Patents

Literature

41results about How to "Has self-lubricating properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum-silicon series deforming alloy and manufacturing method thereof

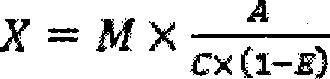

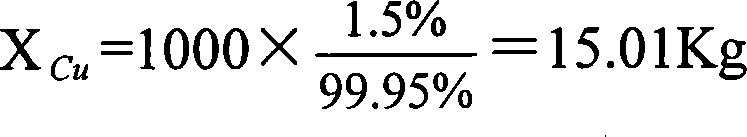

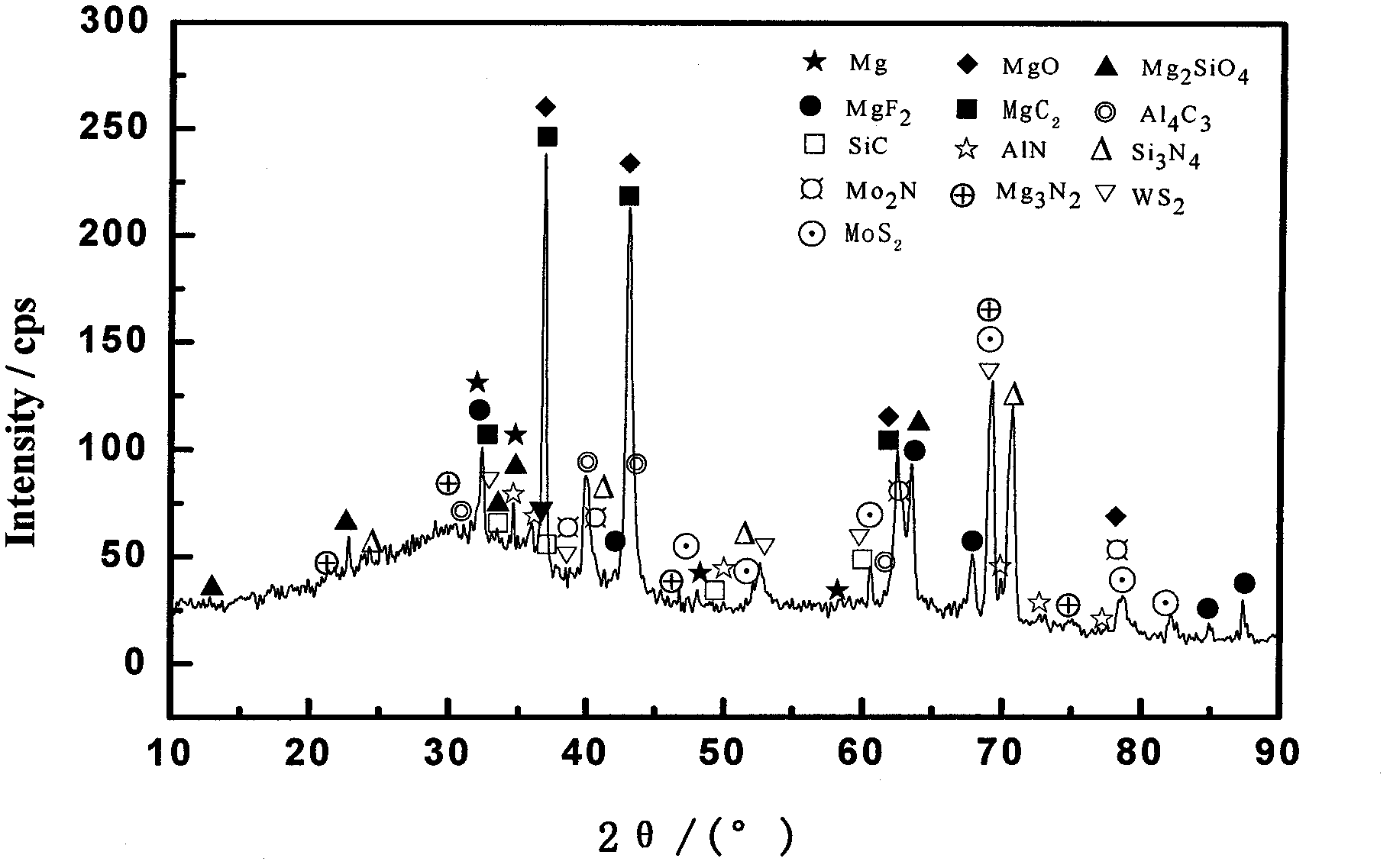

The present invention discloses aluminum silicon deformable aluminum alloy and the preparation method thereof. According to the weight percentages, the alloy contains 9.0-12.6 percent of silicon, 1.5-4.0 percent of copper, 0.3-0.6 percent of magnesium, 0.1-3.5 percent of bismuth, less than 0.30 percent of iron, less than 0.20 percent of zinc, less than or equal to 0.15 percent of impurity, and aluminum as the residual. The raw material is molten and fined in a reflecting smelting furnace, after Al-Sr intermediate alloy modification to the alloy liquid, cast rods are obtained through semi continuous casting, and after hot extrusion and deformation to the cast rods, the aluminum silicon deformable aluminum alloy is produced through forging and T6 heat treatment. After adding the element bismuth into the alloy, the present invention greatly enhances the wear-resisting performance of the alloy, leads the alloy to have self lubricating property, prolongs the service life of the product produced with the alloy, reduces the use cost, and leads the alloy to have the tensile strength of above 390 MPa, the elongation rate after breaking of 6 percent, and the hardness degree of 136-141 HB. The present invention is mainly used for producing vehicle components of wheels, pistons, bearings, and two-side swash plates of vehicles and motorcycles which have high demands on the intensity, the toughness and the abrasion resistance.

Owner:李贞宽 +1

Preparation method of composite film on surface of magnesium alloy and solution formula for preparation method

InactiveCN102321906AImprove performanceImprove carrying capacityAnodisationFriction reductionPlasma electrolytic oxidation

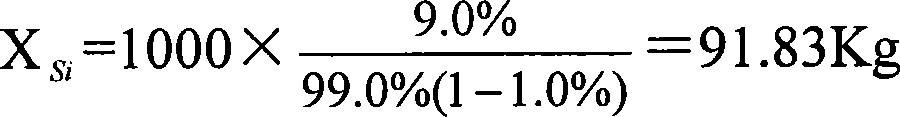

The invention relates to a preparation method of a composite film on the surface of a magnesium alloy and a solution formula for the preparation method. The preparation method comprises the following steps of: (1) placing a polished and washed magnesium alloy work piece into electrolyte containing elements to be permeated and then carrying out plasma electrolytic permeation treatment to form a surface modified layer containing distributed permeated elements on the surface of the magnesium alloy work piece; (2) washing the processed work piece, placing the processed work piece into alkaline electrolyte and carrying out plasma electrolytic oxidation treatment; and finally, obtaining a composite film on the surface of the work piece, wherein the composite film has excellent combination properties, such as high hardness, corrosion resistance, wear resistance and friction reduction. The solution formula for the preparation method is as follows: the electrolyte for carrying out the plasma electrolytic permeation treatment contains 10-140 g / L of compound A containing elements C, N, B and S to be permeated and 2-30 g / L of sodium hydroxide; and the compound A is one or combination of more of formamide, urea, ethanolamine, borax and thiourea.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Preparation method of composite film on surface of metallic material and solution composition for preparation method

InactiveCN102321903AImprove carrying capacityImprove performanceAnodisationFriction reductionPlasma electrolytic oxidation

The invention relates to a preparation method of a composite film on the surface of a metallic material and a solution composition for the preparation method. The preparation method comprises the following steps of: (1) placing a polished and washed metal work piece into electrolyte containing elements to be permeated and then carrying out plasma electrolytic permeation treatment to form a surface modified layer containing distributed permeated elements on the surface of the metal work piece; (2) washing the processed work piece, then placing the processed work piece into alkaline electrolyte and carrying out plasma electrolytic oxidation treatment, and finally, obtaining a composite film on the surface of the work piece, wherein the composite film has excellent combination properties, such as high hardness, corrosion resistance, wear resistance and friction reduction. The solution composition for the preparation method is as follows: the electrolyte for carrying out the plasma electrolytic permeation treatment contains 10-140 g / L of compound A containing elements C, N, B and S to be permeated and 2-30 g / L of sodium hydroxide; and the compound A is one or the combination of more of formamide, urea, ethanolamine, borax and thiourea.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

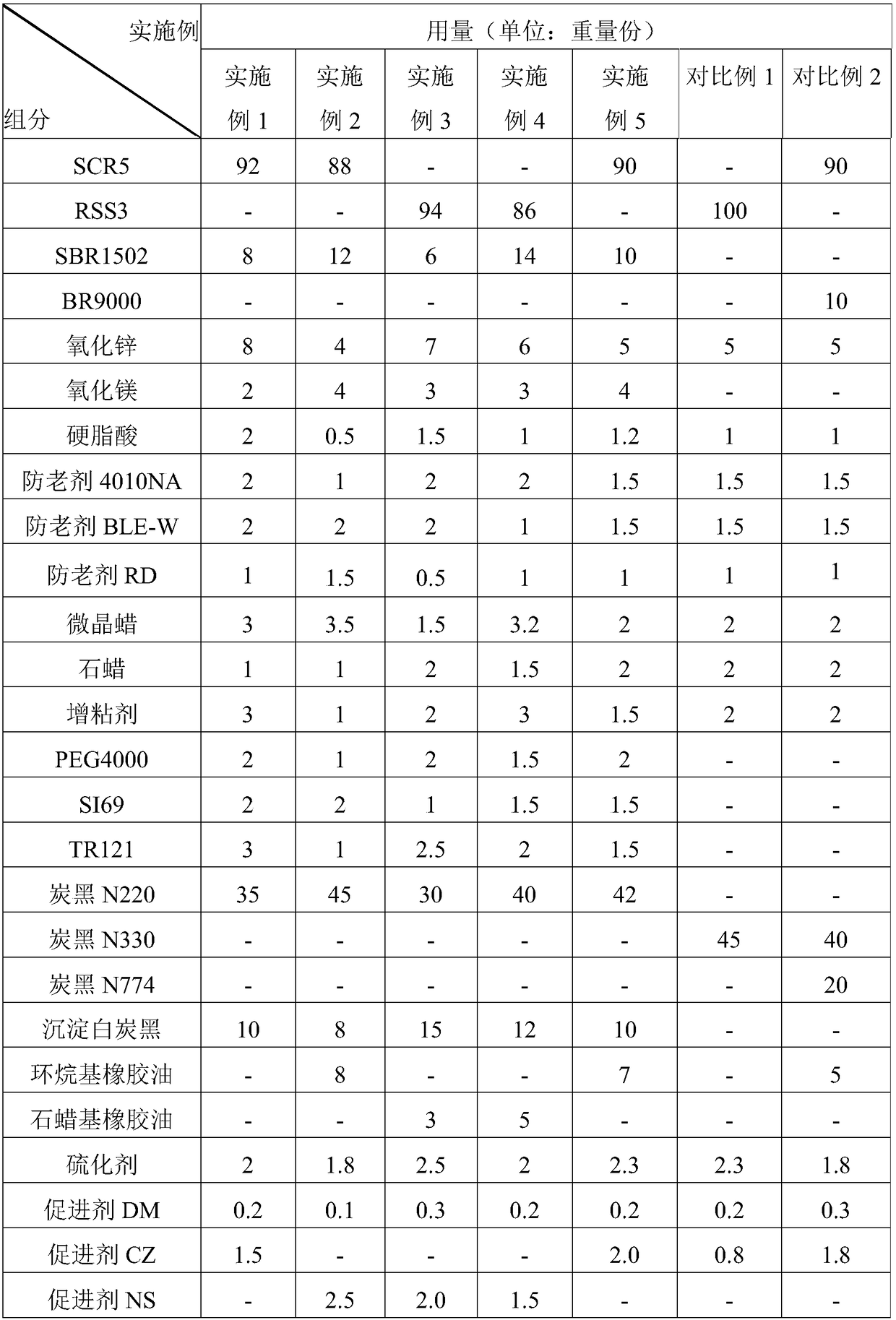

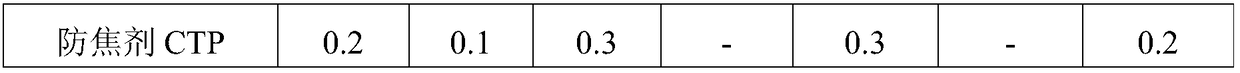

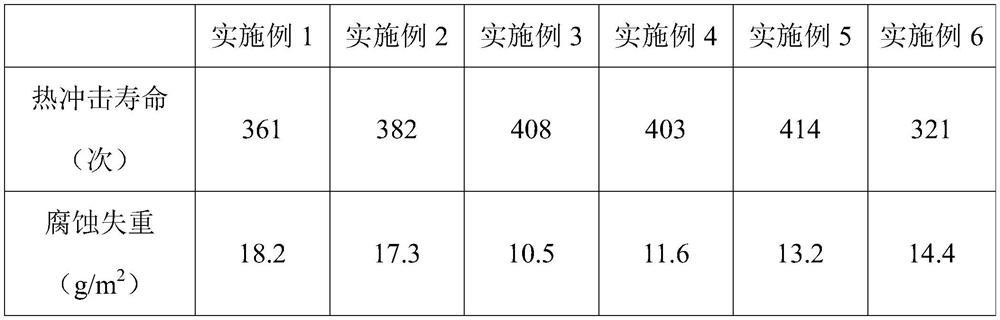

Natural rubber-butadiene styrene rubber composition material and preparation method and application thereof

The invention discloses a natural rubber-butadiene styrene rubber composition material and a preparation method and application thereof. The natural rubber-butadiene styrene rubber composition material comprises, by weight, 86-94 parts of natural rubber, 6-14 parts of butadiene styrene rubber, 4-10 parts of activator A, 0.5-2 parts of activator B, 3-6 parts of antiager, 2-4.7 parts of protection wax, 1-3 parts of tackifier, 1-2 parts of polyethylene glycol, 1.8-2.5 parts of silane coupling agent, 1-3 parts of amide lubricant, 30-45 parts of carbon black, 8-15 parts of white carbon black, 1.8-2.5 parts of vulcanizing agent, 0.1-0.4 part of promoter A and 1.2-2.5 parts of promoter B. A torsion beam bush obtained by using the material is excellent in resistance to impact fatigue and tear fatigue, gentle in fatigue heat generation and easy in heat radiation and is high in fatigue endurance and long in service life in extreme working conditions. The preparation method is simple in step, convenient to operate and suitable for industrial production.

Owner:JIANGSU LUOSHI DAMPING MEMBER CO LTD

Preparation method of diamond-coated drawing mold for water lubrication

ActiveCN105200391AReduce coefficient of frictionStrong corrosion resistanceDrawing profiling toolsChemical vapor deposition coatingCemented carbideAnodic oxidation

The invention discloses a preparation method of a diamond-coated drawing mold for water lubrication. The preparation method comprises corroding the surfaces of inner pores of a hard alloy drawing mold as a base with various pore sizes by hydrogen peroxide dropwisely added with dilute hydrochloric acid so that cobalt is removed, carrying out SiC powder sand blasting, carrying out diamond powder-based grinding coarsening, carrying out cleaning, carrying out diamond coating deposition by a hot-filament CVD method, and orderly carrying out anodic oxidation on the diamond-coated drawing mold under the condition of dilute sulphuric acid and coating grinding polishing on the diamond-coated drawing mold under the aerobic conditions or alternately carrying out the anodic oxidation and the coating grinding polishing on the diamond-coated drawing mold so that the diamond coating has the final surface smoothness Ra less than or equal to 0.1 microns. The diamond-coated drawing mold has high work surface hardness and can resist corrosion. Through the surface hydrophily of the diamond-coated drawing mold, water can form a continuous lubricating film and a self-lubricating graphite ingredient is uniformly distributed on the coating surface. In metal wire drawing and pipe size-reduction wall thickness-reduction drawing, water can replace lubricating oil so that a cost is reduced and ecological environment pollution caused by use of a lot of oil-based lubricating oil is avoided.

