Patents

Literature

68results about How to "Not easy to wet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

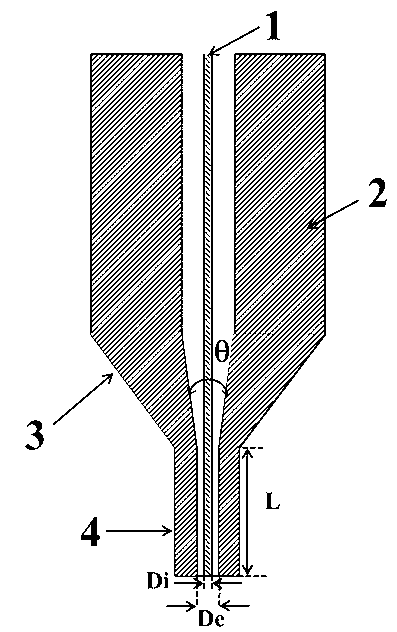

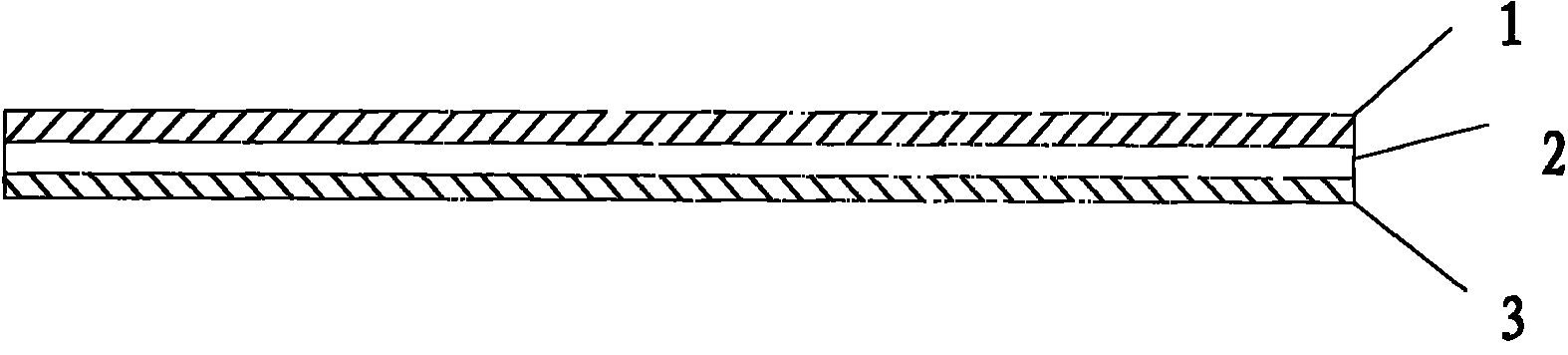

Preparation method of teflon hollow fiber membrane for membrane distillation

InactiveCN102941025ALow costAvoid loss of product water qualitySemi-permeable membranesIndustrial effluentPhysical chemistry

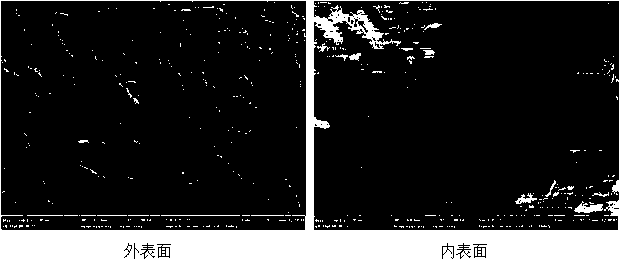

The invention discloses a preparation method of a teflon hollow fiber membrane for membrane distillation, which comprises the following steps of: mixing teflon dispersion powder and a extruding-aid agent, pressing a blank, extruding the blank into a teflon hollow tube through a pushing and pressing machine with a cone mould and a mouth mould, and performing longitudinal stretch, sintering and heat setting on the teflon hollow tube in a drying oven to obtain the teflon hollow fiber membrane. The processed teflon hollow fiber membrane is in an asymmetric structure, the mean pore size of an outer layer is 0.10-1.0 micrometer, the mean pore size of an inner layer is 5.0-20 micrometers, the wall thickness is 0.1-0.5 millimeter, the bubble point pressure is 0.5-2.0 kgf / square centimeter, and the water resistance pressure is 1.5-6kgf / square micrometer. The invention is mainly used for the membrane distillation separation process, and can be applied to the fields of sea water desalination, industrial wastewater treatment, cryoconcentration of food and biological products, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Aluminum oxide electric furnace cover pouring material and preparation method thereof

InactiveCN101113098AImprove thermal shock resistanceImprove slag erosion resistanceFiberShock resistance

The invention relates to a casting material of alumina eafroof and the preparation material thereof. The technic proposal is as following: 1. white corundum of 50-80wt percent, high alumina- bauxite clinker of 3-30wt percent, zirconium corundum of 5-25wt percent, kyanite fine powder of 3-15wt percent, alumina micro-powder of 3-12wt percent, pure aluminate calcium cement of 0-10wt percent and silicon-aluminum gel of 1-5wt percent are mixed together; 2. water reducing agent of 0.10-0.25wt percent, organic fiber of 0.03-0.08wt percent, and water of 5.0-6.5wt percent are then added to the obtained mixture and are stirred for 5-10 minutes, and the mixture is cast for molding; 3. the mold is naturally cured for 12-24 hours and then demolded; 4. the mold is dried for 24 hours under 110 DEG C. According to the size of furnace cover and application requiremenst, the casting molding is designed for whole casting molding or block pouring molding. The block molds are assembled thereafter. The invention is characterized by no environmental pollution, dense structure, good thermal and shock resistance and erosive resistance, and long service life.

Owner:WUHAN UNIV OF SCI & TECH

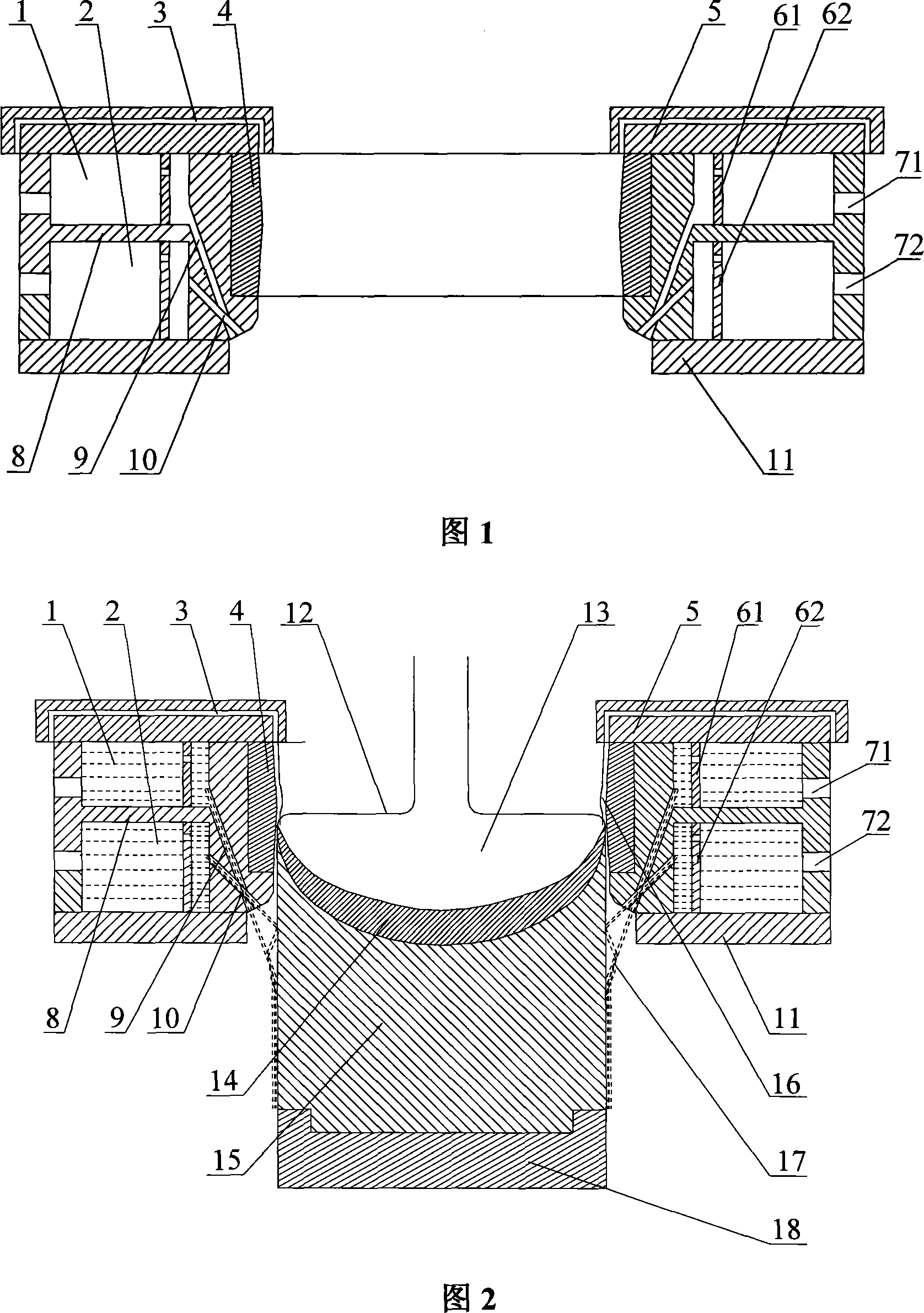

Continuous lubricating crystallizer for aluminum alloy semi-continuous casting

The invention relates to a continuous lubrication crystallizer used for casting aluminum alloy semi-continuously, wherein the inner wall of the crystallizer is inlaid with a graphite lining, a top cover of the crystallizer is internally provided with an independent oil cavity, the graphite lining presents up-down symmetric construction with a taper, a body of the crystallizer is provided with a top water cavity and a lower cavity which are independent, the top water cavity and the lower cavity are respectively opened with an independent water inlet and are respectively provided with a splash plate, the bottom of the top water cavity is provided with a row of water passing ports, the bottom of the lower water cavity is also provided with a row of water passing ports, the angel of the water passing ports of the top water cavity is different from and presents interlaced shape with the water passing ports of the lower water cavity's, when casting, a layer of continuous oil film forms via infiltrating oil forming the oil cavity to the graphite lining, which has effects of heatproof, reducing once cooling of ingot casting at the same time when improving graphite lubricating oil effects, two independent water cavities realize the independent or double water-cavity water supply, which improves the aftercooling effect on the premise of ensuring heat cracks not to appear at the early stage of aluminum alloy ingot casting, thereby realizing a low liquid level on the inner portion of the crystallizer, and distinctively improving surface quality of the ingot casting.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

