Method for preparing high-adhesion wear-resistant paint used for polycarbonate

A high-adhesion, wear-resistant coating technology, applied in coatings and other directions, can solve the problems of poor crack growth resistance, weather resistance, low surface hardness, and poor wear resistance, so as to enhance interaction and bonding strength and improve wear resistance. , Improve the effect of surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

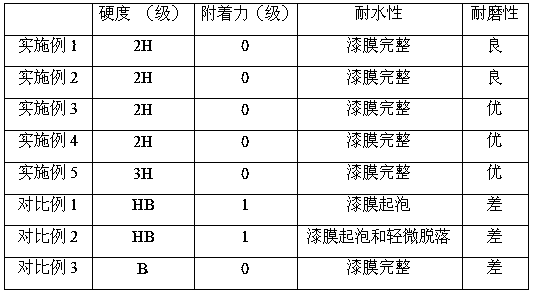

Examples

Embodiment 1

[0017] A preparation method for polycarbonate with high adhesion wear-resistant paint, comprising the following steps:

[0018] S1. Weigh the following ingredients by weight: 30 parts of chlorinated polypropylene resin, 35 parts of maleic anhydride modified C5 petroleum resin, 1.2 parts of BYK-163 type dispersant, 0.6 part of BYK-071 type defoamer, dilaurel 0.05 parts of dibutyltin acetate, 4 parts of cellulose acetate butyrate, 14 parts of xylene, 16 parts of ethyl acetate, 18 parts of isopropanol, 3 parts of aliphatic polyisocyanate, 5 parts of white corundum micropowder, 1 part of superfine mica powder, silane 0.5 parts of coupling agent KH-560, 8 parts of porous spherical silica;

[0019] S2. Mix chlorinated polypropylene resin and maleic anhydride modified C5 petroleum resin, stir for 5 minutes, add BYK-163 type dispersant, BYK-071 type defoamer, dibutyltin dilaurate, butyl acetate under stirring state Acid cellulose, white corundum micropowder, ultrafine mica powder and...

Embodiment 2

[0021] A preparation method for polycarbonate with high adhesion wear-resistant paint, comprising the following steps:

[0022] S1. Weigh the following ingredients by weight: 42 parts of chlorinated polypropylene resin, 18 parts of hydroxy-modified vinyl acetate resin, 1.8 parts of BYK-163 type dispersant, 0.2 parts of BYK-071 type defoamer, dilauric acid 0.08 parts of dibutyltin, 8 parts of cellulose acetate butyrate, 25 parts of isopropanol, 18 parts of ethyl acetate, 17 parts of butyl acetate, 8 parts of aromatic polyisocyanate, 2 parts of white corundum micropowder, 3 parts of superfine mica powder , 1.2 parts of silane coupling agent KH-570, 4 parts of porous spherical zirconium silicate, wherein, the preparation method of hydroxyl-modified vinyl acetate resin is to mix methanol and sodium hydroxide, heat to 35 ° C in a water bath, and stir for 20 min Afterwards, add vinyl acetate, react 8h, remove mother liquor and wash and filter to obtain hydroxyl-modified vinyl acetat...

Embodiment 3

[0025] A preparation method for polycarbonate with high adhesion wear-resistant paint, comprising the following steps:

[0026] S1. Weigh the following ingredients by weight: 35 parts of chlorinated polypropylene resin, 9 parts of maleic anhydride modified C5 petroleum resin, 19 parts of hydroxyl modified vinyl acetate resin, 1.4 parts of BYK-163 dispersant, BYK-071 0.3 parts of antifoaming agent, 0.07 parts of dibutyltin dilaurate, 7 parts of cellulose acetate butyrate, 15 parts of ethyl acetate, 30 parts of isopropanol, 12 parts of methyl isobutyl ketone, 5 parts of aliphatic polyisocyanate , 3 parts of white corundum micropowder, 3 parts of superfine mica powder, 0.7 parts of silane coupling agent KH-550, 4 parts of porous spherical silica, 3 parts of porous spherical zirconium silicate, of which, hydroxyl modified chloroacetic acid The resin preparation method is to mix methanol and sodium hydroxide, heat to 45°C in a water bath, and stir for 10 minutes, then add chloroace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com