Owner:SHANGHAI JIAOYOU DIAMOND COATING

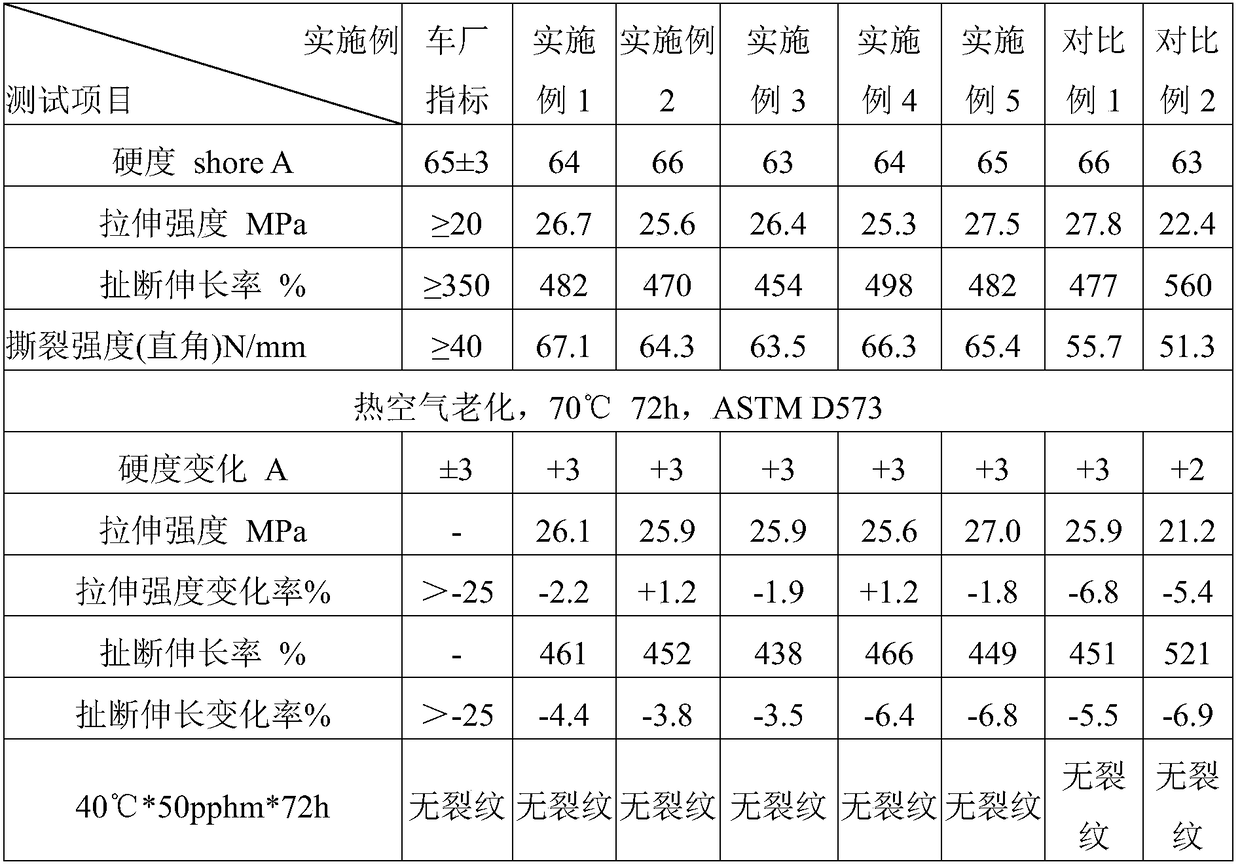

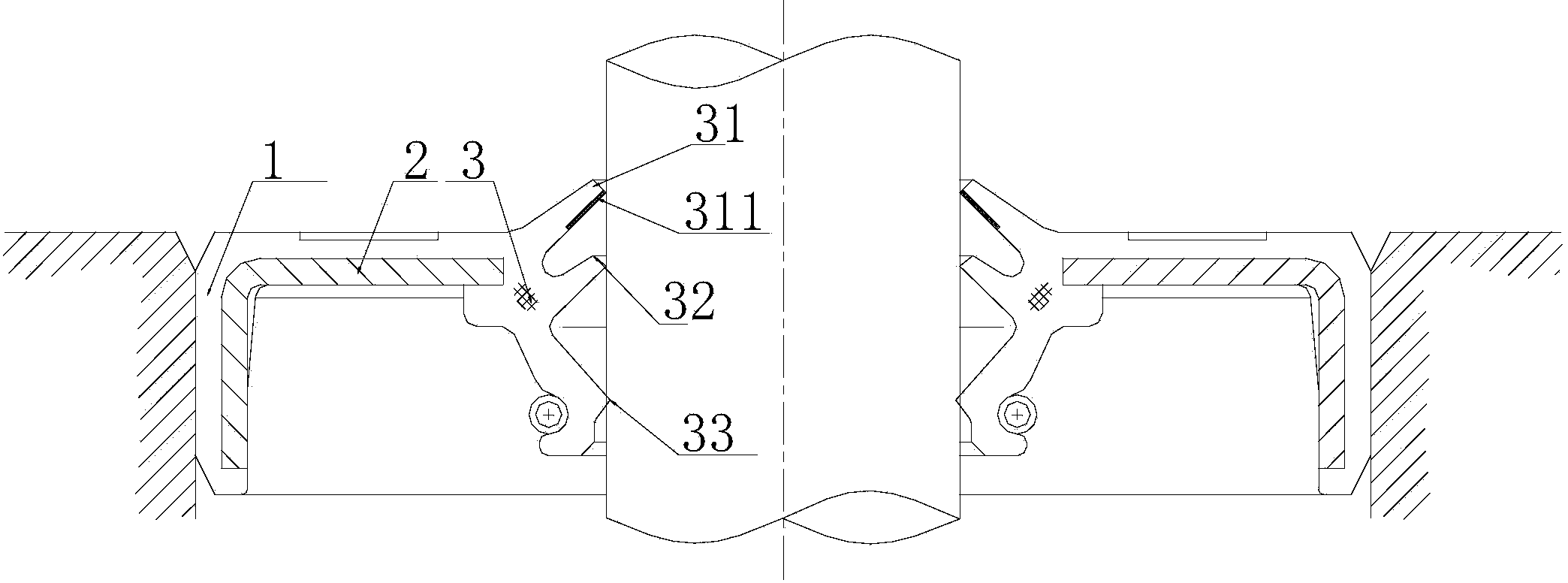

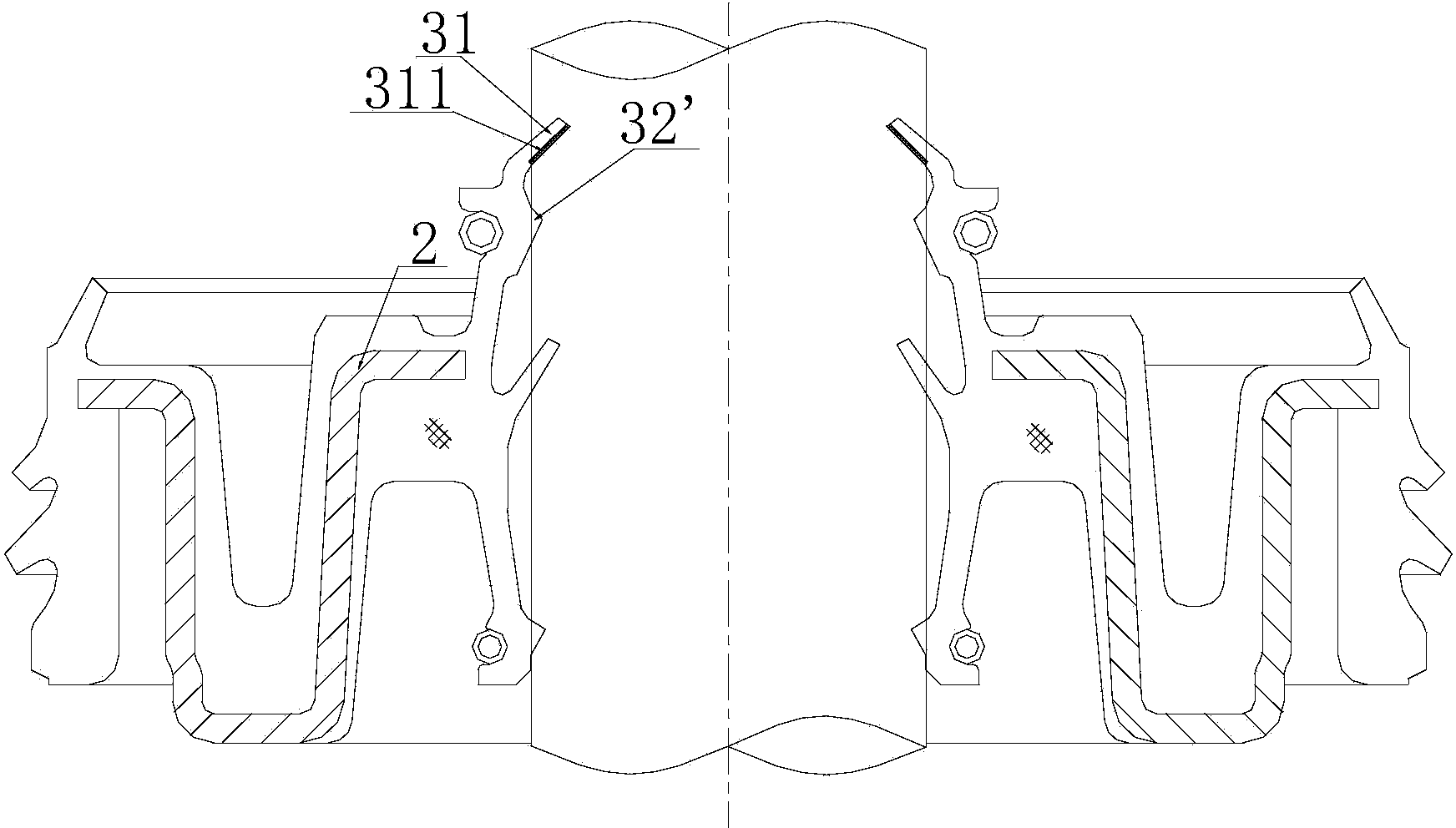

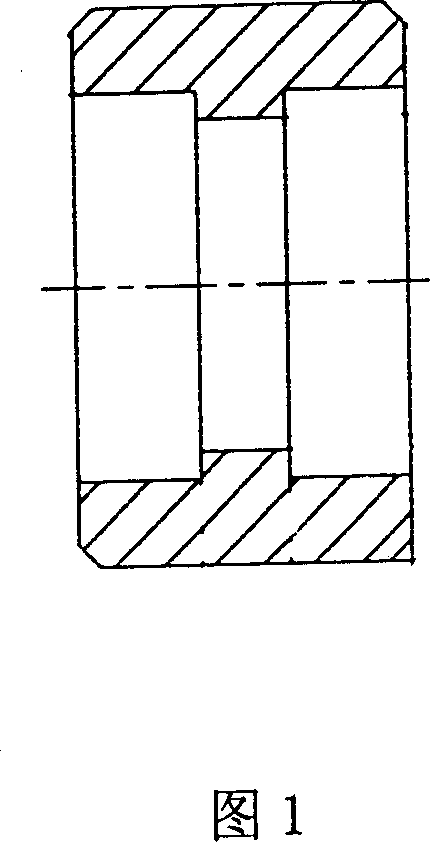

Durable washing machine seal ring

InactiveCN103410976AStrong resistanceHas self-lubricating propertiesEngine sealsInterference fitEngineering

The invention relates to a sealing part, in particular to a durable washing machine seal ring. The durable washing machine seal ring comprises an outer sealing part, a supporting ring and an inner sealing part, the outer sealing part is matched with a mounting base hole, the inner sealing part is matched with a dewatering shaft in an interference fit manner, the supporting ring is arranged between the outer sealing part and the inner sealing part, and is connected with outer sealing part and the inner sealing part, the inner sealing part comprises a first sealing lip, a second sealing lip and a third sealing lip, the second sealing lip is located between the first sealing lip and the third sealing lip, wherein the first sealing lip comprises a flexible PTFE (polytetrafluoroethylene) sheet. The sealing stability of the first sealing lip is enhanced, and thereby the durable washing machine seal ring can have a stable sealing effect when in use for a long time.

Owner:QINGDAO TKS SEALING IND

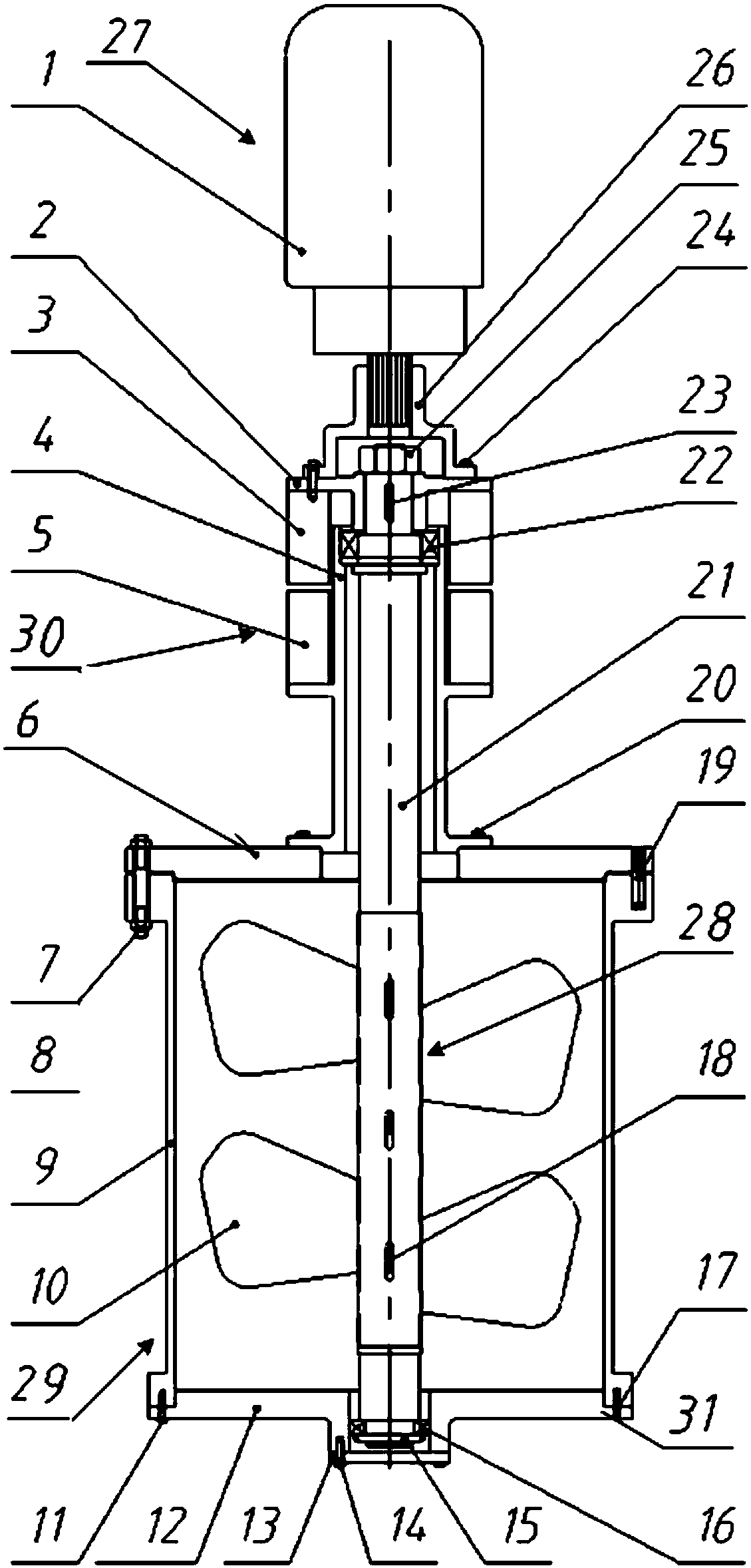

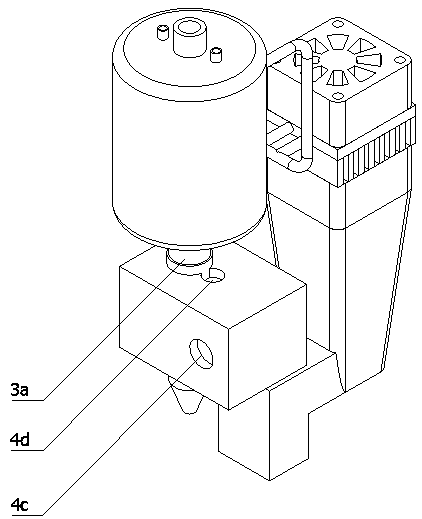

Permanent magnet suspending stirrer for high-temperature heavy load working condition

PendingCN108067150ANon-abrasive friction surfaceSmall resistance torqueTransportation and packagingMixer accessoriesEngineeringHeavy load

The invention provides a permanent magnet suspending stirrer for a high-temperature heavy load working condition, which comprises a driving device, a stirring axis structure, a stirring kettle and a permanent magnet suspending component; the stirring kettle comprises a stirring kettle body, an upper cover plate of the stirring kettle fixed at the upper end opening of the stirring kettle body, anda lower cover plate of the stirring kettle fixed at the lower end opening of the stirring kettle body; the stirring axis structure comprises a bearing base and a stirring axis; the bearing base is fixed at the upper part of the upper cover plate of the stirring kettle, the upper and lower ends of the stirring axis are supported at the inner part of the bearing base and the center hole of the lowercover plate of the stirring kettle through a roil bearing I and a roll bearing II; the upper end of the stirring axis is fixed with a lower connecting flange fixedly connected with the driving device, and the permanent magnet suspending component is arranged between the lower connecting flange and an outer step plate of the bearing base. The stirring axis structure can realize non-contact suspending location axially through mutually exclusive magnetic force of the permanent magnet suspending component, and adopts roll bearing location on a radical direction; thus the problems of quick wear ofaxis shoulder end face of the existing device, big resistance torque, and need of big power motor, and others are solved.

