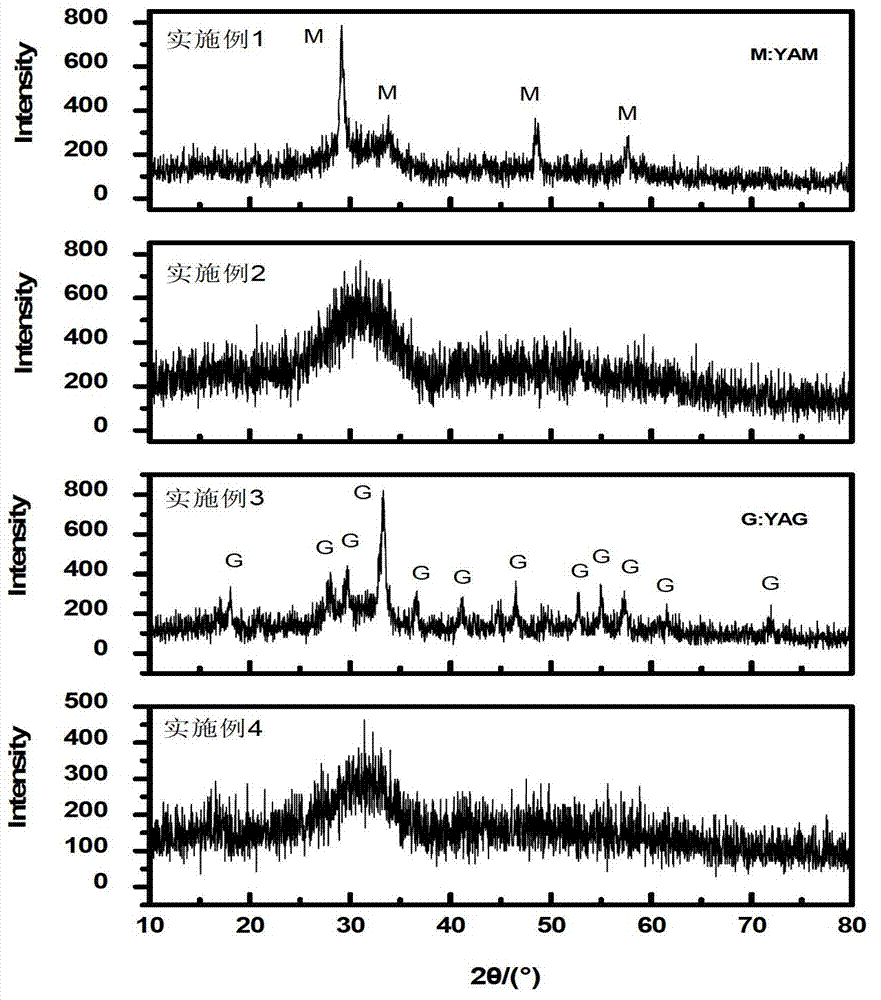

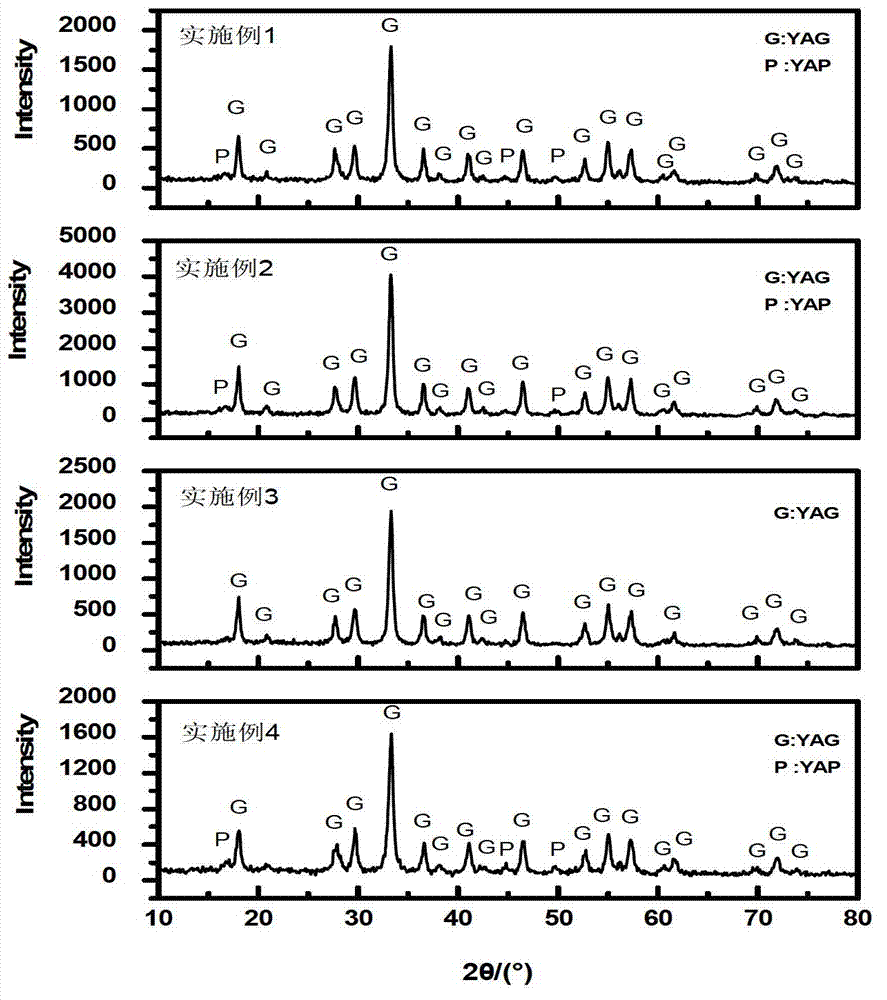

Preparation method for yttrium aluminium garnet nano-powder

InactiveCN102898148AReduce Process Control ParametersSimplify process operationAluminium nitrateNitrate

The invention discloses a preparation method for yttrium aluminium garnet nano-powder, which relates to the material technology. The preparation method for the yttrium aluminium garnet nano-powder comprises the following steps of: 1) configuring Al(NO3)3.9H2O water solution, Y(NO3)3.6H2O water solution and NH4HCO3 water solution; 2) respectively weighing the nitrate solution containing yttrium and aluminium of the equal volume, and evenly mixing; 3) weighing the NH4HCO3 solution which has the equal volume with the aluminium nitrate solution in step 2), adding dodecylbenzene sulfonic acid which accounts for 0.1-1.0wt% of total material mass ratio as dispersing agent, and evenly stirring for standby; 4) injecting mixed precipitating agent solution obtained in step 3) into the mixed raw material solution in step 2), and violently stirring while injecting; 5) continuously violently stirring reaction solution obtained in step 4) for 2-6 hours, and ageing to form milk white colloidal precipitation solution; 6) carrying out ultrasonic treatment; 7) pumping, filtering and flushing in vacuum; 8) drying, grinding and screening; and 9) calcining. According to the preparation method for the yttrium aluminium garnet nano-powder, the technical control parameter is reduced so as to simplify a technical operation flow and improve the efficiency.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Capacitive type lithium manganate power lithium-ion battery

InactiveCN105406136AStrong equipment applicabilitySimplified wound or stacked structuresHybrid capacitor electrodesFinal product manufactureCurrent collectorComposite structure

