Aluminum-based composite material and preparation method thereof

An aluminum-based composite material, aluminum alloy technology, applied in the direction of improving energy efficiency and process efficiency, can solve the problems of complex operation process, uneven composition, long production cycle, etc. Excellent abrasiveness and high economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] An aluminum-based composite material, its raw materials include: 15% boron carbide, 3% graphene, and 82% aluminum alloy according to volume percentage; wherein the average particle size of boron carbide is 3 μm, the average size of graphene is 100 nm, and the aluminum alloy is Al-Cu aluminum alloy.

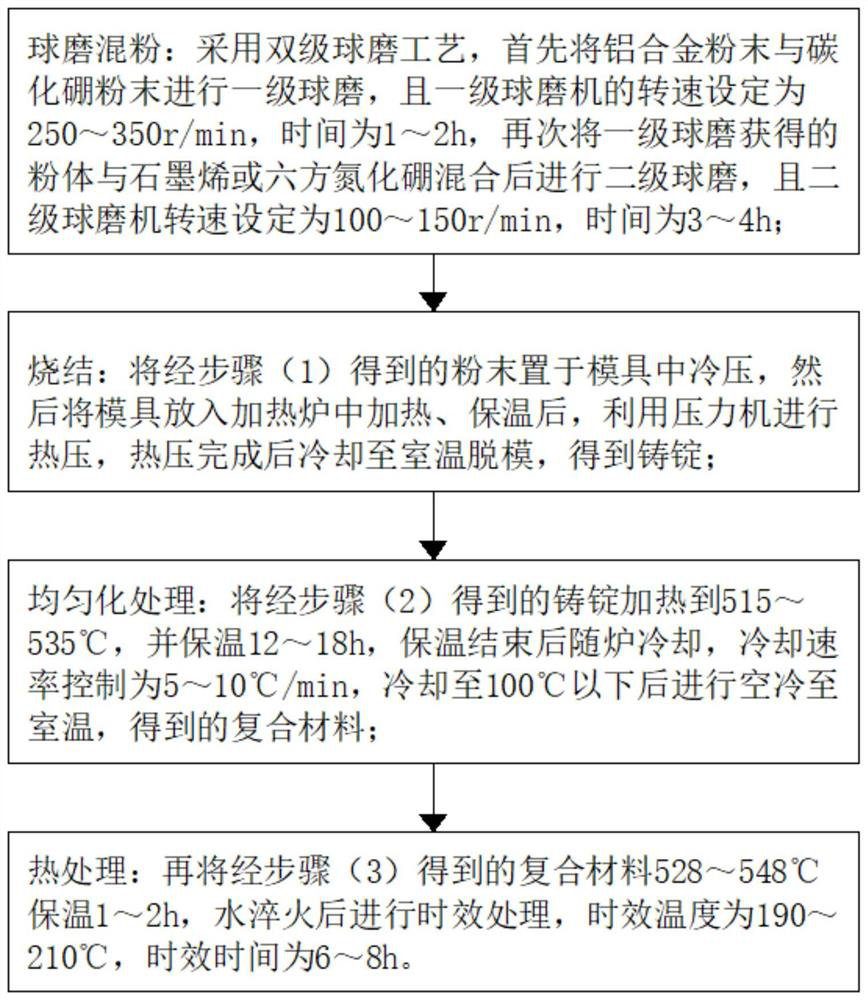

[0046] Such as figure 1 Shown, its preparation method of a kind of aluminum matrix composite material, comprises the following steps:

[0047] (1) Ball milling and powder mixing: Two-stage ball milling process is adopted. Firstly, the aluminum alloy powder and boron carbide powder are subjected to primary ball milling, and the speed of the primary ball mill is set at 250r / min, and the time is 1h. The powder is mixed with graphene or hexagonal boron nitride and then subjected to secondary ball milling, and the speed of the secondary ball mill is set to 100r / min, and the time is 3h;

[0048] (2) Sintering: Put the powder obtained in step (1) into a mold for cold pressing, t...

Embodiment 2

[0052] An aluminum-based composite material, its raw materials include: 20% boron carbide, 4% graphene or hexagonal boron nitride, and 76% aluminum alloy according to volume percentage; wherein the average particle size of boron carbide is 5 μm, and the average size of graphene is 100 nm , the aluminum alloy is Al-Cu aluminum alloy.

[0053] Such as figure 1 Shown, its preparation method of a kind of aluminum matrix composite material, comprises the following steps:

[0054] (1) Ball milling and powder mixing: Two-stage ball milling process is adopted. Firstly, the aluminum alloy powder and boron carbide powder are firstly ball-milled, and the speed of the first-stage ball mill is set to 300r / min, and the time is 1.5h. The obtained powder is mixed with graphene or hexagonal boron nitride and then subjected to secondary ball milling, and the speed of the secondary ball mill is set at 130r / min for 3.5h;

[0055] (2) Sintering: Put the powder obtained in step (1) into a mold fo...

Embodiment 3

[0059] An aluminum-based composite material, its raw materials include: 25% boron carbide, 5% hexagonal boron nitride, and 70% aluminum alloy according to volume percentage; wherein the average particle size of boron carbide is 8 μm, and the average size of stone hexagonal boron nitride is 100nm, the aluminum alloy is Al-Cu aluminum alloy.

[0060] Such as figure 1 Shown, its preparation method of a kind of aluminum matrix composite material, comprises the following steps:

[0061] (1) Ball milling and powder mixing: Two-stage ball milling process is adopted. Firstly, the aluminum alloy powder and boron carbide powder are firstly ball-milled, and the speed of the first-stage ball mill is set at 350r / min, and the time is 2h. The powder is mixed with graphene or hexagonal boron nitride and then subjected to secondary ball milling, and the speed of the secondary ball mill is set to 150r / min, and the time is 4h;

[0062] (2) Sintering: Put the powder obtained in step (1) into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com