Owner:BAOJI TAIHUA MAGNETIC ELECTROMECHANICAL TECH RES INST CO LTD

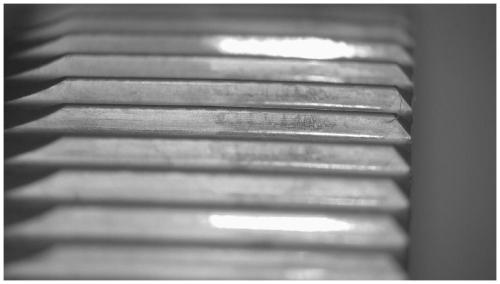

Al2O3-TiC/Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die and preparation method thereof

The invention relates to a drawing die and particularly relates to an Al2O3-TiC / Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die and also relates to a preparation method of the laminated ceramic drawing die. The technical scheme is as follows: the Al2O3-TiC / Al2O3-TiC-CaF2 self-lubricating laminated ceramic drawing die mainly comprises an Al2O3-TiC layer ceramic material and an Al2O3-TiC-CaF2 layer ceramic material, wherein the Al2O3-TiC layer ceramic material comprises the following components according to the volume ratio: 45% of aluminum oxide, 50% of titanium carbide, 0.5% of molybdenum, 4.5% of nickel and trace magnesium oxide and yttrium oxide; the Al2O3-TiC-CaF2 layer ceramic material comprises the following components according to the volume ratio: 30% of aluminum oxide, 60% of titanium carbide and 10% of calcium fluoride. The Al2O3-TiC layer ceramic material and the Al2O3-TiC-CaF2 layer ceramic material are laminated according to the design requirements of different wire processing sizes for the ceramic drawing die, and the ceramic die obtained after sintering retains higher hardness and strength, meanwhile, the toughness of the die is improved, and in addition, the whole die has a self-lubricating characteristic in the drawing process, so that the wear reducing and resisting effects are remarkable.

Owner:UNIV OF JINAN

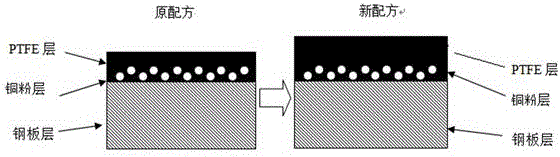

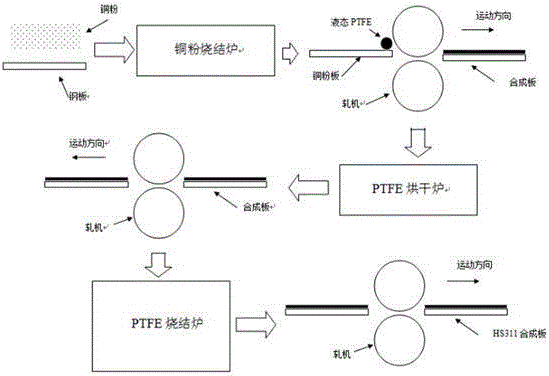

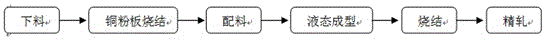

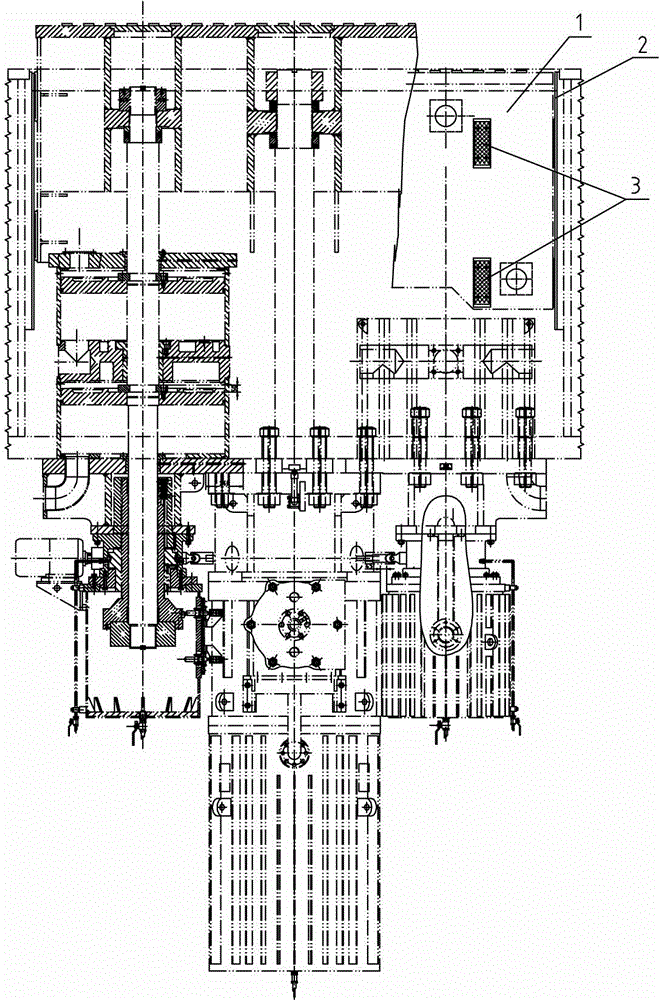

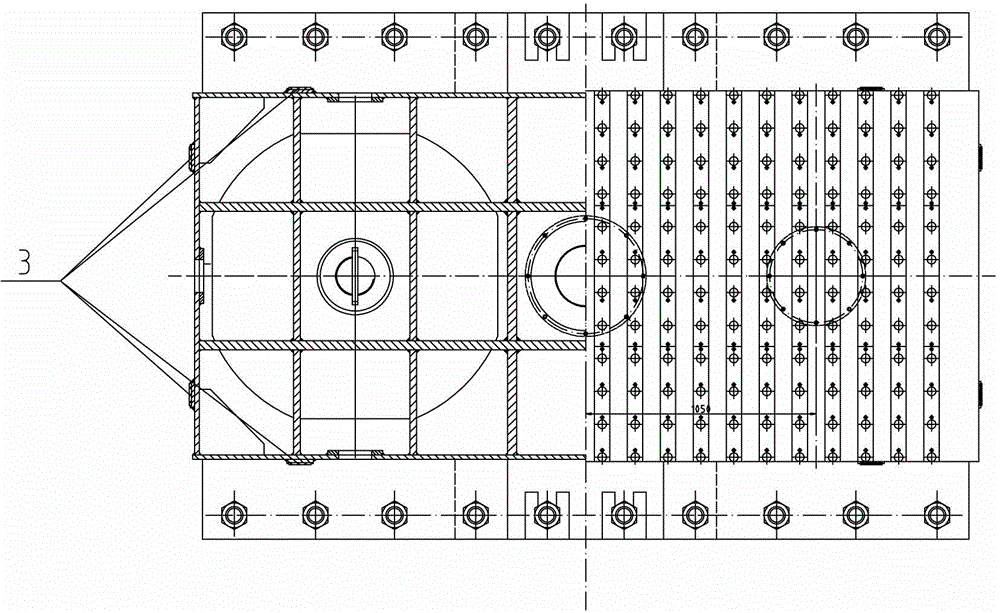

Production process for HS311 steel-based copper plastic self-lubrication material

ActiveCN105689708AHas self-lubricating propertiesGood weather resistanceCopperTemperature resistance

The invention discloses a production process for an HS311 steel-based copper plastic self-lubrication material. The production process specifically comprises the following steps of blanking, copper powder plate sintering, burdening, liquid formation, sintering and finish rolling. The production process has the beneficial effects that a PTFE steel-based copper plastic composite material has the advantages of the self-lubrication property, good weathering resistance, high(low)-temperature resistance, pollution resistance and the like of common solid lubrication materials, and further has the outstanding advantages of being long in life and high in bearing capacity. The PTFE steel-based copper plastic composite material is suitable for vibration and impact load occasions. The PTFE steel-based copper plastic composite material can also be directly machined into a standard part, and usage is convenient.

Owner:ANHUI HANSHENG NEW METAL TECH

Air cushion top crown guide rail self-lubricating device

InactiveCN104456028AHas self-lubricating propertiesEasy to wearEngine lubricationInterior spaceCushion

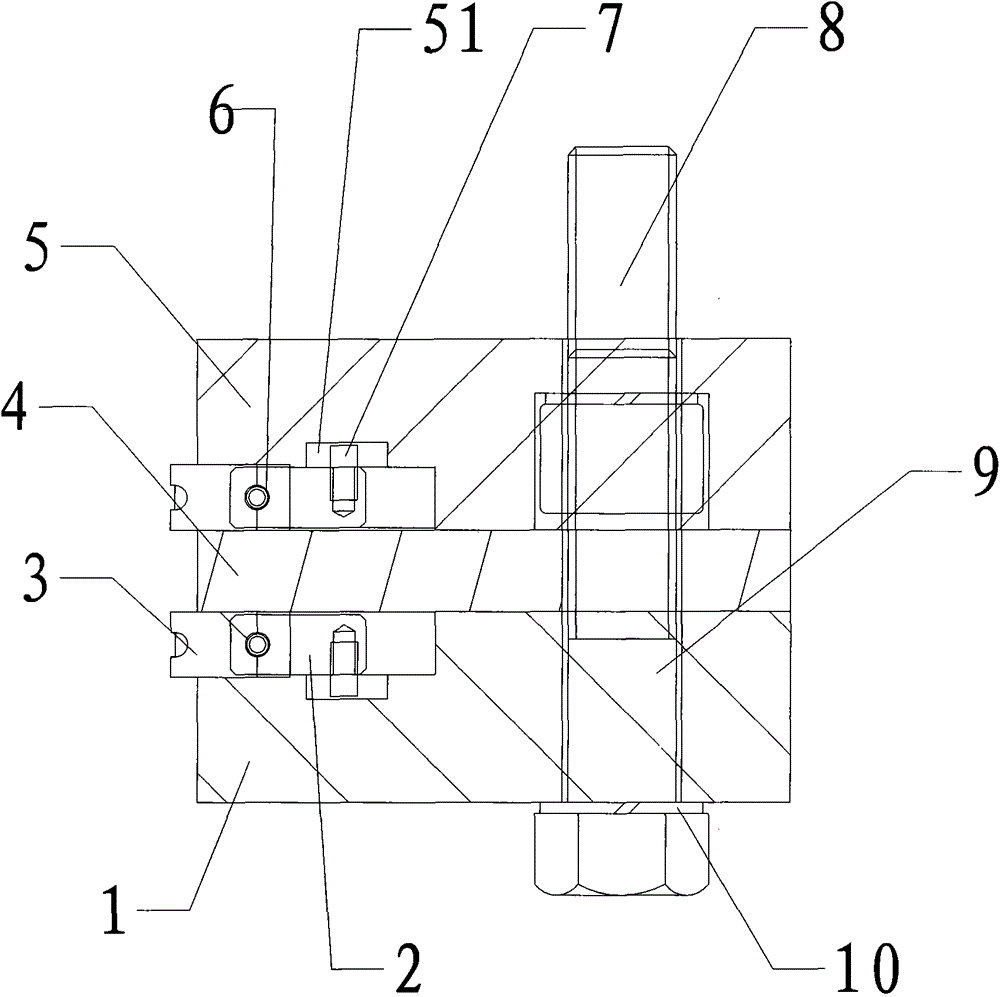

The invention discloses an air cushion top crown guide rail self-lubricating device. The air cushion top crown guide rail self-lubricating device comprises a top crown and a base. Self-lubricating guide rail plates are installed on the top crown. Base guide rail plates are installed on the base. The self-lubricating guide rail plates and the base guide rail plates slide relatively. The air cushion top crown guide rail self-lubricating device is used for connection between an air cushion top crown or a hydraulic cushion top crown of a press and a base guide rail. The air cushion top crown guide rail self-lubricating device is structurally characterized in that the air cushion top crown and the base slide relatively, lubricating oil does not need to be supplied externally, and wear-proof plates inlaid into the top crown guide rails have the self-lubricating characteristics. A top crown load is normally an eccentric load, the number of movement times is large, and the top crown guide rails and the base guide rails are prevented from being abraded by each other severely. Self-lubricating materials reduce environmental pollution, the installation time is shortened, internal space is saved, and the manufacturing cost and the use cost are greatly reduced.

Owner:JIER MACHINE TOOL GROUP

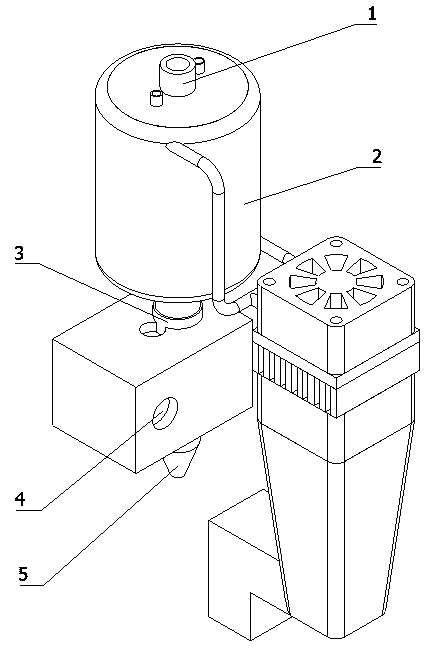

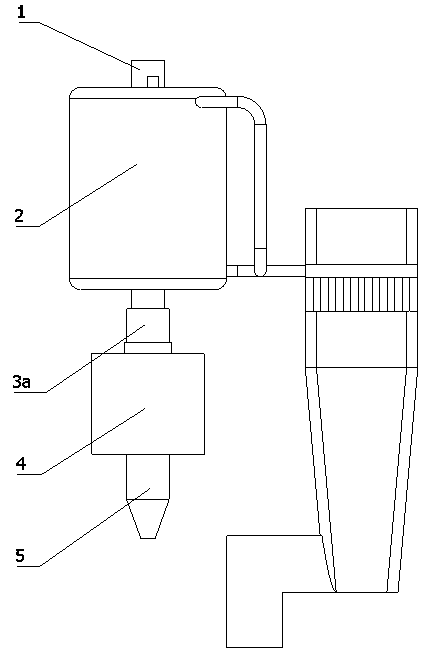

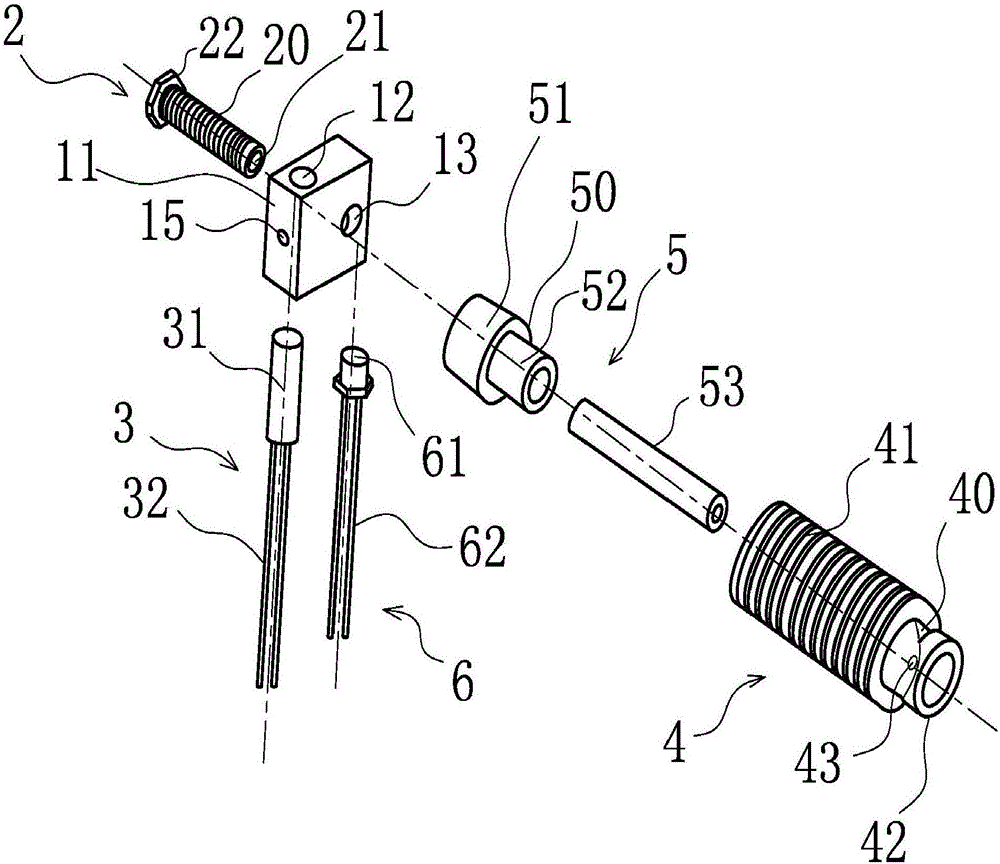

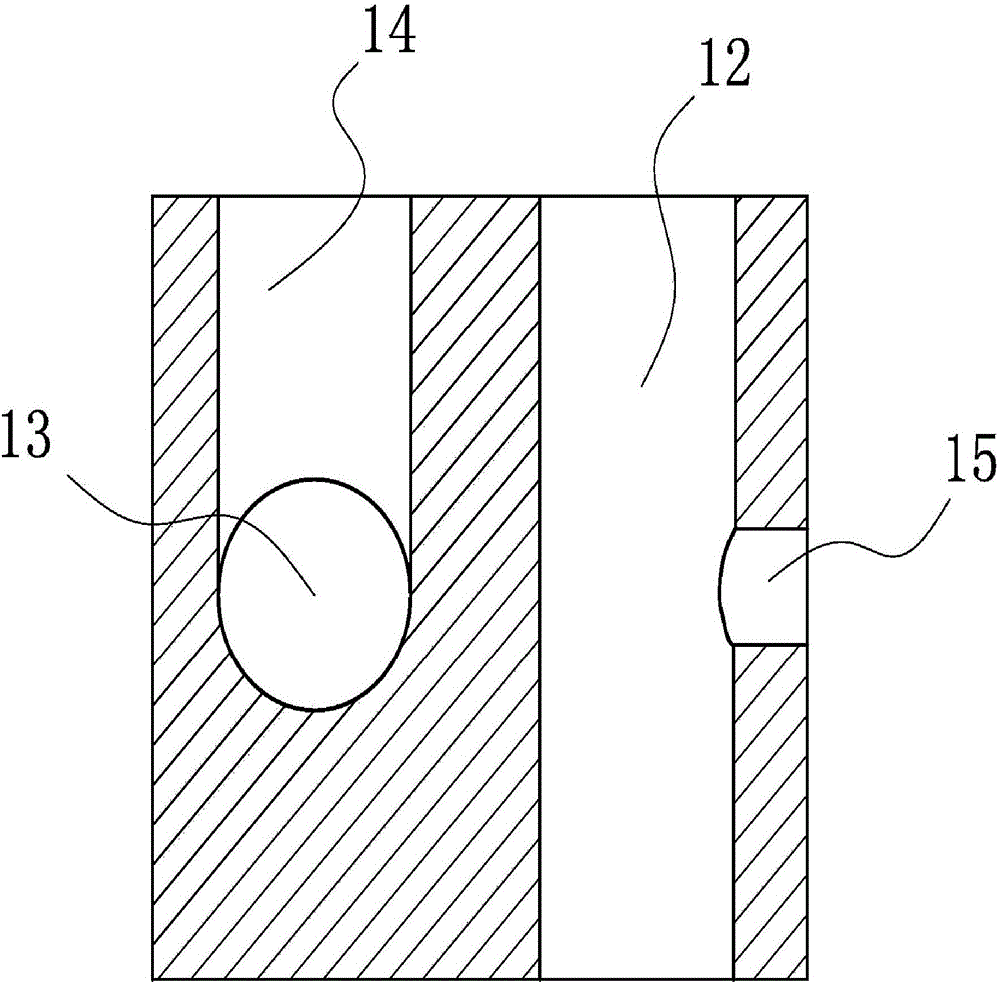

High-temperature 3D printing head

InactiveCN111113890AGuaranteed patencyImprove hot melt effectManufacturing heating elements3D object support structuresThermodynamicsComputer printing