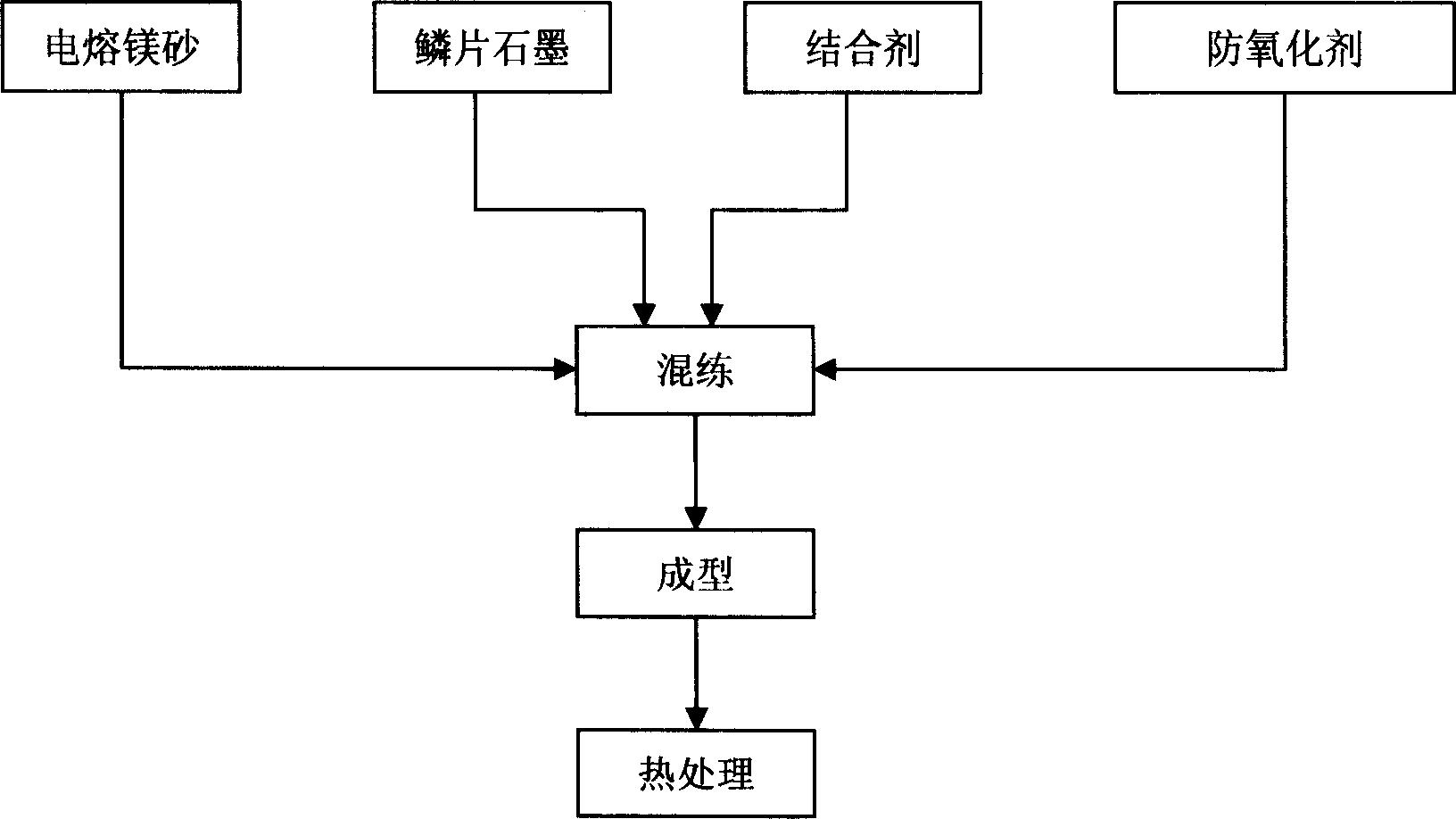

Magnesia brick containing antioxidant C-TiN composite powder and method for preparing the same

The invention provides a magnesite-carbon brick containing anti-oxidization agent of C-TiN composite powder, which comprises the following constituents: MgO 70-90%, C 6-22%, TiN 0.5-10%, Al 0-5%, Si 0-5%, and B4C 0-2%, the preparing process comprises raw material mixing, melting, forming and thermally processing.

Owner:UNIV OF SCI & TECH LIAONING

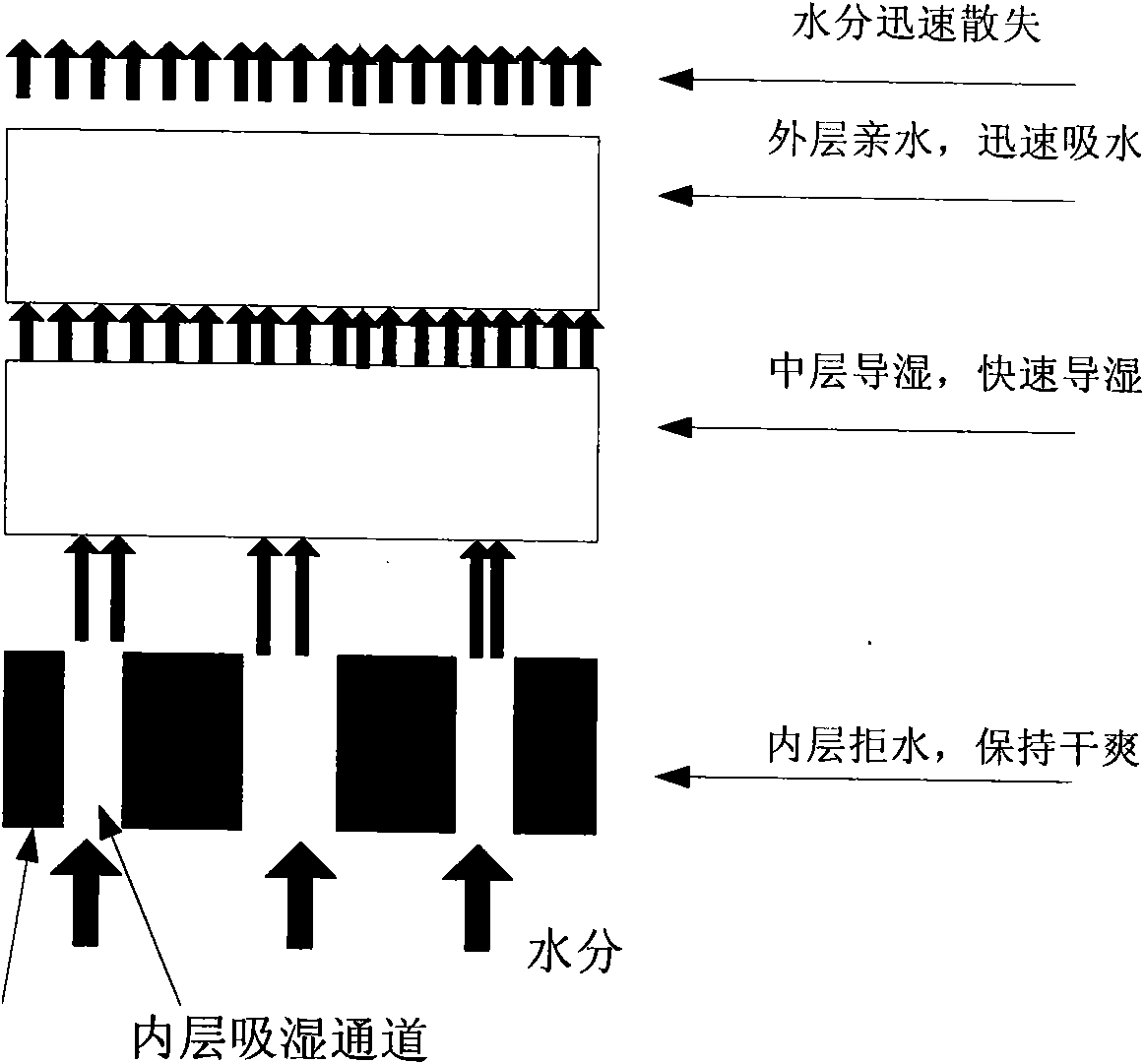

Trapezoidal moisture-transfer knitted fabric

The invention relates to a trapezoidal moisture-transfer knitted fabric, which comprises a multilayer body compounded from an outer layer, an inner layer and a middle layer, wherein the fabric is an air layer knitted fabric; the water repellency area in the inner layer accounts for 50-60 percent relative to the total area of the inner layer; the hydrophile area in the outer layer accounts for 90-100 percent relative to the total area of the outer layer; and the outer layer is connected with the inner layer through the middle layer. The trapezoidal moisture-transfer knitted fabric has the advantages of reasonable structure, hydrophilicity in the outer layer and water repellency in the inner layer, sweat can be quickly exhausted from the inner layer to the outer layer under the moisture transfer and transition actions of the middle layer, a small amount of moisture is kept in the inner layer, a moisture diffusion area is small, and thus, the skin is kept dry and comfortable.

Owner:江苏金纺针织有限公司

Polyvinylidene fluoride-hexafluoropropylene super-hydrophobic composite film and preparation method thereof

ActiveCN104307387AImprove performanceHigh mechanical strengthSemi-permeable membranesComposite filmDistillation

The invention discloses a method for preparing a polyvinylidene fluoride-hexafluoropropylene super-hydrophobic composite film. According to the method, the surface of a non-woven fabric is respectively coated with a porous supporting layer and a super-hydrophobic layer in a blade coating manner by adopting an immersion-precipitation phase transformation method, and the size of the pore diameter of a composite film is controlled by virtue of the porous supporting layer. According to the polyvinylidene fluoride-hexafluoropropylene super-hydrophobic composite film, six fluorine atoms in the structure unit show high hydrophobic performance, and the super-hydrophobic layer is formed on the surface of the porous supporting layer by delayed phase transformation. The method is simple to operate, low in manufacture cost and easy to industrialize; the super-hydrophobic composite film has a water contact angle of 153+ / -3 degrees, a rolling angle of 3+ / -1 degrees and pore diameter of 0.05-2 microns, is stable in performance and high in mechanical strength, shows excellent super-hydrophobic performance and self-cleaning function, and can be used in liquid degassing, defoaming, film distillation and other industries.

Owner:JIANGSU JIUMO HIGH TECH CO LTD

Dual-direction high-elastic warp-knitted fabric and production method thereof

The invention discloses a dual-direction high-elastic warp-knitted fabric and a production method thereof. The dual-direction high-elastic warp-knitted fabric is formed by interweaving polyurethane yarns and other non-elastic yarns, and when in weaving, guide bar for guiding the coiling of the polyurethane yarns transversely moves for 2 to 4 stitch lengths and is opposite to the moving direction of other guide bar yarn inlays. The dual-direction high-elastic warp-knitted fabric has balanced elasticity proportion in the longitudinal and the transverse directions and has excellent elasticity recoverability. Swimsuits made of the warp-knitted fabric have strong guide effect and excellent hydrophobic effect. Moreover, the dual-direction high-elastic warp-knitted fabric has low running water resistance and is particularly suitable for producing close-fitted sportswear with high elasticity requirements such as swimsuit, rock climbing clothing, exercise clothing and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Low-carbon aluminous-carbon refractory material for continuous casting and preparation method thereof

InactiveCN102001860AImprove antioxidant capacityImproved thermal shock stabilityAntioxidantNitrogen gas

Owner:HENAN UNIV OF SCI & TECH +1

Methanol gasoline rubber anti-swelling agent

InactiveCN101613629AEasy to useLow costLiquid carbonaceous fuelsFuel additivesSulfonatePolymer science

The invention relates to a methanol gasoline rubber anti-swelling agent and belongs to the field of alcohol ether fuel additives. The methanol gasoline rubber anti-swelling agent consists of 30 to 60 percent of fatty alcohol, 10 to 30 percent of calcium petroleum sulfonate, 8 to 20 percent of sulfonate, 7 to 18 percent of synthetic calcium sulfonate salt and 2 to 15 percent of alkylphenol calcium salt in percentage by weight. 0.012 to 0.028 percent of industrial product of the methanol gasoline rubber anti-swelling agent is added in methanol gasoline with different brands of between M15 and M100 and can reduce the volume swelling of the rubber by 40 to 46 percent. After methanol gasoline added with the methanol gasoline rubber anti-swelling agent is used in an automobile, the driving journey is 50,000 kilometers; compared with the methanol gasoline without methanol gasoline rubber anti-swelling agent, the test shows that the volume swelling of the rubber is reduced by 45 to 50 percent. Compared with lead-free gasoline, the test shows that the swelling rate of the methanol gasoline added with the methanol gasoline rubber anti-swelling agent is equal to that of the lead-free gasoline and achieves the equivalent effect with the lead-free gasoline. The methanol gasoline rubber anti-swelling agent has the characteristics of low cost, easy preparation, convenient use, good effect and the like.

