Patents

Literature

41 results about "Square Micrometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A SI unit of area measurement equal to a square whose sides are one micrometer long. (NCI)

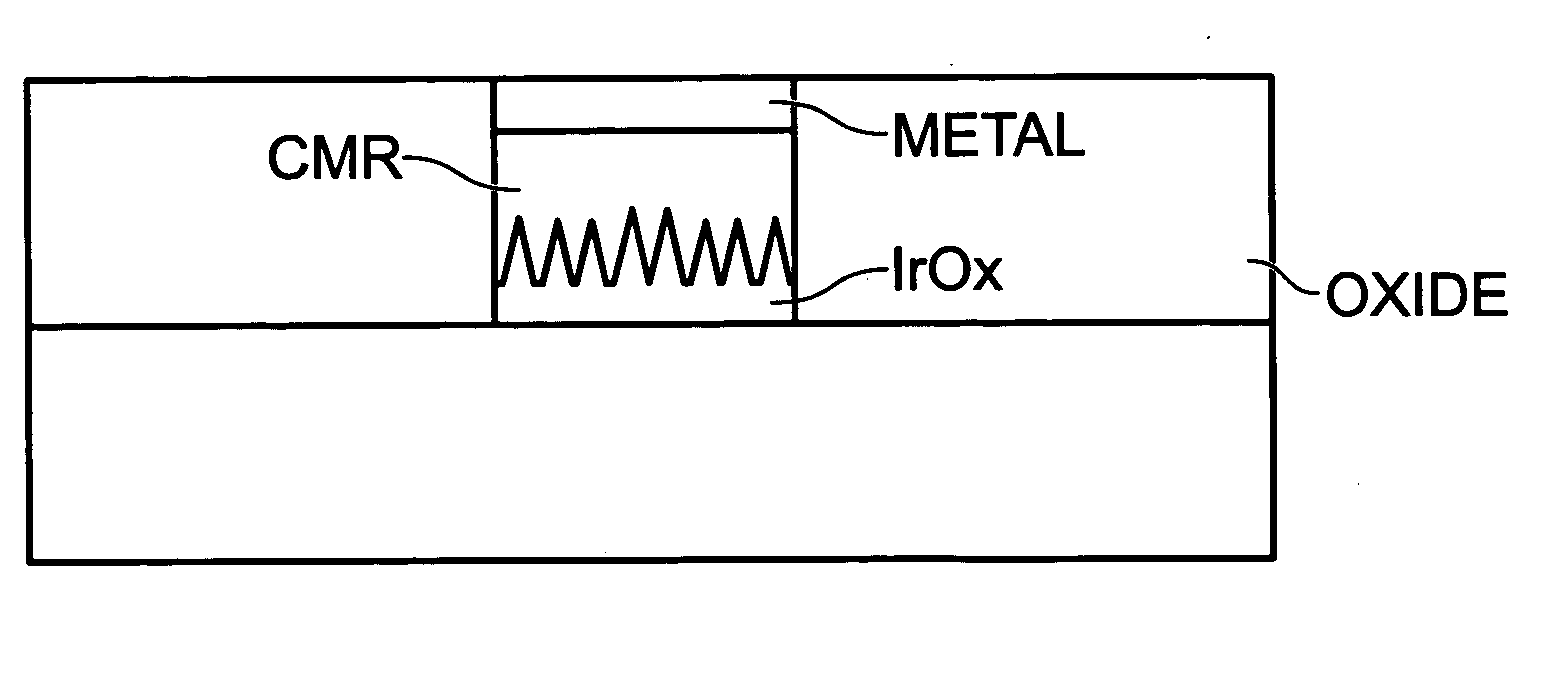

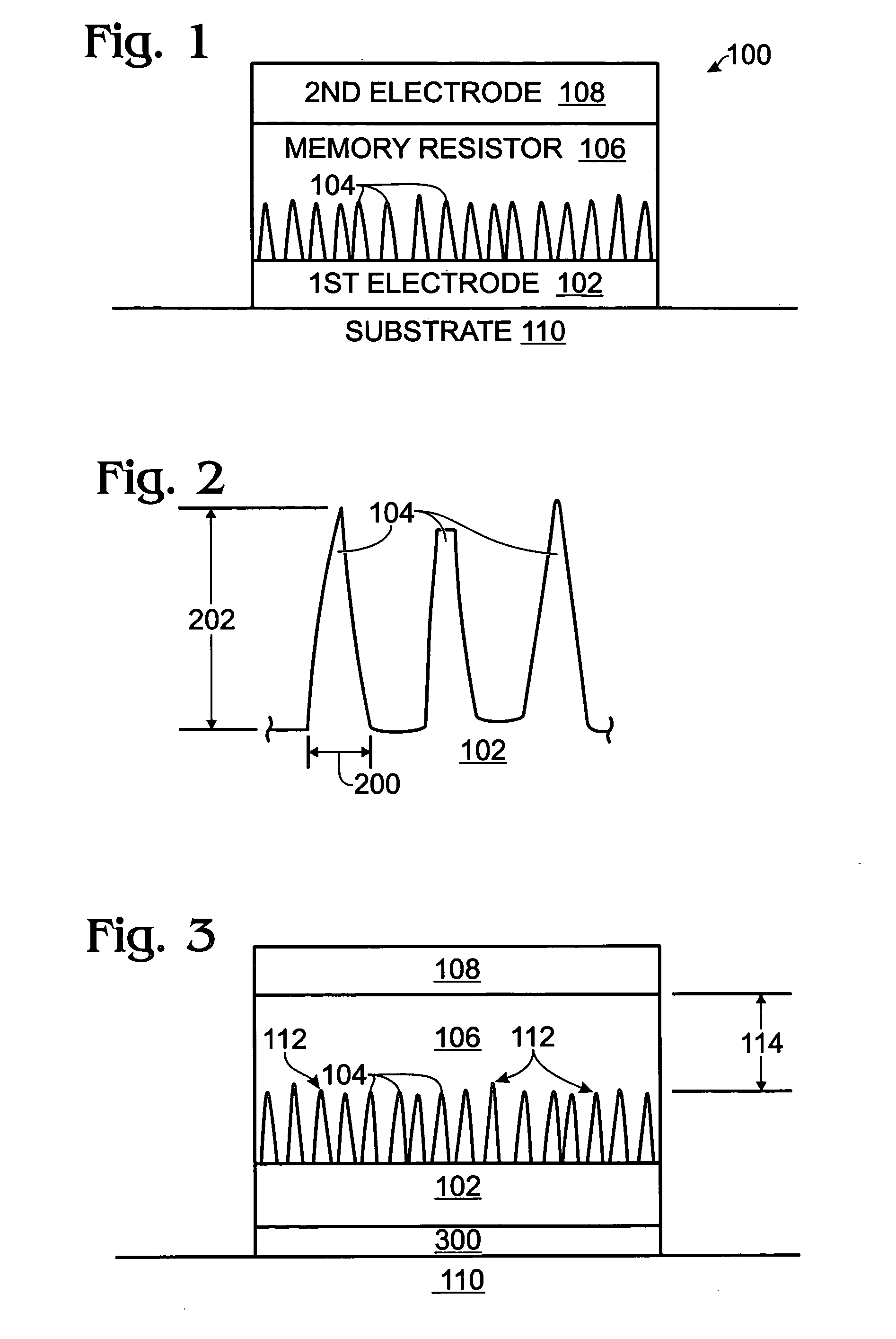

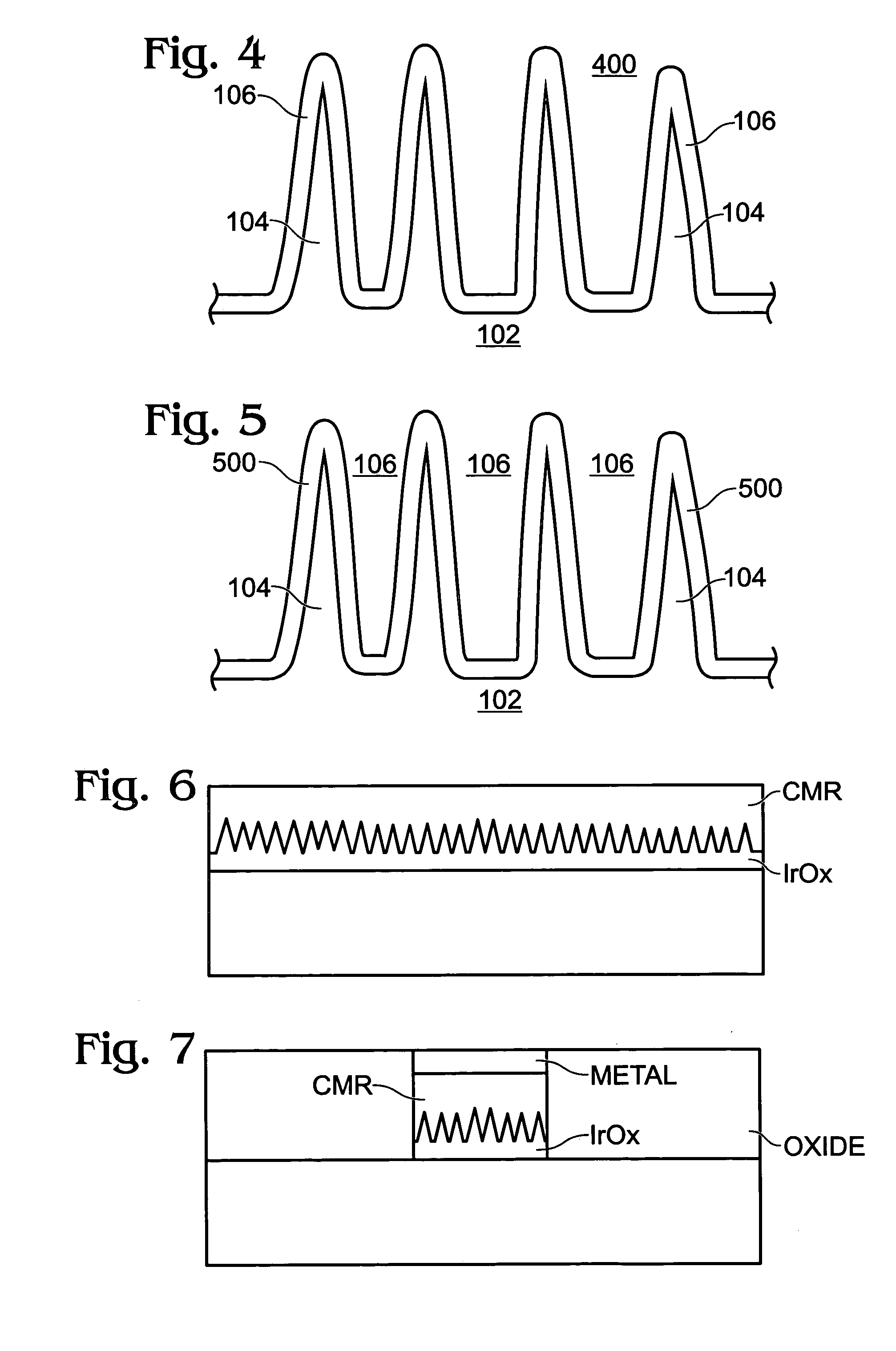

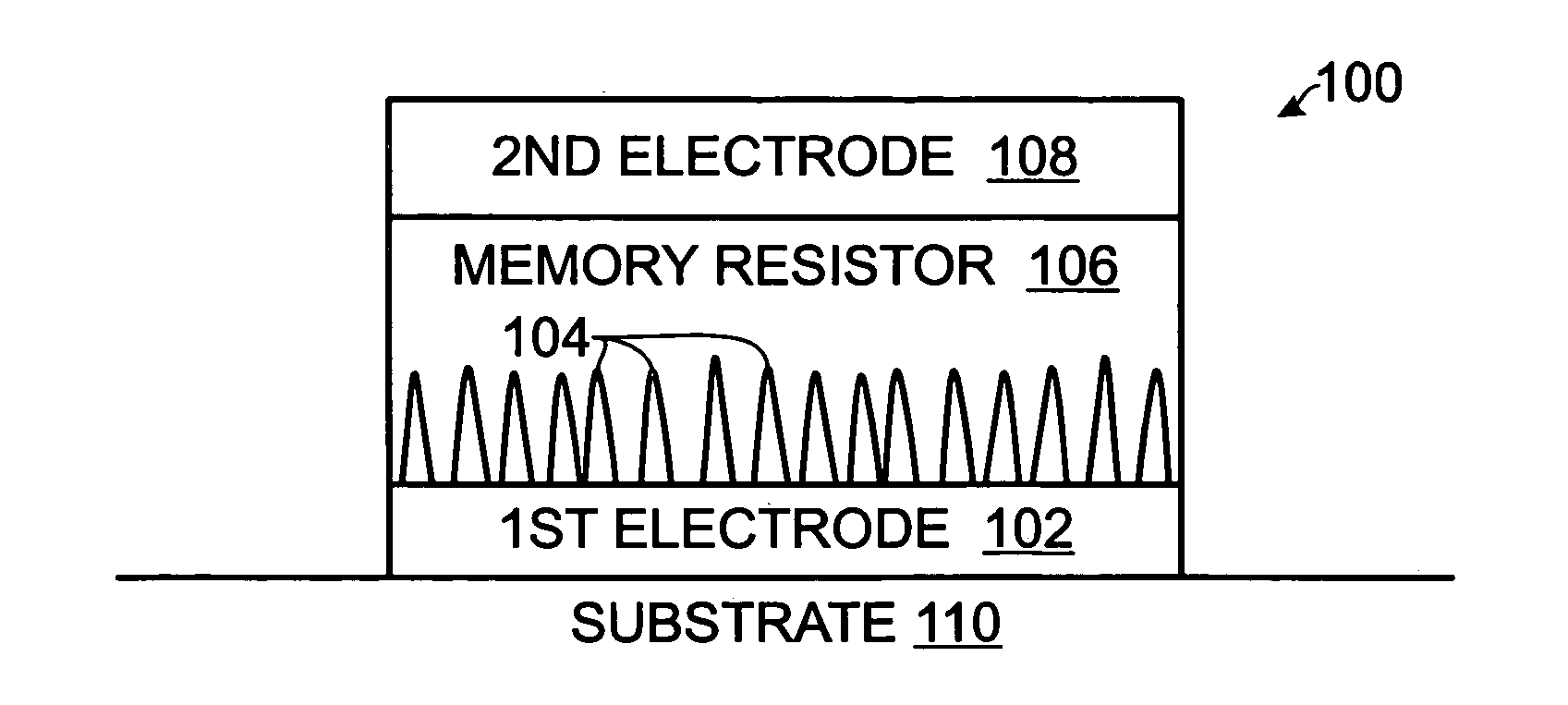

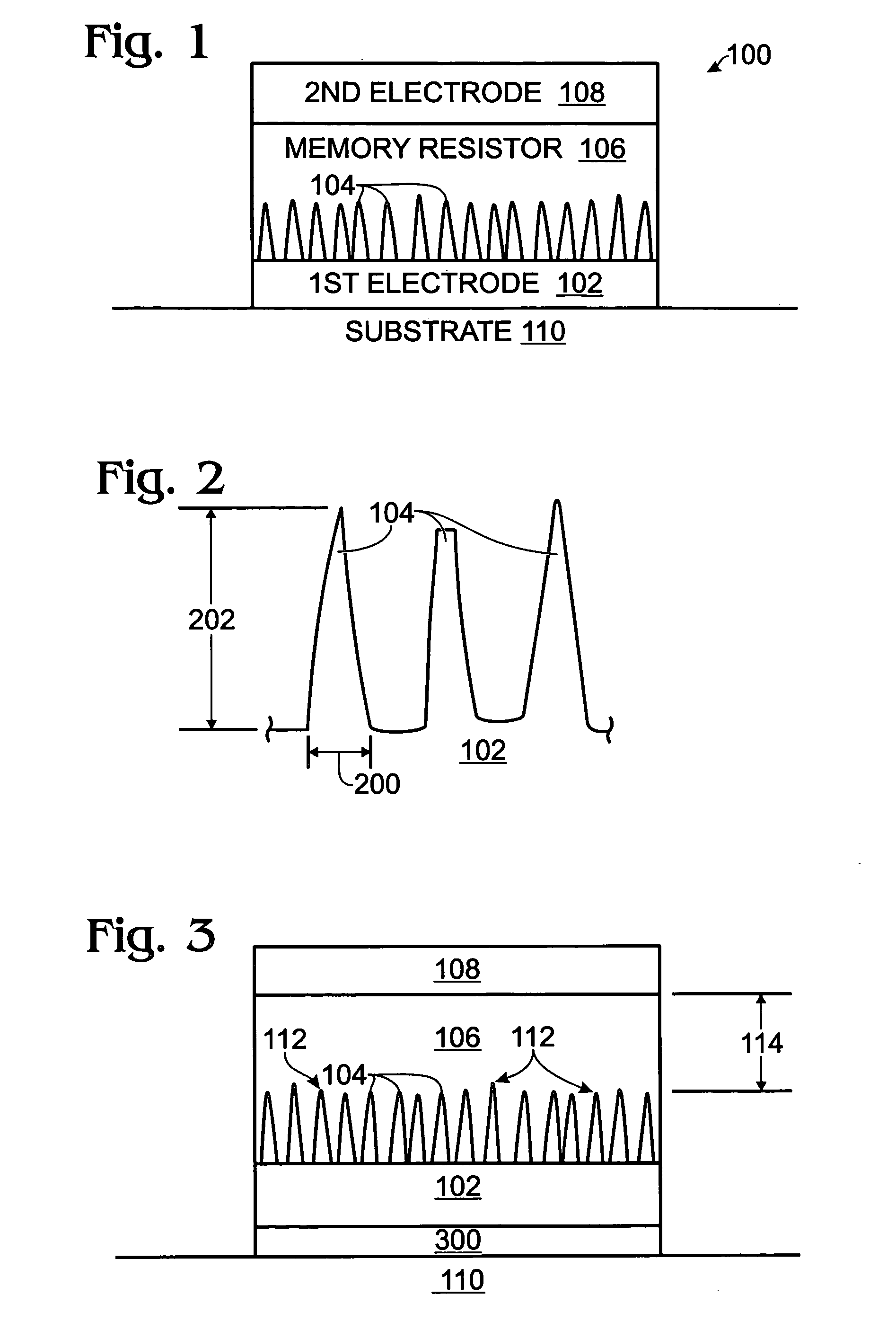

Non-volatile memory resistor cell with nanotip electrode

InactiveUS20060160304A1Promote bipolar switching characteristicReduce voltageSolid-state devicesSemiconductor/solid-state device manufacturingGas phaseEngineering