The invention relates to the technical field of 3D printing and particularly relates to a high-temperature 3D printing head. The high-temperature 3D printing head comprises a material guide pipe, a heat dissipating assembly, a heat insulation assembly, a heating assembly and a discharging spray nozzle. The initial end of the material guide pipe is fixedly installed on a printer body and communicates with a feeding mechanism, the heat dissipating assembly is connected to the outer wall of the material guide pipe in a sleeving mode, the heat insulation assembly, the heating assembly and the discharging spray nozzle are connected with the material guide pipe in sequence, and the material guide pipe is made of a PTFE material. According to the technical scheme, the problem that an existing 3Dprinting head is prone to blockage is solved, the hot melting effect is good, the smoothness of the printing head is better ensured, the heat dissipating effect is good, blockage caused by expansion deformation of a wire in the printing head is avoided, and the manpower consumed for cleaning the printing head is reduced.

Owner:浙江高米网络科技有限公司

Composite coating for lead-based reactor pump impeller and preparation method of composite coating

PendingCN114318208AImprove wear resistanceExtended service lifeMolten spray coatingNuclear energy generationThermal dilatationChemical composition

The invention provides a composite coating for a lead-based reactor pump impeller. The composite coating adopts a three-layer gradient composite structure; the innermost layer of the three-layer gradient composite structure is composed of a high-entropy alloy coating matched with a metal matrix in chemical composition and thermal expansion coefficient, the outermost layer of the three-layer gradient composite structure is composed of a Ti3AlC2 coating good in abrasion resistance and excellent in lead alloy erosion corrosion resistance, the middle layer of the three-layer gradient composite structure is composed of a high-entropy alloy and a Ti3AlC2 composite coating, and the mass ratio of Ti3AlC2 in the middle layer is 40-60%. Wherein the high-entropy alloy is composed of Fe, Cr, Ni, Al and Ti according to the molar ratio of 1: 1: 1: 1: (0-0.4). The invention also provides a preparation method of the coating. Through the gradient structure design, the thermal stress between the coating and a metal matrix can be relieved, the binding force between the coating and the matrix is improved, and the friction resistance and corrosion resistance of the coating are considered, so that the high-flow-velocity lead alloy erosion corrosion resistance of the coating is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

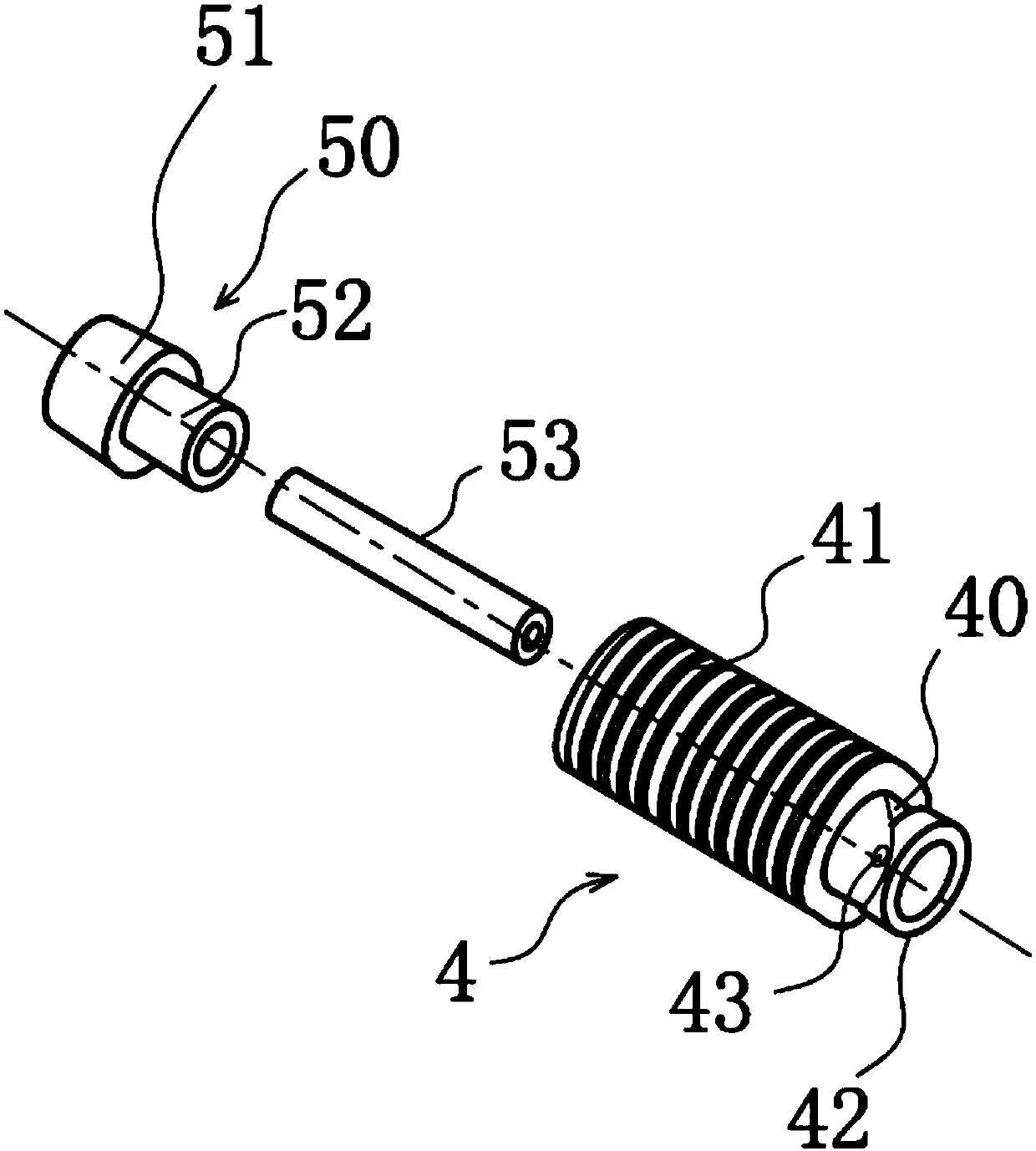

Efficient heat dissipating and blockage preventing 3D printing nozzle

InactiveCN106363921AHigh silk production efficiencyAvoid conductionAdditive manufacturing apparatusHigh energyHeat sink

The invention provides an efficient heat dissipating and blockage preventing 3D printing nozzle. The 3D printing nozzle comprises a heating mechanism; a nozzle module and a heating module are arranged in the heating mechanism; the heating mechanism is connected with a cylindrical heat dissipating mechanism; a thermal insulating mechanism is arranged between the heating mechanism and the heat dissipating mechanism, and is communicated with the nozzle module and the heat dissipating mechanism; the heat dissipating mechanism includes a cylindrical heat dissipating pipe; multiple heat dissipating pieces are uniformly arranged on the outer wall of the heat dissipating pipe; a small pipe is inserted in the heat dissipating pipe, and is screwed with the heat dissipating pipe; a clamping port is formed in one end, far from the small pipe, of the heat dissipating pipe; the connected places of the clamping port and the end part of the heat dissipating pipe form a shrinking port; and one end of a guide pipe is inserted in the small pipe, and the other end is inserted in the heat dissipating pipe to bond with the shrinking port. The efficient heat dissipating and blockage preventing 3D printing nozzle solves such technical problems as high energy consumption, low nozzle wire discharge effici8ency, easiness in nozzle blockage and difficult consumable extrusion in the prior art.

Owner:海南兴兴智能科技有限公司

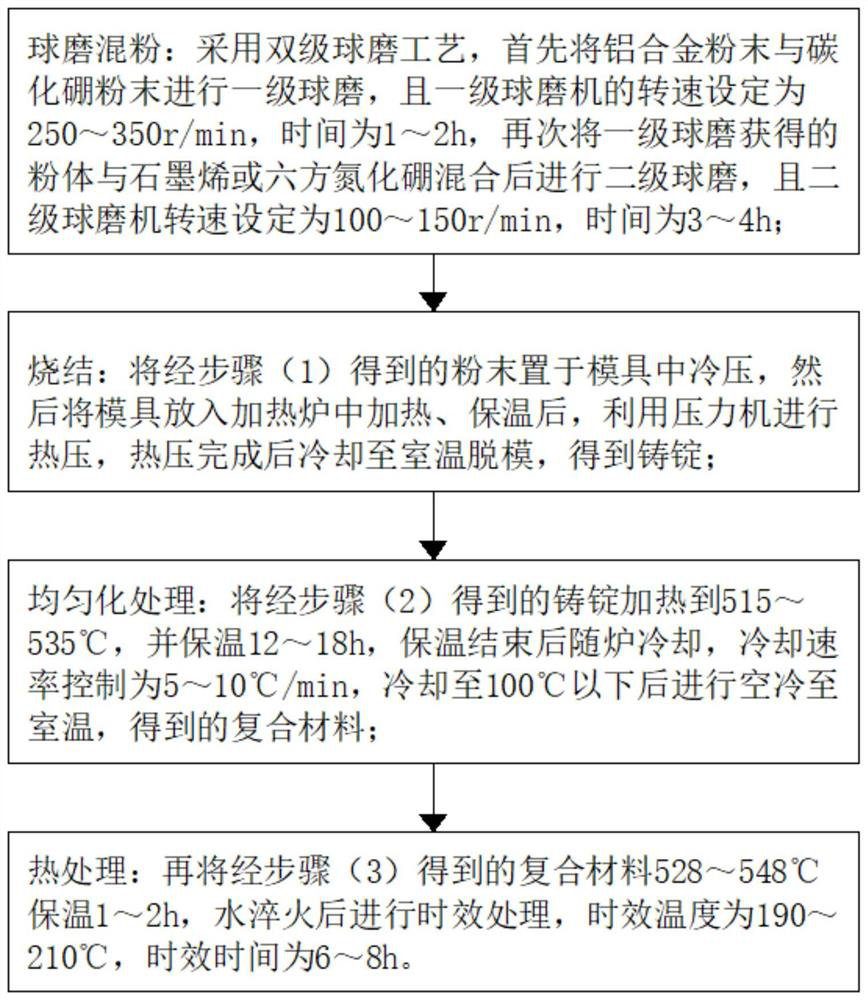

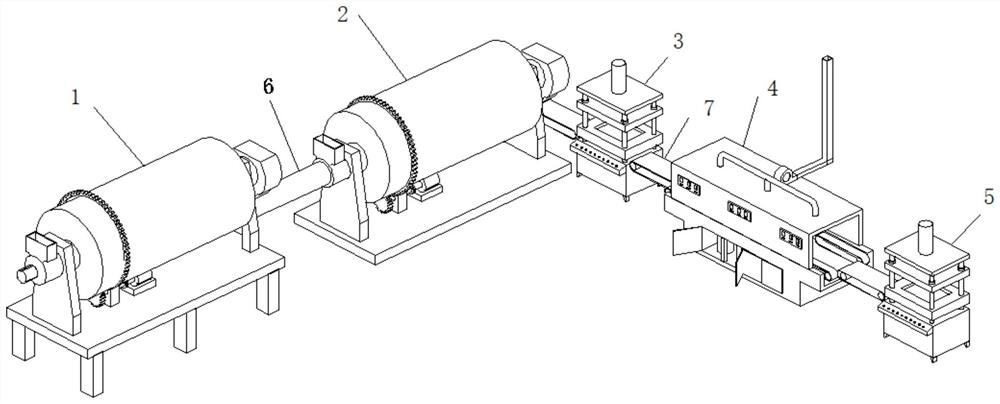

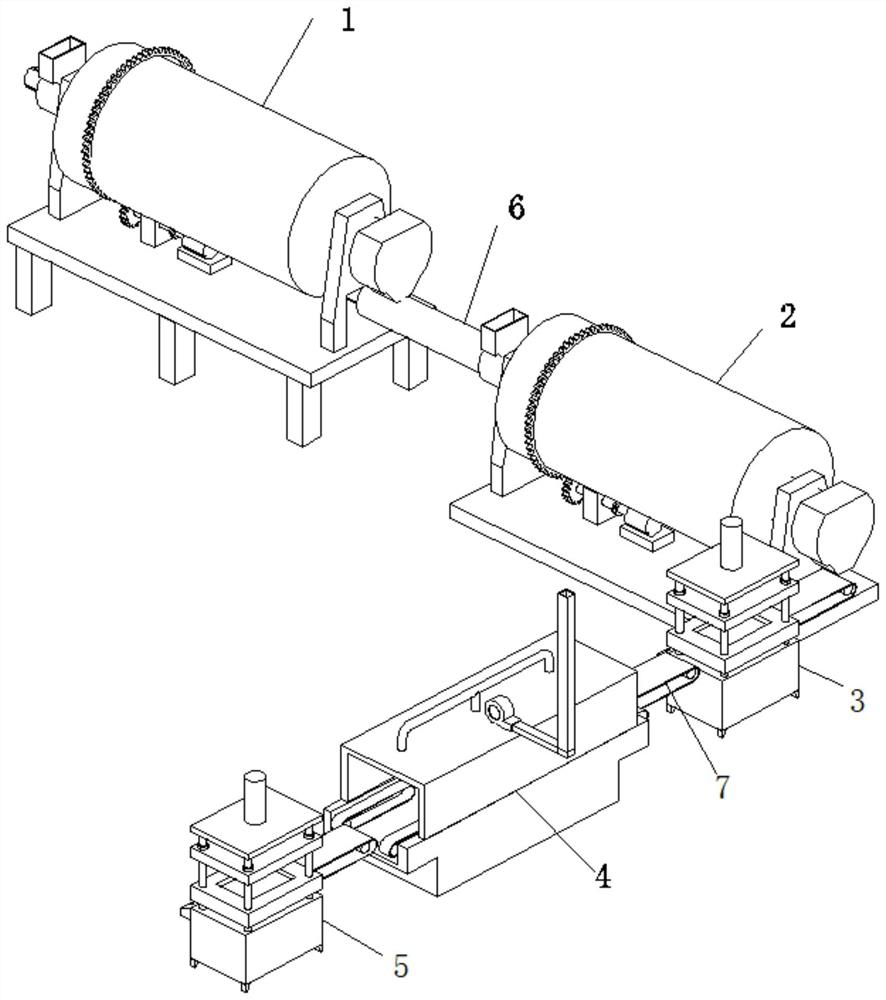

Aluminum-based composite material and preparation method thereof

ActiveCN113684410AImprove wear resistanceHas self-lubricating propertiesIncreasing energy efficiencyHexagonal boron nitrideBoron nitride

The invention discloses an aluminum-based composite material and a preparation method thereof, and relates to the technical field of metal-based composite materials. The aluminum-based composite material comprises the following raw materials by volume percentage: 15-25% of boron carbide, 3-5% of graphene or hexagonal boron nitride, and 70-82% of an aluminum alloy. The preparation method of the aluminum-based composite material comprises the following steps of ball milling and powder mixing, sintering, homogenization treatment and heat treatment. A preparation device comprises a first-stage ball mill, a second-stage ball mill, a cold pressing forming machine, a heating furnace and a hot pressing forming machine which are sequentially connected, a powder conveyor is connected between the first-stage ball mill and the second-stage ball mill, and the cold pressing forming machine, the heating furnace and the hot pressing forming machine are conveyed through a conveying line. The density of the prepared aluminum-based composite material is 2.5-2.6g / cm<3>, the boron carbide reinforcement in the composite material is the third hard ceramic particles in the nature, so that the wear resistance is excellent; and meanwhile, the aluminum-based composite material has the self-lubricating characteristic, graphene and hexagonal boron nitride are both of a layered structure, and the composite material can be effectively spread on the surface to form a self-lubricating film in the working state.