Owner:占小玲

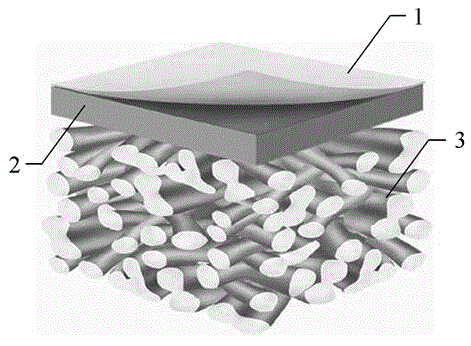

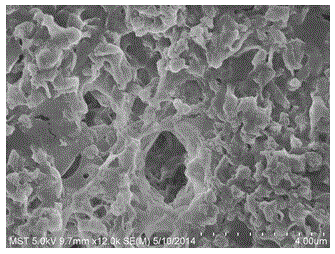

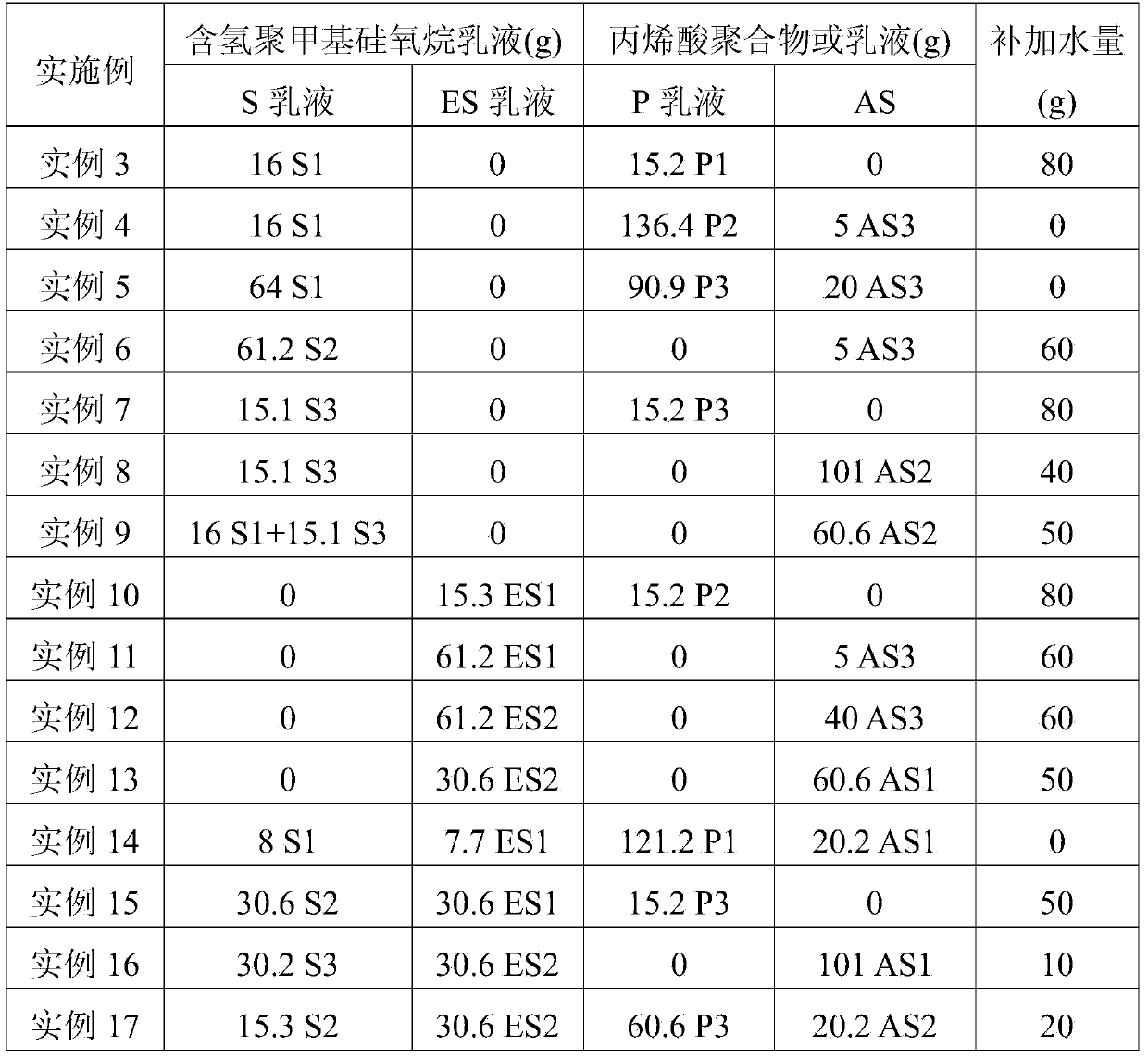

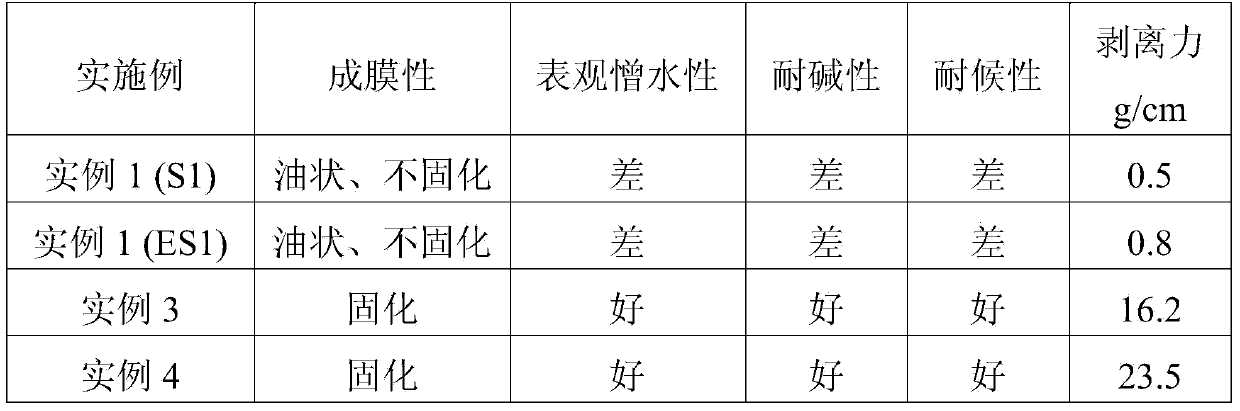

Acrylic organosilicone water-emulsion coating as well as preparation method and application for same

The invention belongs to the technical field of acrylic coatings, and discloses an acrylic organosilicone water-emulsion coating as well as a preparation method and an application for the same. The acrylic organosilicone water-emulsion coating comprises the following components in the following parts by weight: 100 parts of water, 0.1-4 parts of an emulsifier, 5-20 parts of liquid hydrogen-containing polymethyl siloxane, and 5-50 parts of acrylic polymers. The organosilicone content of the acrylic organosilicone water-emulsion coating disclosed by the invention is up to more than 10% in the polymers, organosilicone and the acrylic polymers are compounded in a wide range, and curing film-forming is performed at a room temperature. The preparation process disclosed by the invention is simple, and the obtained emulsion is good in stability; and after curing film-forming, the acrylic organosilicone water-emulsion coating is good in mechanical performance (wherein the hardness can be up to 3 H), excellent in waterproof and hydrophobic performances, acid-base resistance, weather resistance, and adhesive force (which can be up to 2.5 MPa), and proper in peel strength (which can be up to 23 g / cm).

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Calcium hexaluminate/silicon carbide casting material for garbage incinerator and preparation method of casting material

The invention relates to a calcium hexaluminate / silicon carbide casting material for a garbage incinerator and a preparation method of the casting material. The preparation method adopts the technical scheme that the preparation method comprises the steps of taking 40-60wt% of calcium hexaluminate, 35-55wt% of silicon carbide, 1-8wt% of carbon black, 0.5-4wt% of a monatomic silicon powder and 0.5-6wt% of a silicon micropowder as raw materials, adding a water reducing agent accounting for 0.1-0.3wt% of the raw materials, performing uniform mixing to obtain a premix compound, mixing the premix compound with silicasol accounting for 5-15wt% of the raw materials, and performing uniform stirring to obtain the calcium hexaluminate / silicon carbide casting material for the garbage incinerator. The prepared calcium hexaluminate / silicon carbide casting material for the garbage incinerator has the characteristics of excellent medium-high-temperature mechanical property, high heat conductivity, gas corrosion resistance, good thermal shock stability, long service life, energy conservation and environmental protection.

Owner:WUHAN UNIV OF SCI & TECH +1

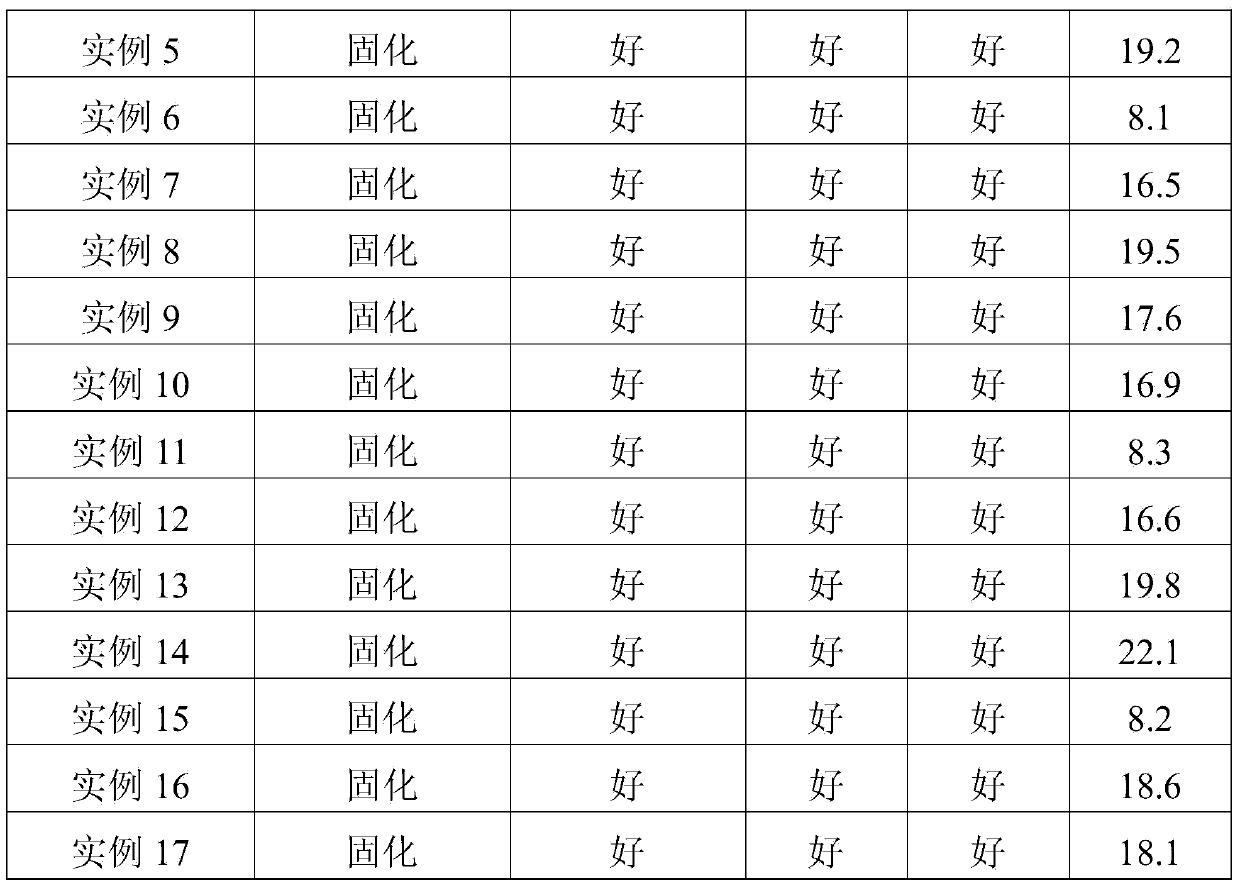

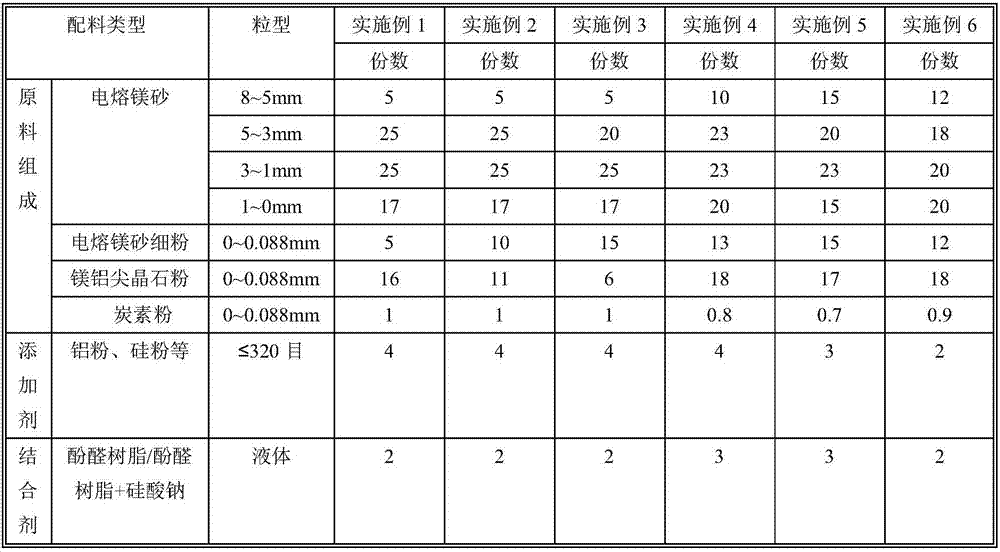

Ultra-low carbon periclase-spinel-carbon brick for steel ladle and preparing method