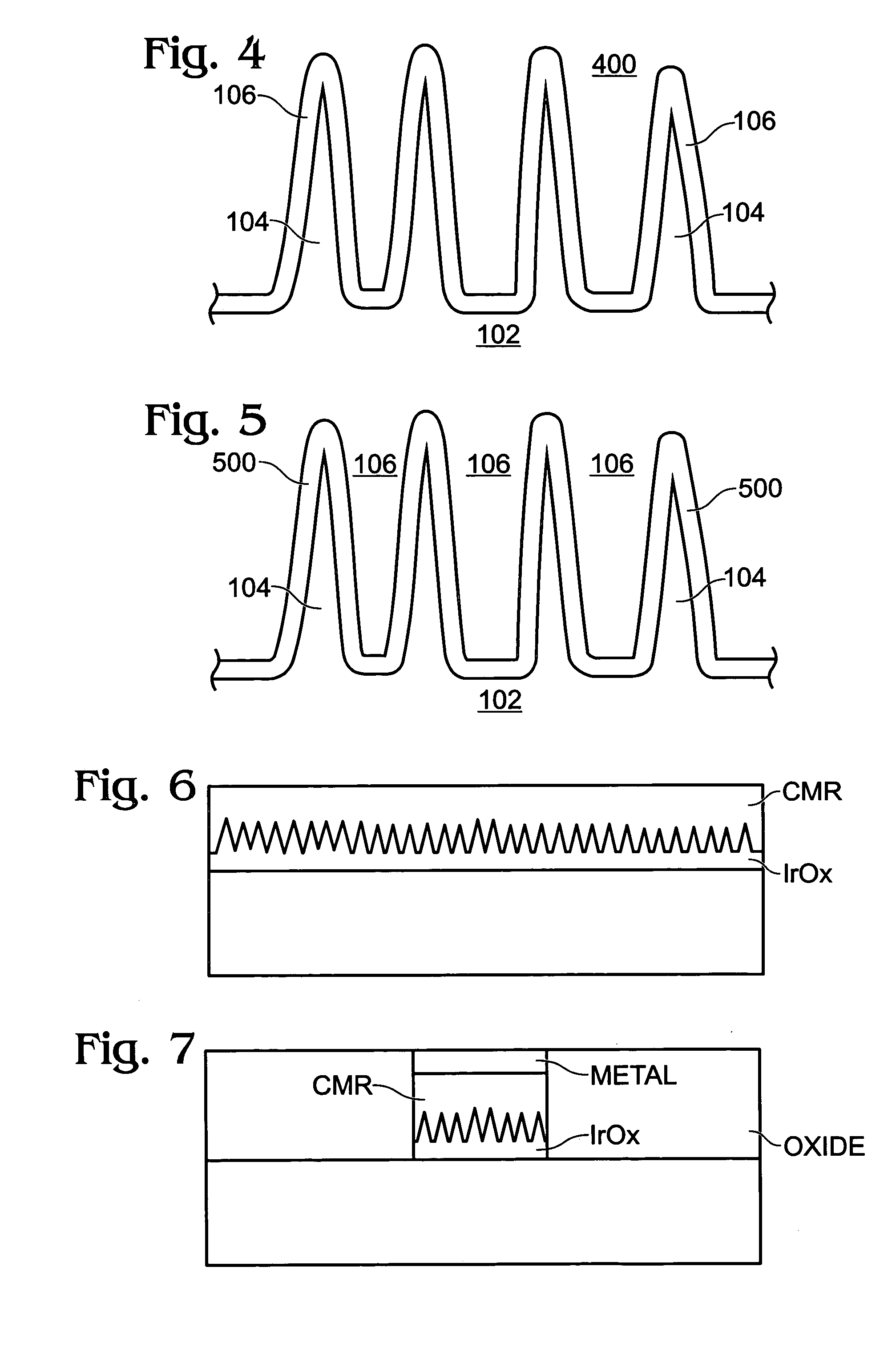

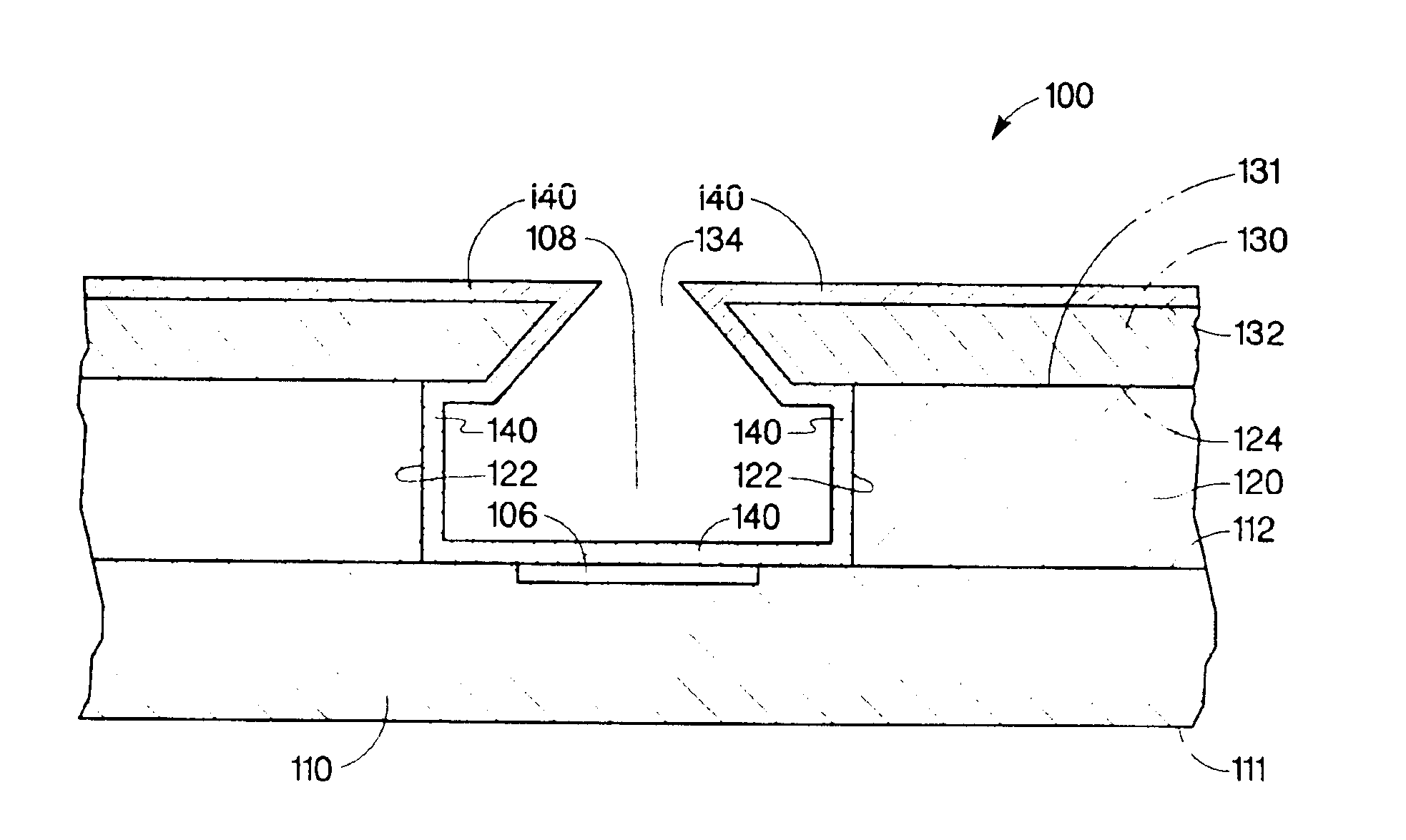

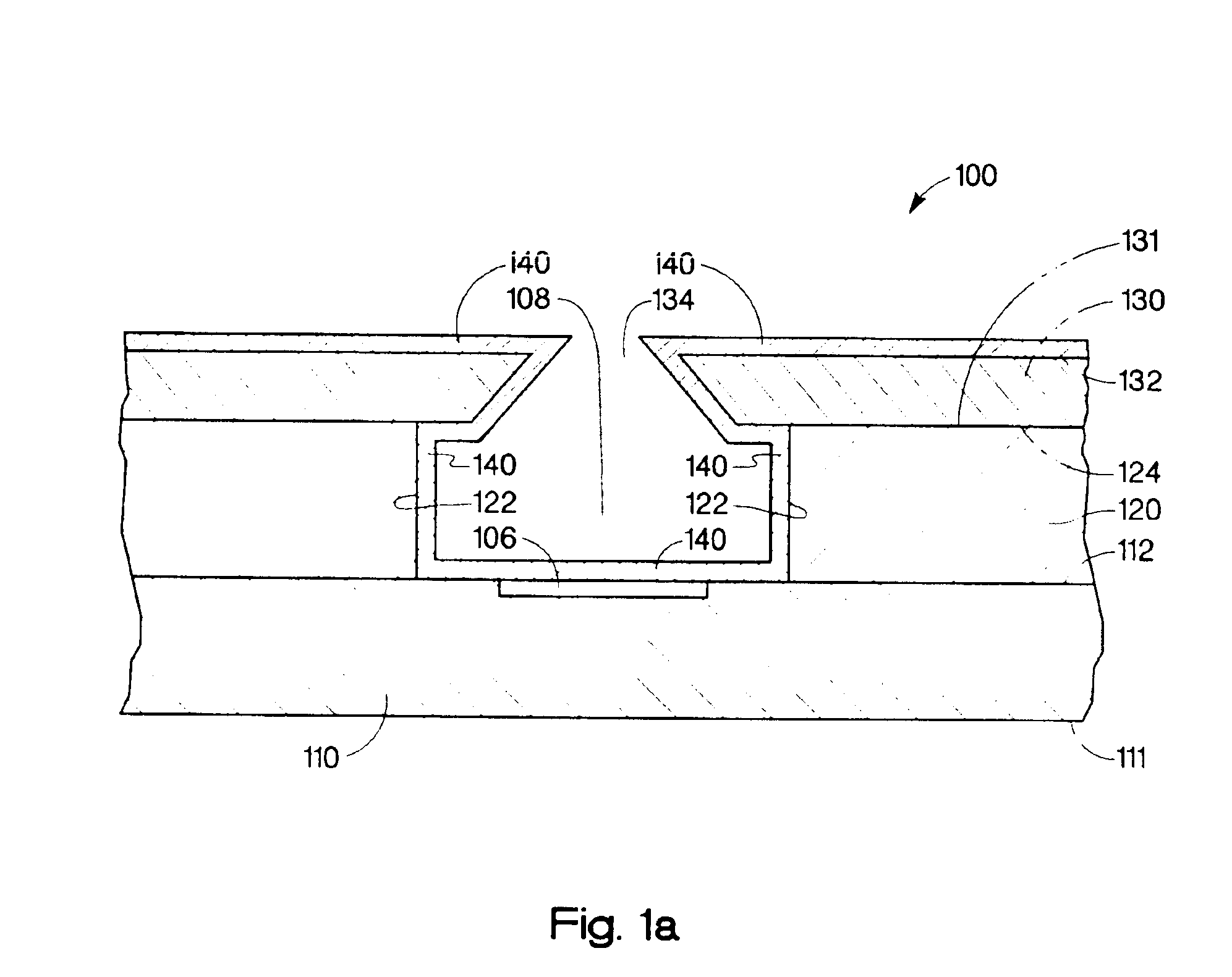

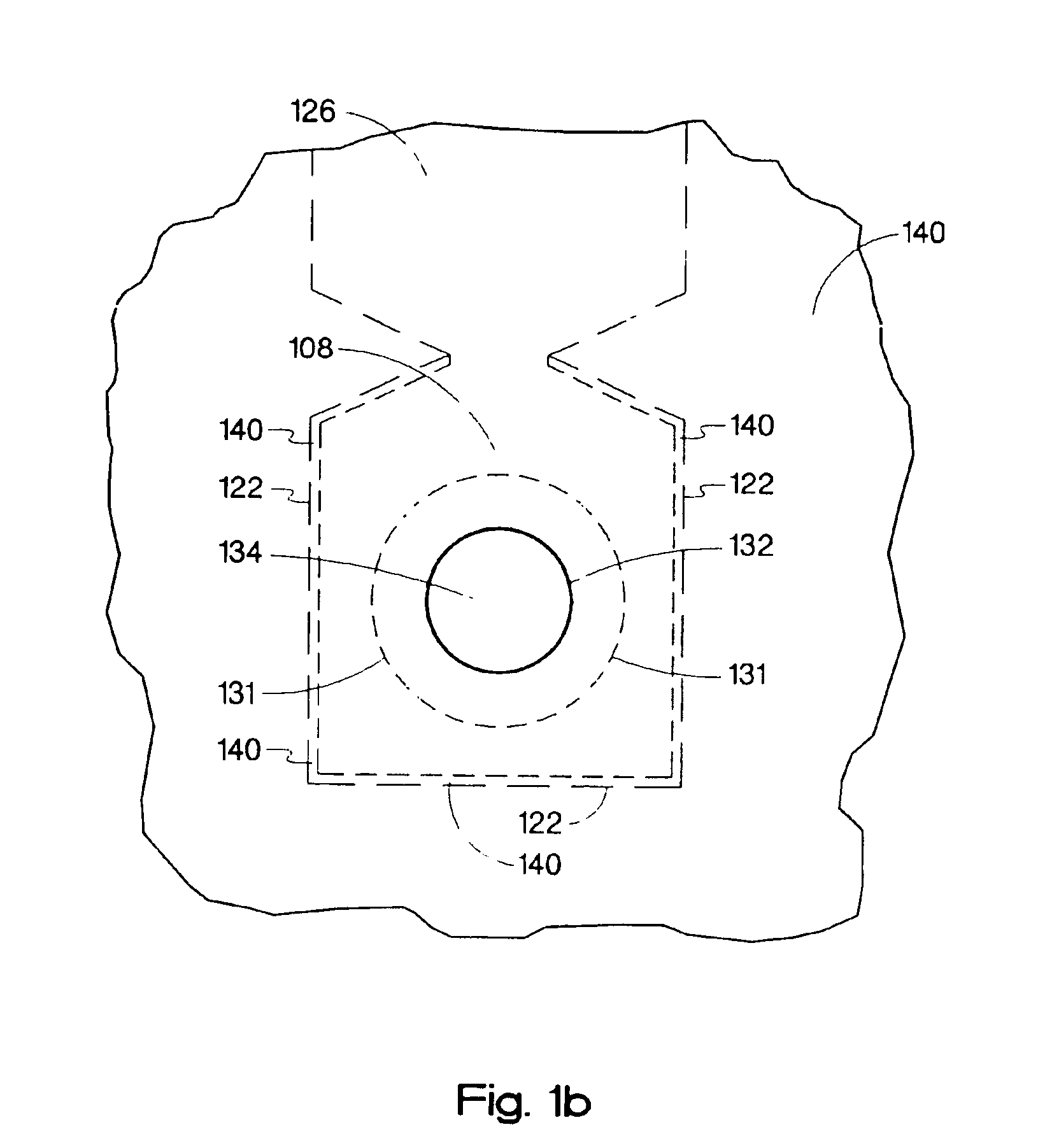

A non-volatile memory resistor cell with a nanotip electrode, and corresponding fabrication method are provided. The method comprises: forming a first electrode with nanotips; forming a memory resistor material adjacent the nanotips; and, forming a second electrode adjacent the memory resistor material, where the memory resistor material is interposed between the first and second electrodes. Typically, the nanotips are iridium oxide (IrOx) and have a tip base size of about 50 nanometers, or less, a tip height in the range of 5 to 50 nm, and a nanotip density of greater than 100 nanotips per square micrometer. In one aspect, the substrate material can be silicon, silicon oxide, silicon nitride, or a noble metal. A metalorganic chemical vapor deposition (MOCVD) process is used to deposit Ir. The IrOx nanotips are grown from the deposited Ir.