Owner:福建祥鑫轻合金制造有限公司

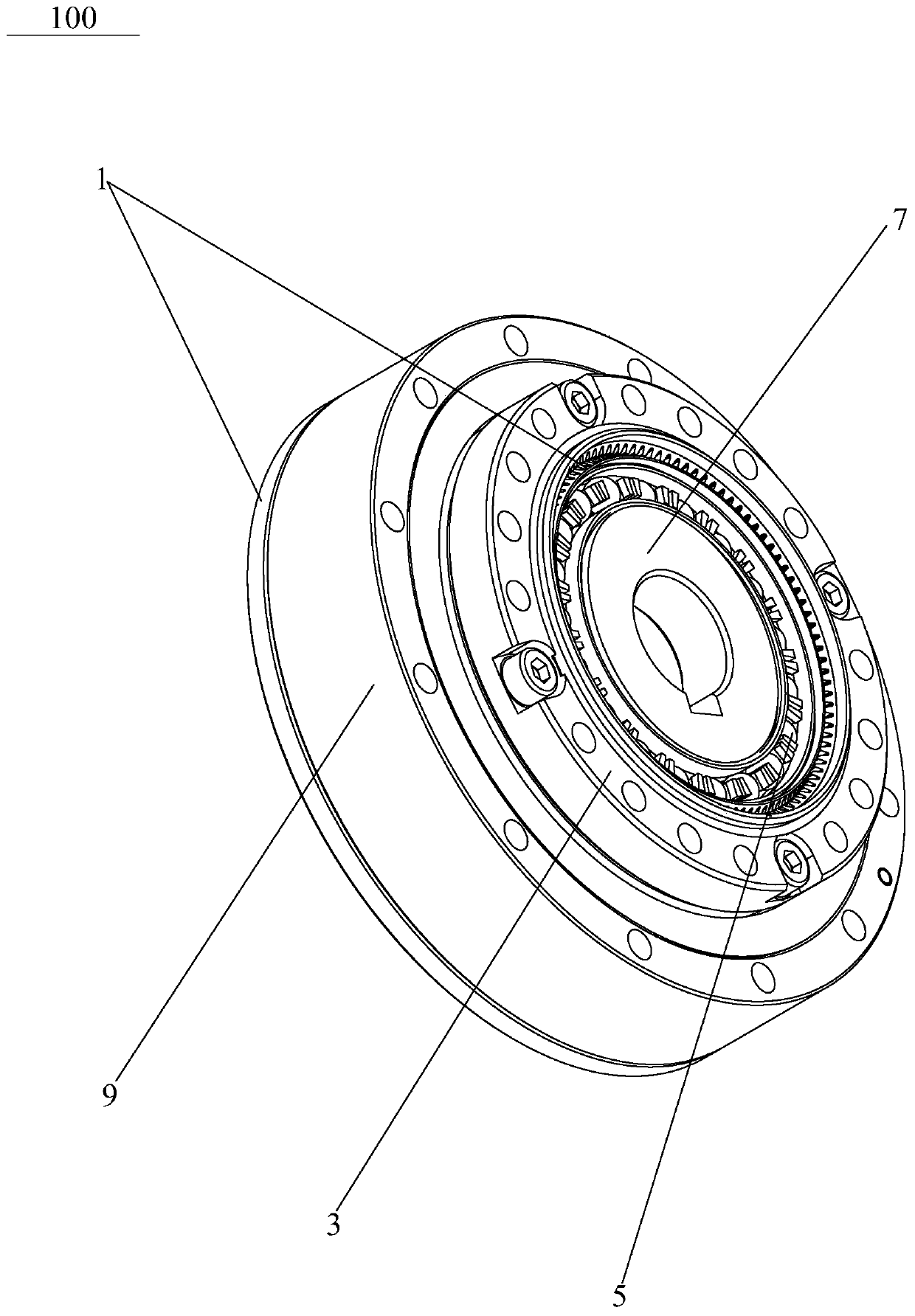

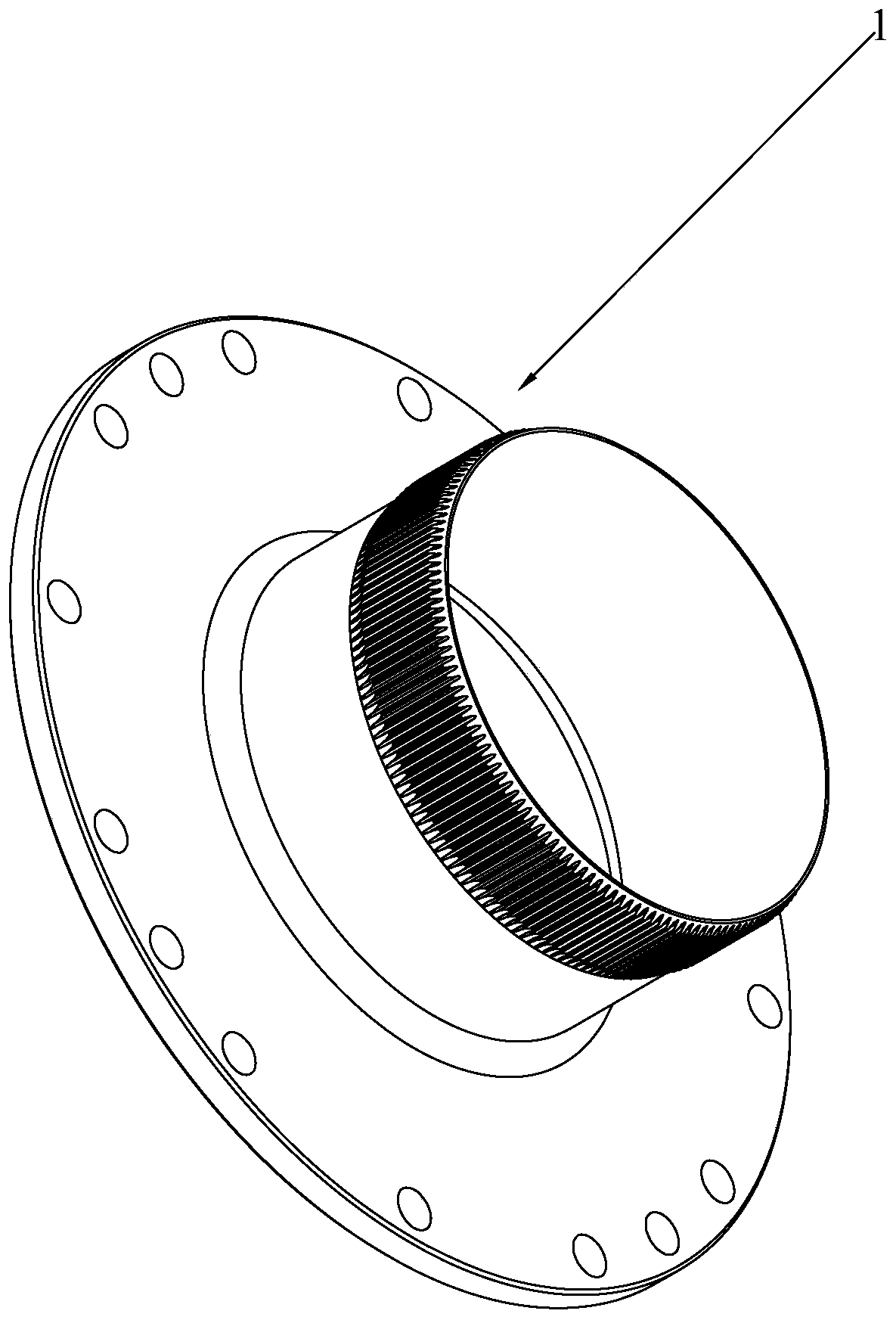

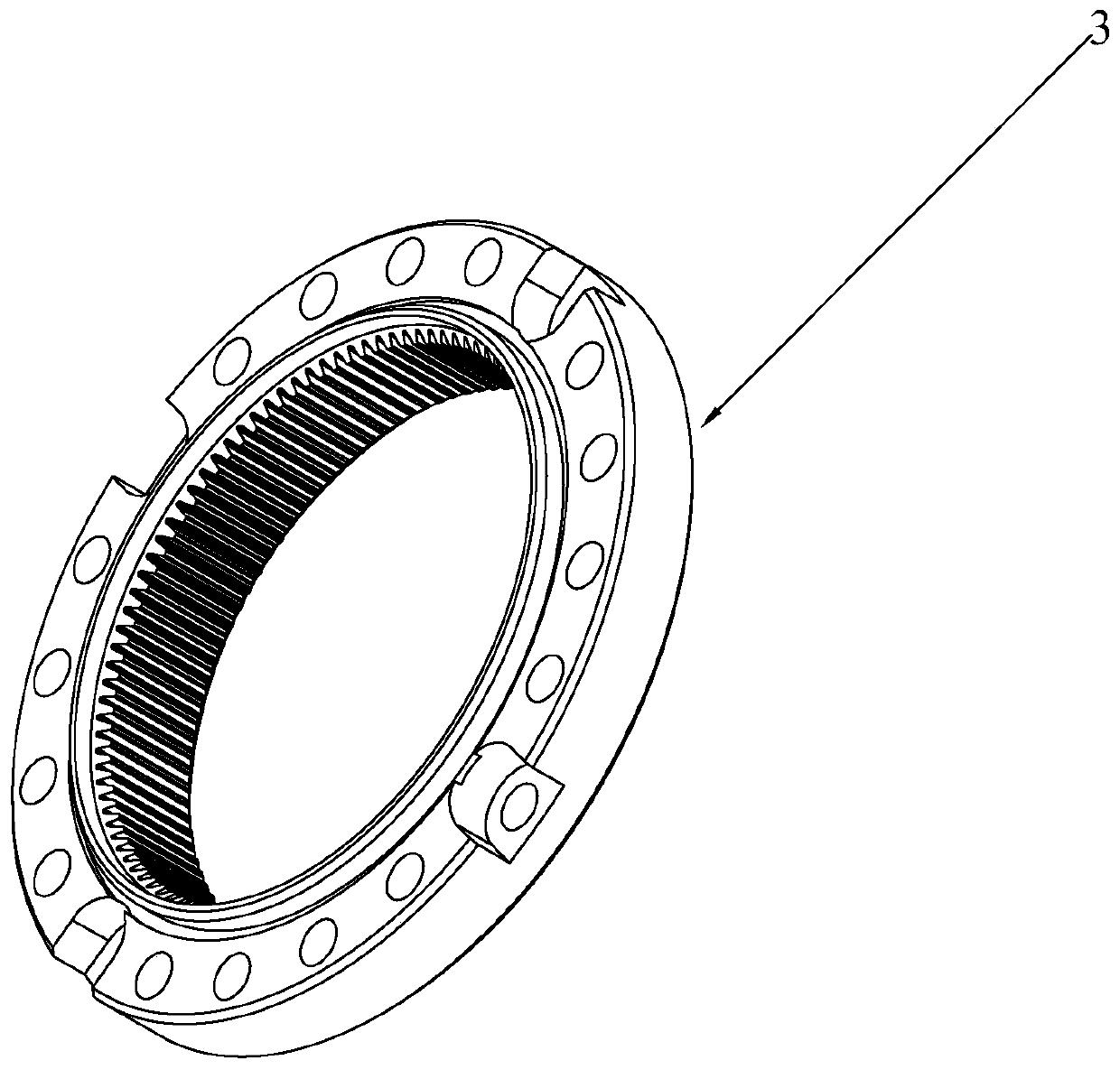

Harmonic reducer flexible gear with DLC coating

InactiveCN111503239AWear-resistantHigh hardnessVacuum evaporation coatingSputtering coatingDlc coatingReduction drive

The invention relates to a harmonic reducer flexible gear with a DLC coating. A transitional layer and a working layer are distributed on the surface of a base body material of the harmonic reducer flexible gear with the DLC coating in sequence from inside to outside; the internal thickness of the transitional layer is 0.4-0.6 microns; the material of the transitional layer is chromium or titanium; the working layer is the DLC coating with thickness of 0.8-3 microns, SP2 bond content of 70-95% and SP3 bond content of 5-30%; and the surface hardness of the flexible gear is 1200-2500 HV, and thesurface friction coefficient of the flexible gear is 0.1.

Owner:东莞市国森科精密工业有限公司

Surface treatment process of extending shaft sealing section

InactiveCN113136538AUniform thicknessImprove bindingMolten spray coatingSpecial surfacesMechanical engineeringMaterials science

The invention discloses a surface treatment process of an extending shaft sealing section. The process comprises the following steps that 1, copper powder is evenly laid onto the outer circular surface of the extending shaft sealing section by adopting a thermal spraying method to form a transition layer; and 2, plastic powder is laid onto the transition layer through a thermal spraying or spraying and sintering method, and a wear-resistant layer is formed. The surface treatment process has the advantages that the plastic powder adopted in the process has the self-leveling characteristic in the cooling process after hot melting, the surface of the wear-resistant layer can be smoother and flatter due to the characteristic, and the sealing effect of an oil seal on the extending shaft sealing section is improved. Besides, the plastic powder adopted in the process also has a self-lubricating property, so that when the extending shaft sealing section treated by the method and the oil seal form a sealing pair together, the frictional wear can be reduced, and the service life of the oil seal can be prolonged.

Owner:ANHUI QUANCHAI ENGINE

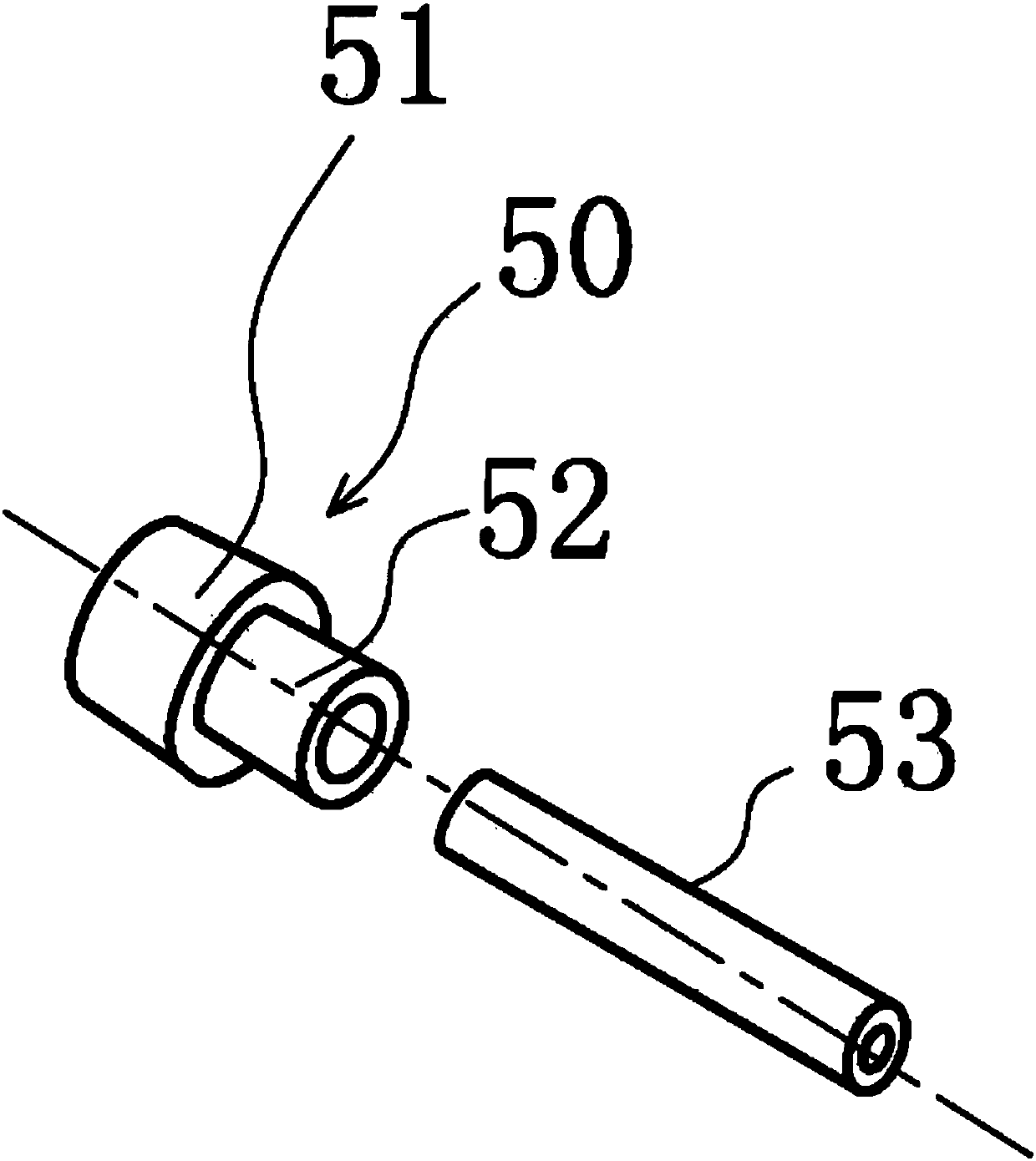

Manufacturing method of bearing and manufacturing method of harmonic reducer

InactiveCN110657162AReduce weightHigh strengthToothed gearingsBearing componentsNanoceramicEngineering

The invention provides a manufacturing method of a bearing and a manufacturing method of a harmonic reducer. In the manufacturing method of the bearing, nano ceramic materials are adopted for machining of rolling balls or rolling columns, and vacuum graphite electroplating is carried out on the surface; machining of an inner ring and an outer ring comprises the steps that a rod is sequentially subjected to forge pressing, annealing, spinning, intermediate treatment, accurate grinding of the end face, the inner circle and the outer circle, accurate grinding and grinding of a bearing channel andaftertreatment; and then, assembling is carried out, the precision, stability and wear resistance of the bearing manufactured through the manufacturing method are greatly improved, temperature increase and weight are reduced, and the service life of the bearing is greatly prolonged. Meanwhile, after a flexible wheel and a rigid wheel of the harmonic reducer are forged and pressed, spinning is carried out, a product can have good toughness and is not prone to breaking, through combination with a series of treatment of accurate grinding of the end face, the inner circle and the outer circle andultrasonic treatment, the dimensional precision is improved, surface roughness is reduced, friction is reduced, and temperature increase is reduced. Thus, the harmonic reducer has high precision, long service life and high durability.

