Capacitive type lithium cobalt oxide power battery

A power battery and capacitive technology, applied in hybrid capacitor electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of difficult processing, unfavorable dependence on uniformity, poor safety, etc., and achieve simplified winding or stacking The structure, improving the applicability of equipment, the effect of strong applicability of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

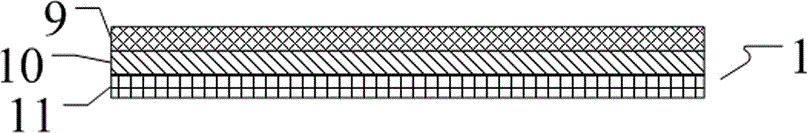

[0030] Such as figure 1As shown, the present invention discloses a capacitive lithium cobalt oxide power battery, which includes a positive electrode sheet 1, a negative electrode sheet 2 and a separator 3, and the positive electrode sheet 1, negative electrode sheet 2 and separator 3 are designed to be wound or laminated at intervals. The diaphragm 3 is arranged between the positive electrode sheet 1 and the negative electrode sheet 2, the positive electrode sheet 1 is a capacitive positive electrode sheet, the capacitive positive electrode sheet is a three-layer composite structure, and the positive electrode sheet includes a supercapacitor positive electrode layer 9, Lithium-ion battery positive electrode layer 11 and positive electrode current collector layer 10, described supercapacitor positive electrode layer 9 and lithium ion battery positive electrode layer 11 are respectively coated on the negative side and positive surface of positive electrode current collector 10, ...

Embodiment 2

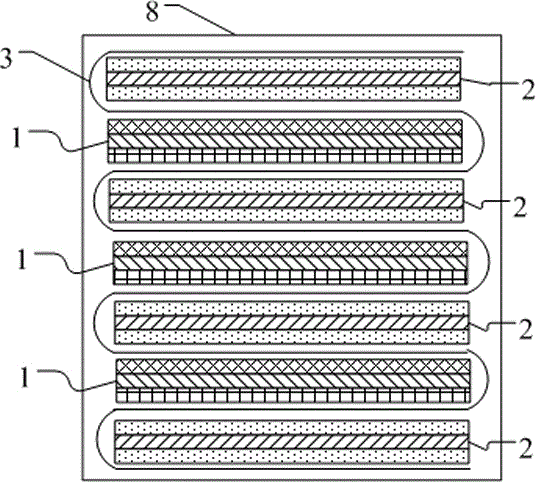

[0032] Such as figure 2 As shown, the positive electrode sheet 1, the negative electrode sheet 2 and the separator 3 are stacked at intervals to form a square structure. The capacitive lithium cobalt oxide power battery described in this application has a square laminated structure, and the battery is packaged into a square shape through an aluminum-plastic film 8, and the separator 3 covers the negative electrode sheet 2 and the positive electrode sheet 1, and the negative electrode sheet 2 and the positive electrode sheet 1 are spaced apart from each other. The positive electrode layer 9 of the supercapacitor and the positive electrode layer 11 of the lithium ion battery are dislocated and spaced apart in stacking. The capacitive lithium cobaltate power battery also includes lithium ion battery electrolyte, and described lithium ion battery electrolyte is made up of solvent, electrolyte salt and additive, and wherein solvent is by dimethyl carbonate (DMC), diethyl carbonate...

Embodiment 3

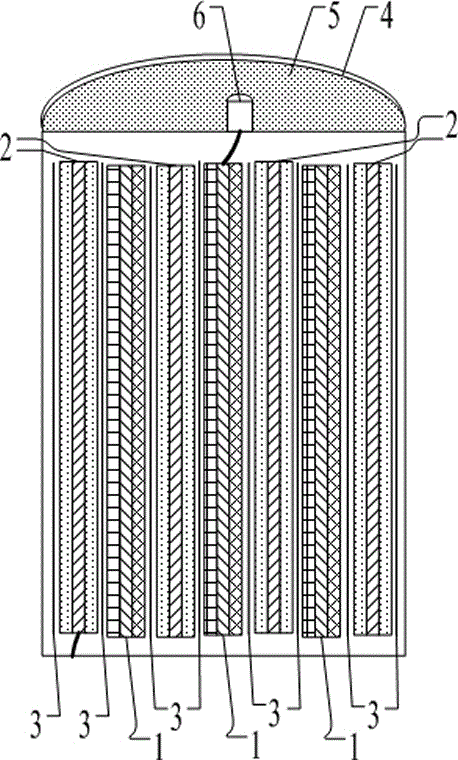

[0034] Such as image 3 As shown, the positive electrode sheet 1, the negative electrode sheet 2 and the separator 3 are wound at intervals to form a cylindrical structure. The capacitive lithium cobalt oxide power battery described in this application has a cylindrical winding structure, and the wound battery core is arranged in a cylindrical steel shell 4, and the separator 3 covers the negative electrode sheet 2 and the positive electrode sheet 1, and the negative electrode sheet 2 and the positive electrode sheet. The positive electrode sheets 1 are spaced apart from each other, the positive electrode layer 9 of the supercapacitor and the positive electrode layer 11 of the lithium-ion battery are dislocated and spaced apart in the lamination, and a cap 6 is welded on the steel shell 4, and an insulating sheet 5 and a cap 6 are arranged between the cap 6 and the cell. It is connected with the positive electrode sheet 1, and the bottom of the steel case 4 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com