Owner:SHARP KK

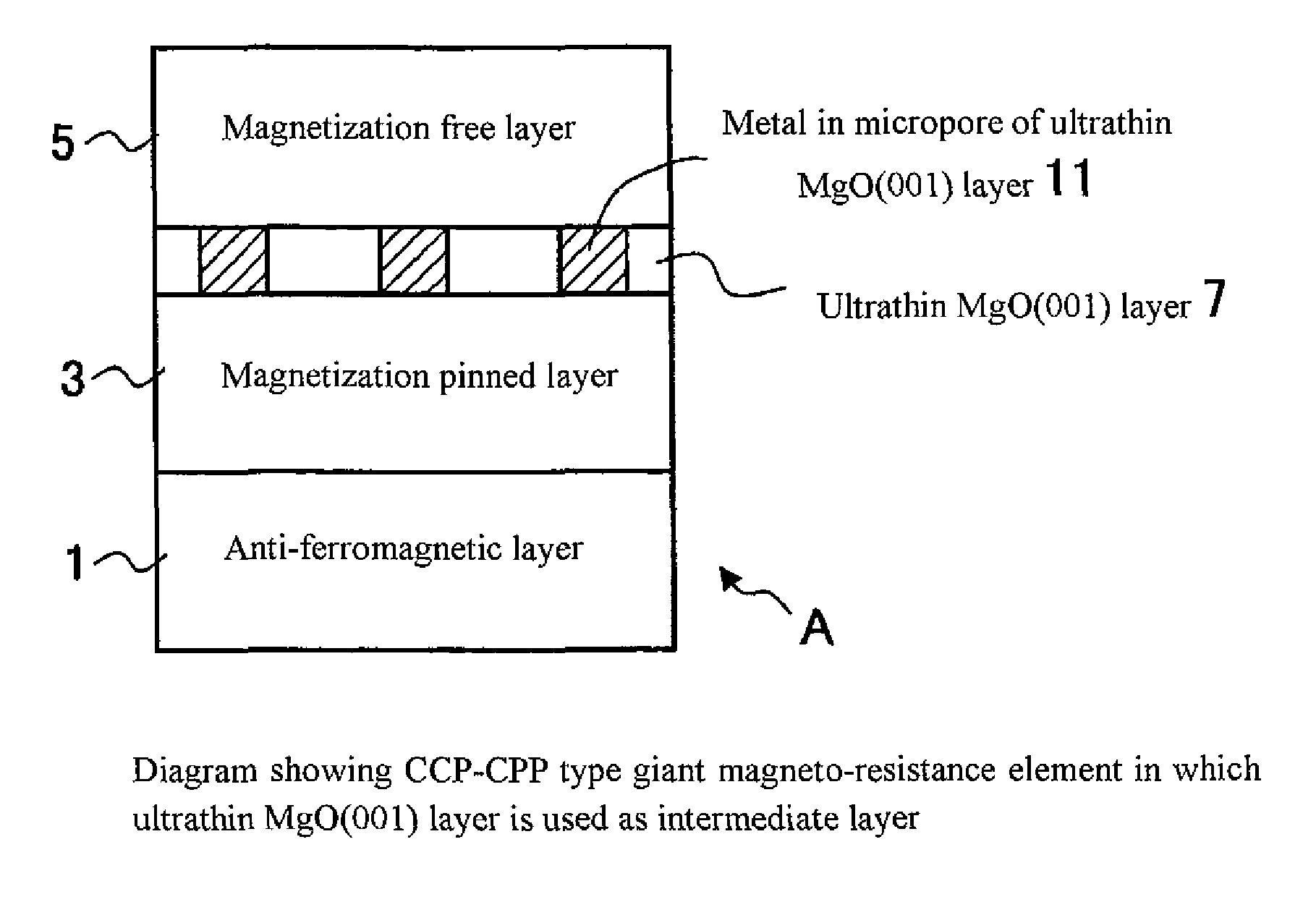

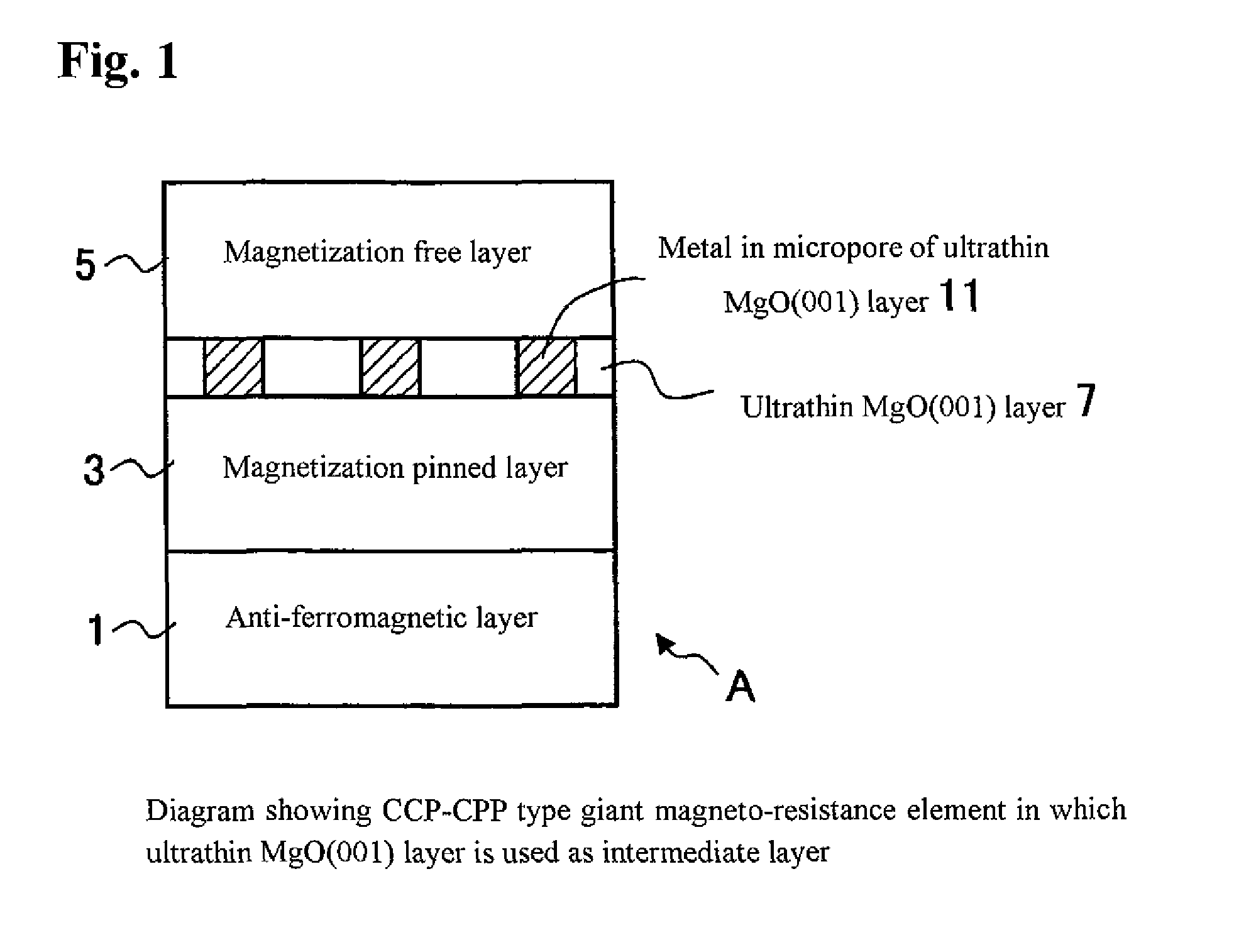

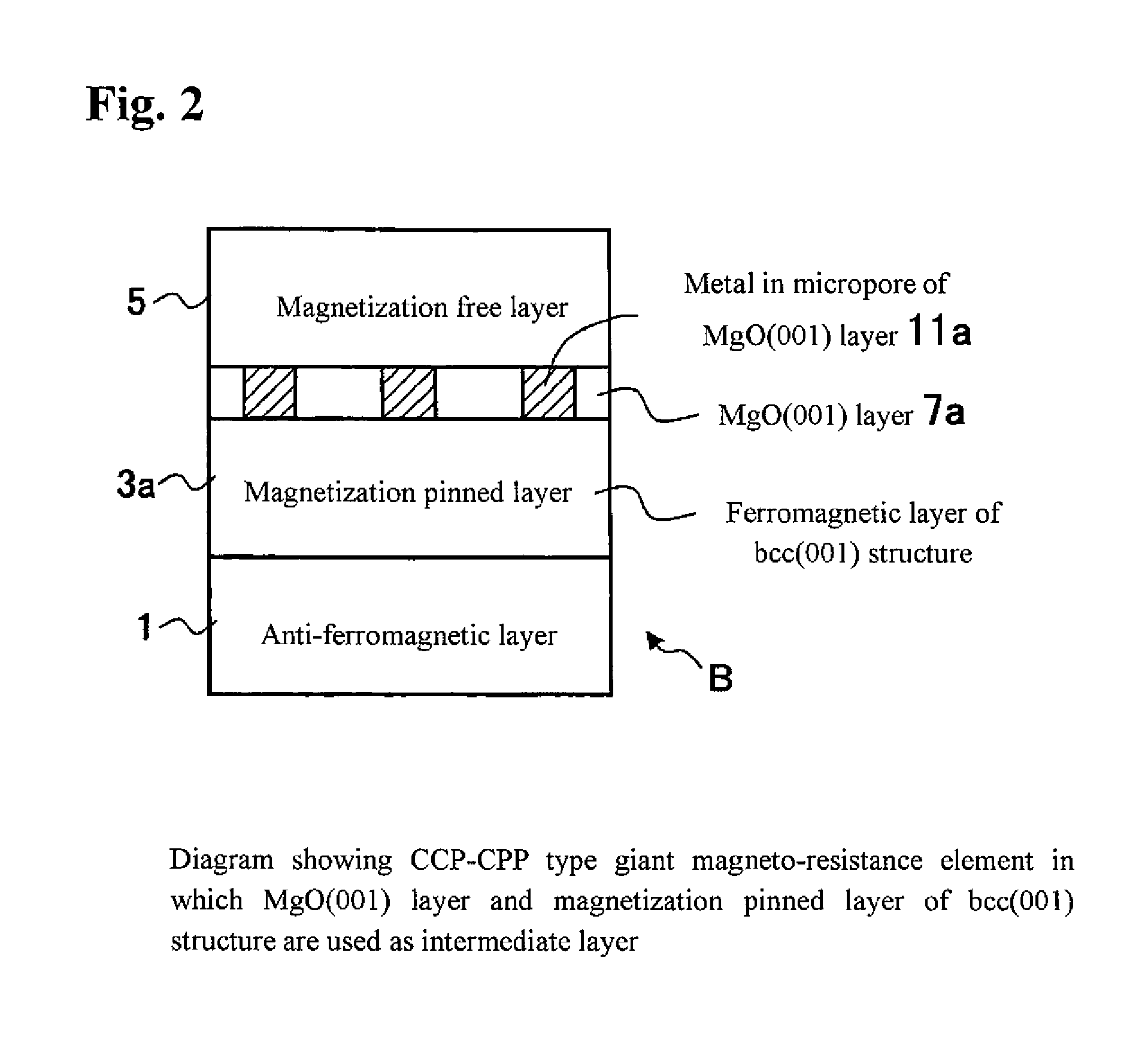

Cpp type giant magneto-resistance element and magnetic sensor

InactiveUS20080026253A1Lower resistanceRaise the ratioNanomagnetismMagnetic measurementsMagnetic reluctanceMagnetization

Provided are a CCP (current confined path)-CPP (current-perpendicular-to-plane) type giant magneto-resistance (GMR) element having a giant magneto-resistance ratio in a low resistance region (a region of not more than 1 ohm per square micrometer) and a magnetic sensor using this GMR element. The CCP-CPP type GMR element A has a laminated structure of an anti-ferromagnetic layer, a magnetization pinned layer, an intermediate layer and a magnetization free layer, and is formed to have a construction in which a current flows perpendicularly to a film plane. By using an ultrathin magnesium oxide layer having micropores that is preferentially oriented in the (001) direction as the intermediate layer, the magneto-resistance ratio is enhanced, because a current flowing from the magnetization free layer to the magnetization pinned layer (or in the opposite direction) is confined by the metal in the micropores.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Non-volatile memory resistor cell with nanotip electrode

InactiveUS7208372B2Solid-state devicesSemiconductor/solid-state device manufacturingSilicon oxideEngineering

A non-volatile memory resistor cell with a nanotip electrode, and corresponding fabrication method are provided. The method comprises: forming a first electrode with nanotips; forming a memory resistor material adjacent the nanotips; and, forming a second electrode adjacent the memory resistor material, where the memory resistor material is interposed between the first and second electrodes. Typically, the nanotips are iridium oxide (IrOx) and have a tip base size of about 50 nanometers, or less, a tip height in the range of 5 to 50 nm, and a nanotip density of greater than 100 nanotips per square micrometer. In one aspect, the substrate material can be silicon, silicon oxide, silicon nitride, or a noble metal. A metalorganic chemical vapor deposition (MOCVD) process is used to deposit Ir. The IrOx nanotips are grown from the deposited Ir.

Owner:SHARP KK

High-strength aluminum alloy product and method of producing the same

A heat-treated high-strength Al—Cu—Mg—Si aluminum alloy product exhibits excellent extrudability and high strength. The high-strength Al—Cu—Mg—Si aluminum alloy product obtained by extrusion is characterized in that the microstructure of the entire surface of the cross section of the aluminum alloy product is formed of recrystallized grains, the grains have an average aspect ratio (L / t) of 5.0 or less (wherein L is the average size of the grains in the extrusion direction, and t is the average thickness of the grains), and the orientation density of the grains in the microstructure, for which the normal direction to the {001} plane is parallel to the extrusion direction in comparison with the grains orientated to random orientations, is 50 or less. The high-strength Al—Cu—Mg—Si aluminum alloy product obtained by extrusion and cold working is characterized in that rod-shaped precipitates are arranged in the grains of the matrix in the <100> direction, the precipitates have an average length of 10 to 70 nm and a maximum length of 120 nm or less, and the number density of the precipitates in the [001] direction measured from the (001) plane is 500 or more per square micrometer.

Owner:SUMITOMO LIGHT METAL INDS LTD

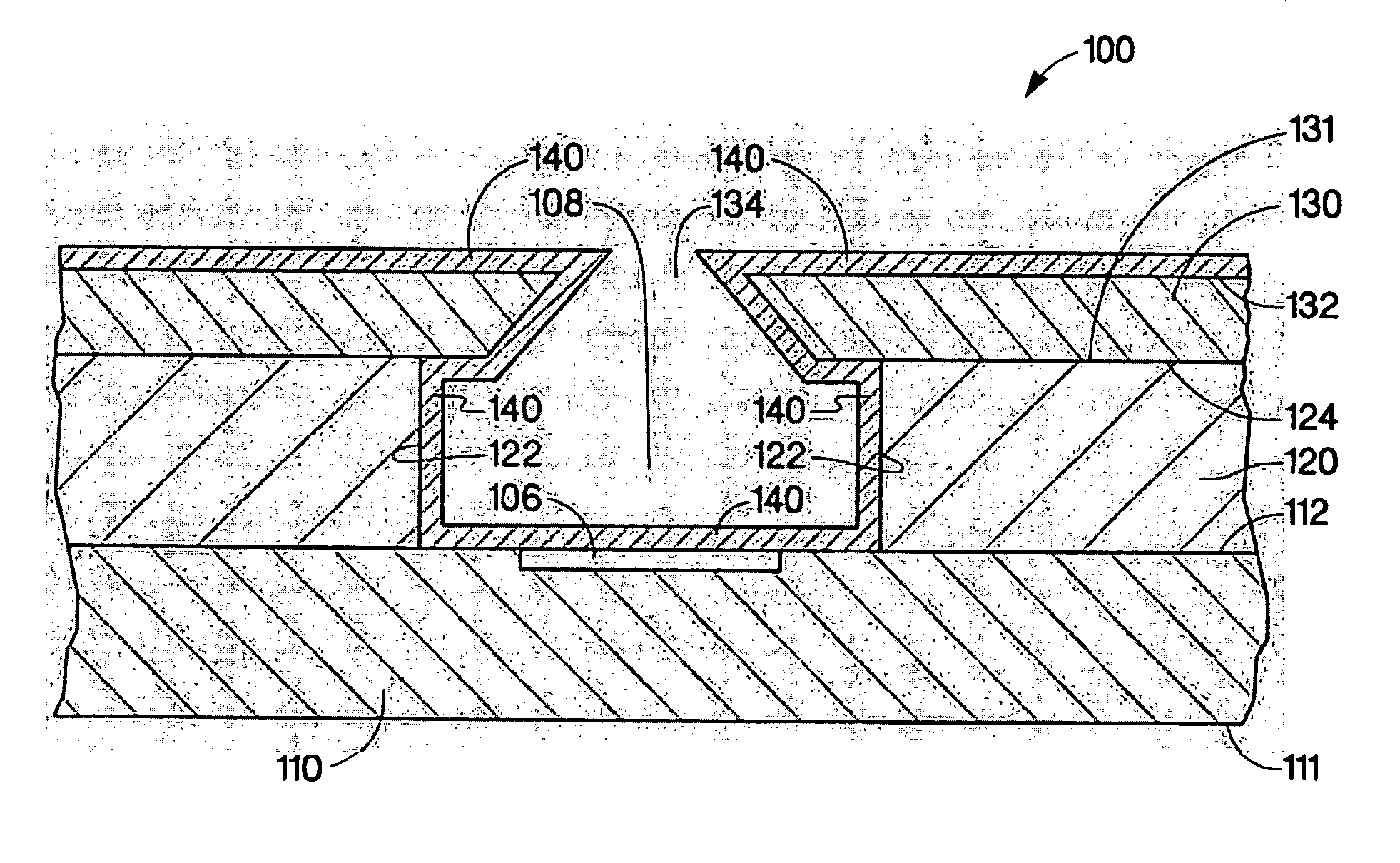

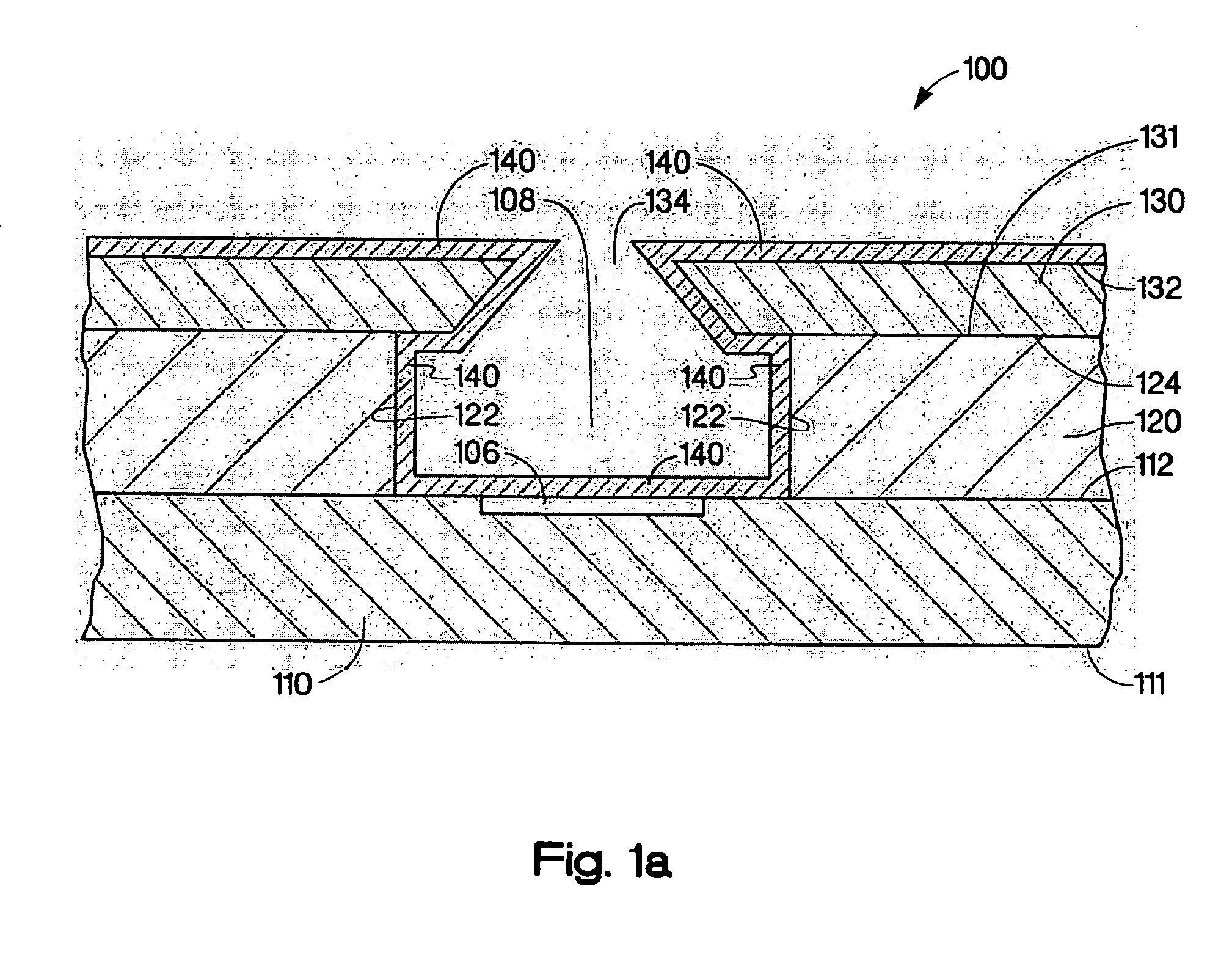

Chamber having a protective layer

InactiveUS6942318B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringSquare Micrometer

A chamber includes a substrate, a chamber layer disposed on the substrate that defines the sidewalls of the chamber, and the chamber layer has a chamber surface. The chamber has an area in the plane formed by the chamber surface in the range from about 1 square micrometer to about 10,000 square micrometers. The chamber also includes an orifice layer disposed over the chamber layer. The orifice layer has a first and second orifice surface and a bore wherein the bore has an area in the plane formed by the first orifice surface less than the chamber area. The chamber further includes a protective layer deposited, through the bore, on the sidewalls of the chamber layer and a portion of the first orifice surface.