Owner:DONGGUAN WORLD PRECISION MACHINERY

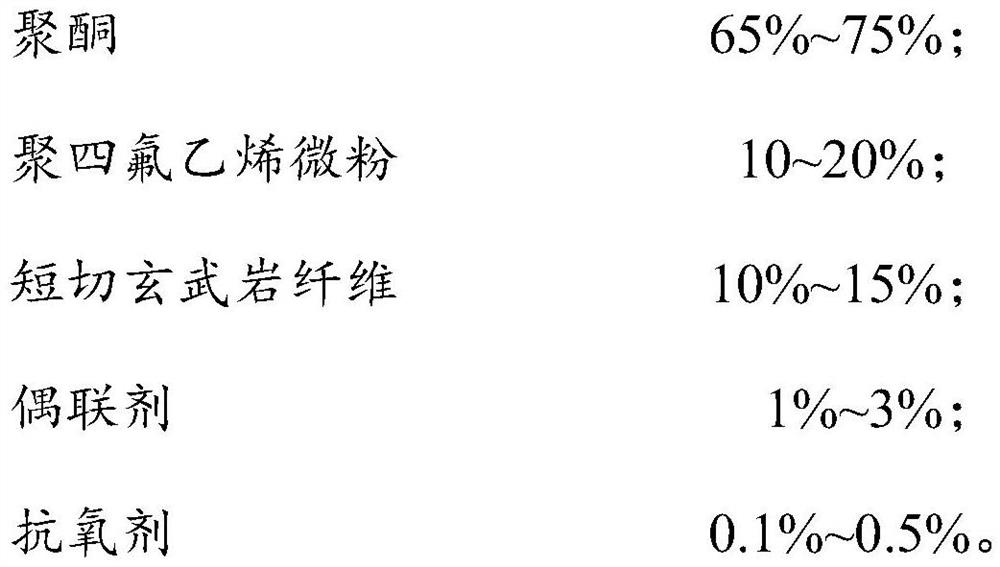

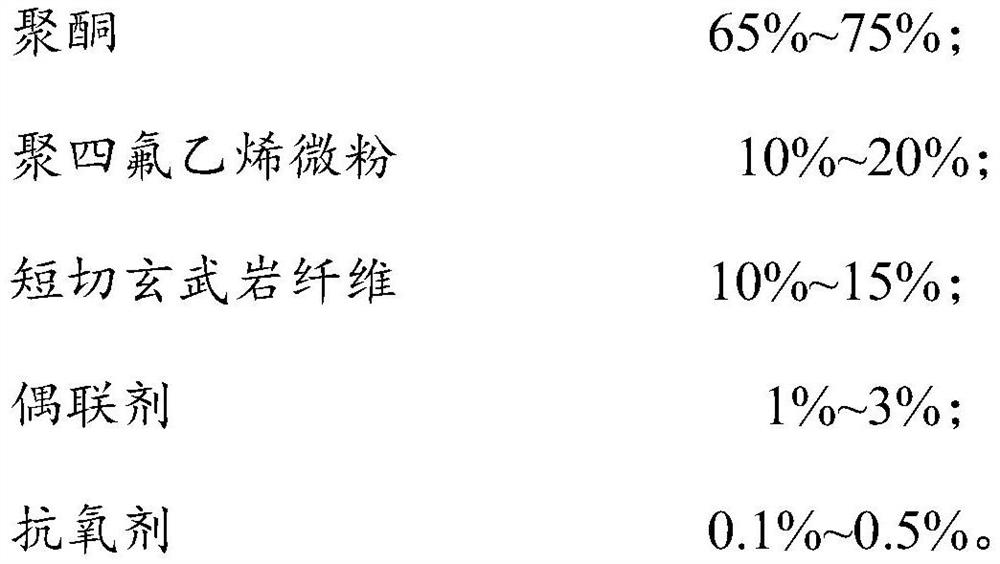

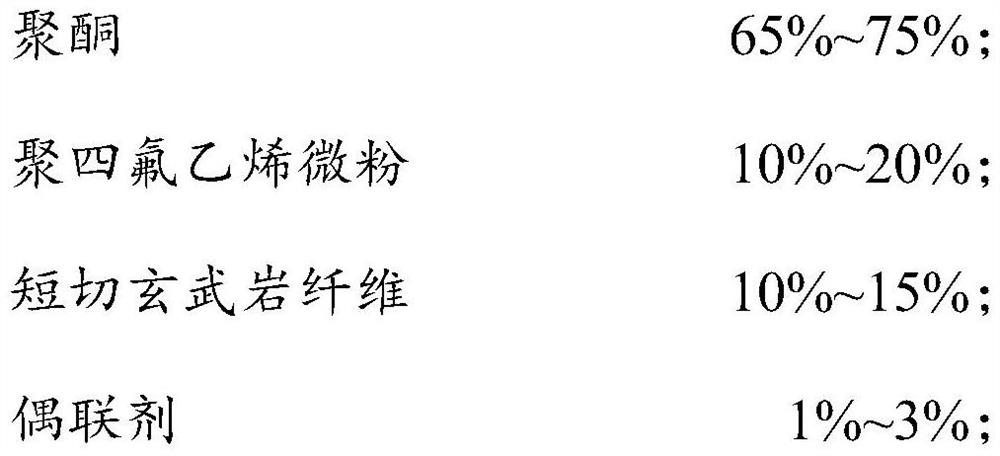

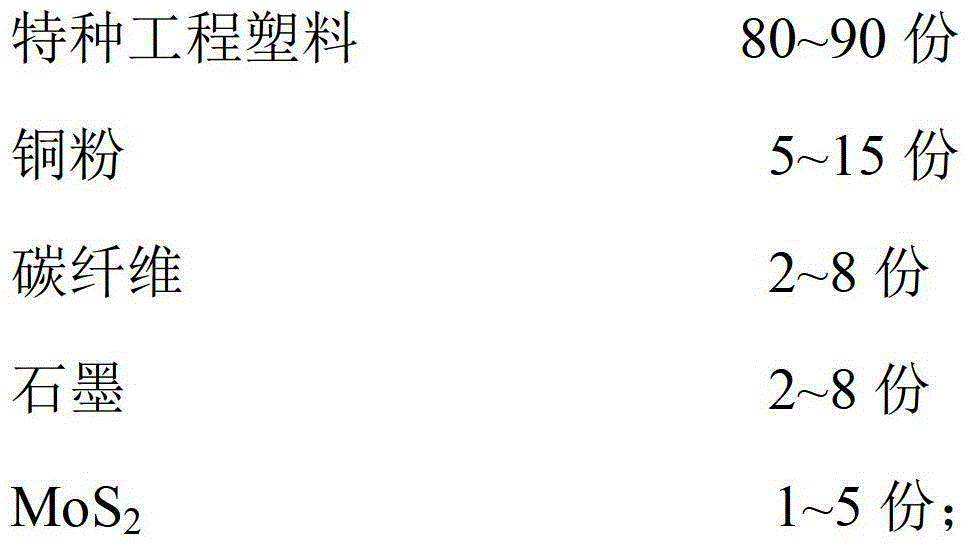

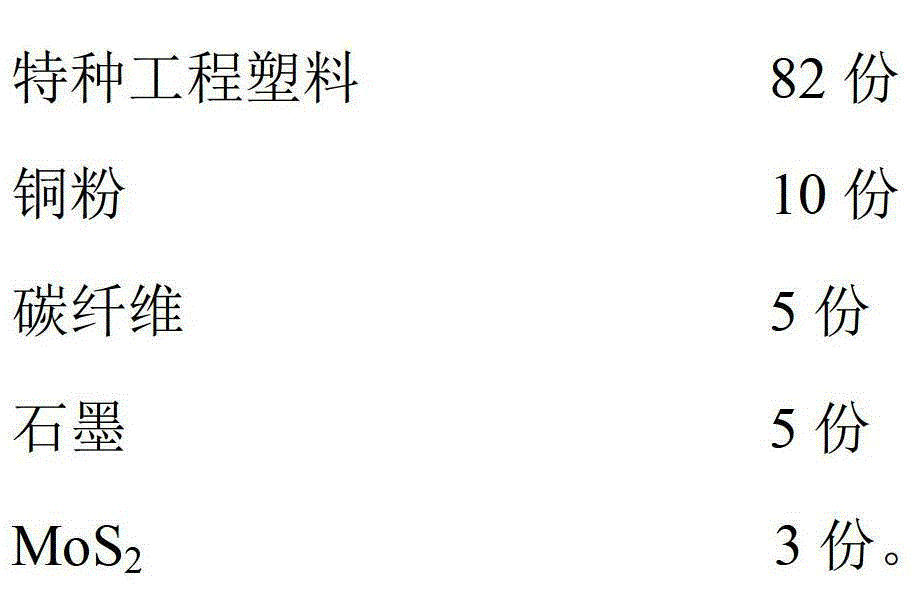

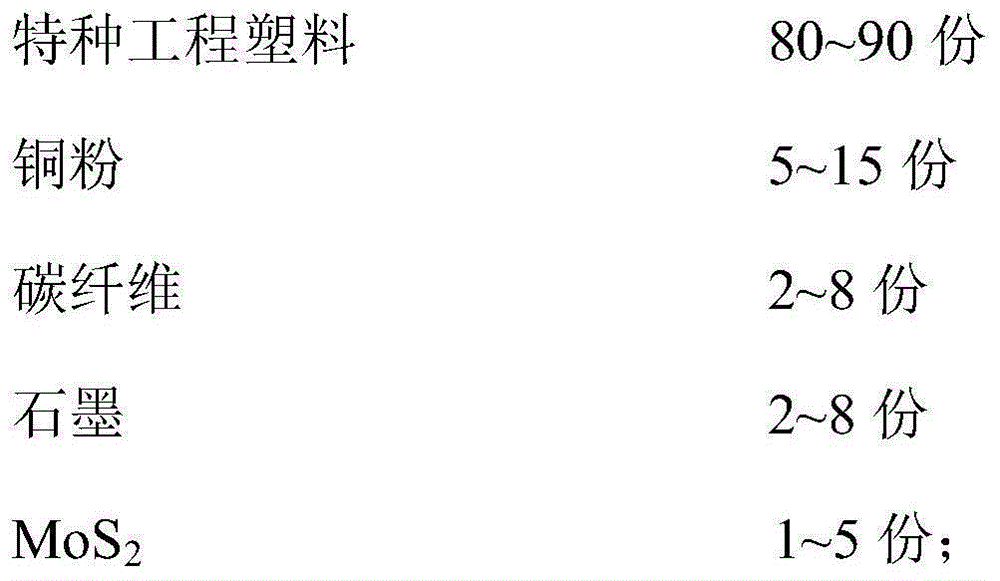

High-temperature-resistant and high-humidity-resistant self-lubricating polyketone composition and application thereof

PendingCN113372708AImprove mechanical propertiesHas self-lubricating propertiesPolymer chemistryBasalt fiber

The invention discloses a high-temperature-resistant and high-humidity-resistant self-lubricating polyketone composition and application thereof, and the high-temperature-resistant and high-humidity-resistant self-lubricating polyketone composition comprises the following components in percentage by weight: 65-75% of polyketone; 10%-15% of polytetrafluoroethylene micro powder; 10%-15% of chopped basalt fiber; 1%-3% of a coupling agent; and 0.1%-0.5% of an antioxidant. The high-temperature-resistant and high-humidity-resistant self-lubricating polyketone composition can be prepared into high-temperature-resistant and high-humidity-resistant self-lubricating workpieces through an injection molding or extrusion molding process, and is particularly used for manufacturing automobile parts. The high-temperature-resistant and high-humidity-resistant self-lubricating workpiece prepared through the method has high mechanical performance, the bending modulus can reach 3417 MPa, the bending strength can reach 94 MPa, the friction coefficient can be as low as 0.12, the abrasion loss is as low as 3.6 mm < 3 >, the hydrolysis resistance is good, after a hydrothermal aging experiment, the bending modulus can still be kept 93% or above, the bending modulus can reach 3363 MPa, the bending strength can reach 85 MPa, and the product has self-lubricating property and longer service life.

Owner:DONGFENG COMML VEHICLE CO LTD

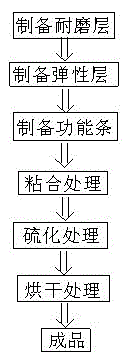

A kind of preparation method of high-performance dragon belt

InactiveCN103465601BHigh bonding strengthImprove practicalityLaminationLamination apparatusVulcanizationUltimate tensile strength

The invention discloses a preparation method of a high-performance tangential belt. The preparation method comprises the following steps: (a) preparing an abrasion-resistant layer; (b) preparing an elastic layer; (c) preparing a functional bar; (d) carrying out adhesion treatment; (e) carrying out vulcanization treatment; and (f) drying. The invention discloses a preparation method of the high-performance tangential belt. According to the preparation method, working procedure arrangement is reasonable, implementation is simple and convenient, cost is appropriate, the interlayer bonding intensity of the prepared tangential belt is high, and favorable intensity, elasticity and abrasion resistance are shown during the using process; meanwhile, the abrasion resistant layer has a certain self-lubricating performance due to a functional bar structure added in the abrasion resistant layer, and the abrasion quantity of the abrasion resistant layer is effectively controlled, so that the tangential belt is suitable for various high-speed spinning devices, and the practicability of the tangential belt is improved greatly.

Owner:CHANGSHU JIANHUA WEAVING

Method for manufacturing steel inlaid guide rail sheet of large tonnage tester for metal tension test

InactiveCN100343651CHigh hardnessGuaranteed service lifeShaping toolsFurnace typesChemical treatmentDecomposition

Owner:MTS IND SYST CHINA

Printing head heat-insulation connecting piece for 3D (Three-dimensional) printer

InactiveCN107672166AAvoid lostReduce energy consumptionApplying layer meansHigh energyPipe insulation

The invention provides a printing head heat-insulation connecting piece for a 3D (Three-dimensional) printer. The printing head heat-insulation connecting piece for the 3D printer solves the technicalproblems of high energy consumption, untimely consumable softening and the like caused by a poor heat insulation effect in the prior art, and comprises a heat-insulation connection pipe. The heat-insulation connection pipe is formed by a large pipe and a small pipe formed integrally; cross sections of the large pipe and the small pipe are in 'T' shapes; bore diameters of the large pipe and the small pipe are the same; and the large pipe and the small pipe are plastic pipes with low thermal conductivity. The printing head heat-insulation connecting piece for the 3D printer provided by the invention has the advantages that a heat insulation effect is good, the energy consumption can be reduced, consumables are prevented from being softened untimely, the yielding efficiency of the 3D printeris improved, and the like.

Owner:CHANGSHA YUANDAHUA INFORMATION TECH CO LTD

Preparation method of diamond-coated drawing die suitable for water lubrication

ActiveCN105200391BAvoid pollutionImprove working conditionsChemical vapor deposition coatingEcological environmentAlloy

The invention discloses a preparation method of a diamond-coated drawing mold for water lubrication. The preparation method comprises corroding the surfaces of inner pores of a hard alloy drawing mold as a base with various pore sizes by hydrogen peroxide dropwisely added with dilute hydrochloric acid so that cobalt is removed, carrying out SiC powder sand blasting, carrying out diamond powder-based grinding coarsening, carrying out cleaning, carrying out diamond coating deposition by a hot-filament CVD method, and orderly carrying out anodic oxidation on the diamond-coated drawing mold under the condition of dilute sulphuric acid and coating grinding polishing on the diamond-coated drawing mold under the aerobic conditions or alternately carrying out the anodic oxidation and the coating grinding polishing on the diamond-coated drawing mold so that the diamond coating has the final surface smoothness Ra less than or equal to 0.1 microns. The diamond-coated drawing mold has high work surface hardness and can resist corrosion. Through the surface hydrophily of the diamond-coated drawing mold, water can form a continuous lubricating film and a self-lubricating graphite ingredient is uniformly distributed on the coating surface. In metal wire drawing and pipe size-reduction wall thickness-reduction drawing, water can replace lubricating oil so that a cost is reduced and ecological environment pollution caused by use of a lot of oil-based lubricating oil is avoided.

