Production process for HS311 steel-based copper plastic self-lubrication material

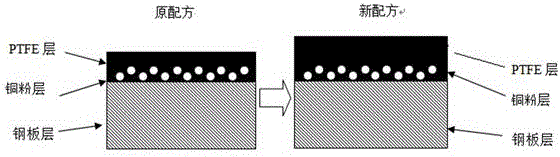

A self-lubricating material and production process technology, applied in the field of steel-based copper-plastic self-lubricating wear-resistant engineering materials, can solve the problems of low PTFE hardness, poor bearing capacity, and high wear rate, and achieve excellent weather resistance, high bearing capacity, and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

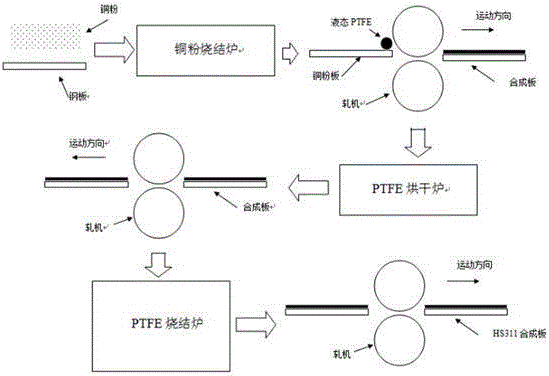

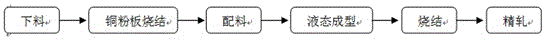

[0026] Example 1, such as figure 1 , 2 , Shown in 3, a kind of production technology of HS311 steel-based copper-plastic self-lubricating material, comprises blanking, copper powder board sintering, batching, liquid forming, sintering, finish rolling steps and makes, specifically as following steps;

[0027] (1) Blanking, selection of copper powder, stainless steel plate;

[0028] (2) Copper powder plate sintering; the surface of the stainless steel plate is copper-plated, the copper powder is evenly laid on the stainless steel plate, and then put into a high-temperature sintering furnace for sintering, so that the metal particles and between the particles and the matrix are partially sintered , forming a porous skeleton;

[0029] (3) Ingredients:

[0030] Blended into dry powder, which is composed of raw materials in weight ratio: 40% polytetrafluoroethylene, 13% lead powder, 35% glass fiber, and 12% graphite powder;

[0031] Blended into a liquid; composed of raw materia...

Embodiment 2

[0039] Example 2, such as figure 1 , 2 , Shown in 3, a kind of production technology of HS311 steel-based copper-plastic self-lubricating material, comprises blanking, copper powder board sintering, batching, liquid forming, sintering, finish rolling steps and makes, specifically as following steps;

[0040] (1) Blanking, selection of copper powder, stainless steel plate;

[0041] (2) Copper powder plate sintering; the surface of the stainless steel plate is copper-plated, the copper powder is evenly laid on the stainless steel plate, and then put into a high-temperature sintering furnace for sintering, so that the metal particles and between the particles and the matrix are partially sintered , forming a porous skeleton;

[0042] (3) Ingredients:

[0043] Blended into dry powder, which is composed of raw materials in weight ratio: 50% polytetrafluoroethylene, 20% lead powder, 45% glass fiber, and 20% graphite powder;

[0044] Blended into a liquid; composed of raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com