Owner:HEWLETT PACKARD DEV CO LP

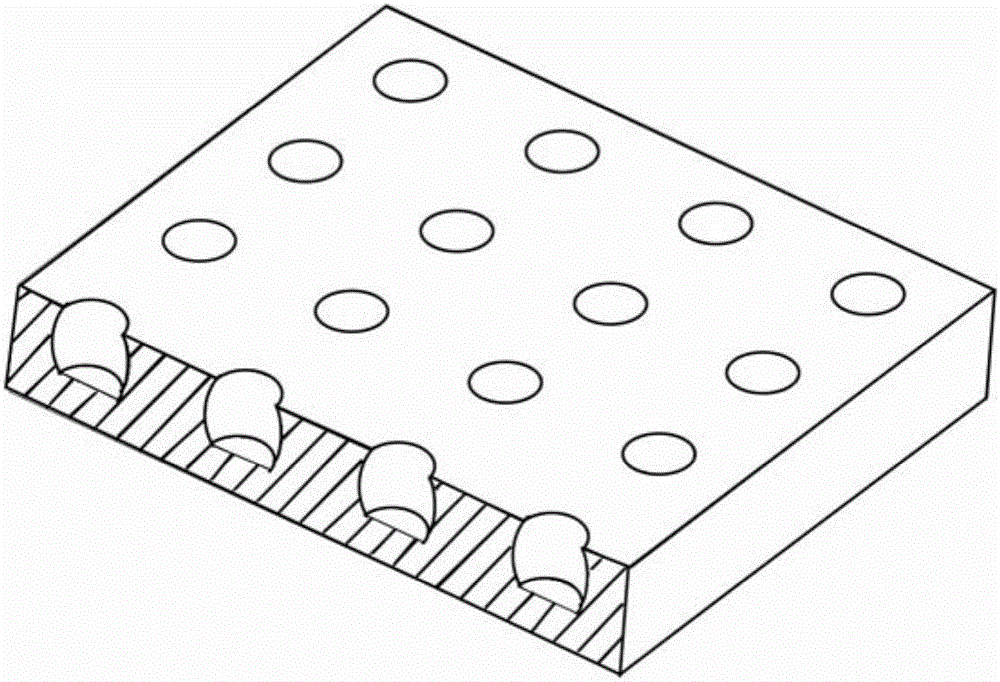

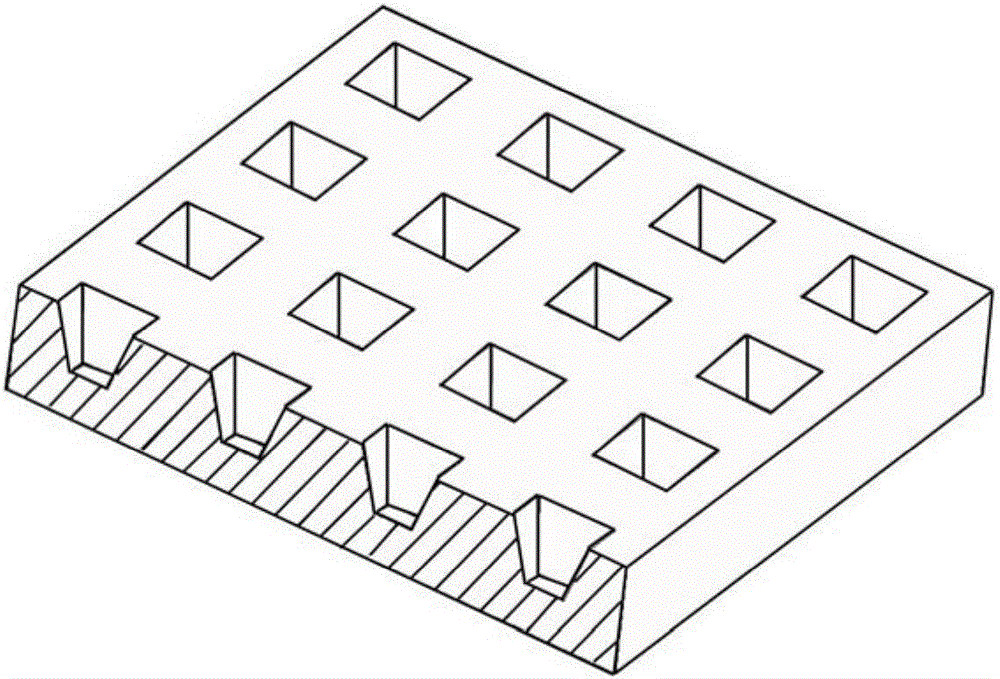

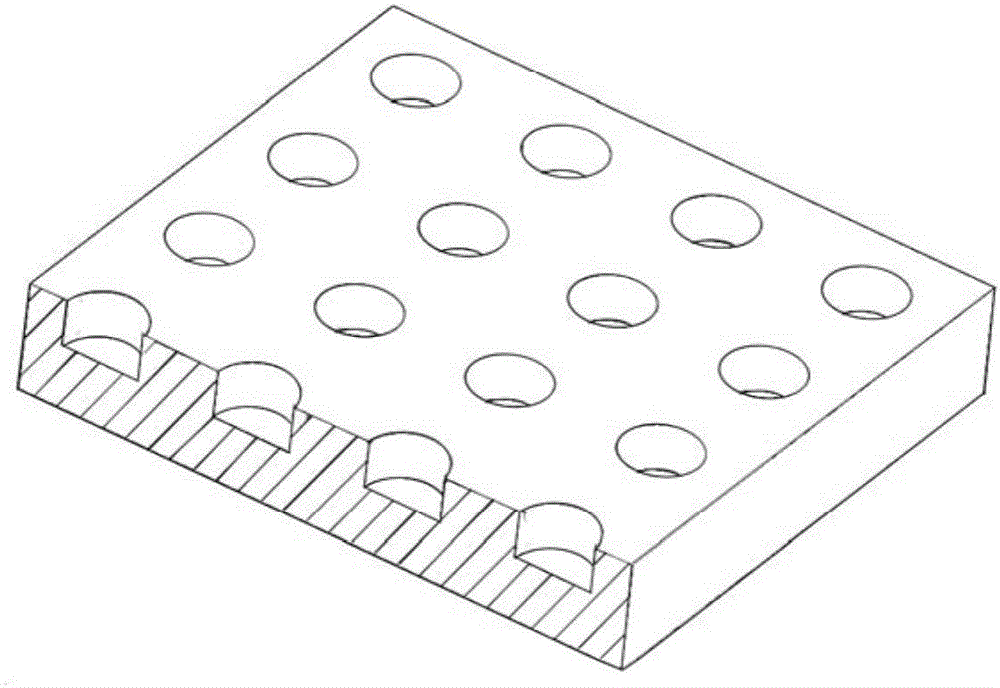

Electrode with pit patterns for secondary battery, and preparation method and application of electrode

ActiveCN106784611ALimit volume changeMaintain stabilityElectrochemical processing of electrodesFuel and secondary cellsLithiumMicrometer

The invention discloses an electrode for a secondary battery. At least one of an upper surface and a lower surface of the electrode is provided with a plurality of pits, the top projection area of each pit is 25 square nanometers to 250000 square micrometers, a depth of each pit is 10 nanometers to 500 micrometers, and a central distance between two adjacent pits is 10 nanometers to 1000 micrometers. When used as a secondary battery electrode, the electrode can effectively limit an electrochemical active metal such as metal lithium in the pits, so that dendritic crystals (for example, lithium dendritic crystals) of the electrochemical active metal can be prevented from appearing on the surface of the electrode, the huge volume deformation of the electrode in an alloy reaction process can be buffered, and the safety performance and cycle life of the metal secondary battery can be improved and prolonged. The invention also provides a preparation method and application of the electrode.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

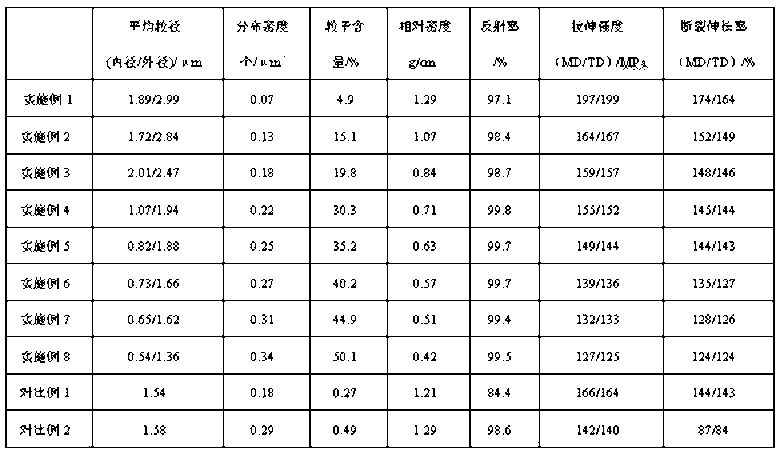

Reflecting film

Disclosed is a reflecting film. The reflecting film contains hollow resin particles incompatible with polyester, the average outer diameter of the hollow resin particles is smaller than 3 micrometers, the average inner diameter of the hollow resin particles is smaller than 2 micrometers, and the distribution density of the hollow resin particles in the reflecting film is higher than 0.07 per square micrometer. The particle consumption of the reflecting film is low, the reflecting film keeps good stiffness and tenancy while the refractivity of the reflecting film is improved, and the reflecting film is excellent in mechanical performance. Besides, the relative reflectivity of the reflecting film is higher than 97%, and the reflecting film is suitable for the field of panel display backlight modules.

Owner:HEFEI LUCKY SCI & TECH IND +2

Chamber having a protective layer

InactiveUS20050253902A1Liquid surface applicatorsWriting implementsSquare MicrometerElectrical and Electronics engineering

Owner:HEWLETT PACKARD DEV CO LP

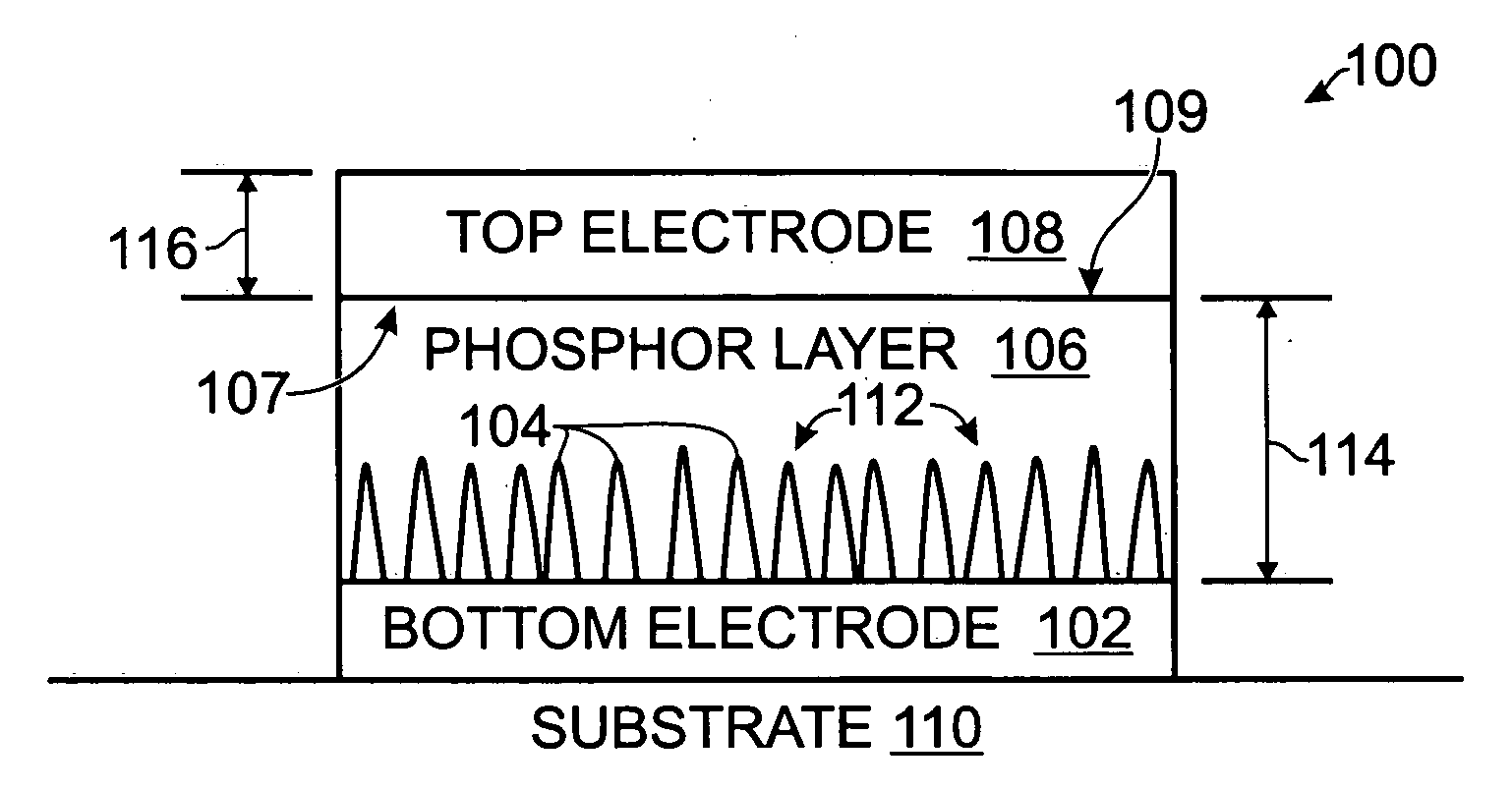

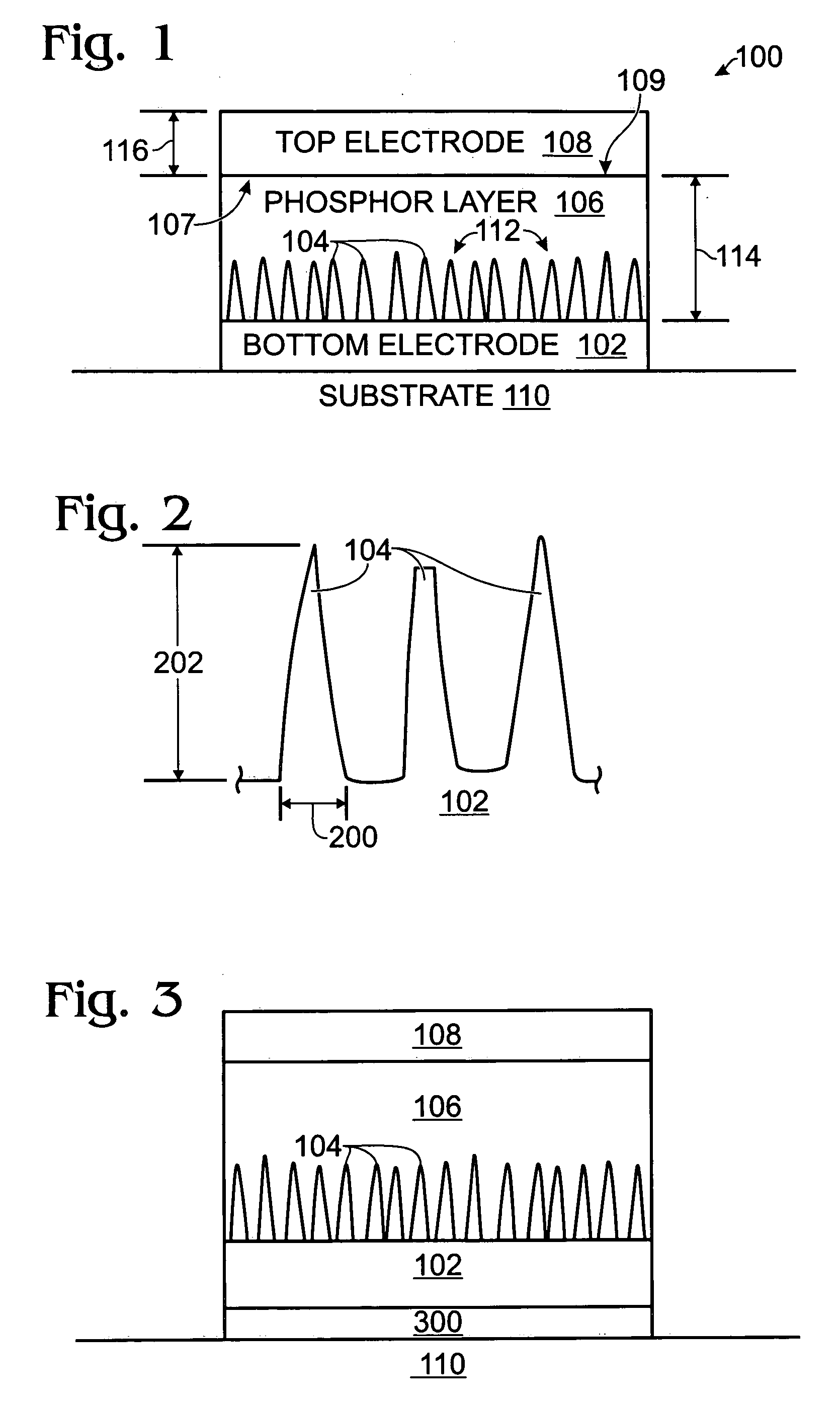

Silicon phosphor electroluminescence device with nanotip electrode

An electroluminescence (EL) device and a method are provided for fabricating said device with a nanotip electrode. The method comprises: forming a bottom electrode with nanotips; forming a Si phosphor layer adjacent the nanotips; and, forming a transparent top electrode. The Si phosphor layer is interposed between the bottom and top electrodes. The nanotips may have a tip base size of about 50 nanometers, or less, a tip height in the range of 5 to 50 nm, and a nanotip density of greater than 100 nanotips per square micrometer. Typically, the nanotips are formed from iridium oxide (IrOx) nanotips. A MOCVD process forms the Ir bottom electrode. The IrOx nanotips are grown from the Ir. In one aspect, the Si phosphor layer is a SRSO layer. In response to an SRSO annealing step, nanocrystalline SRSO is formed with nanocrystals having a size in the range of 1 to 10 nm.