The invention discloses a capacitive type lithium manganate power lithium-ion battery. The capacitive type lithium manganate power lithium-ion battery comprises positive electrode plates, negative electrode plates and a membrane, wherein the positive electrode plates, the negative electrode plates and the membrane are wound or laminated with one another at intervals, the membrane is arranged between the positive electrode plates and the negative electrode plates, the positive electrode plates are capacitive type positive electrode plates, the capacitive type positive electrode plates are of three-layer composite structures, each positive electrode plate comprises a supercapacitor positive electrode layer, a lithium-ion battery positive electrode layer and a positive electrode current collector layer, the supercapacitor positive electrode layer and the lithium-ion battery positive electrode layer are respectively coated on a negative surface and a positive surface of a positive electrode current collector, the supercapacitor positive electrode layer is an activated carbon electrode material layer, the lithium-ion battery positive electrode layer is a lithium manganate positive electrode material layer, and the negative electrode layer is a mixture of a natural graphite layer, an artificial graphite layer, soft carbon and hard carbon. The capacitive type lithium manganate power lithium-ion battery disclosed by the invention has the characteristics of high device applicability, excellent performance, moderate quality, high production efficiency and low cost, and is convenient to process.

Owner:李朝

Anticorrosion, fireproof and antiradiation type solid wood composite door manufacturing process

PendingCN111136754AImprove fire performanceImprove radiation protection performanceLiquid surface applicatorsRadiation protectionSolid woodMetallic materials

The invention discloses an anticorrosion, fireproof and antiradiation type solid wood composite door manufacturing process. The anticorrosion, fireproof and antiradiation type solid wood composite door manufacturing process includes the following steps that A, door core framework manufacturing is conducted, wherein a rectangular door core framework with multiple cavities is formed by splicing multiple wood strips; B, door core filler manufacturing is conducted, wherein wood chips, an anticorrosion material, a flame-retardant material and a binding agent are mixed, the cavities of the rectangular door core framework are filled with the mixture, pressing is conducted, and a door core board is formed; C, antiradiation layer manufacturing is conducted, anticorrosion processing is conducted onthe surface of the door core board, and in other words, a metal material layer is manufactured on the surface of the door core board; D, solid wood veneering is conducted, wherein a preprocessed solidwood face plate is bonded on the surface of the door core board; and E, UV solidification paint layer roller painting is conducted, wherein UV roller painting is conducted on a solid wood veneered door plate. According to the anticorrosion, fireproof and antiradiation type solid wood composite door manufacturing process, by filling the door core board with the anticorrosion material and the flame-retardant material and arranging the antiradiation layer on the surface of the door core board, the anticorrosion, fireproof and antiradiation performance of the solid wood composite door can be effectively improved, the environmental friendliness is good, and the product service life is long.

Owner:重庆市豪迈家具有限公司

Synthesis process of 4-amino-6-hydroxybenzyl bromide

InactiveCN111662192ALow yellow indexGood for thorough curingOrganic compound preparationInksPtru catalystCresol

A synthesis process of 4-amino-6-hydroxybenzyl bromide comprises the following steps: adding 5-nitroo-cresol, a PdC catalyst and methanol into a high-pressure kettle, using hydrogen for replacement for three times, 1.0 MPa hydrogen is introduced, the temperature is set to be 66 DEG C, stirring and heating are started, circulating cooling water is introduced into a stirring shaft sleeve, then carrying out filter pressing, decolorizing, synthesizing 4-amino-6-hydroxybenzyl bromide, cooling a 4-amino-6-hydroxybenzyl bromide crude product, carrying out temperature reduction filter pressing, washing the obtained filter cake with water, and drying the filter cake to obtain the finished product. The 4-amino-6-hydroxybenzyl bromide has the advantages of low cost, outstanding photo-initiation activity, storage stability, low toxicity, small yellowing index of the adhesive film and favorable deep curing, and is beneficial to thorough curing of the thick film. In a contrast test, the photo-initiation efficiency is 3-6 times higher than that of a 2% photo-initiator 651. The product is subjected to hydrogenation reaction and synthesis reaction, the technological operation process is simplified,wastewater and waste gas generated in the reaction process are recycled, the environment is protected, industrial production is promoted, the production efficiency is improved, and the obtained product is high in quality and superior to imported products.

Owner:XIANTAO XIANSHENG FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com