Preparation method of everolimus

A technology of everolimus and deprotection, which is applied in the field of preparation of everolimus, can solve the problems of many by-products, difficulty in separation, and many impurities, and achieve the goals of increasing yield, improving selectivity, and simplifying the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

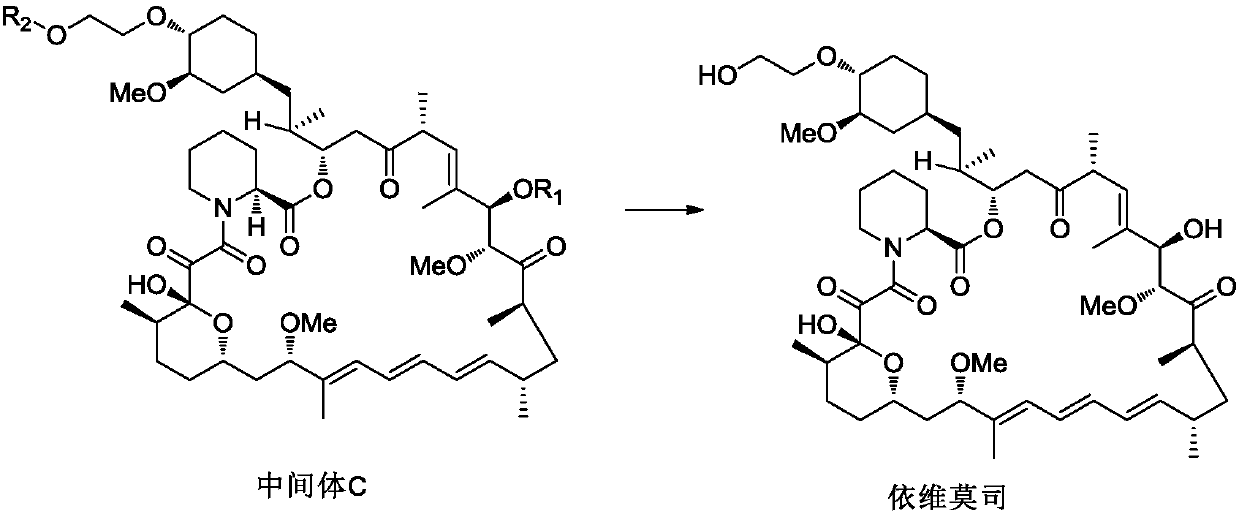

[0060] The reaction process of the present embodiment is as follows:

[0061]