Owner:SHARP KK

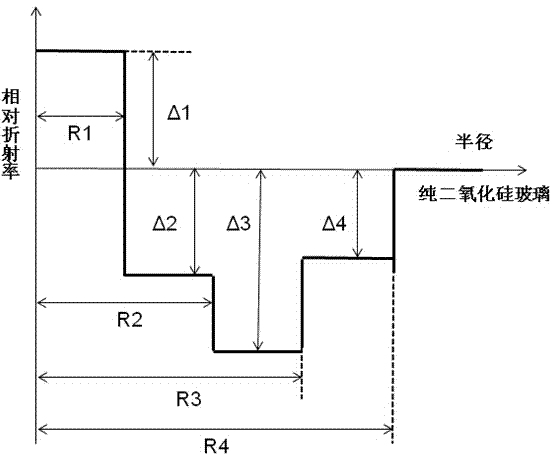

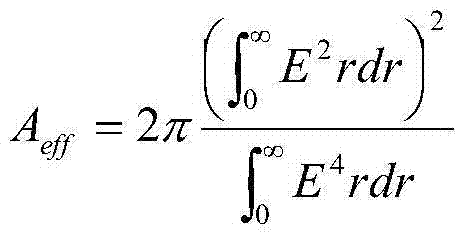

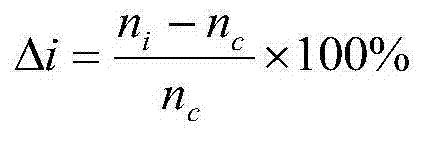

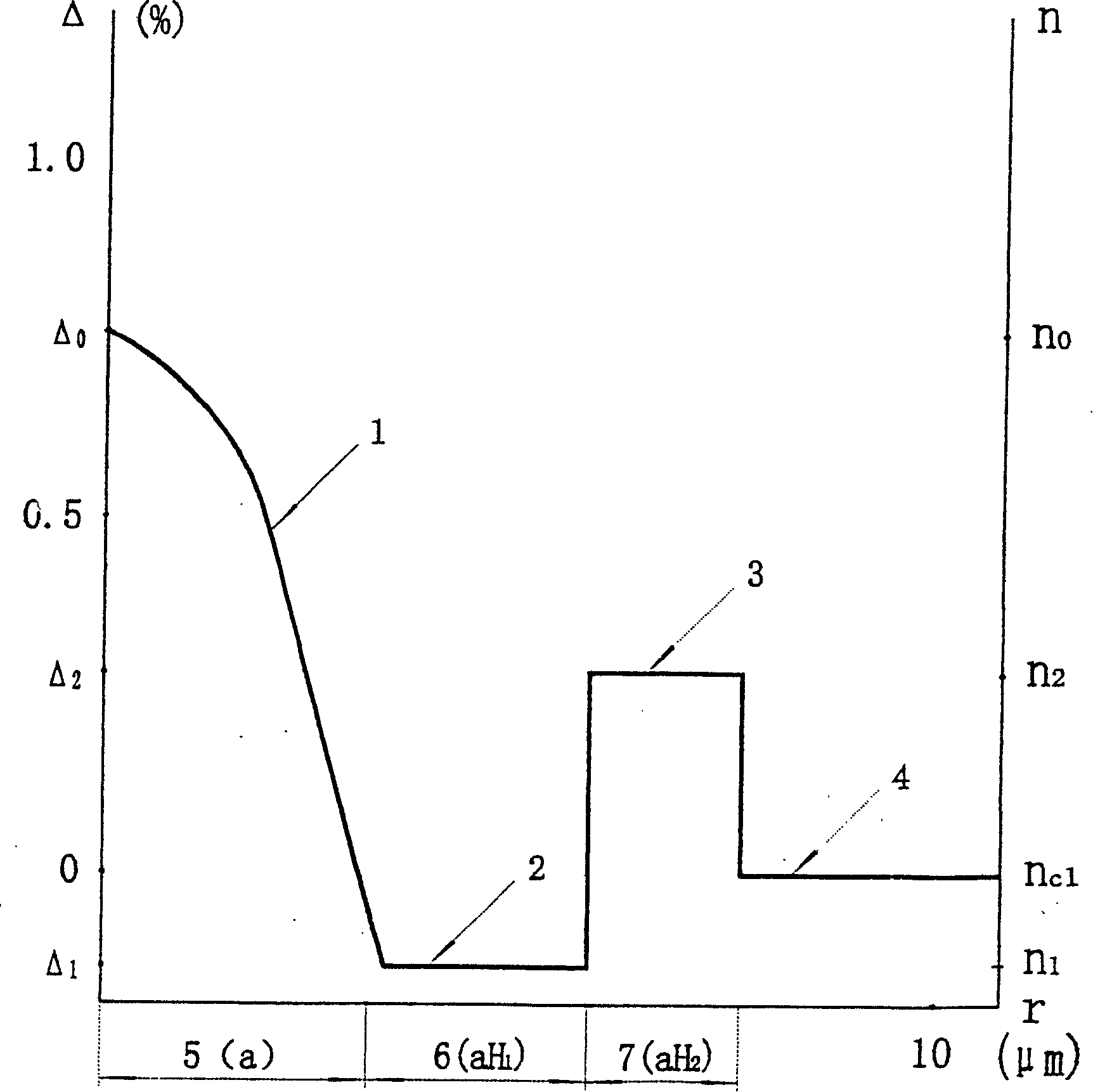

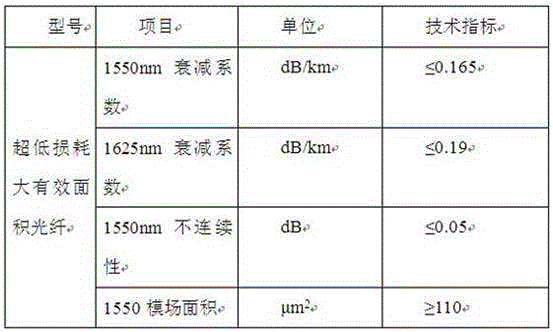

Low-attenuation and large-effective-area single-mode optical fiber

ActiveCN104777551AReduce defectsDecrease the attenuation parameterOptical fibre with multilayer core/claddingOptical waveguide light guideUltrasound attenuationRelative refractive index

The invention relates to a low-attenuation and large-effective-area single-mode optical fiber. The single-mode optical fiber comprises a core layer and wrapping layers and is characterized in that the radius r1 of the core layer is 4.8 micrometers-6.5 micrometers, and the relative refraction index delta1 of the core layer is 0.10%-0.24%; the core layer is wrapped with the inner wrapping layer, the sunk inner wrapping layer, the transitional outer wrapping layer and the outer wrapping layer in sequence from inside to outside; the radius r2 of the inner wrapping layer of the optical fiber is 8.5 micrometers-15 micrometers, the relative refraction index delta2 of the inner wrapping layer of the optical fiber is -0.3%--0.05%, the radius r3 of the sunk inner wrapping layer is 14 micrometers-22 micrometers, the relative refraction index delta3 of the sunk inner wrapping layer is -0.45%--0.2%, the radius r4 of the transitional outer wrapping layer is 35 micrometers-50 micrometers, and the relative refraction index delta4 of the transitional outer wrapping layer is -0.25%--0.05%; the outer wrapping layer is a pure silica glass layer. The attenuation parameter of the optical fiber is decreased; through reasonable design of all fiber core layer sections of the optical fiber, the optical fiber has an effective area larger than or equal to 100 square micrometers. The overall performance parameters of cutoff wavelength, bending loss and chromatic dispersion of the optical fiber are good in an application wave band, and a multilayer stepped sunk wrapping layer structure is adopted for the section of the optical fiber and well reduces the bending loss of the optical fiber.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Full-wave nonzero dispersion flat single-mode optical fiber

InactiveCN101169497ATake advantage ofCladded optical fibreOptical waveguide light guideCommunications systemFull wave

The invention relates to a complete wave nonzero dispersive flat single mode optical fiber, which comprises a fiber core circular shaped center delamination, a first ring-shaped delamination, a second ring-shaped delamination and a uniform outer cladding. The refractive index of the first ring-shaped delamination is lower than that of the uniform outer cladding. The optimum choose of the refractive index section shape of each delamination, relative refractive index difference and semidiameter or width can guarantee that the chromatic dispersion is between 0.1ps / nm-km and 12.0ps / nm-km in a wavelength range of 1300nm to 1625nm. The valid section Aeff is more than or equel to 50 square micrometers under the condition that the wavelength is 1550nm. The performance of the optical fiber can be changed in different intervals in the range according to the different requirements of communicating systems such as DWDM and CWDM.

Owner:汪业衡

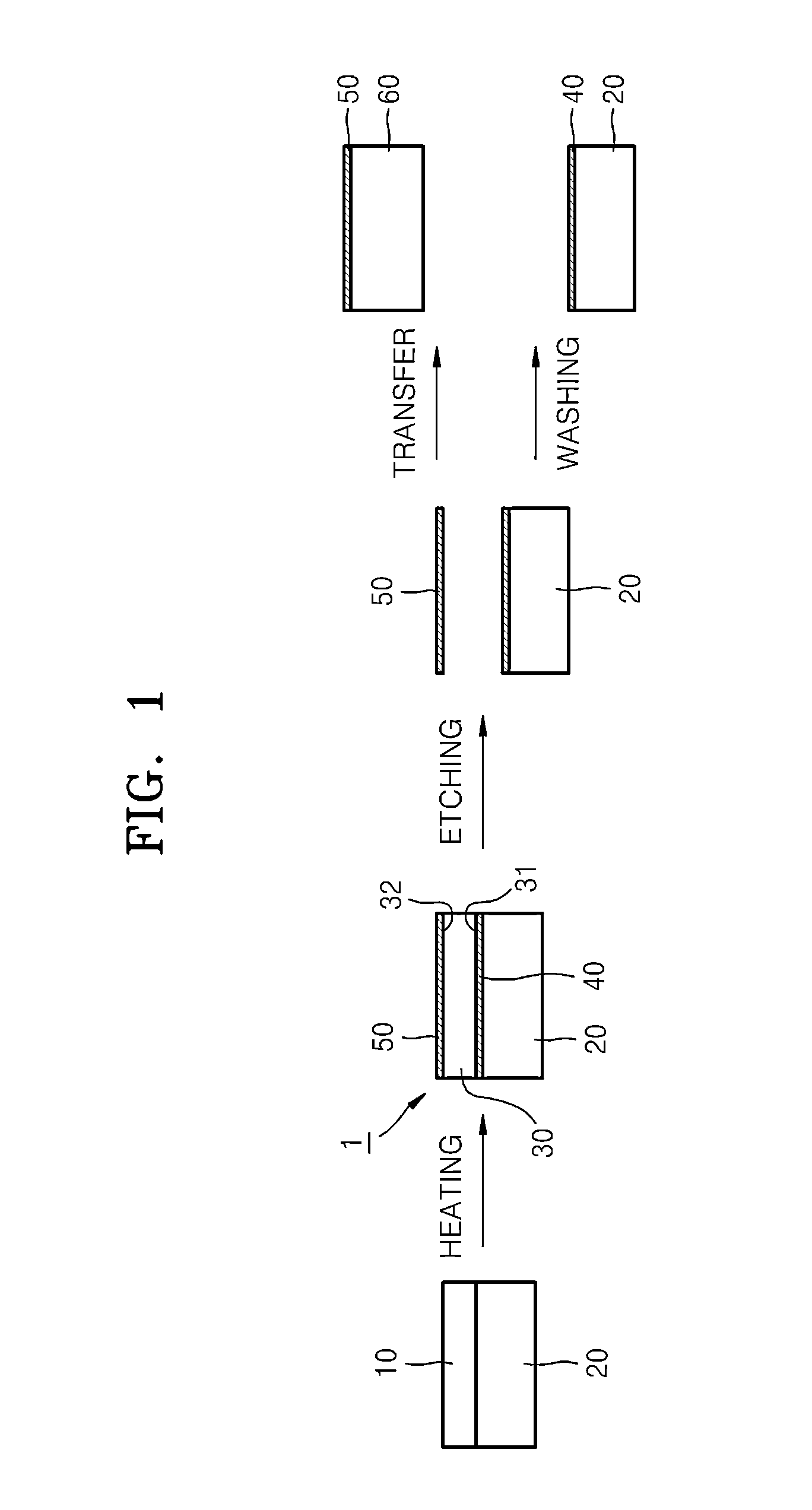

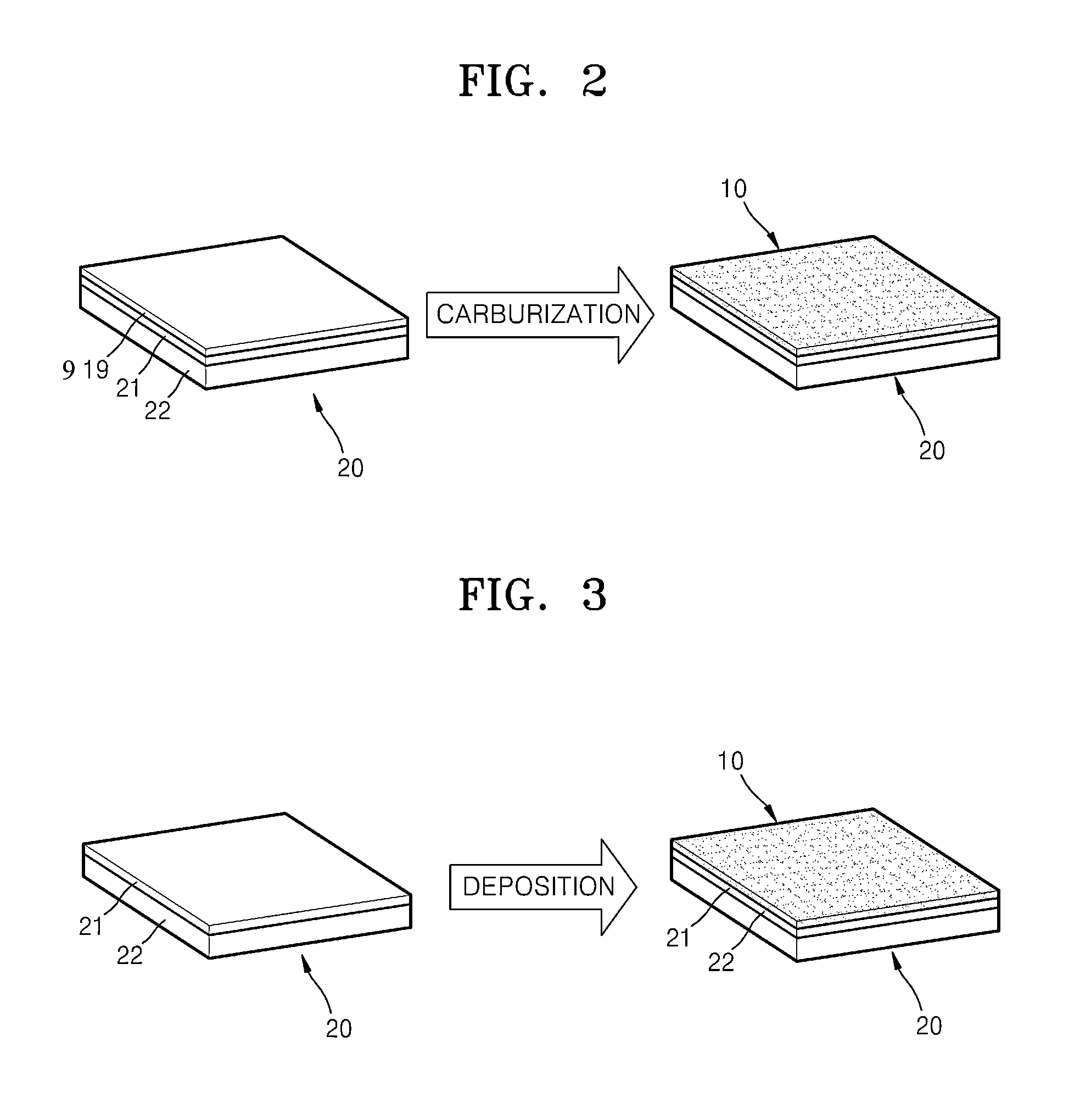

Graphene sheet, graphene base including the same, and method of preparing the graphene sheet

ActiveUS9187332B2Small sizeFew defectMaterial nanotechnologyDecorative surface effectsGrapheneSquare Micrometer