The invention relates to an ultra-low carbon periclase-spinel-carbon brick for a steel ladle and a preparing method. The ultra-low carbon periclase-spinel-carbon brick is prepared from, by weight, 5-15 parts of fused magnesite with the particle size being larger than or equal to 5 mm and smaller than 8 mm, 5-25 parts of fused magnesite with the particle size being larger than or equal to 3 mm and smaller than 5 mm, 5-25 parts of fused magnesite with the particle size being larger than or equal to 1 mm and smaller than 3 mm, 10-20 parts of fused magnesite with the particle size being smaller than 1 mm, 5-15 parts of fused magnesite fines, 5-20 parts of magnesium aluminate spinel powder, 0-1 parts of carbon powder, 1-3 parts of binding agent and 0-4 parts of additive, wherein the carbon powder and the additive exist in the brick certainly. The ultra-low carbon periclase-spinel-carbon brick has the advantages that the fused magnesite, the magnesium aluminate spinel powder and carbon are used as main raw materials, a small part of carbon powder is used as replacement to ensure that a matrix is not wet by refining slag, and spinel powder high in thermal shock resistance and alkali slag resistance is added to ensure thermal shock resistance of the brick.

Owner:海城利尔麦格西塔材料有限公司

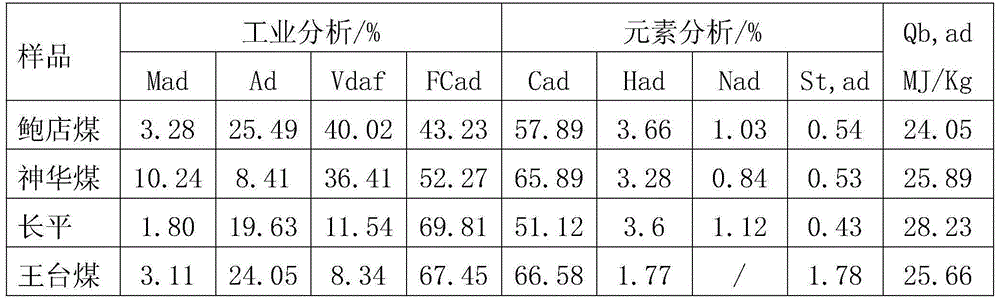

Application of coal water slurry additive

InactiveCN105038879APrevent coalescenceImprove wettabilityLiquid carbonaceous fuelsFuel additivesCoal waterViscosity

The invention relates to the technical field of additives, and particularly discloses an application of a coal water slurry additive. The application comprises the following steps of manufacturing, liquid preparation and mixing of the coal water slurry additive. The dosage is small, and efficiency is high. The prepared coal water slurry is low in surface viscosity, high in concentration and good in stability. Meanwhile, the coal water slurry additive can be used for coal of different metamorphic grades and is high in applicability.

Owner:XIAN BAYER COMPOSITE MATERIAL CO LTD

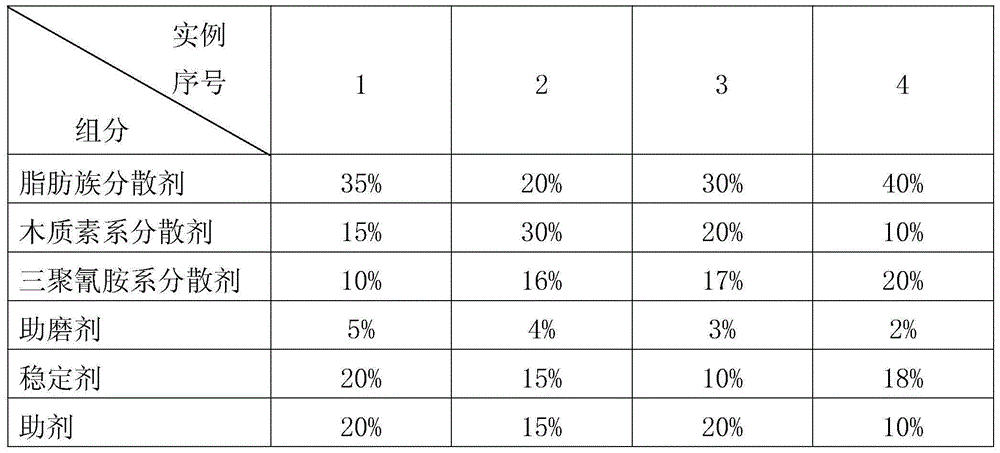

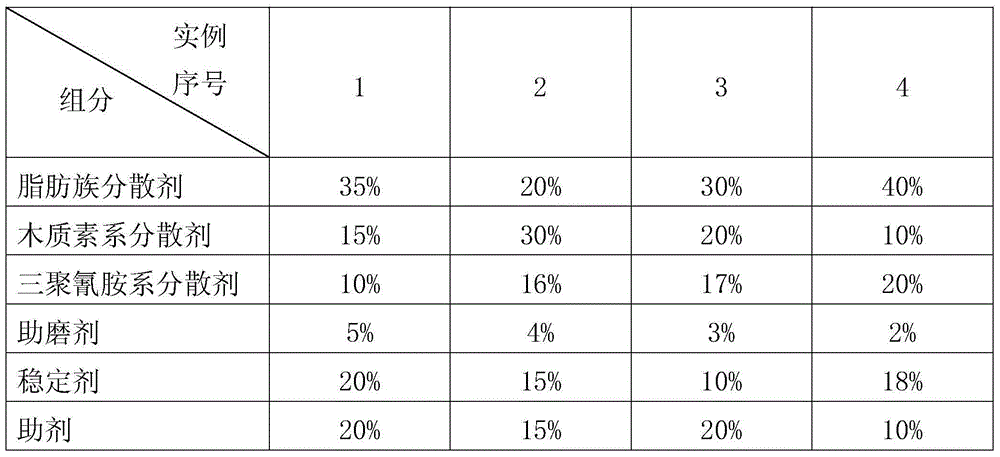

Multi-component water-coal-slurry additive

InactiveCN104804785APrevent coalescenceImprove wettabilityLiquid carbonaceous fuelsMelamineComponents of crude oil

The invention relates to the technical field of additives, and particularly discloses a multi-component water-coal-slurry additive. The additive comprises the following components in percentage by weight: 30 to 50 percent of an aliphatic dispersant, 10 to 30 percent of a lignin-based dispersant, 10 to 20 percent of a melamine dispersant, 2 to 5 percent of a grinding aid, 10 to 20 percent of a stabilizing agent, and 5 to 10 percent of an auxiliary agent. The additive is low in dosage and high in efficiency, and the prepared water coal slurry is low in surface viscosity, high in concentration and good in stability; as the additive can be applied to coals with different metamorphic grades, the additive has wide applicability.

Owner:XIAN BAYER COMPOSITE MATERIAL CO LTD

Para-aramid nanofiber/high-performance carbon fiber composite paper and preparation method thereof

ActiveCN113293640AIncrease surface areaDeep scarPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPolymer scienceAdhesive

The invention belongs to the field of papermaking technologies and materials, and particularly relates to para-aramid nanofiber / high-performance carbon fiber composite paper and a preparation method thereof. By utilizing the characteristics of a large specific surface area, easy dispersion in an aqueous solution and the like of para-aramid nanofibers, the para-aramid nanofibers can replace a traditional wet strength agent and an adhesive for pulp; the para-aramid nanofibers can be fully and uniformly mixed with a high-performance carbon fiber solution, and a wet paper sheet of para-aramid and carbon fibers is prepared through wet papermaking; then a para-aramid nanofiber dispersion liquid is subjected to spraying and sizing on the surface of the aramid wet paper sheet; then compounding, drying and forming are conducted; and thus, the sprayed and compounded paper sheet can remarkably improve the uniformity and mechanical strength of the composite paper, improve the production efficiency of a composite paper-based material and the like, and can fully realize the compounding of the carbon fibers and the aramid fibers. A composite material prepared by using the method has good heat resistance and chemical stability and excellent heat conduction and electric conduction performance.

