A self-correcting compressor with assembly precision

An assembly precision, compressor technology, applied in mechanical equipment, non-variable displacement pumps, machines/engines, etc., can solve problems such as blade damage, and achieve the effect of eliminating vibration, reducing vibration intensity, and eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

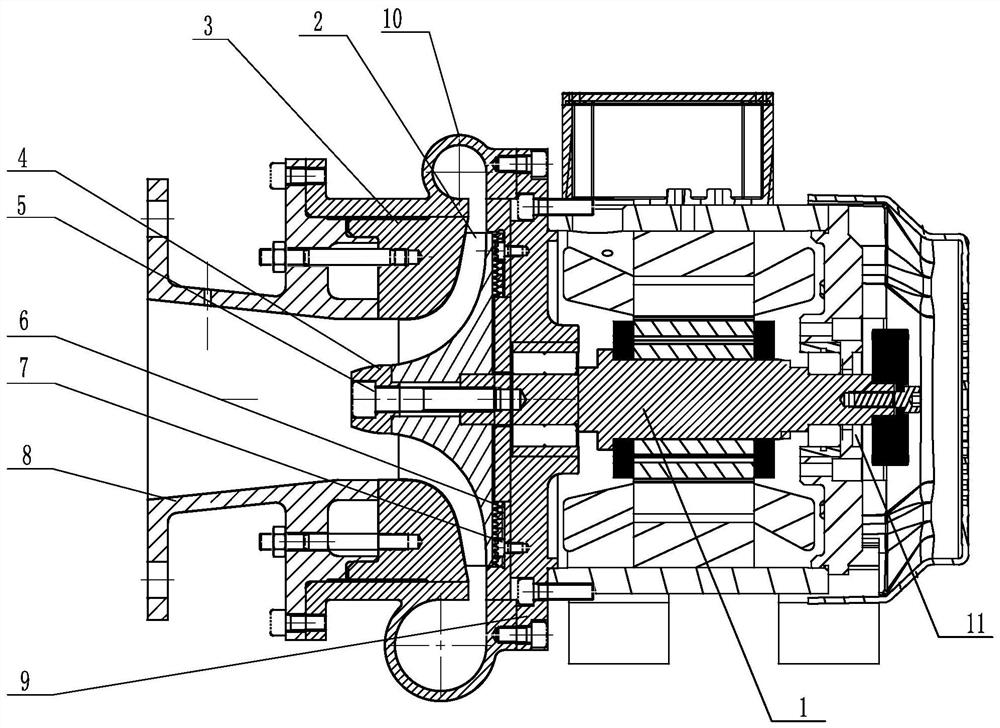

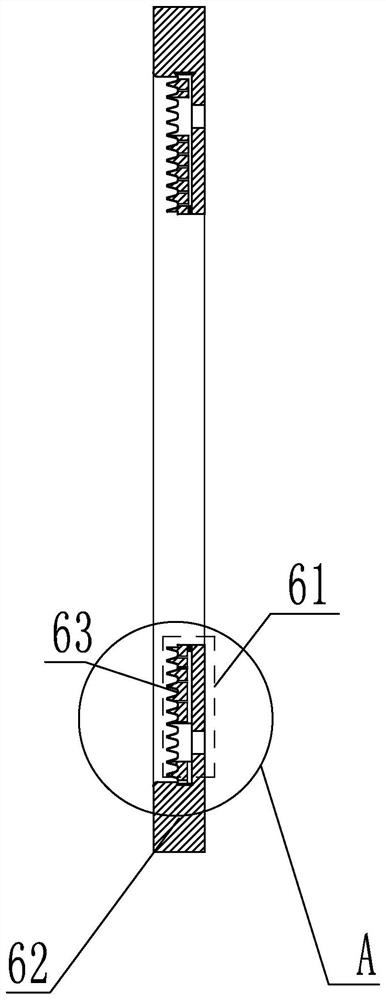

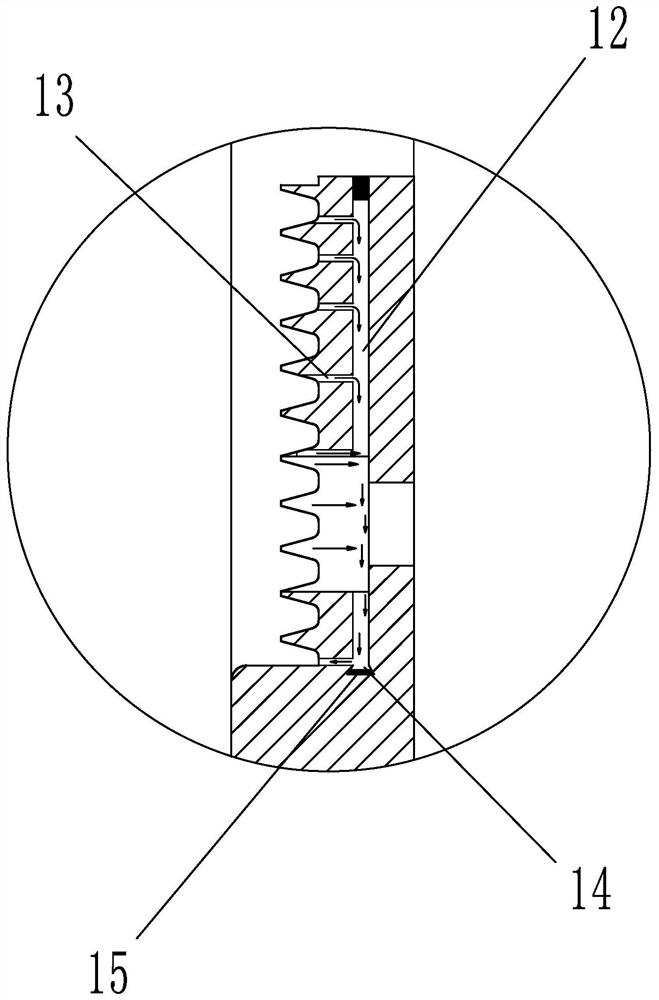

[0037] Such as figure 1 As shown, a self-correcting compressor with assembly accuracy includes a housing and an impeller shaft 1 arranged in the middle of the housing. The front end of the impeller shaft 1 is provided with an impeller 2, and an assembly assembly is provided on the outside of the impeller 2. The assembly assembly includes a 2 The self-correcting ring 3 at the front end is provided with a volute 10 on the outer edge of the self-correcting ring 3; The power core of the compressor includes the impeller shaft 1 set in the casing, the impeller shaft 1 drives the impeller 2 to rotate at high speed, and the front end of the casing is closed by the volute 10, and the self-correcting ring is used to fill the gap between the impeller 2 and the volute 10 To prevent the compressed medium from leaking out of the cavity, a self-correcting ring with a better sealing effect is used as the shaft end seal. In this application, the self-correcting ring is made of polymer material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com