Owner:SAMSUNG ELECTRONICS CO LTD

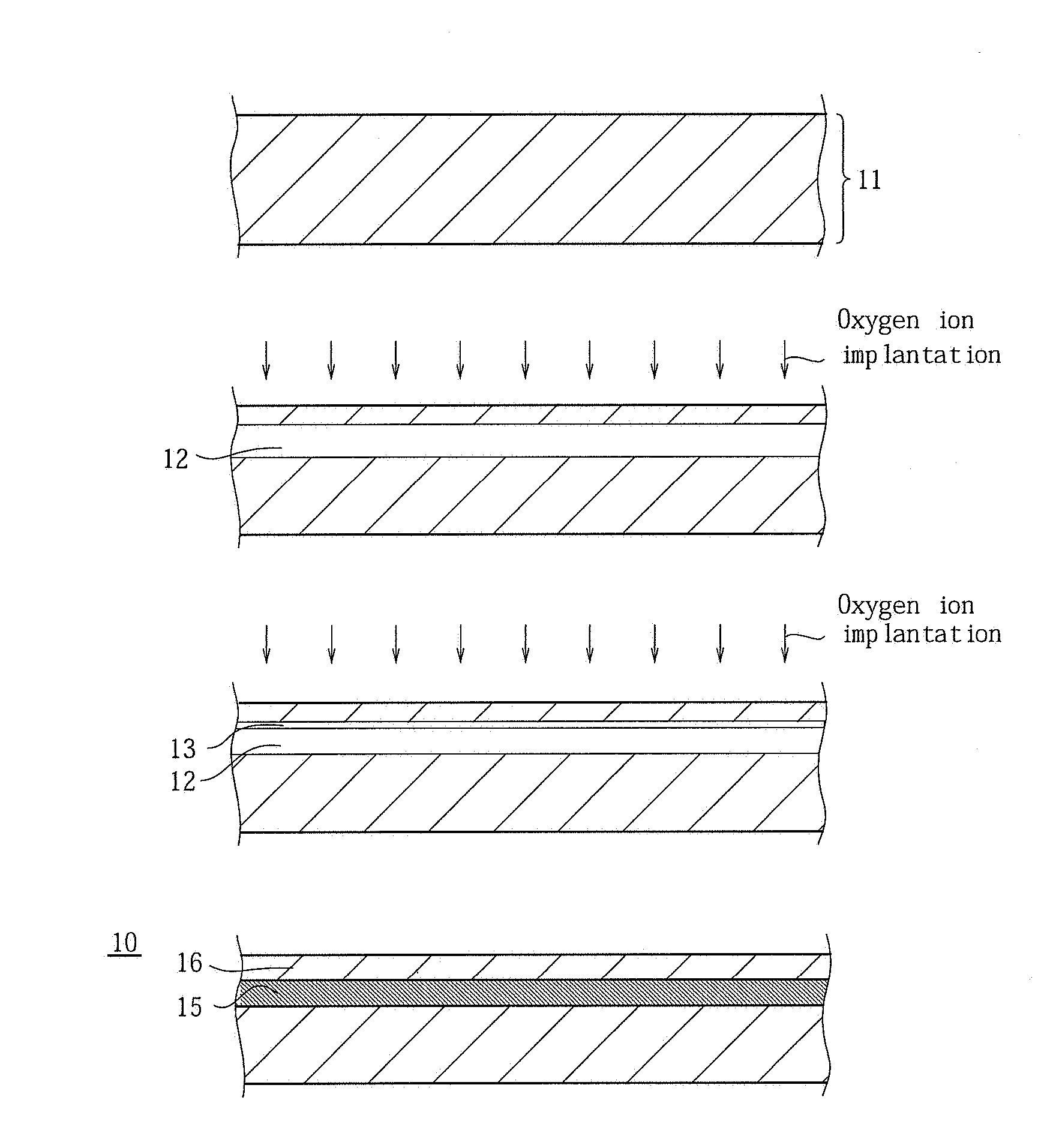

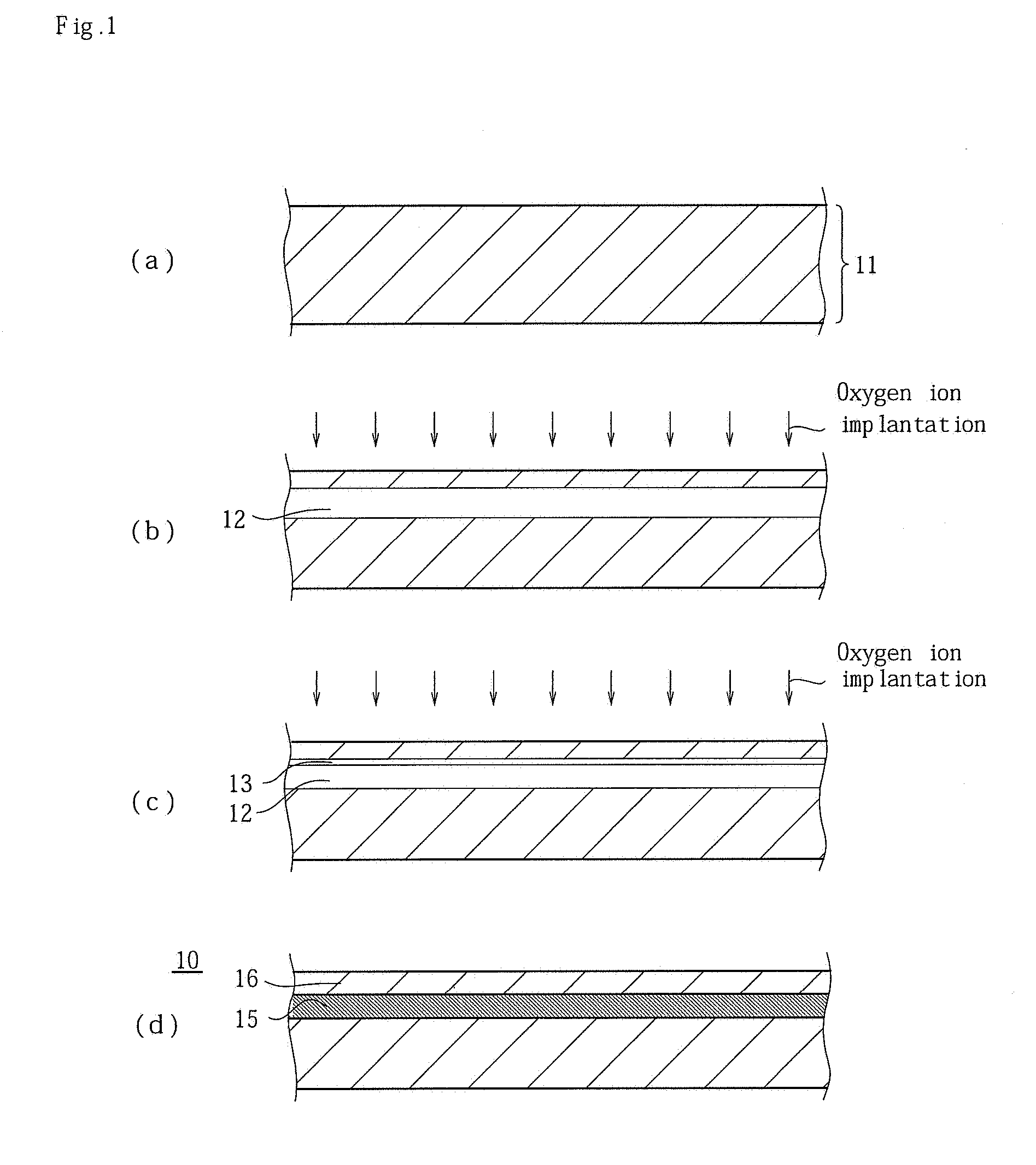

Method for Manufacturing Simox Wafer and Simox Wafer Obtained by This Method

InactiveUS20070238269A1Reduce roughnessReduce variationSemiconductor/solid-state device manufacturingOxygenIon implantation

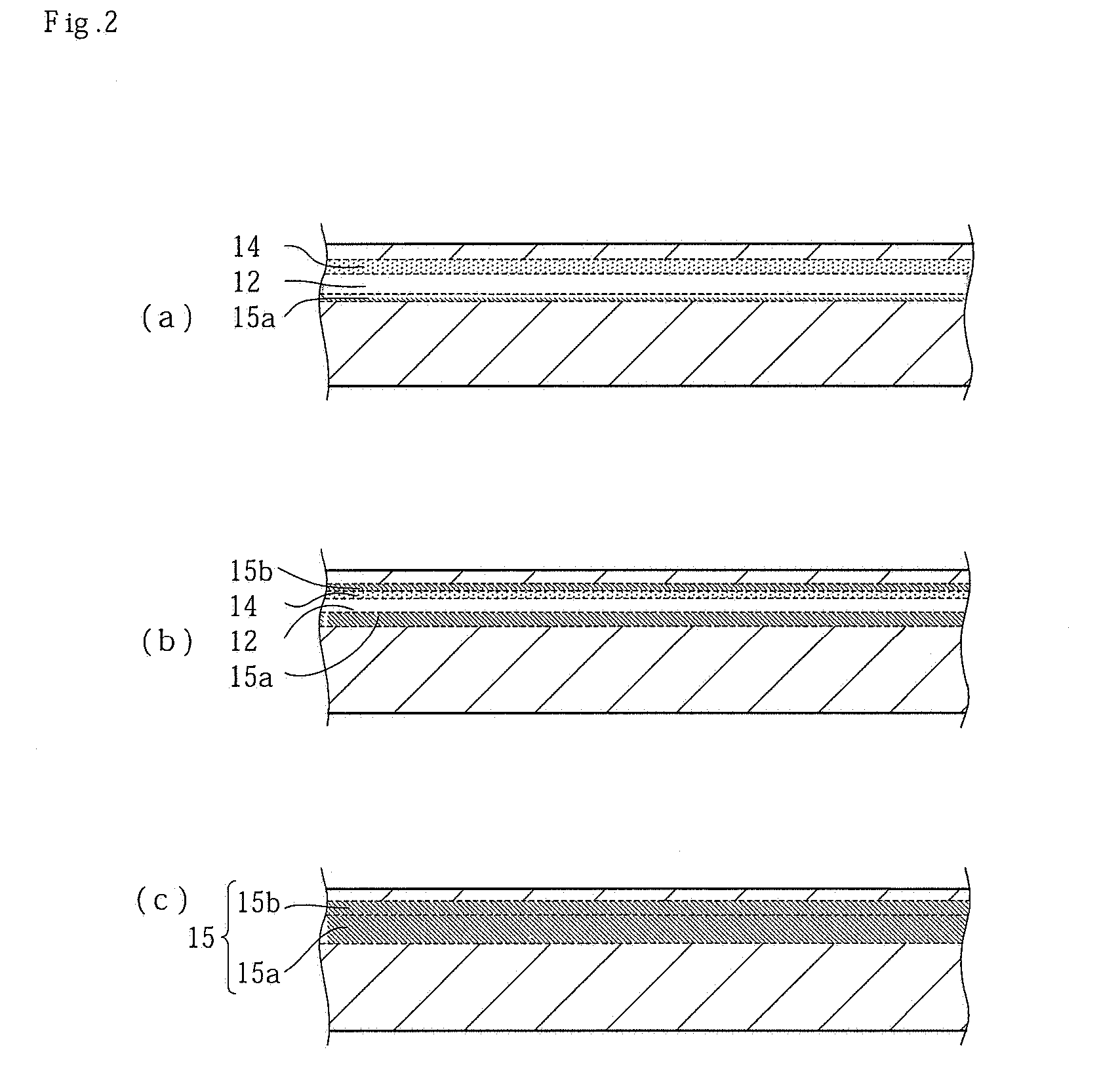

It is an object of the present invention to provide a method for manufacturing SIMOX wafer, wherein roughness Rms of a measurement area of 10 square micrometers in a surface of an SOI layer and roughness Rms of a measurement area of 10 square micrometers in an interface between the SOI layer and a BOX layer can be reduced respectively and a SIMOX obtained by the method. The method is to manufacture a SIMOX wafer comprising; a step of forming a first ion-implanted layer 12 containing highly concentrated oxygen within a wafer 11; a step of forming a second ion-implanted amorphous layer 13; and a high temperature heat treatment step of transforming the first and second ion-implanted layers into a BOX layer 15 by holding the wafer at a temperature between 1300° C. or more and a temperature less than a silicon melting point in an atmosphere containing oxygen, wherein when a first dose amount in the step of forming the first ion-implanted layer is set to 2×1017 to 3×1017 atoms / cm2, the first implantation energy is set to 165 to 240 keV and a second dose amount in the step of forming the second ion-implanted layer is set to 1×1014 to 1×1016 atoms / cm2.

Owner:SUMCO CORP

Method for separating impurities in solution by chemically modified solid nanopore arrays

The invention relates to a method for separating impurities in a solution by chemically modified solid nanopore arrays. The area of the solid nanopore arrays is not less than 250 square micrometers. The diameter of a single nanopore is 1-200nm. Pore density is not less than 1 pore / square micrometer. The inner wall of pores is modified with one component or a mixture of more than two components ata random ratio, wherein the components are selected from the group consisting of 6-28bp nucleic acid molecule, antigen molecule, 60-200kDa antibody molecule, peptide molecule containing 6-50 amino acid and silane molecule. When 1-50 microliters of a solution which contains impurity molecule at the concentration of 1-10 nmol.ml<-1> or impurity particles of less than 1microgram / ml passes through the solid nanopore arrays, the impurity molecule or particles are intercepted by the chemically modified nanopore arrays. The structural formula of the silane molecule is Y(CH2)nSiXmZ3-m, wherein n is 0-3.

Owner:SOUTHEAST UNIV

Optical fiber with large effective area

InactiveCN106199823AImprove roundnessIncrease the effective areaOptical fibre with multilayer core/claddingOptical waveguide light guideRelative refractive indexSilicon dioxide

The invention relates to optical fiber with a large effective area. The mold field diameter of the optical fiber at the 1550 nm position is 12.0-13.6 micrometers, and the mold field area is larger than or equal to 120 square micrometers; the optical fiber sequentially comprises a core layer, cladding layers and coating layers, the core layer is a silicon dioxide glass layer with the radius of 5-7 micrometers, an inner cladding layer is a fluorine-doped inner cladding layer, the relative refringence difference is -0.4--0.2 %, the radius r3 of the middle cladding layer is 12-25 micrometers, and the outer cladding layer is a quartz glass layer with the radius r4 of 25-45 micrometers; the coating layers include an inner coating layer and an outer coating layer, the diameter of the inner coating layer is 192 micrometers, and the diameter of the outer coating layer is 245 micrometers. The cut-off wavelength, the bending loss, chromatic dispersion and other comprehensive performance parameters in the application wave band are good, the optical fiber can be used as long-distance optical fiber communication under bad conditions such as super crossing gobi and deep sea, the circular degree of all layers of the optical fiber is good, the round formed shape is ensured, and strain of the optical fiber can reach 2% or more.

Owner:QINGDAO WINCHANCE TECH

Thermal chemical vapor deposition coating

Thermal chemical vapor deposition coated articles and thermal chemical vapor deposition processes are disclosed. The thermal chemical vapor deposition coated article includes a substrate and a coating on the substrate, the coating having multiple layers and being positioned on regions of the thermal chemical vapor deposition coated article that are unable to be concurrently coated through line-of-sight techniques. The coating has a concentration of particulate from gas phase nucleation, per 100 square micrometers, of fewer than 6 particles having a dimension of greater than 0.5 micrometers. The thermal chemical vapor deposition process includes introducing a multiple aliquot of a silicon-containing precursor to the enclosed vessel with intermediate gaseous soaking to produce the coated article.

