Special pigment carbon black dye and preparation method thereof

A pigment carbon black and dye technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of poor color singleness, large amount of addition, and many components, and achieve good blackness and brightness. Safety and environmental protection, more color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

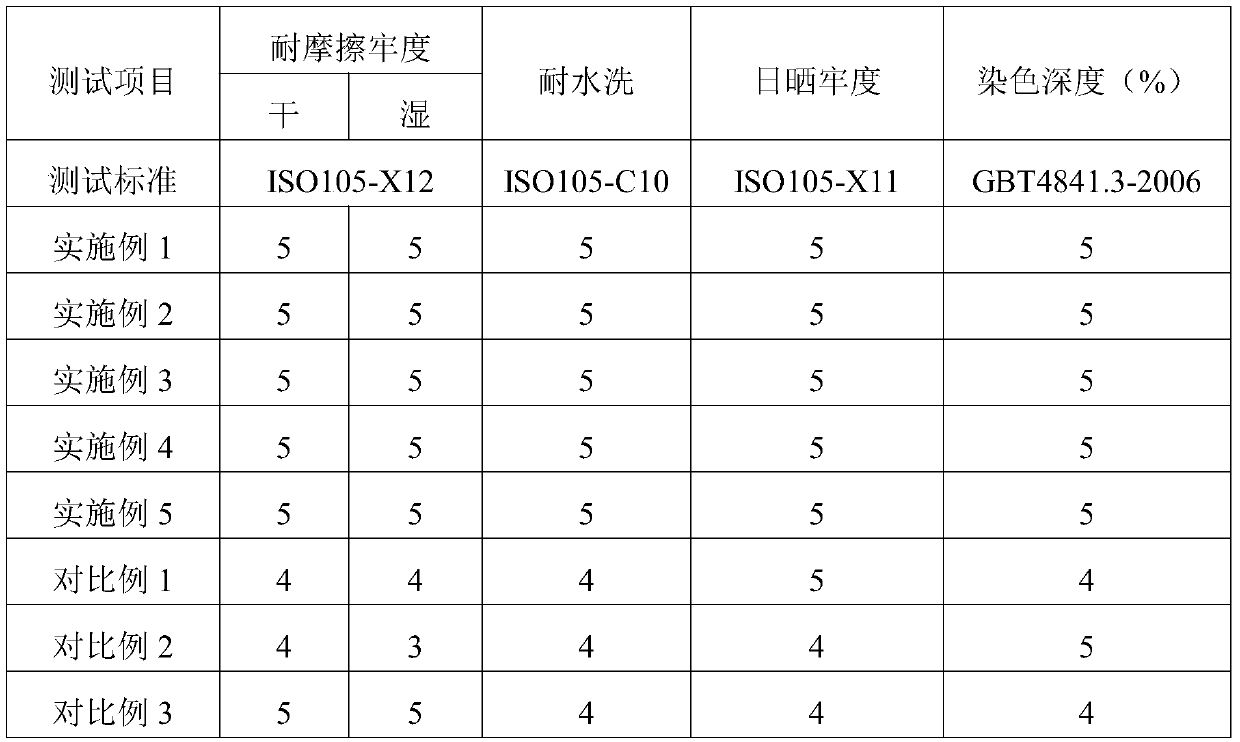

Examples

Embodiment 1

[0029] A special pigment carbon black dye, comprising the following components by weight: 10 parts of surface-modified nano ferric oxide; 20 parts of surface-modified carbon black; 3 parts of monomethoxy polyethylene glycol amine; quaternary ammonium Silicone oil 5 parts; water 60 parts.

[0030] The preparation method of the surface-modified nano ferric oxide comprises the following steps: dispersing 30 g of nano ferric oxide in 100 g of ethanol, and then adding N-(3-triethoxysilylpropyl) glucose 10 g of amide was stirred and reacted at 40° C. for 4 hours, centrifuged, and dried in a vacuum oven at 50° C. to constant weight to obtain surface-modified nanometer ferric oxide.

[0031] The preparation method of the surface modified carbon black comprises the following steps: in a three-necked flask equipped with a condenser, a stirrer and a thermometer, add 10 g of carbon black, 30 g of methyl ethyl ketone, 2-oleoyl-1-palm tin glycerin- 3-phosphocholine 3g, Mulitinib 3g, bis(3-...

Embodiment 2

[0037] A special pigment carbon black dye, comprising the following components by weight: 11 parts of surface-modified nano ferric oxide; 23 parts of surface-modified carbon black; 4 parts of monomethoxy polyethylene glycol amine; quaternary ammonium Silicone oil 6 parts; water 63 parts.

[0038]The preparation method of the surface-modified nano ferric oxide comprises the following steps: dispersing 35 g of nano ferric oxide in 115 g of dichloromethane, and then adding N-(3-triethoxysilyl propyl) Glucamide 10g was stirred and reacted at 45°C for 4.5 hours, then centrifuged, and dried in a vacuum oven at 52°C to constant weight to obtain surface-modified nano-ferric oxide.

[0039] The preparation method of the surface modified carbon black comprises the following steps: in a three-necked flask equipped with a condenser, a stirrer and a thermometer, add 10 g of carbon black, 35 g of methyl ethyl ketone, 2-oleoyl-1-palm tin glycerin- 3-phosphocholine 3g, Mulitinib 3g, bis(3-tr...

Embodiment 3

[0045] A special pigment carbon black dye, comprising the following components by weight: 13 parts of surface-modified nano ferric oxide; 25 parts of surface-modified carbon black; 5 parts of monomethoxy polyethylene glycol amine; quaternary ammonium Silicone oil 7 parts; water 65 parts.

[0046] The preparation method of the surface-modified nano-ferric oxide comprises the steps of: dispersing 40 g of nano-ferric oxide in 135 g of acetone, and then adding N-(3-triethoxysilylpropyl) glucose 10 g of amide was stirred and reacted at 50° C. for 5 hours, centrifuged, and dried in a vacuum oven at 55° C. to constant weight to obtain surface-modified nanometer ferric oxide.

[0047] The preparation method of the surface modified carbon black comprises the following steps: in a three-necked flask equipped with a condenser, a stirrer and a thermometer, add 10 g of carbon black, 40 g of methyl ethyl ketone, 2-oleoyl-1-palm tin glycerin- 3-phosphocholine 3g, Mulitinib 3g, bis(3-trimeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com