Owner:山东聚芳新材料股份有限公司

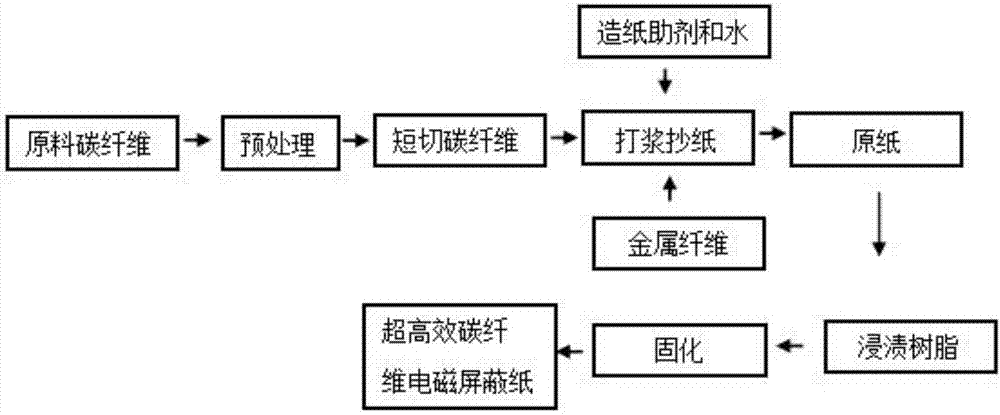

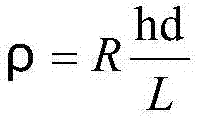

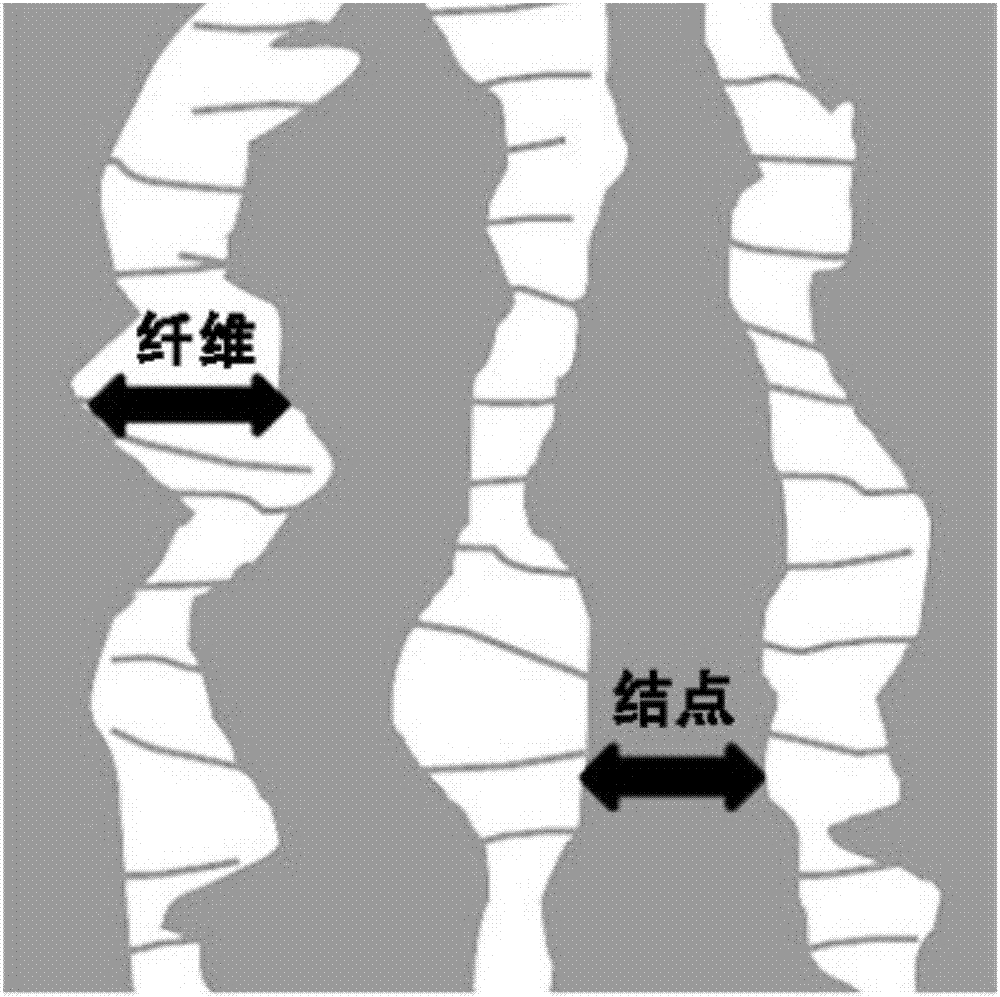

Preparation of superefficient carbon fiber electromagnetic shielding paper

ActiveCN107012721AEvenly dispersedHigh bonding strengthMagnetic/electric field screeningMechanical paper treatmentFiberCarbon fibers

The invention discloses preparation of superefficient carbon fiber electromagnetic shielding paper and belongs to the field of special paper. According to the method, complementary advantages of two fibers, namely carbon fibers and metallic conductive fibers, are innovatively utilized, the defect that the previous single carbon fiber paper-based material is insufficient in toughness is changed, and physical properties and conductivity of the carbon fiber electromagnetic shielding paper are optimized, thereby guaranteeing that the finished paper has good and higher shielding effectiveness and also has good mechanical properties and flexibility; meanwhile, the superefficient carbon fiber electromagnetic shielding paper is wider in applicability and easy to use and has higher conductivity, higher electromagnetic shielding property, better heat resistance and better air permeability, all the indexes are effectively controlled, and the superefficient carbon fiber electromagnetic shielding paper can be cut at will and used.

Owner:JIANGNAN UNIV

Special steel drainage agent and preparation method thereof

ActiveCN109202055AAppropriate refractorinessImprove liquidityMelt-holding vesselsGranularityNuclear power

The invention provides a special steel drainage agent and a preparation method thereof and belongs to the technical field of metallurgical fireproof materials. The special steel drainage agent is prepared by following raw materials of, by weight, 22-75 parts of natural zircon sand with granularity of 0.1-0.5mm, 8-40 parts of chrome ore with granularity of 0.1-0.5mm, 15-35 parts of desert sand withgranularity of 0.3-0.6mm and 1-3 parts of liquid graphite. According to the invention, the pouring rate of a product can be effectively improved; compared with the existing drainage agent, the automatic pouring rate can be improved by 10% or over and the basic automatic pouring rate can reach 100%; requirements are met that there are many types of special steel currently, the difference of components is big and long-time smelting is required; and the drainage agent and better drainage effects for steel types in war industry, nuclear power and special high-quality products are achieved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Automatic-flowing quick-drying pouring material for blast furnace iron runner

The invention discloses an automatic-flowing quick-drying pouring material for a blast furnace iron runner. The automatic-flowing quick-drying pouring material is composed of the following main raw materials in percentage by weight: 65-70% of dense corundum, 14-18% of black silicon carbide, 3-7% of silicon nitride, 1-2% of a composite water-reducing admixture, 1-2% of a compound anti-blasting material, 1-3% of pure aluminum silicate cement, 1-3% of ultrafine silica powder, 2-4% of reactive alumina micro powder and 2-4% of silica powder. The preparation method comprises the following steps: adding various raw materials into a mixing reactor with a powerful stirring propeller for performing strong stirring, and packaging after stirring, thereby obtaining the product, namely the automatic-flowing quick-drying pouring material for the blast furnace iron runner. The product disclosed by the invention has the advantages of being resistant to corrosion of molten iron and slag, high in erosionresistance, excellent in thermal shock resistance, excellent in flaking resistance, high in oxidation resistance, easy in construction, capable of performing rapid baking without burst and preventingproduction of harmful gases and adhesion of iron slag, and long in service life, and the like.

Owner:河南欣昌耐材股份有限公司

High-strength fire-resistant thermal insulation material

The invention discloses a high-strength fire-resistant thermal insulation material. A preparation method of the high-strength fire-resistant thermal insulation material comprises the following steps: preparing a shaped product with the required size by using expanded vermiculite, clay, refractory cement and dextrin as initial materials and adding a waterproof agent and a binding agent in a mechanical pressing forming manner, wherein a nano-modification organic silicon rubber solution is used as the waterproof agent, and the binding agent is an inorganic binding agent, drying, carrying out heat preservation, and baking at a high temperature, thus obtaining the high-strength fire-resistant thermal insulation material. The high-strength fire-resistant thermal insulation material has the advantages of good structure and volume stability, high strength, low cost, simple process, convenience for construction and baking, environmental protection, safety and the like.

Owner:内蒙古包钢利尔高温材料有限公司

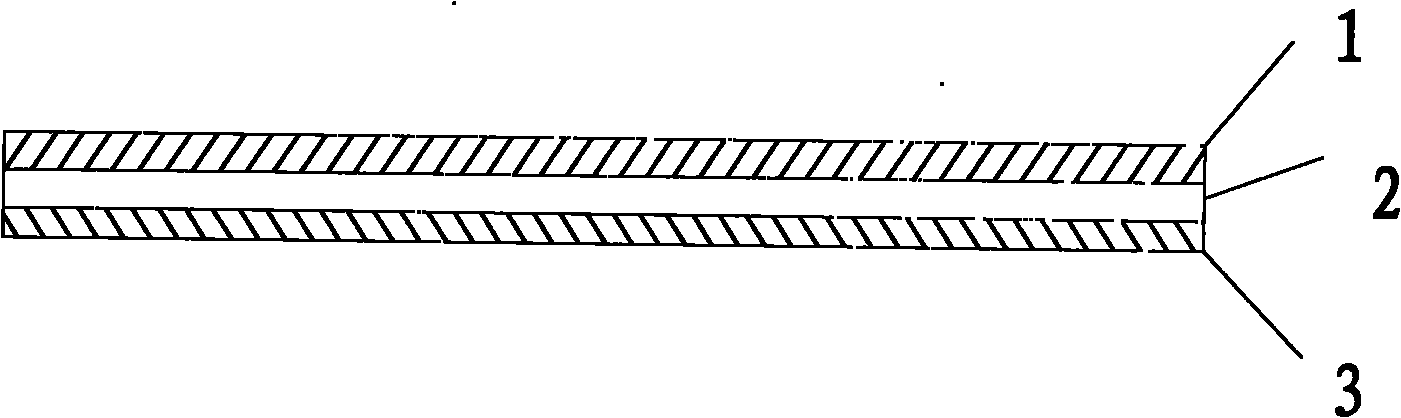

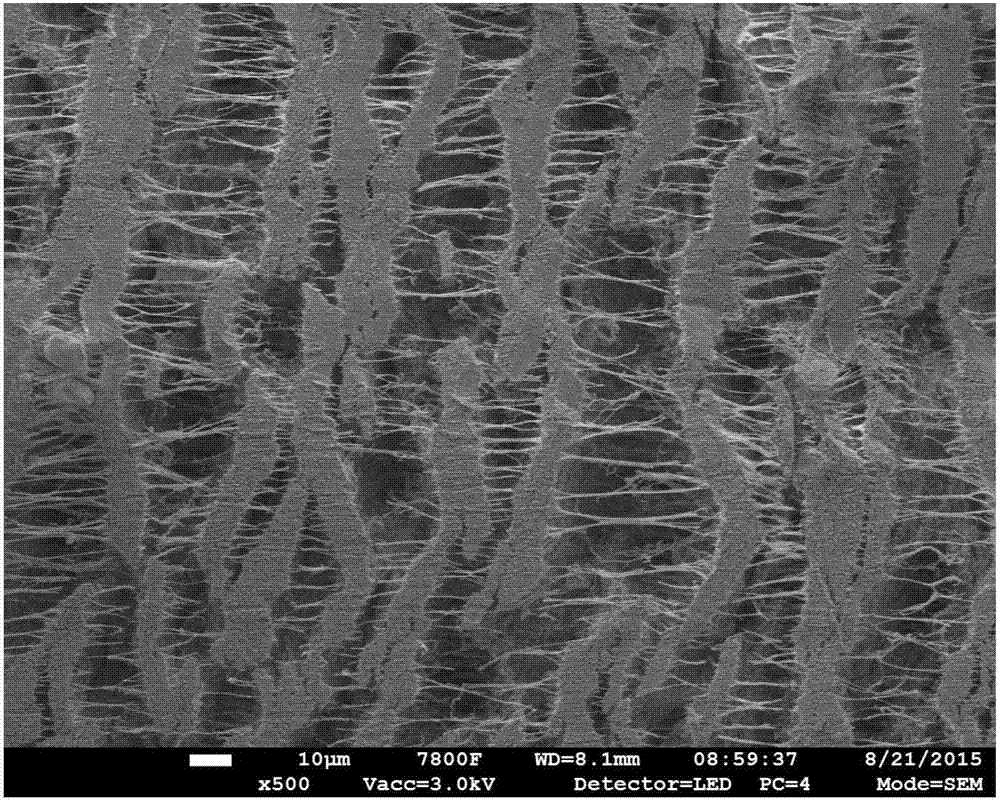

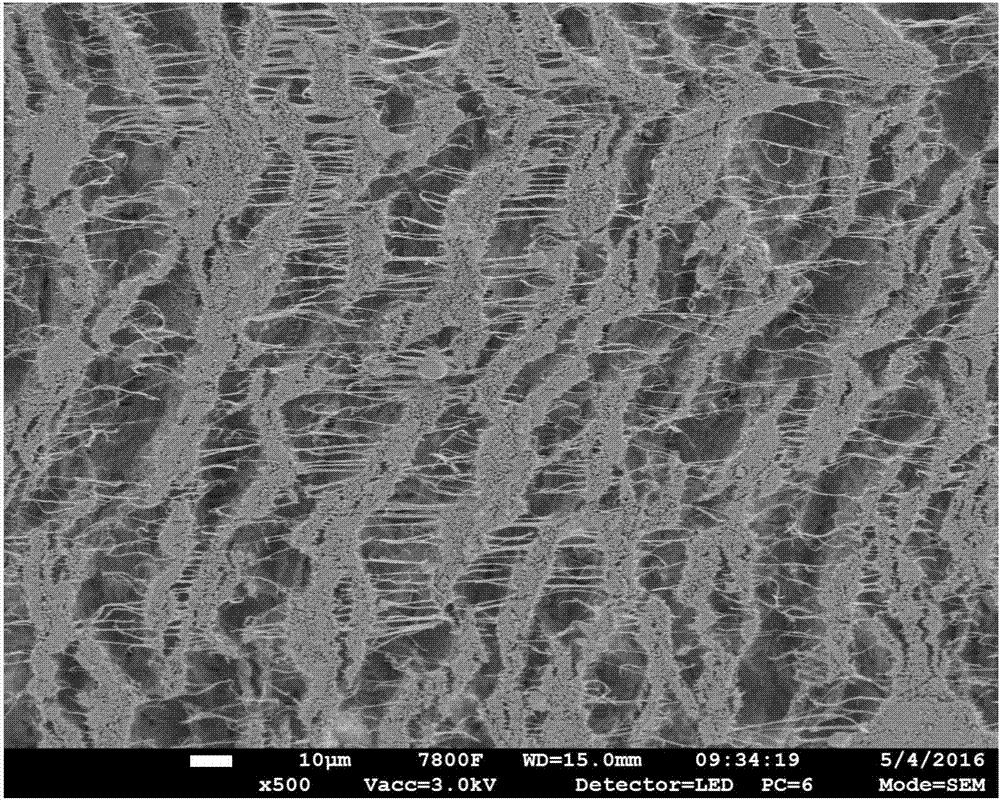

Method for controlling micro-pore structure of polytetrafluoroethylene hollow fiber membrane