Owner:SILCOTEK CORP

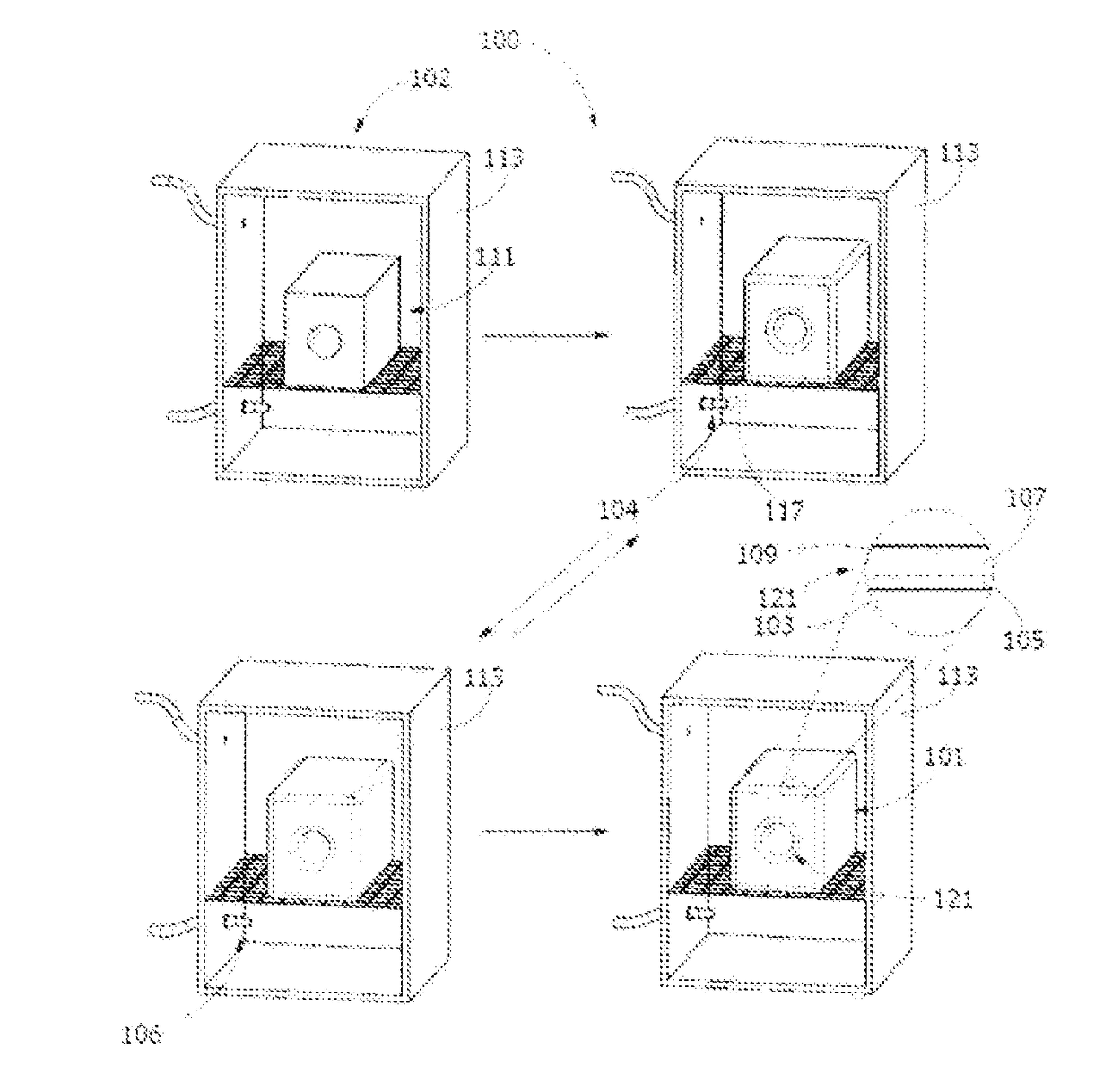

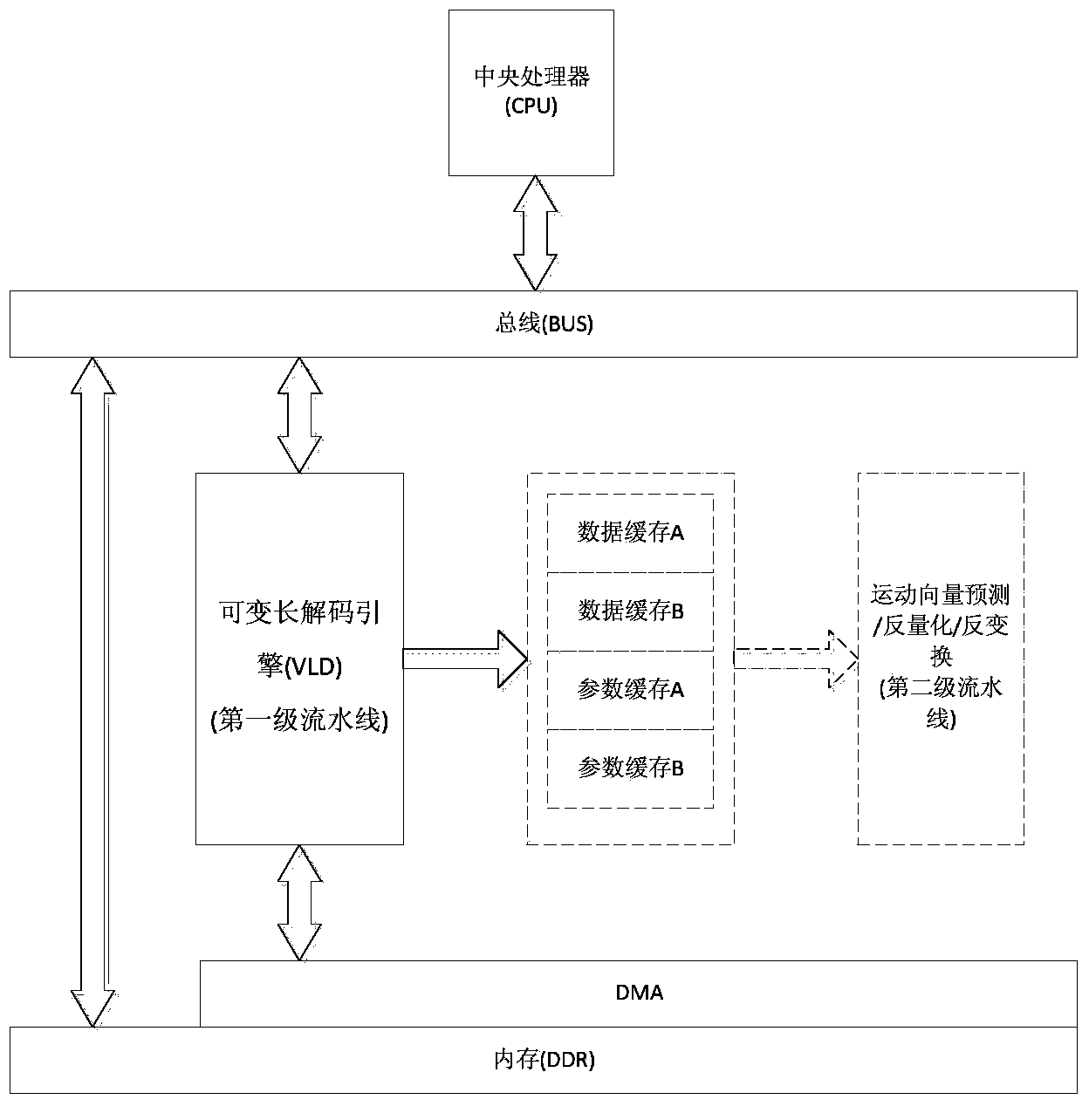

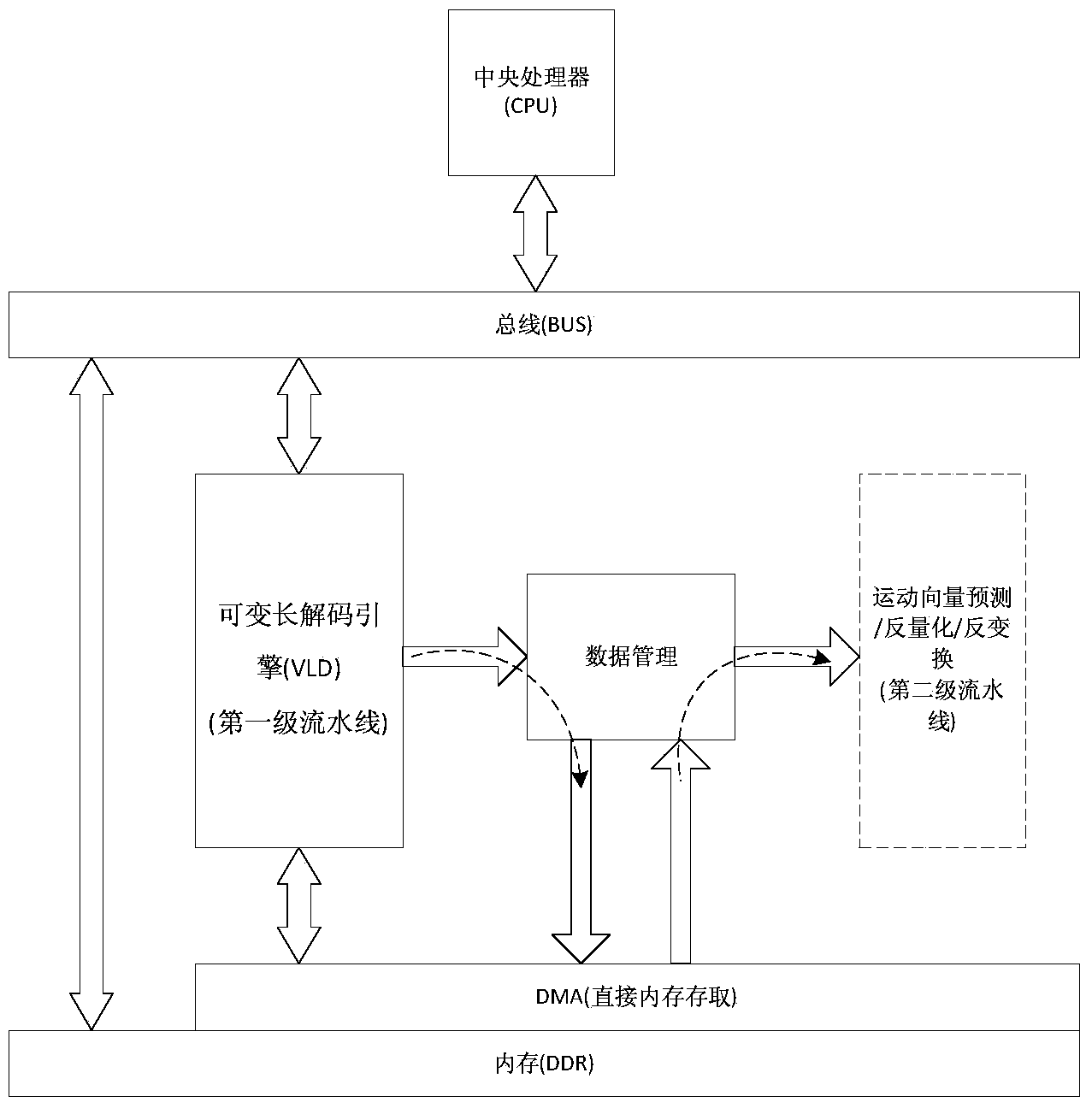

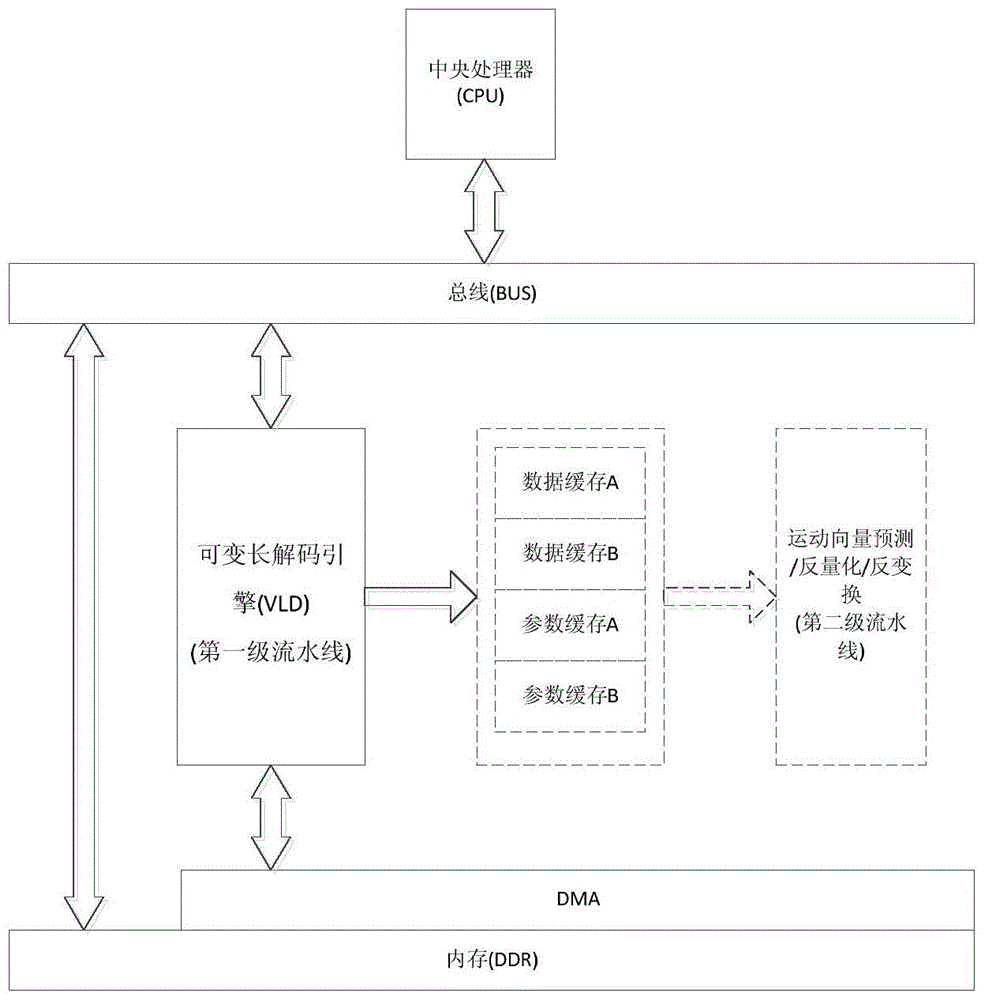

Novel decoder and decoding method

ActiveCN103596013ALow costSave extra spaceDigital video signal modificationVideo bitstreamDecoding methods

The invention provides a novel decoder and a decoding method. The novel decoder at least comprises a DDR, a variable-length decoding engine, a data management module and a direct memory access module, wherein the DDR is used for caching a video bitstream before decoding and output data of the variable-length decoding engine; the variable-length decoding engine is used for decoding the video bitstream obtained from the DDR and outputting the decoded data into the data management module; the data management module is used for outputting the decoded data of the variable-length decoding engine to the direct memory access module and outputting the data obtained from the direct memory access module; the direct memory access module is used for outputting the decoded data, output by the data management module, of the variable-length decoding engine into the DDR and outputting the decoded data, obtained from the DDR, of the variable-length decoding engine to the data management module. According to the novel decoder, a reading channel and a writing channel are added to the direct memory access module, namely a small logic is increased, and two 416X22 single-port SRAMs and two sets of registers for caching parameters are omitted. Thus, compared with design in the prior art, the novel decoder has the advantages that the comprehensive area of a chip is saved by about 80000 square micrometers, the integral area of the chip is reduced by about 6%, and therefore cost of the corresponding chip is greatly reduced.

Owner:SHANGHAI HIGH DEFINITION DIGITAL TECH IND

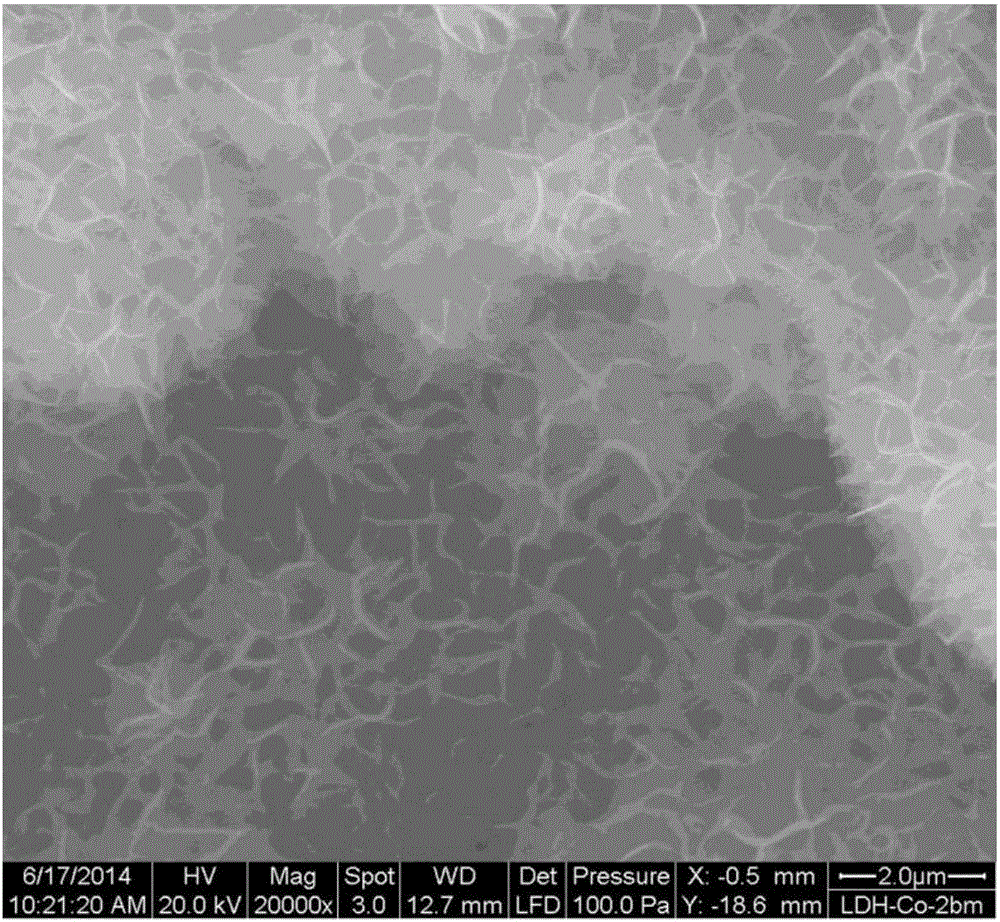

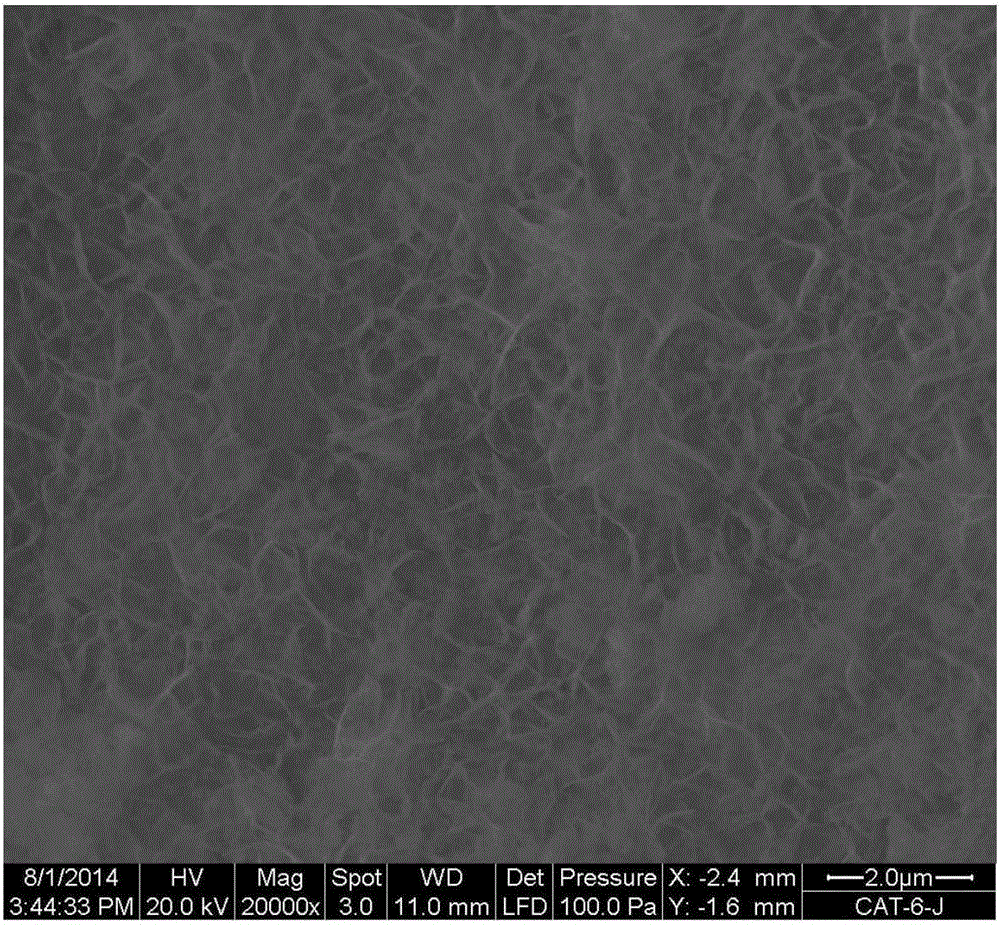

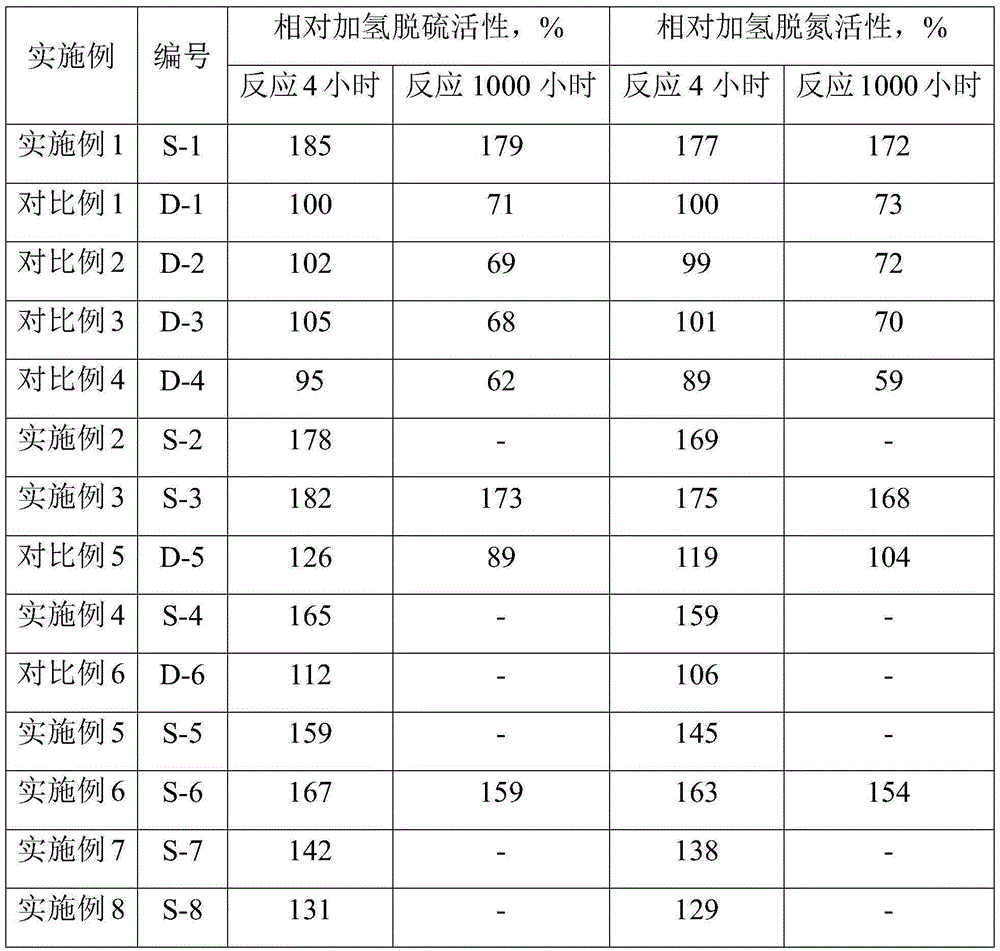

Hydrorefining catalyst and preparation method thereof

ActiveCN106607041AGood dispersionImprove structural stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsGrid densityDivalent metal