Owner:SHANGHAI JIAOYOU DIAMOND COATING

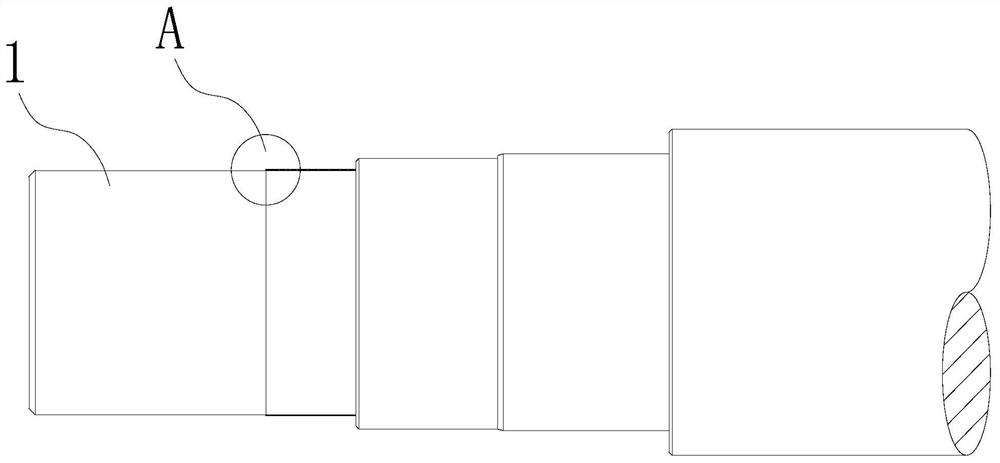

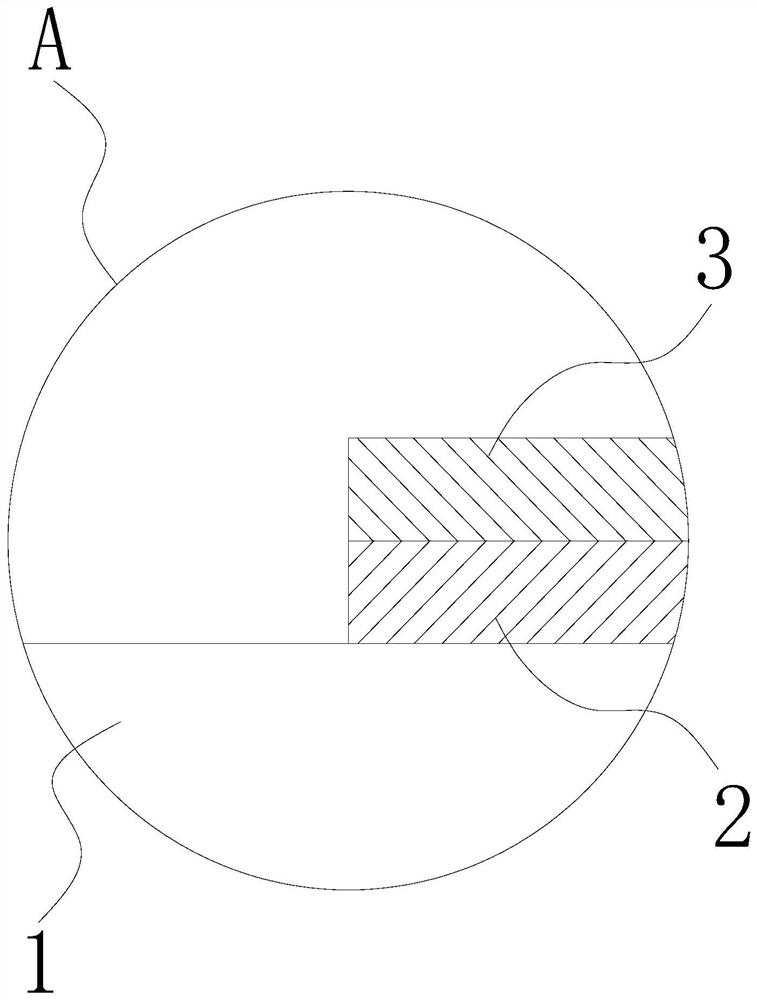

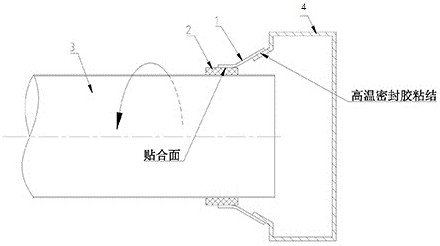

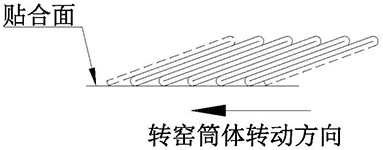

Flexible graphite folding type rotary kiln sealing device

The invention discloses a flexible graphite folding type rotary kiln sealing device. The flexible graphite folding type rotary kiln sealing device comprises a folding belt, a wear-resistant ring, a rotary kiln cylinder and a cover, the wear-resistant ring is fixed in the circumferential direction of the rotary kiln cylinder in a sleeved mode, the folding belt is in a conical ring shape, the small end of the folding belt is tightly attached to the wear-resistant ring, the large end of the folding belt is fixedly connected with the cover in a bonded mode through high-temperature-resistant glue, gas inside and outside a rotary kiln is isolated, and sealing is formed. The folding belt is made of a graphite film, the thickness of the folding belt ranges from 0.2 mm to 1 mm, the highest heat resistance of the folding belt is larger than or equal to 500 DEG C, the folding belt is in a conical ring shape formed by folding multiple layers in the direction of the bevel edge, the thickness of each fold ranges from 1 mm to 5 mm, and the inclination angle between each fold and a outer circle line of a rotary kiln cylinder 3 ranges from 5 degrees to 15 degrees. A wear-resistant ring 2 is made of a hard graphite ring, and the thickness of the wear-resistant ring 2 is 10-40mm. The sealing device has the advantages of simple structure, good sealing effect, long service life, high deformation compensation capability and the like.

Owner:CSSC NANJING LUZHOU ENVIRONMENT PROTECTION CO LTD

Oil-containing nylon roller envelope for warp knitting machine cam swing arm transmission mechanism and its production method

InactiveCN101008129AExtended service lifeWon't overflowWarp knittingBearing componentsWork periodEngineering

The invention provides a nylon roller sheath with self-lubricant function, high strength, and long service life, used in cam swing device of loom, wherein, the invention is formed by 85-93% aminocaprolactam, 2-5% sodium-hydroxide additive, and 5-10% mineral oil. The invention also discloses a method for producing roller sheath, for resolving the abrasion problem, with low cost and simple production.

Owner:康盘方

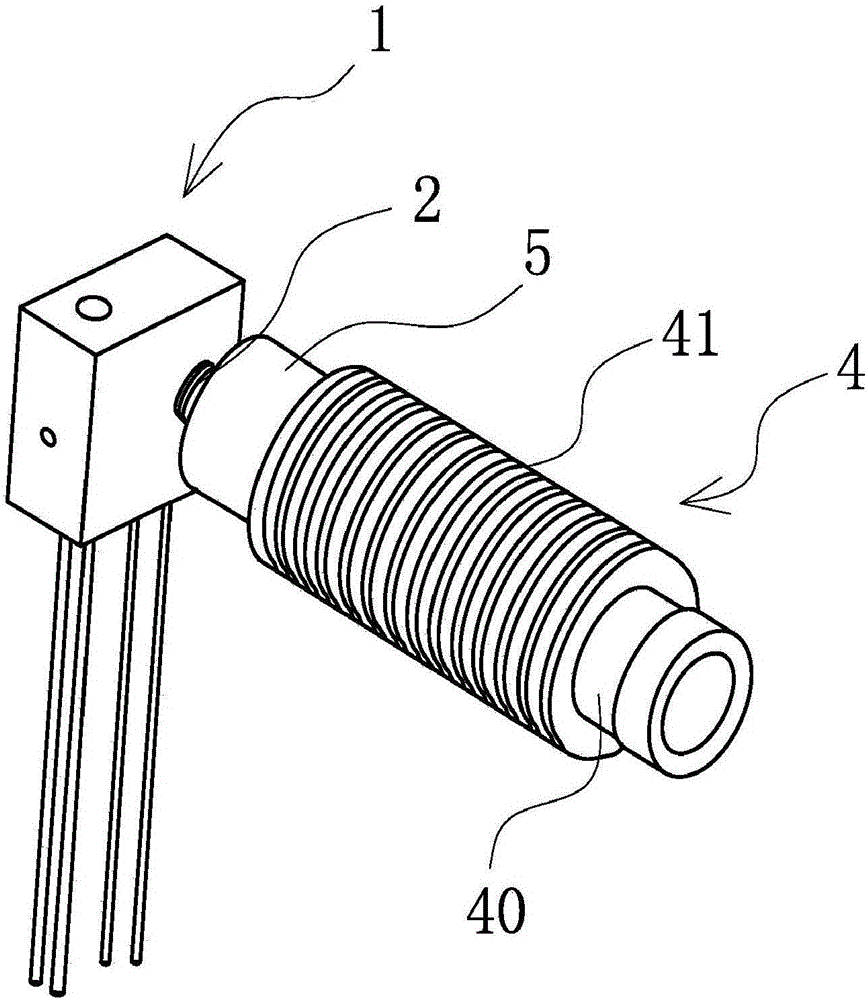

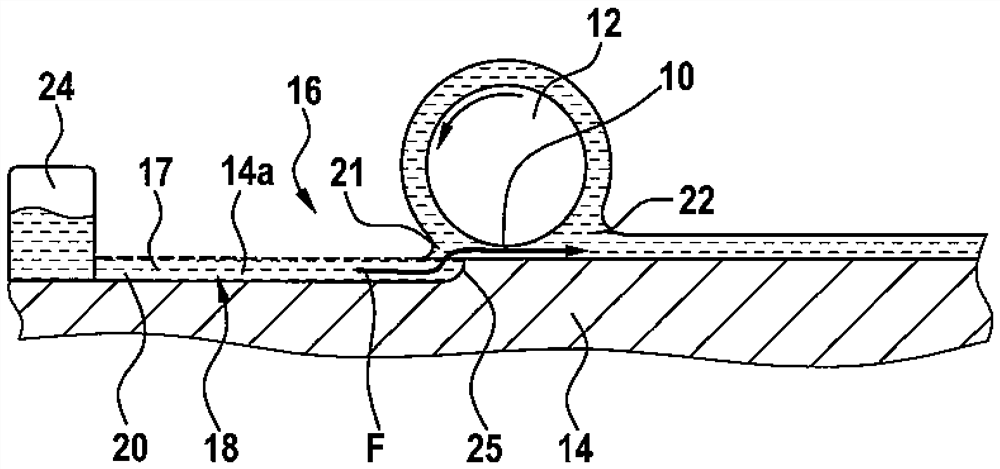

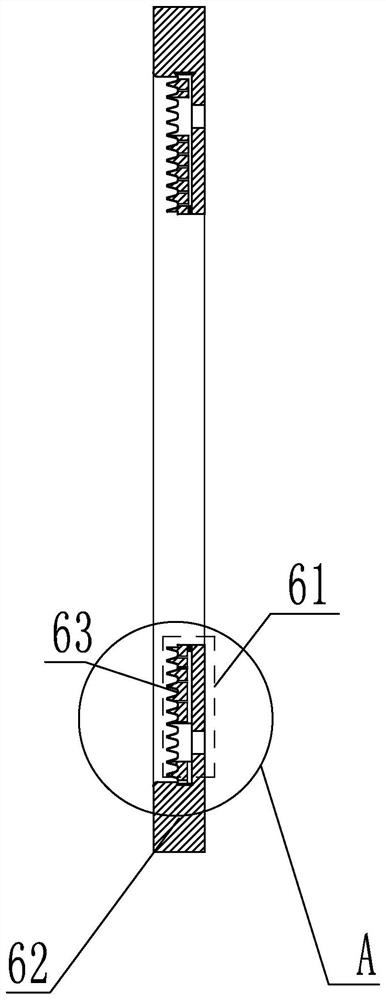

Device with frictional contact and method for operating a device with frictional contact

ActiveCN107289269BSmall structure sizeSimple structureBearing componentsLubrication elementsEngineeringRelative motion

The invention relates to a device (1) with a frictional contact (10), wherein the frictional contact can be provided by a relative movement of the first contact body (12) relative to the second contact body (14). The part (10) provides a lubricant (17), wherein, through the lubricant (17) attached to the first contact body (12), the A liquid column of lubricant (17) is arranged in said lubricant path (16). Furthermore, the invention relates to a method for operating a device ( 1 ) with a friction contact ( 10 ).

Owner:ROBERT BOSCH GMBH

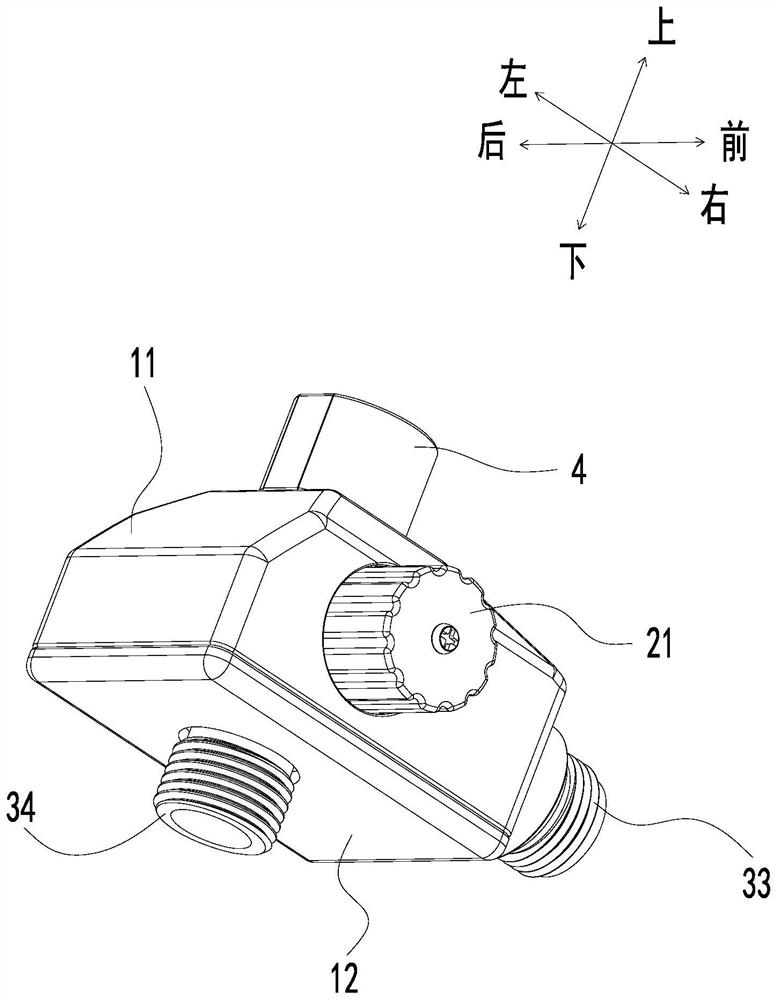

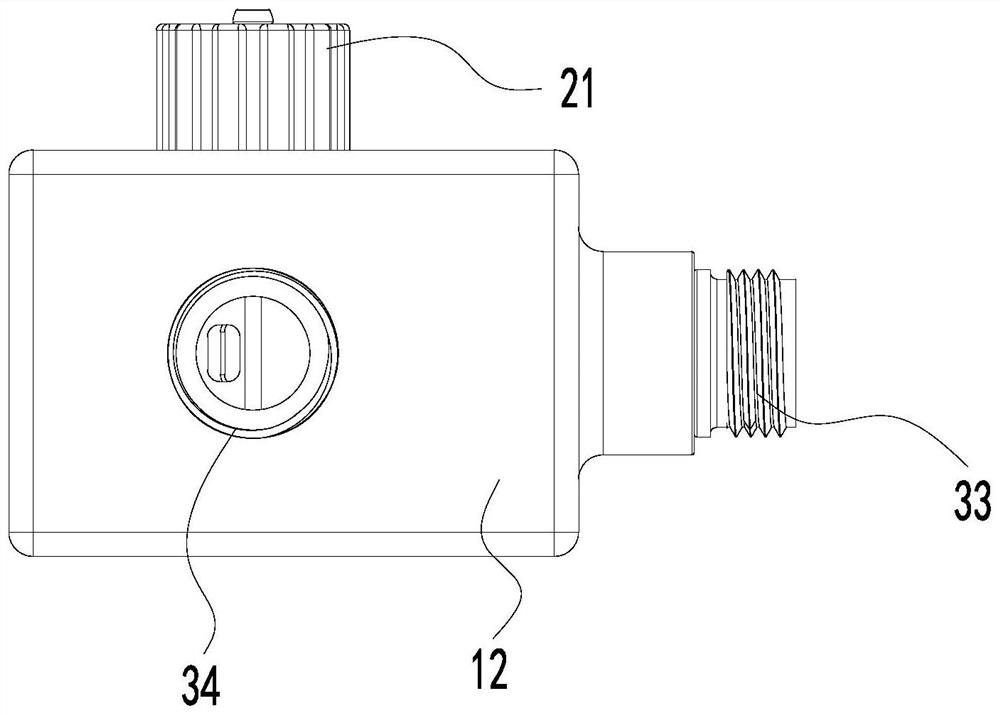

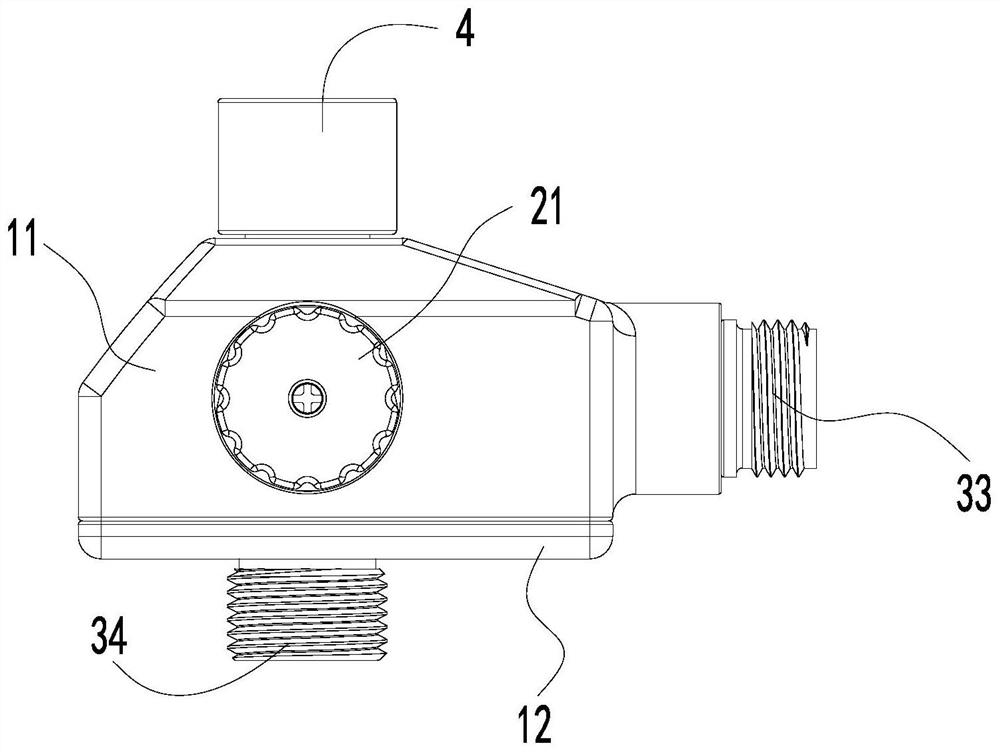

Novel three-way valve switching structure

PendingCN114776834ALight switching forceCompact structureSpindle sealingsOperating means/releasing devices for valvesSlide plateClassical mechanics