PendingCN107537326AHigh filtration precisionStable structureSemi-permeable membranesHollow fibre membraneFiber

The invention relates to a method for producing a polytetrafluoroethylene hollow fiber membrane and a method for controlling the micro-pore structure of the polytetrafluoroethylene membrane. A paste mixture is prepared from polytetrafluoroethylene dispersion resin and a lubricating additive, the hollow fiber membrane is produced through an extrusion technology, and the pore structure of the membrane is controlled and optimized through a two-stage variable temperature stretching technology. The polytetrafluoroethylene hollow fiber membrane produced through the methods has a uniform micro-pore structure and uniform pore distribution.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

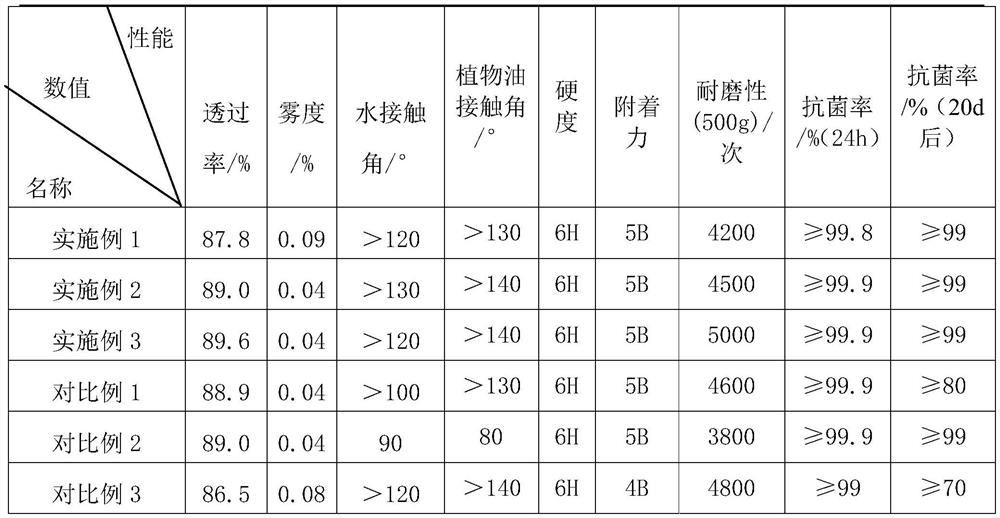

Anti-fingerprint antibacterial glass

ActiveCN113105776AStrong antibacterial abilityGood antifouling performanceAntifouling/underwater paintsPaints with biocidesDichloromethaneOrganosilicon

The invention relates to the field of antibacterial glass, in particular to an anti-fingerprint antibacterial glass. The anti-fingerprint antibacterial glass comprises an original glass sheet and an anti-fingerprint antibacterial layer which coats the upper surface of the original glass sheet, the anti-fingerprint antibacterial layer is formed by coating an antibacterial composition, and the antibacterial composition is prepared from, by mass, 2 to 10 percent of organic modified acrylic resin, 60 to 80 percent of methylbenzene, 10 to 30 percent of dichloromethane and 1 to 8 percent of fluorinated silver-loaded carbon nanohorn ethanol dispersion liquid. The fluorinated silver-loaded carbon nanohorn ethanol dispersion liquid is prepared on the basis of carboxylated single-walled carbon nanohorns and has antibacterial, antifouling and anti-fingerprint effects, and the antibacterial effect reaches 99% or above. According to the antibacterial glass, self-assembly of the antibacterial nano particles and the synergistic effect of the components are induced through solvent volatilization, so that the antibacterial glass has an excellent anti-fingerprint effect and outstanding antibacterial performance, and breeding of bacteria on the surface can be effectively inhibited.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

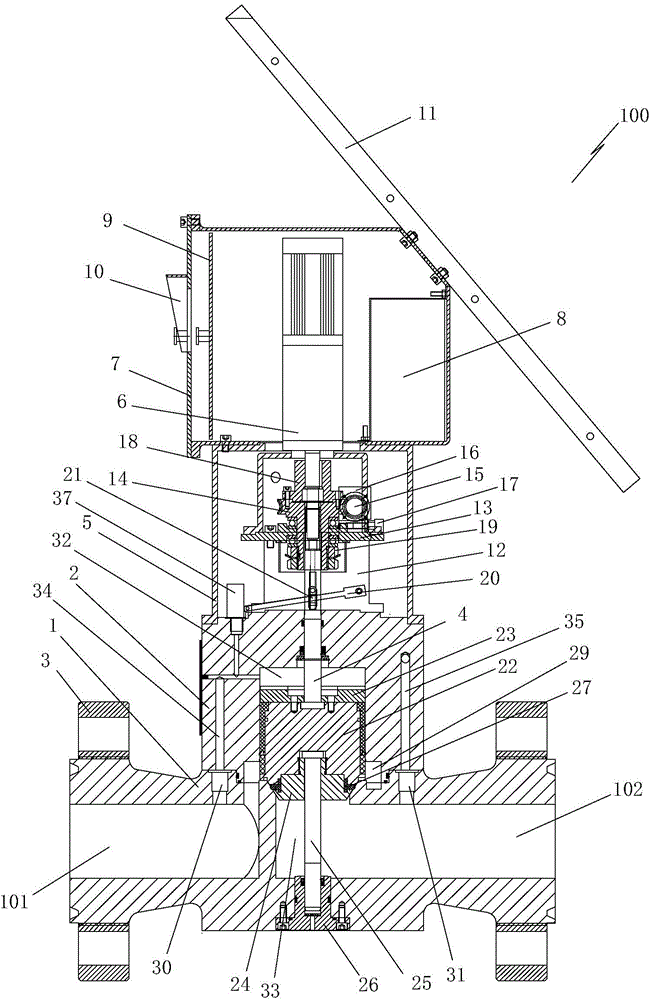

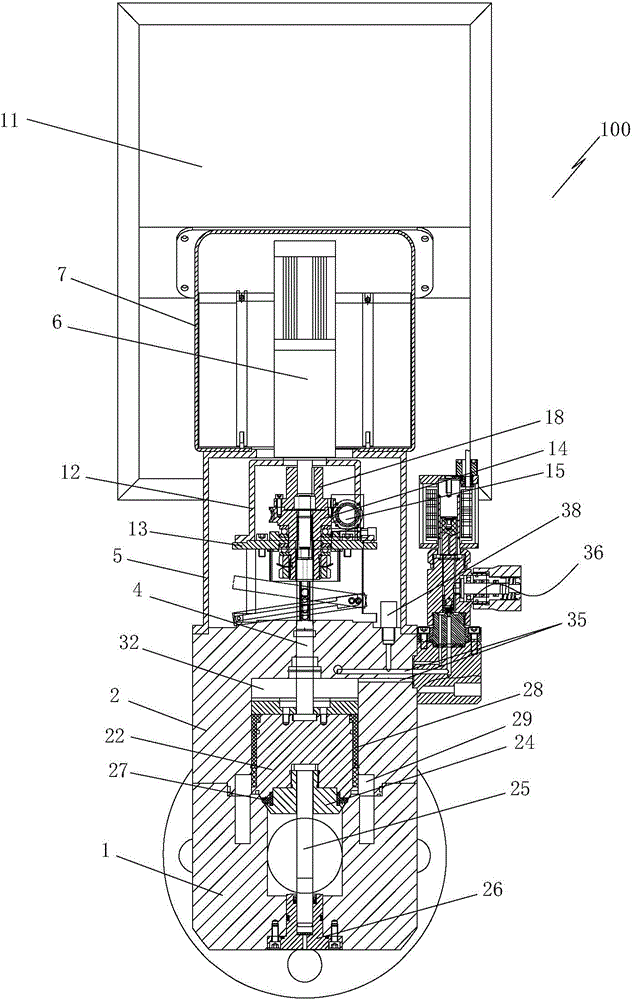

Intelligent explosion-proof solenoid valve

ActiveCN104695900AEasy to wetAvoid stayingOperating means/releasing devices for valvesWell/borehole valve arrangementsInlet channelSolenoid valve

The invention provides an intelligent explosion-proof solenoid valve. The intelligent explosion-proof solenoid valve comprises a valve body and a valve cover, wherein the valve body is internally provided with an air inlet channel and an air outlet channel; a main valve element assembly is arranged in the valve cover; the upper end of the main valve element assembly is connected with a valve element lifting mechanism by a pull rod; the lower end of the pull rod is fixedly arranged at the upper end of the main valve element assembly; the upper end of the pull rod upwards stretches out of the top of the valve cover and is connected with the valve element lifting mechanism. The valve element lifting mechanism is arranged in a shield and the shield is fixedly arranged at the top of the valve cover; a motor which is vertically arranged in arranged above the shield; the output shaft of the motor is connected with the valve element lifting mechanism; the motor is located in a control cabinet; the control cabinet is fixed above the shield; a lithium battery and a control panel are further arranged in the control cabinet; a display screen is arranged on the side wall of the control cabinet; a solar panel for charging the lithium battery is arranged on the outer side of the control cabinet. The intelligent explosion-proof solenoid valve can be used for independently finishing the control of switching on and off the valve in the field, and other existing equipment on a wellhead is not needed; the control reliability is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

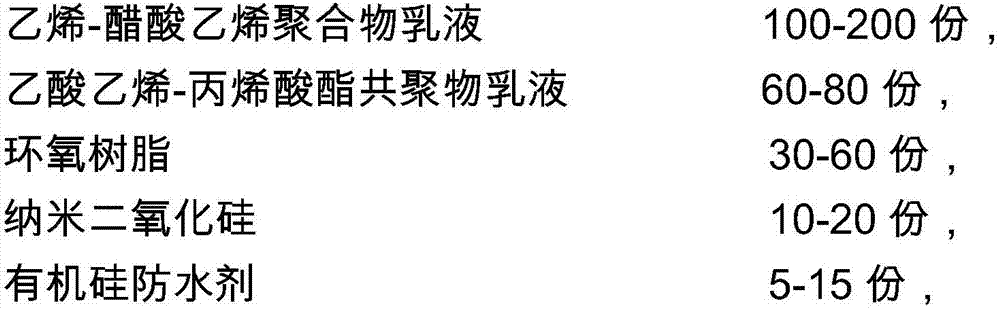

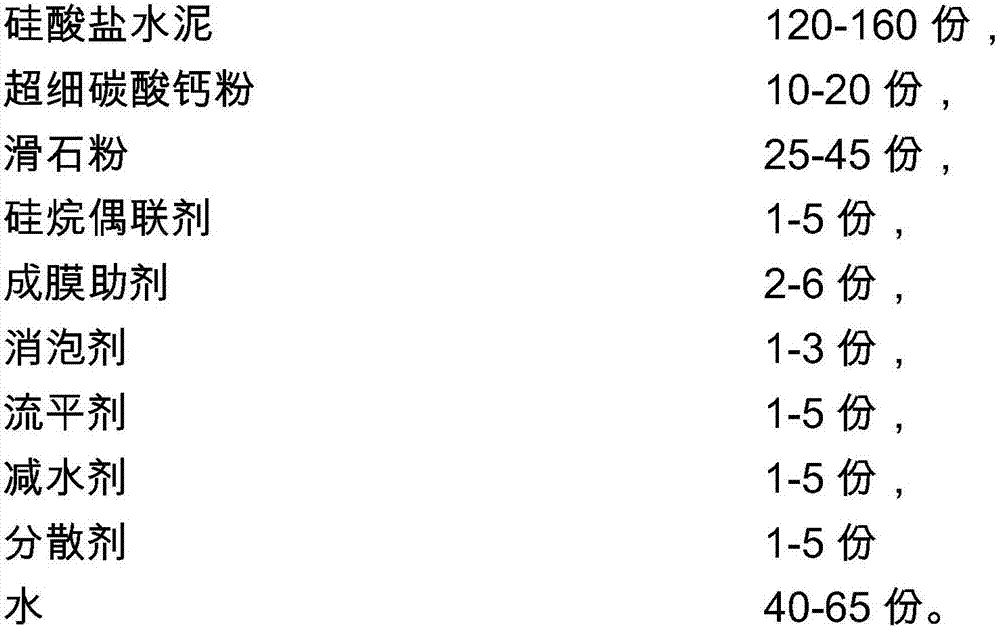

Polymer cement-based waterproof coating

InactiveCN107964287AHigh strengthImprove physical organizationEpoxy resin coatingsEpoxyPolymer science

