Method and device for cloth washing fading treatment by ozone gas

A treatment method and ozone technology, applied in the field of fading treatment, can solve the problems of chemical agent environmental pollution, fabric and clothing damage, chemical environmental pollution, etc., and achieve the effects of low operating cost, saving time and energy consumption, and saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

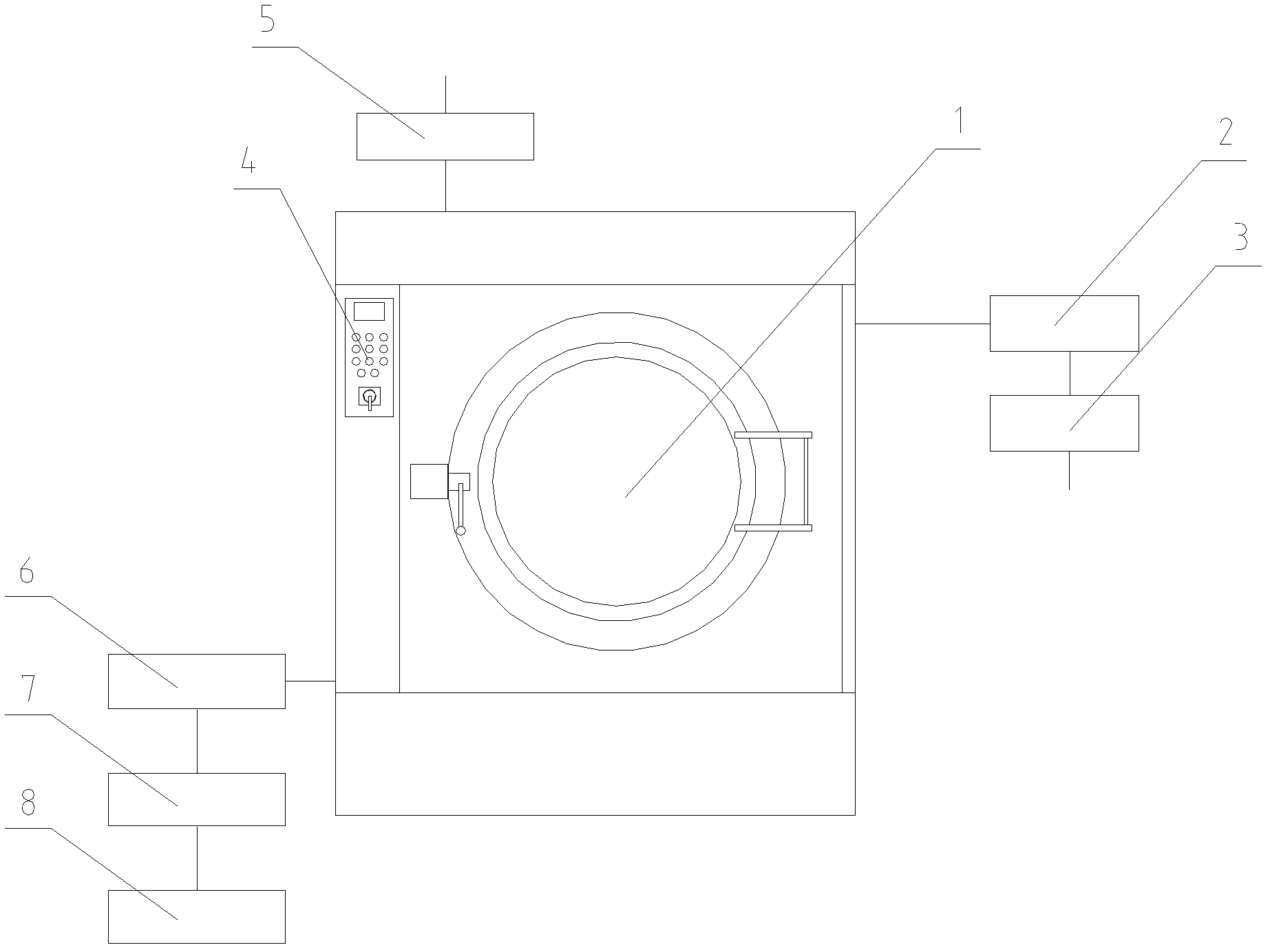

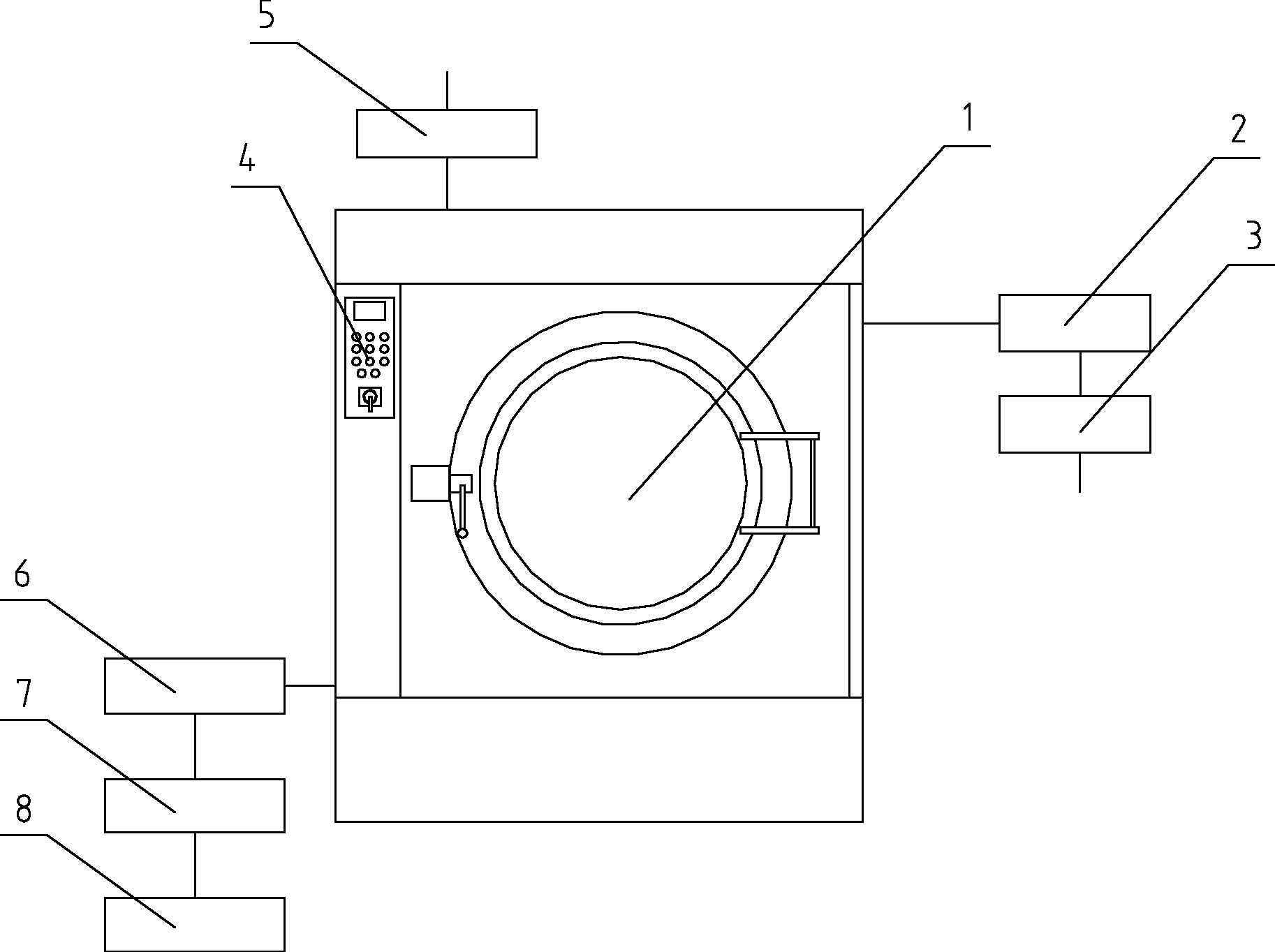

Image

Examples

Embodiment 1

[0015] A kind of treatment method of ozone gas fading, described fading treatment method comprises the following steps:

[0016] a) Put the clothes that need to be faded in a closed and rotatable drum;

[0017] b) Start the drum to roll and stir the clothes in the drum, and at the same time, fill the drum with ozone gas with a concentration of 50PPM to completely immerse the clothes to be faded in the drum in the ozone gas environment of this concentration, keep the drum rotating to make the clothes fully contact with the ozone gas, Keep the above tumbling and stirring operation for 15 minutes, and the clothes can start to fade.

[0018] c) After the fading treatment is completed, stop filling the ozone gas, keep the drum rotating, and discharge the ozone gas in the drum; the discharged ozone gas is reduced to oxygen after catalytic decomposition, and finally discharged directly from the equipment.

Embodiment 2

[0020] A kind of treatment method of ozone gas fading, described fading treatment method comprises the following steps:

[0021] a) Put the clothes that need to be faded in a closed and rotatable drum;

[0022] b) Start the drum to make the clothes tumble and stir in the drum, and at the same time, fill the drum with ozone gas with a concentration of 200PPM to completely immerse the clothes to be faded in the drum in the ozone gas environment of this concentration, keep the drum rotating to make the clothes fully contact with the ozone gas, Keep the above-mentioned tumbling and stirring operation for 30 minutes, and the fading effect of the clothes is more obvious.

[0023] c) After the fading treatment is completed, stop filling the ozone gas, keep the drum rotating, and discharge the ozone gas in the drum; the discharged ozone gas is reduced to oxygen after catalytic decomposition, and finally discharged directly from the equipment.

[0024] The value of ozone concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com