The novel three-way valve switching structure comprises a shell assembly, a water passing assembly and a switching assembly, the water passing assembly and the switching assembly are arranged in the shell assembly, and the switching assembly is movably arranged on the water passing assembly to switch different water passing openings in the water passing assembly; the water passing assembly is provided with at least two water passing openings, the switching assembly is provided with a sliding plate capable of moving on the water passing openings and a rolling shaft connected with the sliding plate, the rolling shaft drives the sliding plate to linearly move on the surfaces of the water passing openings so as to switch among the water passing openings, and the linear transmission structure has the characteristics that the switching force value is small, and the switching force value is small. The structure is compact, the waterway is smooth, the production is stable, and the service life is long.

Owner:厦门欧圣斯卫浴有限公司

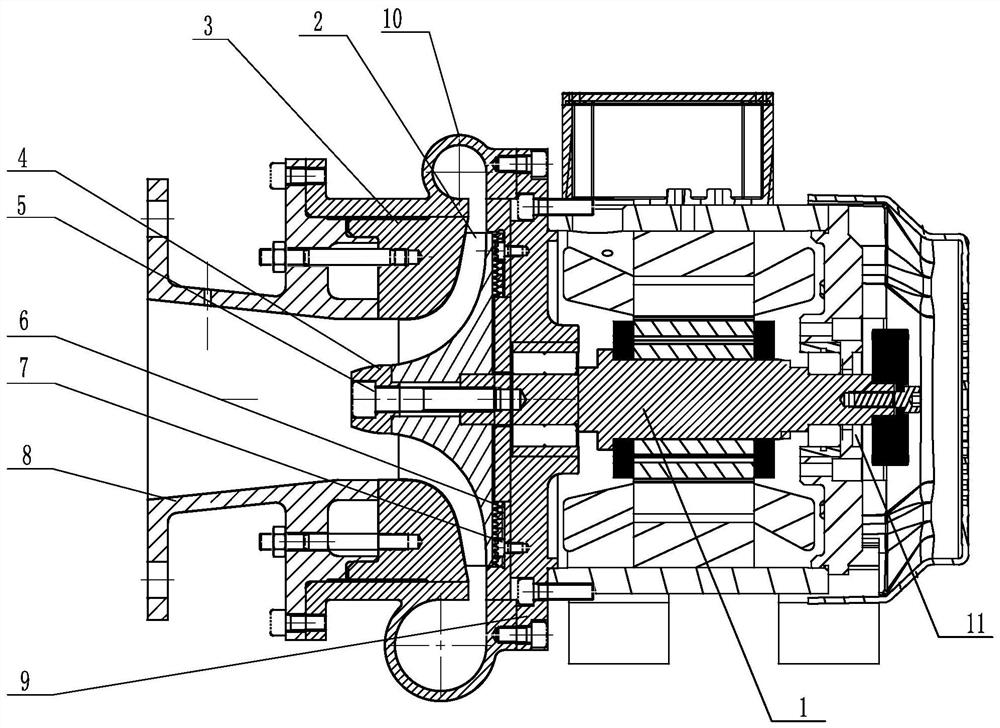

A self-correcting compressor with assembly precision

ActiveCN113513499BEliminate errorsGuaranteed running stabilityPump componentsPumpsEngineeringPolymer

The invention discloses a self-correcting assembly precision compressor, which comprises a casing and an impeller rotating shaft arranged in the middle of the casing, an impeller is arranged at the front end of the impeller rotating shaft, and an assembly assembly is arranged outside the impeller, and the assembly assembly includes The self-correcting ring is arranged at the front end of the impeller, and the outer edge of the self-correcting ring is provided with a volute; wherein, the hardness of the self-correcting ring is smaller than that of the impeller. The self-straightening ring is made of polymer material, which has self-lubricating properties. When the impeller is pre-started, the self-straightening ring will be scraped, so that the self-straightening ring is scraped and corrected according to the "rotation profile" of the impeller, so that the self-straightening The ring is automatically corrected according to the working state of the impeller, eliminating the error generated during the assembly of the compressor and ensuring the overall operation stability of the compressor.

Owner:XINLEI COMPRESSOR CO LTD

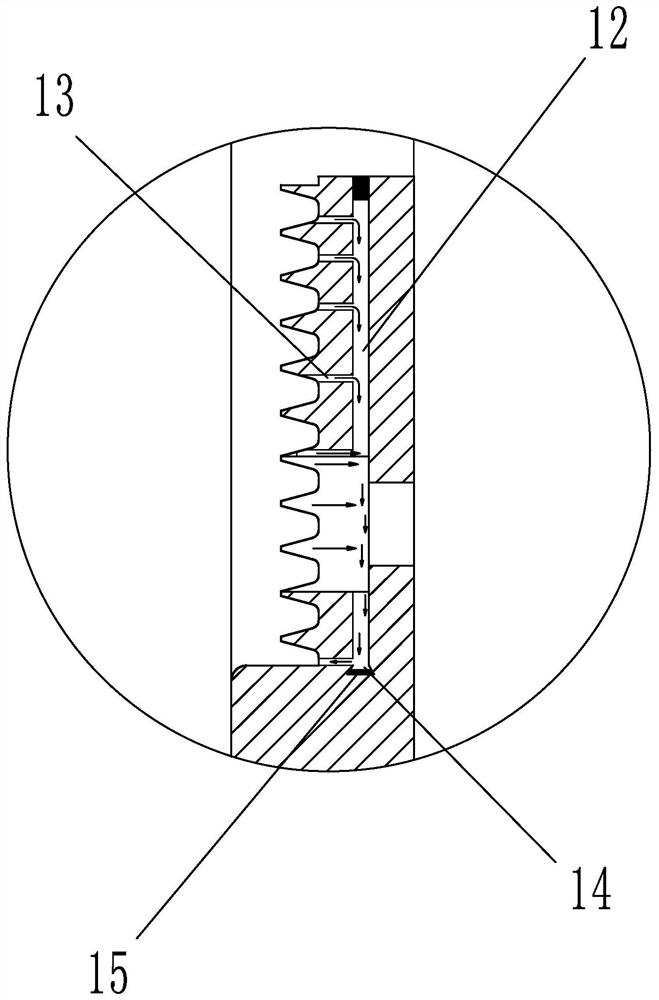

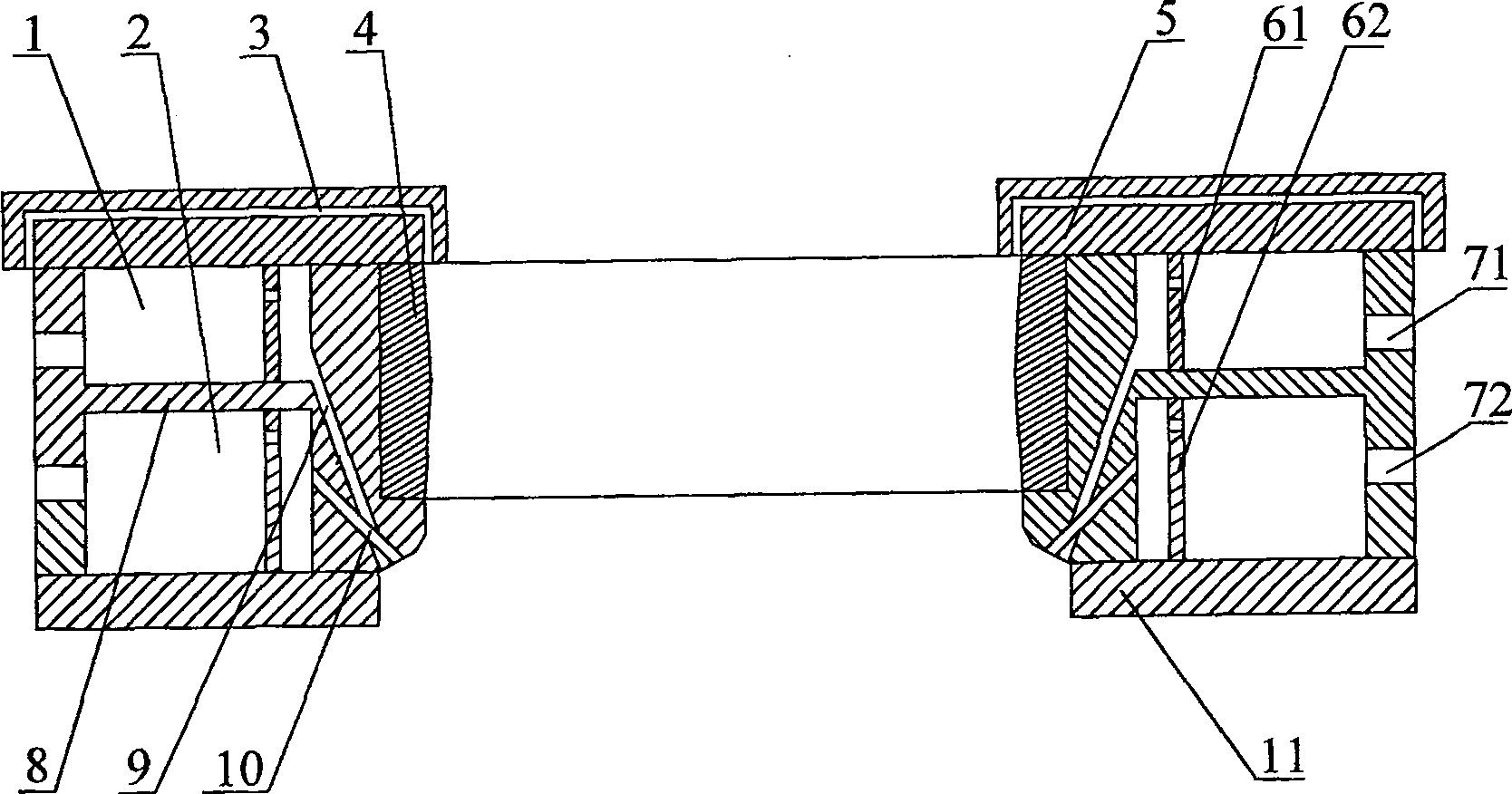

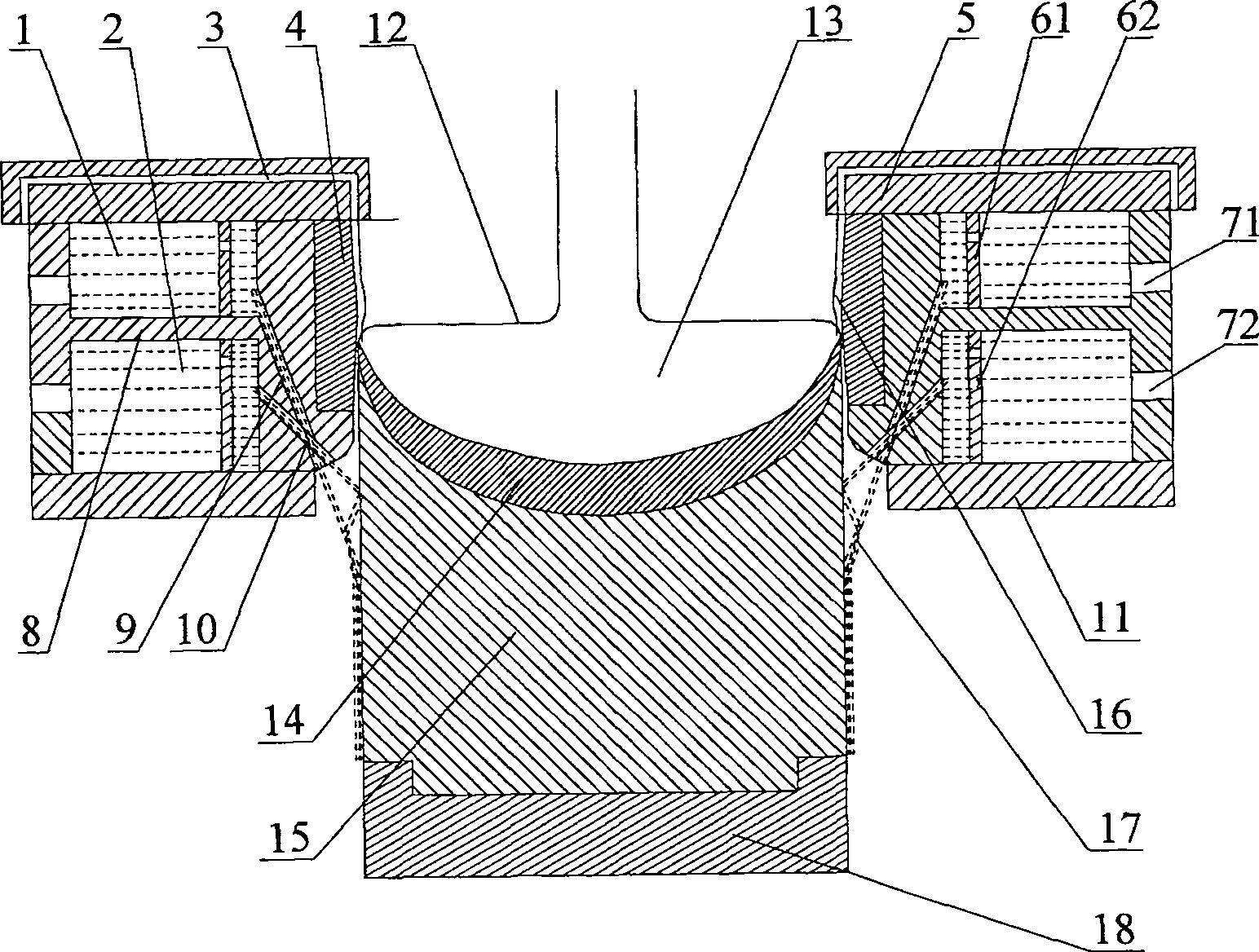

Continuous lubricating crystallizer for aluminum alloy semi-continuous casting

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

A kind of internal sealing structure of hp medium speed coal mill

ActiveCN103591297BWon't wear outReduce overhaul frequencyEngine sealsWork periodReciprocating motion

The invention relates to an internal sealing structure of an HP medium speed coil mill. The internal sealing structure of the HP medium speed coil mill is provided with an upper sealing ring, a middle sealing ring and a lower sealing ring which are arranged on the upper side, in the middle and on the lower side respectively, a gapless radial floating sealing device is provided with a positioning pin capable of making reciprocating motion back and forth in the radial direction of a rotary shaft of the coal mill, and the positioning pin is provided with a carbon sealing ring in a connected mode through a spring. The internal sealing structure of the HP medium speed coil mill has the advantages that the internal sealing structure is resistant to high temperature and abrasion and has the self-lubricating property, the rotary shaft of the coal mill will not be abraded in the operation process, and thus the problems of air leakage and powder leakage of the bottom of the coal mill can be solved fundamentally, and the overhaul frequency of the coal mill is greatly reduced; meanwhile, the internal sealing structure is convenient to detach, the overhaul work period is shortened, the labor intensity of on-site construction is relieved, the on-site environment is greatly improved, and the internal sealing structure has remarkable economical benefits and practical value.

Owner:BEIJING XINYUAN BAOTONG POWER EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com