The invention discloses a polymer cement-based waterproof coating. The polymer cement-based waterproof coating comprises an ethylene-vinyl acetate polymer emulsion, a vinyl acetate-acrylate copolymeremulsion, epoxy resin, nanometer silicon dioxide, an organic silicon waterproof agent, Portland cement, ultrafine calcium carbonate powder, talcum powder and filming additives. Through use of the mixed emulsion of the ethylene-vinyl acetate polymer emulsion and the vinyl acetate-acrylate copolymer emulsion, good synergistic promoting effects are obtained, the compactness and mechanical propertiesof the polymer waterproof coating are improved, elasticity is good, elongation is good, anti-permeability, durability and aging resistance are good, a service life is long and waterproof effects are good.

Owner:SUZHOU BIZUNION ARCHITECTURAL ENG CO LTD

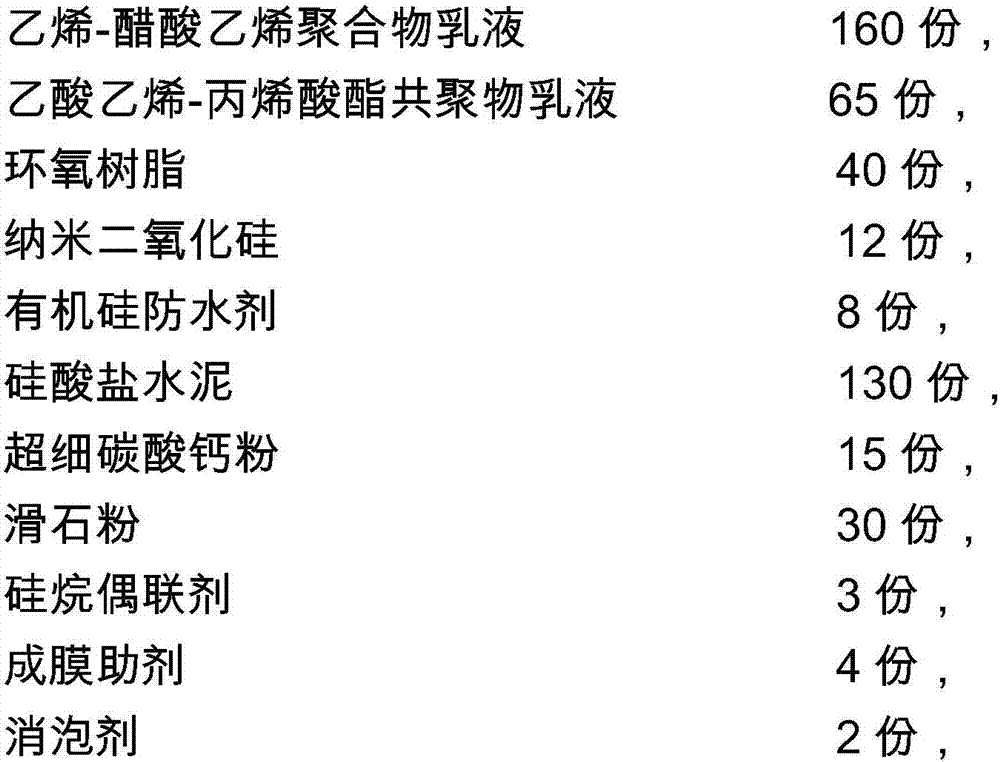

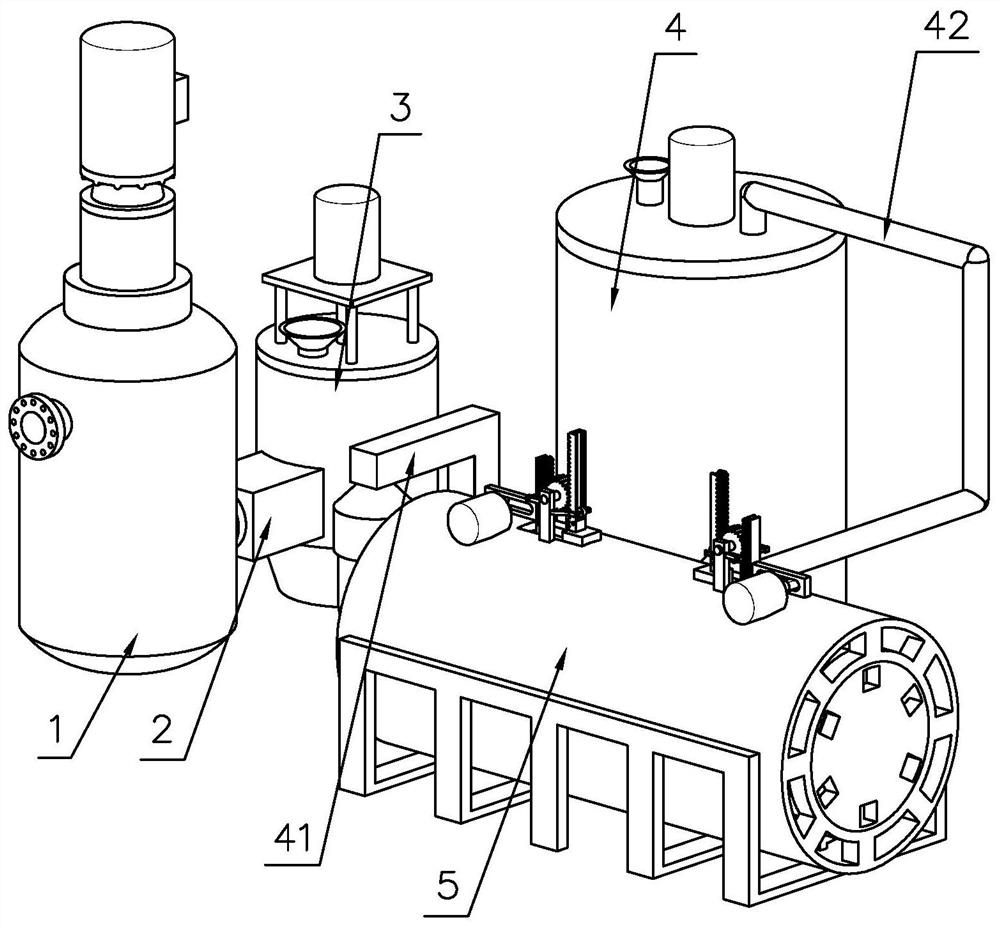

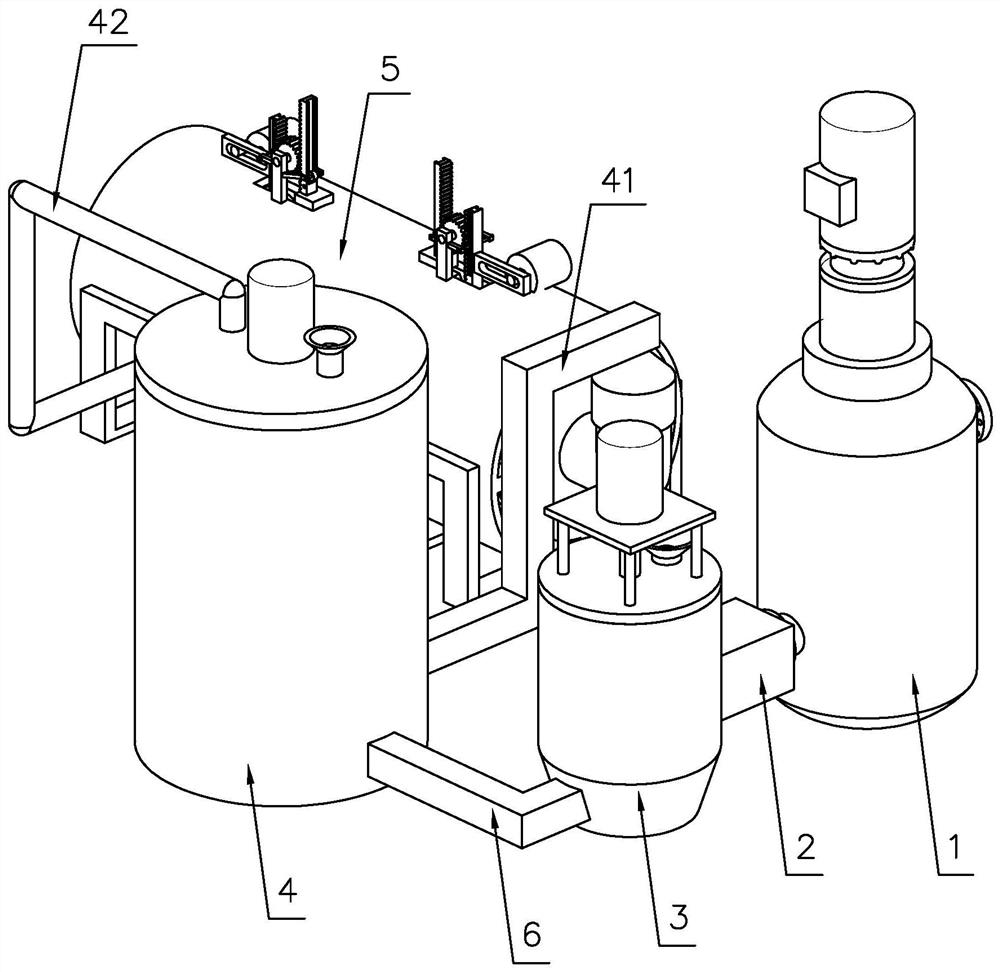

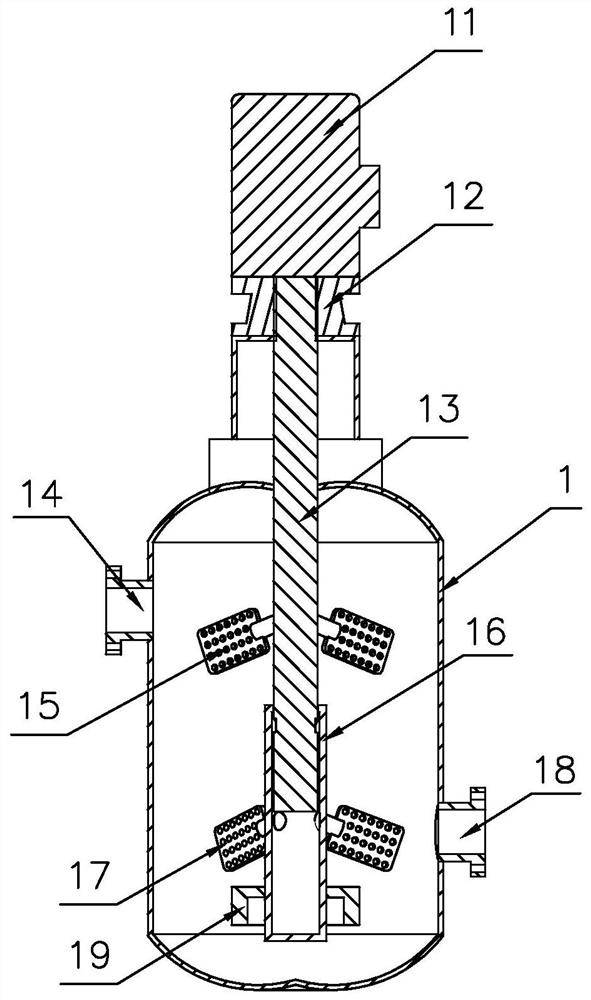

Preparation device and preparation method of hydrophobic slow-release organic-inorganic compound fertilizer

PendingCN112939670AReduce solubilitySlow decompositionAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSpray GranulationSoil science

The invention discloses a preparation device and a preparation method of a hydrophobic slow-release organic-inorganic compound fertilizer, the preparation device of the hydrophobic slow-release organic-inorganic compound fertilizer comprises an activation reaction kettle, a material conveying channel I, a compounding tank, a buffer tank, a spraying granulation dryer and a material conveying channel II; according to the invention, the hydrophobic agent is coated to form a plurality of hydrophobic layer films in the fertilizer particles, so that the pores of the fertilizer particles are blocked, the surface wetting angle of the fertilizer particles is increased, water in soil is not easy to wet the interiors of the fertilizer particles, and water-soluble inorganic nutrients in the fertilizer are not leached; and inorganic nutrients are gradually released from outside to inside only along with gradual decomposition and utilization of organic matters from outside to inside, and the hydrophobic slow-release organic-inorganic compound fertilizer can have multiple nutrient proportions from outside to inside through slurry with multiple nutrient proportions and multi-layer spraying granulation.

