Continuous lubricating crystallizer for aluminum alloy semi-continuous casting

A mold and semi-continuous technology is applied in the field of molds for semi-continuous casting of aluminum alloys and lubricable molds for semi-continuous casting of aluminum alloys. , The equipment cost is small, and the effect of primary cooling is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

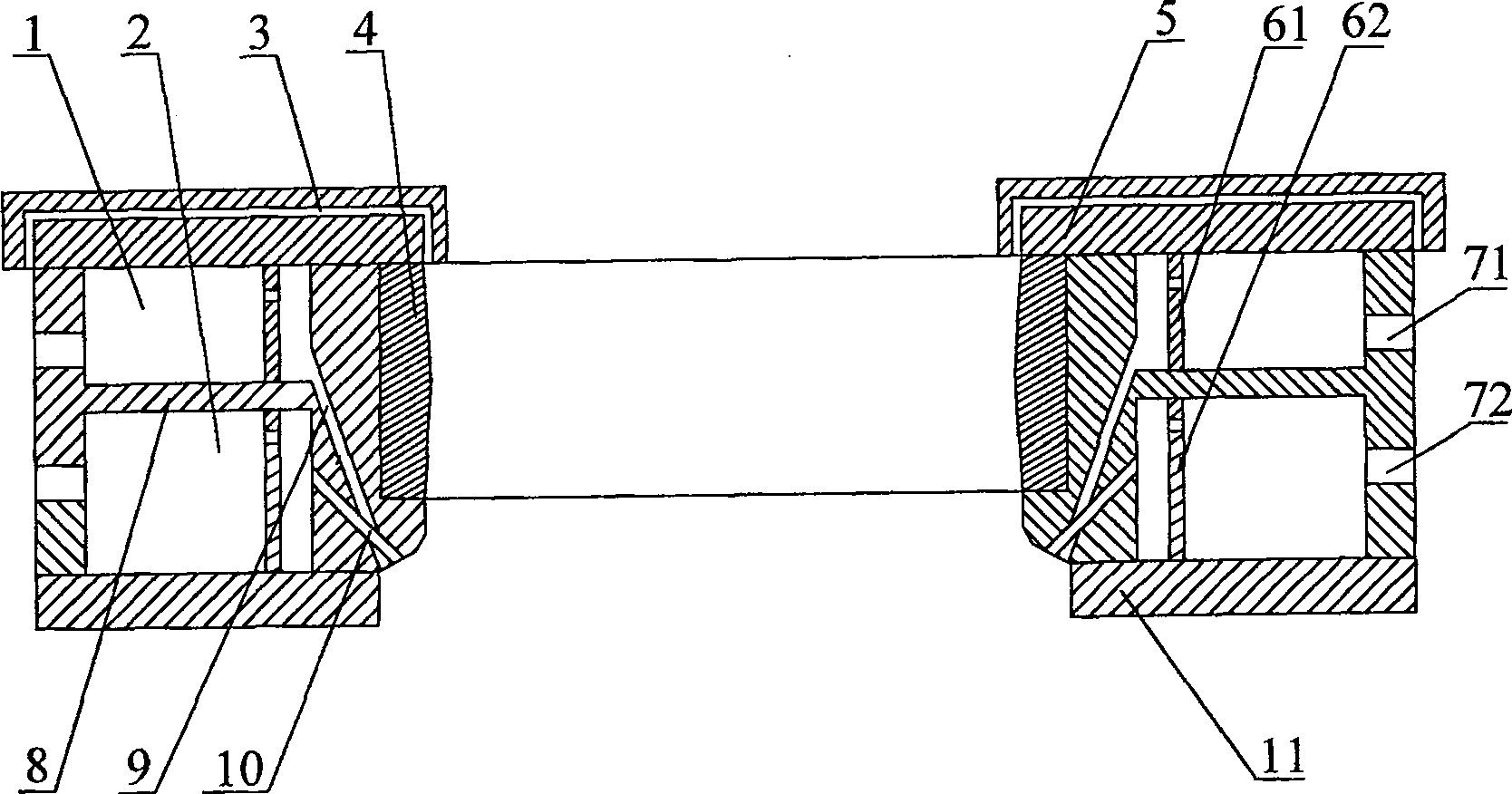

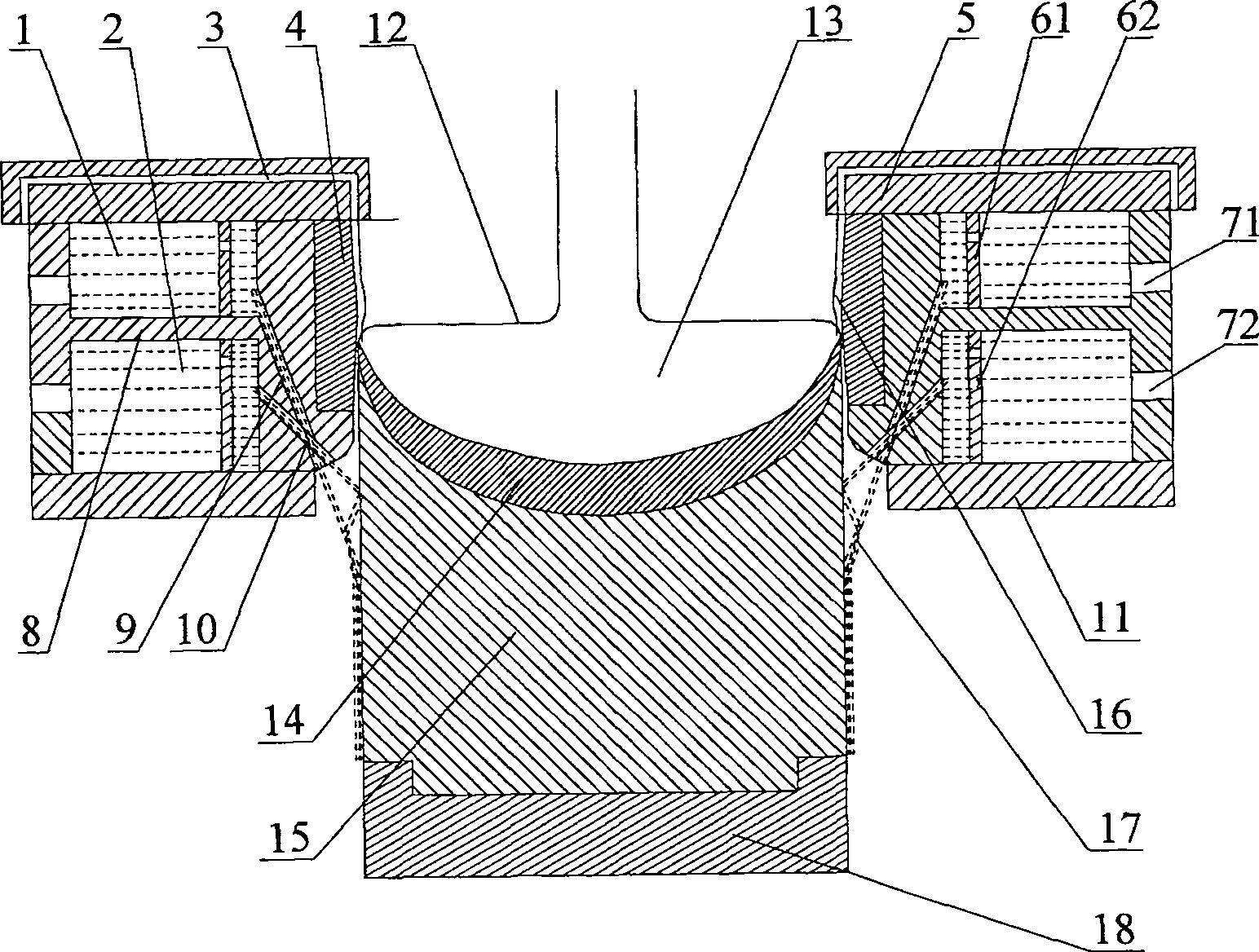

[0022] Such as figure 1 As shown, the continuous lubricating mold for aluminum alloy semi-continuous casting includes a mold body 8, an upper cover 5 and a lower cover 11; the inner wall of the crystallizer is inlaid with a graphite lining 4, and an independent oil chamber is provided in the upper cover 5 3. The graphite lining 4 has a vertically symmetrical structure with a taper, and its taper angle ranges from 174° to 179°; the crystallizer body 8 is provided with two independent water chambers, namely the upper water chamber 1 and the lower water chamber 2, and the upper water chamber 1 and the lower water chamber 2. There is an independent water inlet 71 on the water chamber 1, an independent water inlet 72 on the lower water chamber 2, a water retaining plate 61 is installed in the upper water chamber 1, and a water retaining plate 62 is installed in the lower water chamber 2. A row of water spray holes 9 is arranged at the bottom of chamber 1, and the angle range of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com