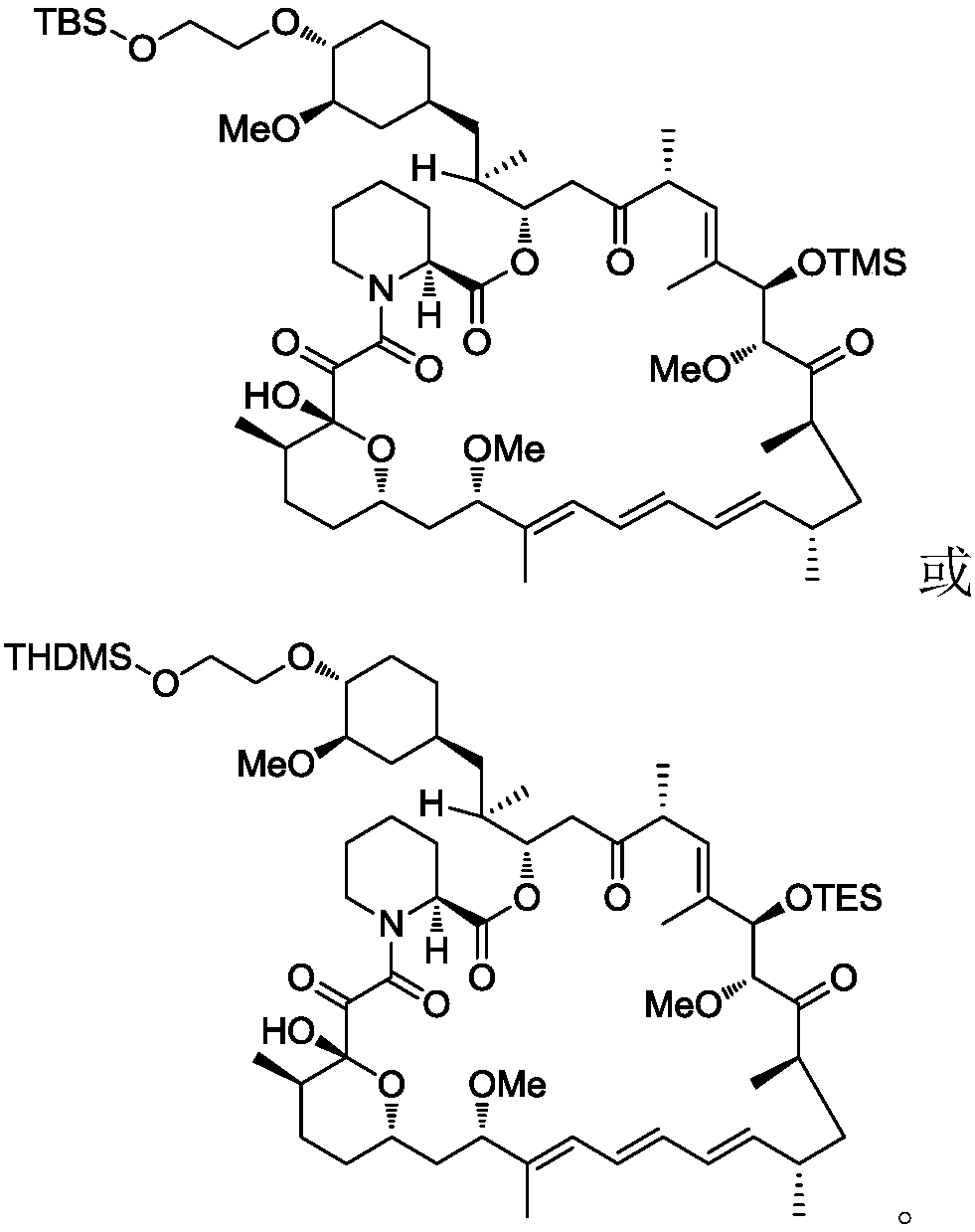

[0062] (1), the synthesis of 28-O-TMS rapamycin (intermediate B-1)

[0063]

[0064] Dissolve rapamycin (5.00g, purity 98.4%) and imidazole (1.86g) in ethyl acetate (100mL), under cooling in an ice-water bath, add trimethylchlorosilane (2.97g) dropwise, and continue The reaction was stirred for 30 minutes under cooling in an ice-water bath, and TLC showed that the starting material disappeared completely.

[0065] Add 0.5M hydrochloric acid (8mL) under ice-water bath and continue to cool, and stir the reaction. TLC shows that the original small polar product completely disappears, and the polarity of the main product is between rapamycin and rapamycin. The reaction was stopped, the reaction liquid was separated, the organic phase was washed with saturated sodium bicarbonate and saturated brine successively, dried over anhydrous sodium sulfate, and concentrated under reduced pressure to obtai...

Embodiment 2

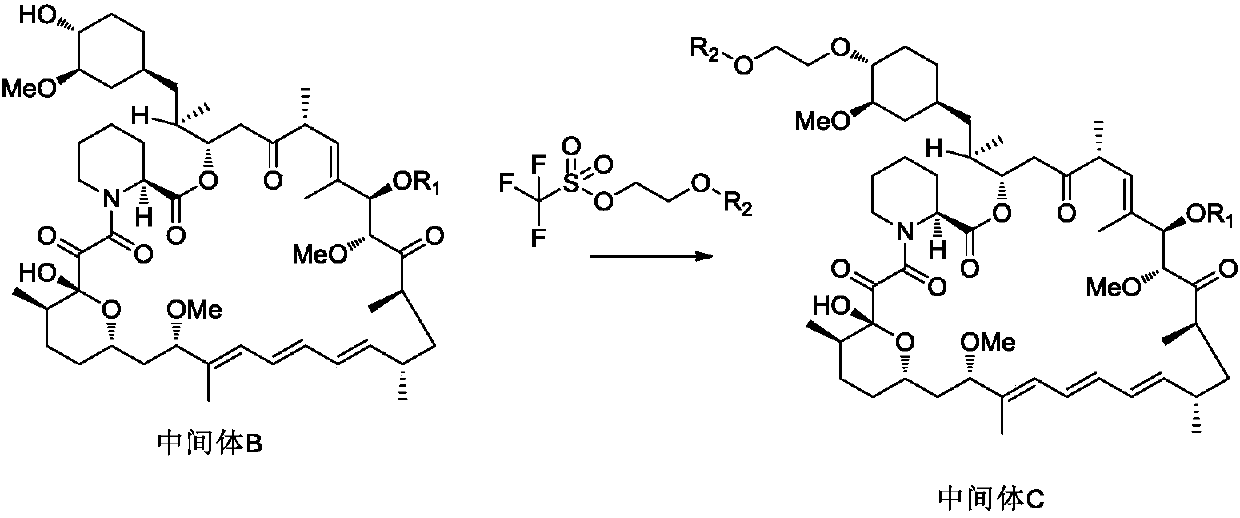

[0073] In this embodiment, the reaction process is as follows:

[0074]

[0075] (1), the synthesis of 28-O-TES rapamycin (intermediate B-2)

[0076]

[0077] Dissolve rapamycin (5.00g, purity 98.4%), triethylamine (2.77g) and 4-dimethylaminopyridine (20mg) in dichloromethane (100mL), and add triethylamine dropwise under ice-water cooling Chlorosilane (4.12g), after the dropwise addition, reacted for 1 hour under cooling in an ice-water bath, then gradually warmed up to room temperature, and reacted overnight. TLC showed that the raw material disappeared completely. The reaction solution was filtered, and the filtrate was washed successively with 0.5M dilute hydrochloric acid, saturated sodium bicarbonate and saturated sodium chloride, and the organic phase was concentrated under reduced pressure.

[0078] The obtained residue was dissolved in acetone (100ml), and 0.25M dilute sulfuric acid (15mL) was added under cooling in an ice-water bath, and the reaction was stirre...

Embodiment 3

[0086] Preparation of Everolimus from 28-O-TES-42-O-THDMS Everolimus (Intermediate C-2)

[0087]

[0088] 28-O-TES-42-O-THDMS everolimus (intermediate C-2, 200 mg) was dissolved in 10 ml of tetrahydrofuran, 1 ml of hydrogen fluoride / pyridine (38.5 M) was added, followed by TLC until the raw material completely disappeared. Add ethyl acetate and saturated sodium bicarbonate, separate the layers, wash the organic phase with dilute hydrochloric acid, saturated sodium bicarbonate, wash with water, and concentrate under reduced pressure to obtain everolimus (142 mg) as an off-white solid. ESI-MS m / z 956(M-H) - .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com