Owner:山东奥德鲁生物科技有限公司

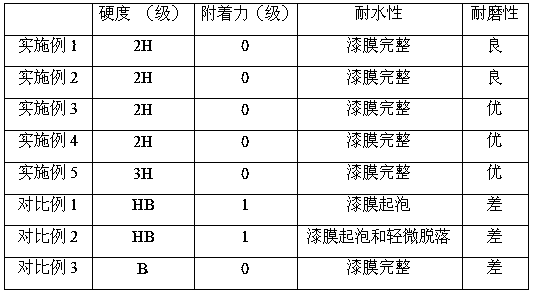

Heat-insulating anticorrosion bi-component coating for outer wall of oil tank and preparation method thereof

InactiveCN109401475AHighlight substantive featuresSignificant progressAnti-corrosive paintsReflecting/signal paintsFoaming agentAcrylic resin

The invention relates to the field of coatings and specifically relates to a heat-insulating anticorrosion bi-component coating for an outer wall of an oil tank and a preparation method thereof. The heat-insulating anticorrosion bi-component coating comprises a component A and a component B; the component A comprises the following raw materials in parts by weight: 50-60 parts of acrylic resin, 15.0-20.0 parts of titanium dioxide, 3.0-5.0 parts of thermal reflection powder, 5.0-8.0 parts of quartz sand, 0.3-0.5 part of surface active agent, 1.5-3.0 parts of dispersing agent, 0.1-0.5 part of anti-settling agent, 0.5-1.0 part of de-foaming agent and the balance of water; the component B comprises the following raw materials in parts by weight: 70-75 parts of biuret and 0.1-2.0 parts of auxiliaries. The coating can achieve ultrahigh reflectivity, is capable of excellently reflecting solar radiation and achieving heat-insulating and cooling effects and has excellent coating hardness, abrasion resistance, alkali resistance and water resistance.

Owner:广西南宁维一防腐科技有限公司

Method for preparing high-adhesion wear-resistant paint used for polycarbonate

InactiveCN108329790AEnhanced interactionIncrease the strength of actionCoatingsPolymer scienceSilanes

The invention provides a method for preparing a high-adhesion wear-resistant paint used for polycarbonate. The method comprises the following steps: chlorinated polypropylene resin and modified resinare mixed, and stirred for 5-10 min, a BYK-163 type dispersant, a BYK-071 type antifoaming agent, dibutyltin dilaurate, cellulose acetate butyrate, corundum micro powder, ultrafine mica powder and a porous inorganic particle material are added under a stirring state, a sand milling machine is used for grinding the materials with fineness being less than or equal to 25 [mu]m, a solvent is added, the materials are heated to the temperature of 30-40 DEG C and is subjected to heating backflow for 1h, a silane coupling agent and a curing agent are added, cooling is carried out to room temperature,and the solvent is used for dilution. The paint has high adhesion, water resistance and excellent wear resistance.

Owner:SUZHOU FUZHONG PLASTIC CO LTD

Ladle edge castable containing alumina magnesia carbon brick slag

The invention relates to a ladle edge castable containing alumina magnesia carbon brick slag, which is prepared by mixing aggregate, fine powder and an admixture. The aggregate is composed of the following components in parts by weight: 20-30 parts of alumina magnesia carbon brick slag waste with the particle size of 3-5mm, 15-25 parts of alumina magnesia carbon brick slag waste with the particle size of 1-3mm and 20-30 parts of alumina magnesia carbon brick slag waste with the particle size of 0-1mm. The fine powder is composed of the following components in parts by weight: 10-20 parts of 625 cement, 2-4 parts of silicon dioxide micropowder and 20-24 parts of 200-mesh high aluminum powder. The admixture is composed of the following components in parts by weight: 0.1-0.3 part of polycarboxylic acid water reducer and 6-8 parts of water. The castable provided by the invention has the advantages of wide raw material sources, low cost and favorable properties, and can satisfy the service performance requirements for the ladle edge in the ladle edge molding process under different technological conditions; and by using the waste refractory reclaimed material as the main raw material, the castable achieves the goal of comprehensive utilization of the waste refractory material.

Owner:河南海格尔高温材料有限公司

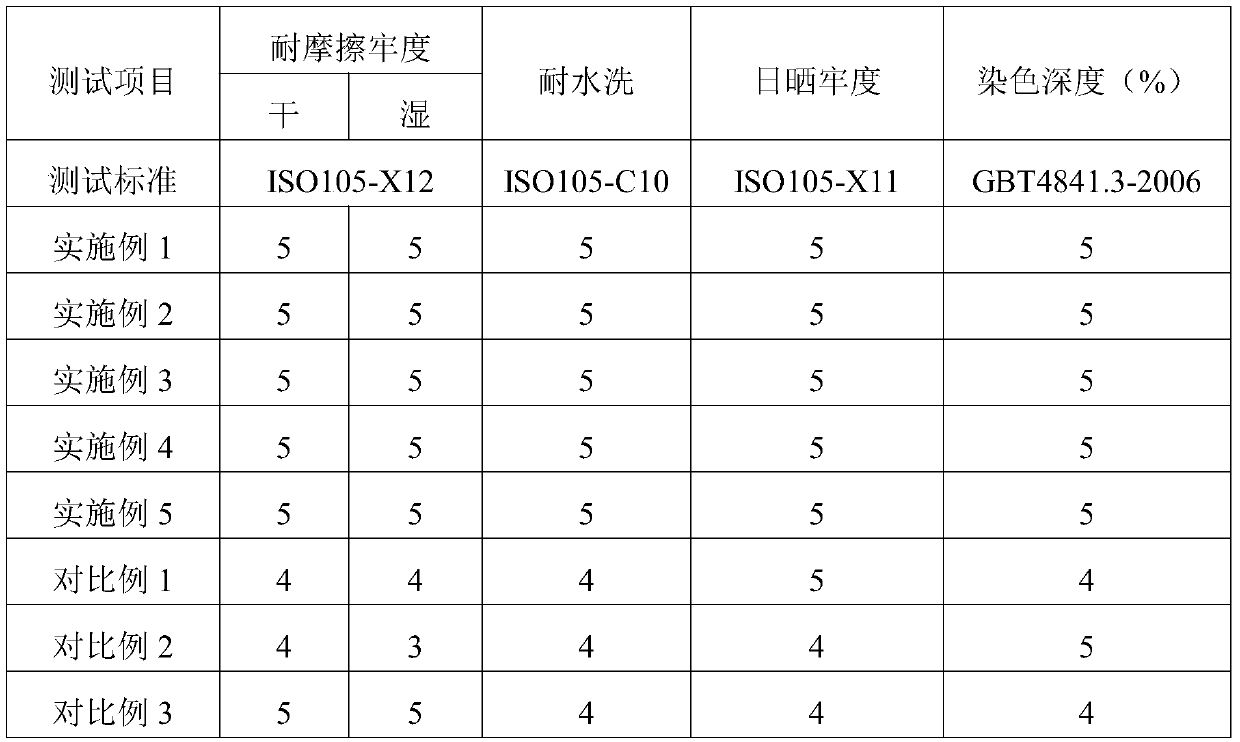

Special pigment carbon black dye and preparation method thereof

InactiveCN110878177ASimple manufacturing methodReduce manufacturing costPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsPolymer scienceMonomethoxypolyethylene glycol

The invention discloses a special pigment carbon black dye which comprises the following components in parts by weight: 10-15 parts of surface modified nano ferroferric oxide; 20 to 30 parts of surface modified carbon black; 3 to 6 parts of monomethoxy polyethylene glycol amine; 5-10 parts of quaternized silicone oil; and 60-70 parts of water. The special pigment carbon black dye disclosed by theinvention has the advantages of being low in preparation cost, remarkable in dyeing and color homogenizing effect, high in color fastness, good in dispersity and acid and alkali resistance, good in hand feeling, not easy to fade, non-irritant to human skin, good in color and luster, good in stability and safe and environment-friendly to use.

Owner:庄明磊

Aluminum oxide electric furnace cover pouring material and preparation method thereof

InactiveCN100478305CImprove thermal shock resistanceImprove slag erosion resistanceFiberShock resistance

The invention relates to a casting material of alumina eafroof and the preparation material thereof. The technic proposal is as following: 1. white corundum of 50-80wt percent, high alumina- bauxite clinker of 3-30wt percent, zirconium corundum of 5-25wt percent, kyanite fine powder of 3-15wt percent, alumina micro-powder of 3-12wt percent, pure aluminate calcium cement of 0-10wt percent and silicon-aluminum gel of 1-5wt percent are mixed together; 2. water reducing agent of 0.10-0.25wt percent, organic fiber of 0.03-0.08wt percent, and water of 5.0-6.5wt percent are then added to the obtained mixture and are stirred for 5-10 minutes, and the mixture is cast for molding; 3. the mold is naturally cured for 12-24 hours and then demolded; 4. the mold is dried for 24 hours under 110 DEG C. According to the size of furnace cover and application requiremenst, the casting molding is designed for whole casting molding or block pouring molding. The block molds are assembled thereafter. The invention is characterized by no environmental pollution, dense structure, good thermal and shock resistance and erosive resistance, and long service life.

Owner:WUHAN UNIV OF SCI & TECH

Refractory sintered clay hollow brick and preparation method thereof

InactiveCN107324823AEasy to makeGood strengthCeramic materials productionCeramicwareEpoxySodium Bentonite

The invention discloses a refractory sintered clay hollow brick, and belongs to the technical field of hollow bricks. The refractory sintered clay hollow brick comprises the following raw materials in parts by weight: 55 to 60 parts of clay, 12 to 16 parts of attapulgite, 10 to 14 parts of silica fume, 8 to 12 parts of glass fibers, 18 to 20 parts of ceramic microbeads, 5 to 9 parts of cement, 3 to 5 parts of corundum powder, 3 to 5 parts of quartz powder, 4 to 6 parts of aluminum oxide, 7 to 9 parts of yttrium oxide, 6 to 8 parts of brominated epoxy resin, 2 to 4 parts of organic bentonite, 1 to 3 parts of starch, 2 to 4 parts of chlorinated paraffin, 4 to 5 parts of melamine cyanurate, 5 to 6 parts of tricresyl phosphate, 1 to 3 parts of antioxidants, 1 to 2 parts of water reducers, 1 to 3 parts of preservatives and an appropriate amount of water. The invention further discloses a preparation method of the refractory sintered clay hollow brick. The refractory sintered clay hollow brick disclosed by the invention is simple to prepare, corrosion resistant and heat-insulated, relatively high in strength and fire resistance, and long in service life.

Owner:HEFEI WANZHIJING DOORS & WINDOWS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com