The invention relates to a hydrorefining catalyst and a preparation method thereof. The method comprises: (1) soaking a gamma-alumina carrier in a mixture containing urea, water-soluble salt of a metal component C and water, and performing heat treatment, filtering, washing and drying to obtain a modified alumina carrier; and (2) introducing a metal component A and a metal component B to the modified alumina carrier obtained from the step (1). The metal component A is selected from at least one of group VIII metal elements, the metal component B is selected from at least one of group VIB metal elements, and the metal component C is at least one of divalent metal elements and is different from the metal component A and the metal component B. The surface of the catalyst has a network structure with the grid density being 0.5-50 grids per square micrometer. The hydrorefining catalyst is obviously improved in activity and prolonged in service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

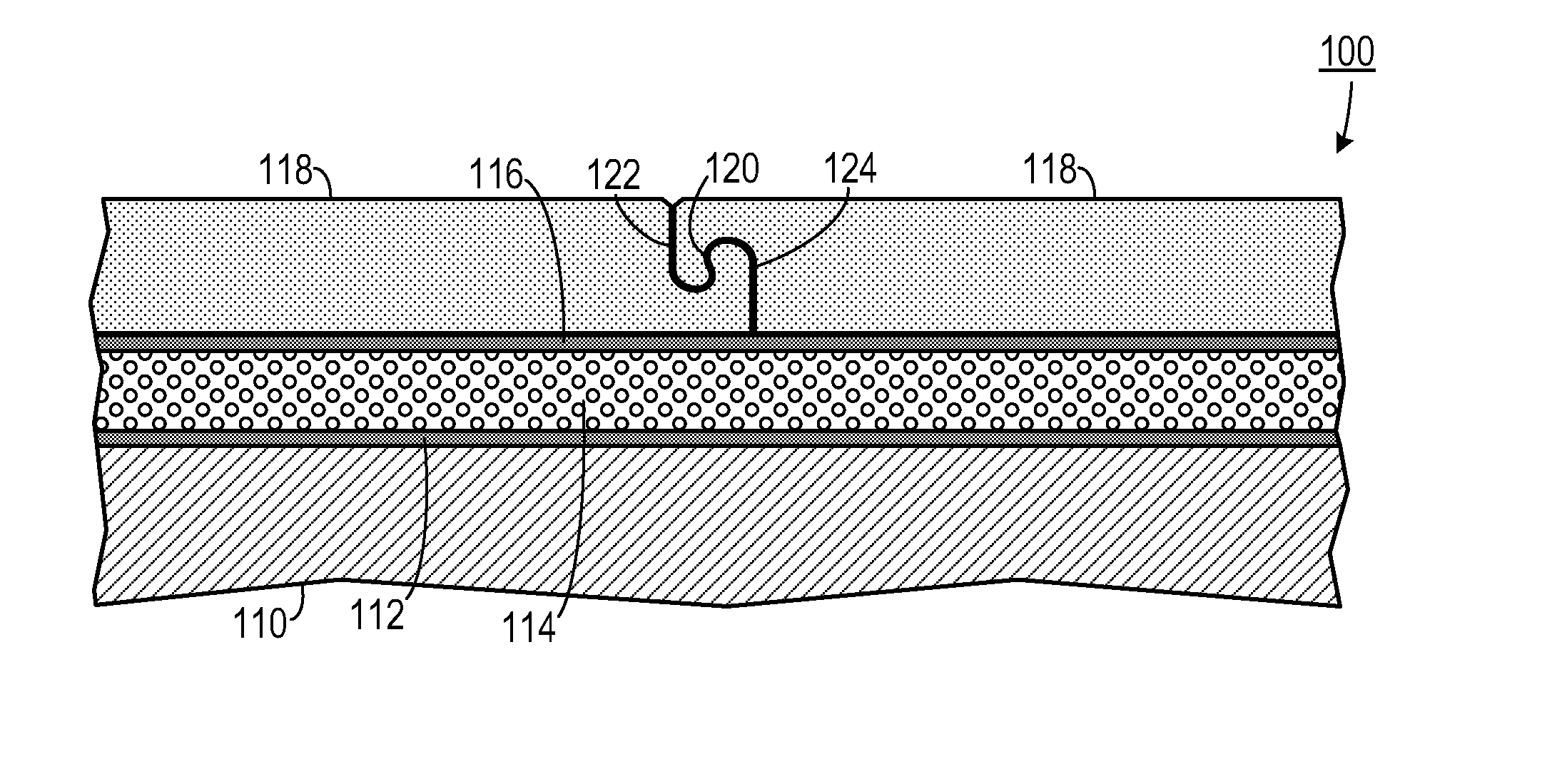

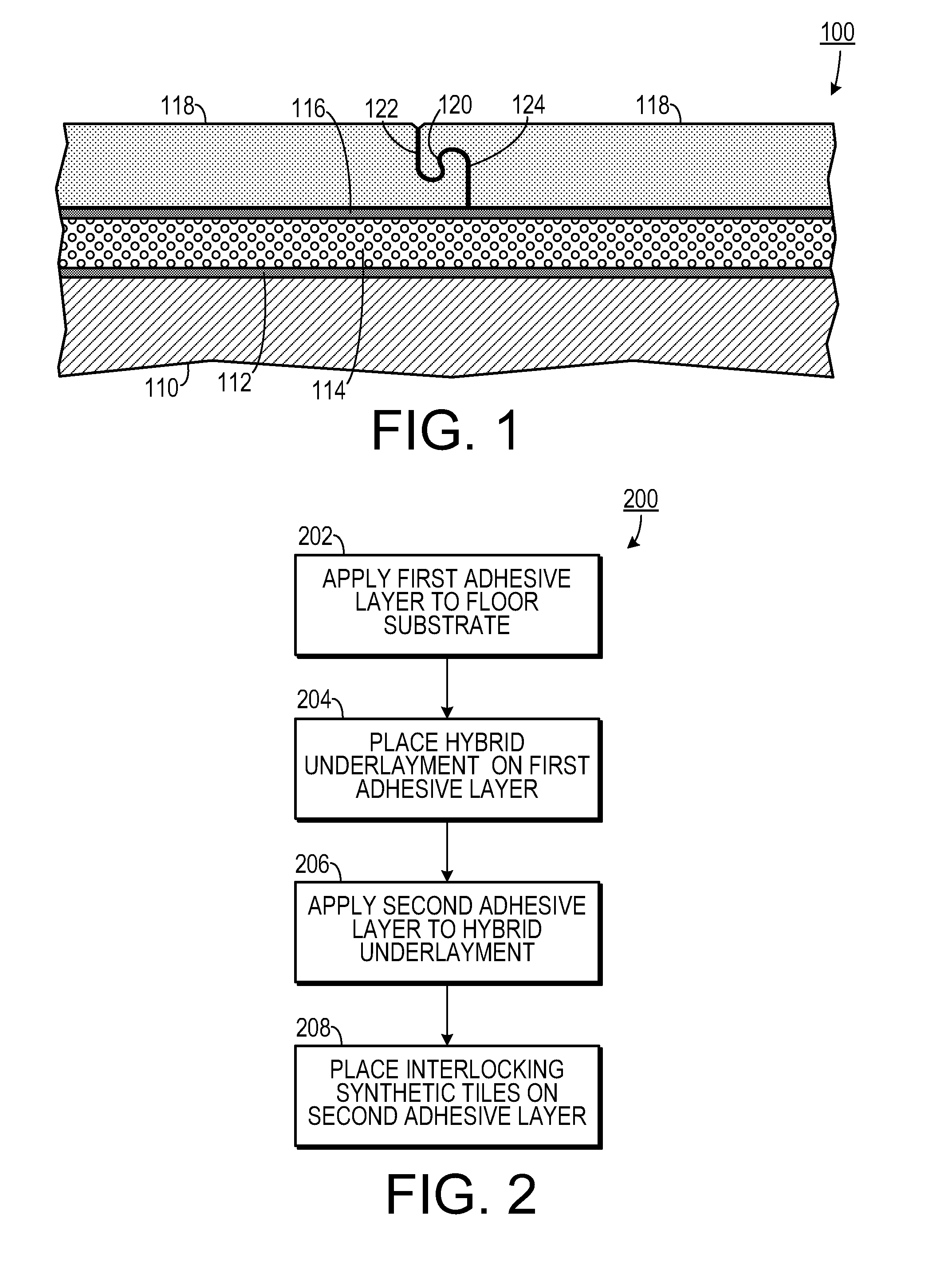

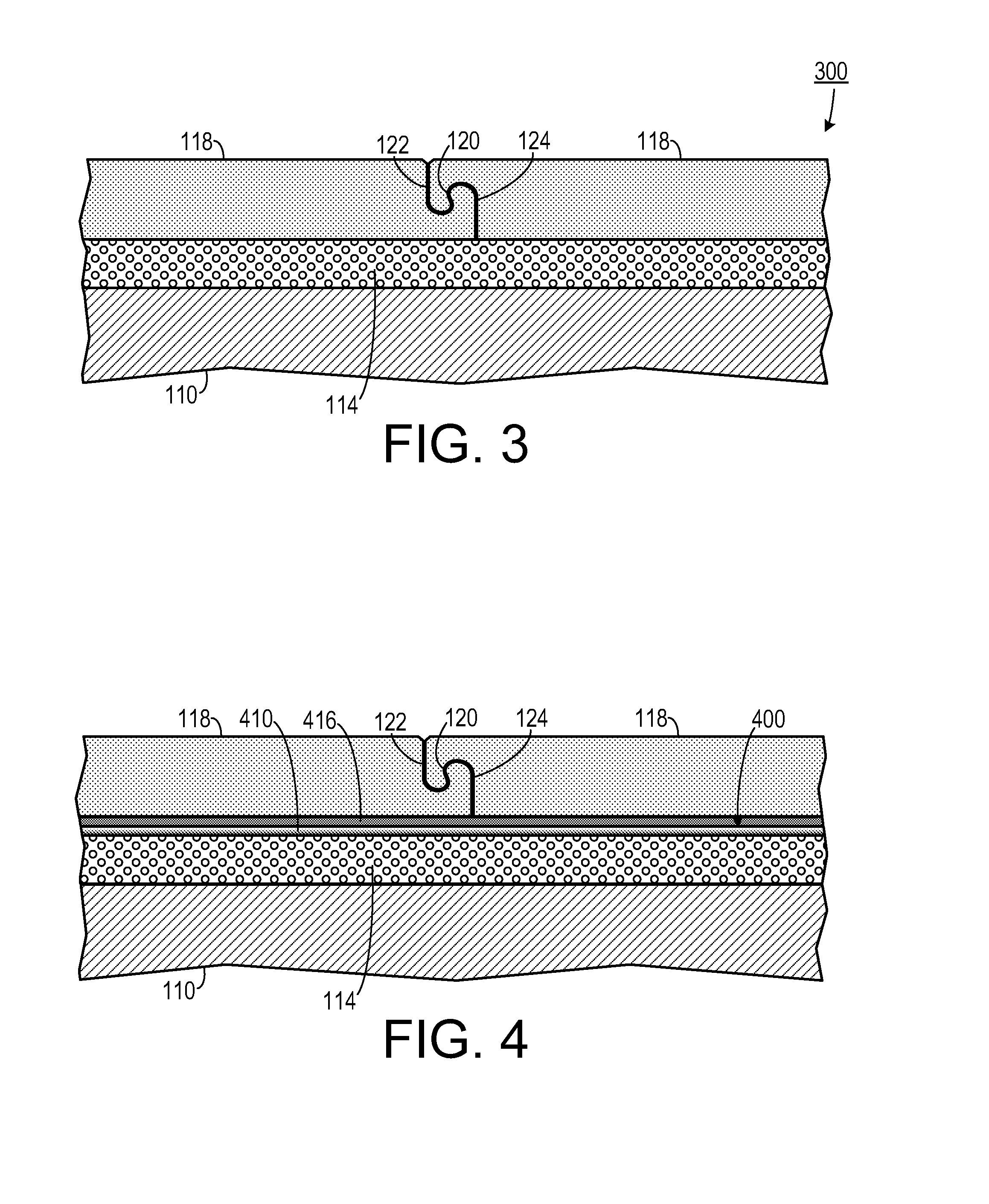

Underlayment With of Non-Woven Polyethylene Mesh

A hybrid underlayment, includes a thermoplastic making up between 92.0% by volume to 95.5% by volume of the hybrid underlayment. A plurality of expanded microspheres is dispersed through the thermoplastic. The microspheres are expanded to a volume in a range of between 180 square micrometers and 1450 square micrometers. The microspheres makeup between 1.0% by volume to 7.5% by volume of the hybrid underlayment. The hybrid underlayment is extruded into a flat sheet having a thickness of between 1.0 mm and 2.0 mm and a density from 7 pcf to 25 pcf. A metalized thermoplastic film is laminated to the top surface of the thermoplastic sheet. A pre-stretched laminated oriented mesh fabric is fused to the metalized thermoplastic film.

Owner:PAKLITE

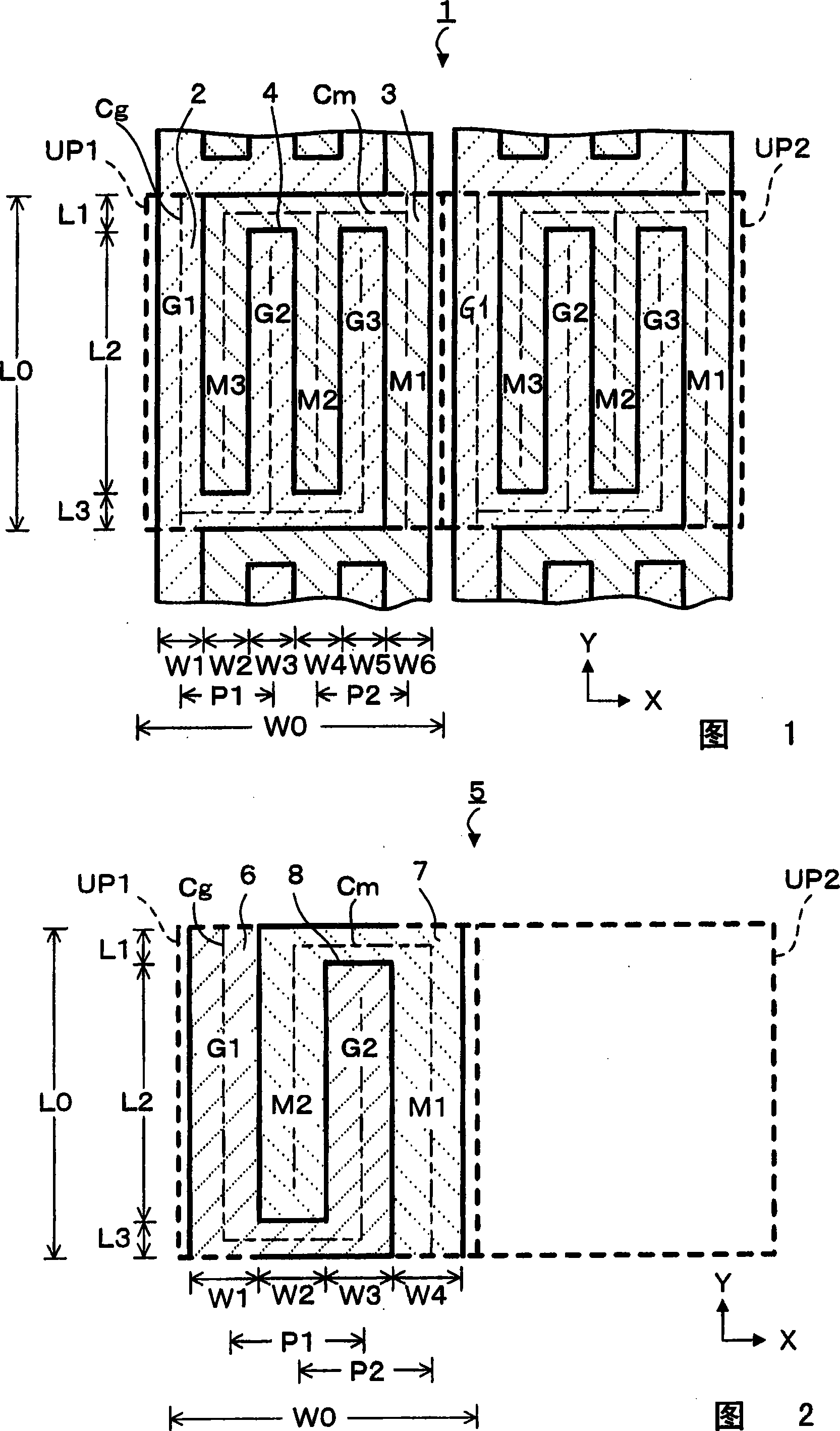

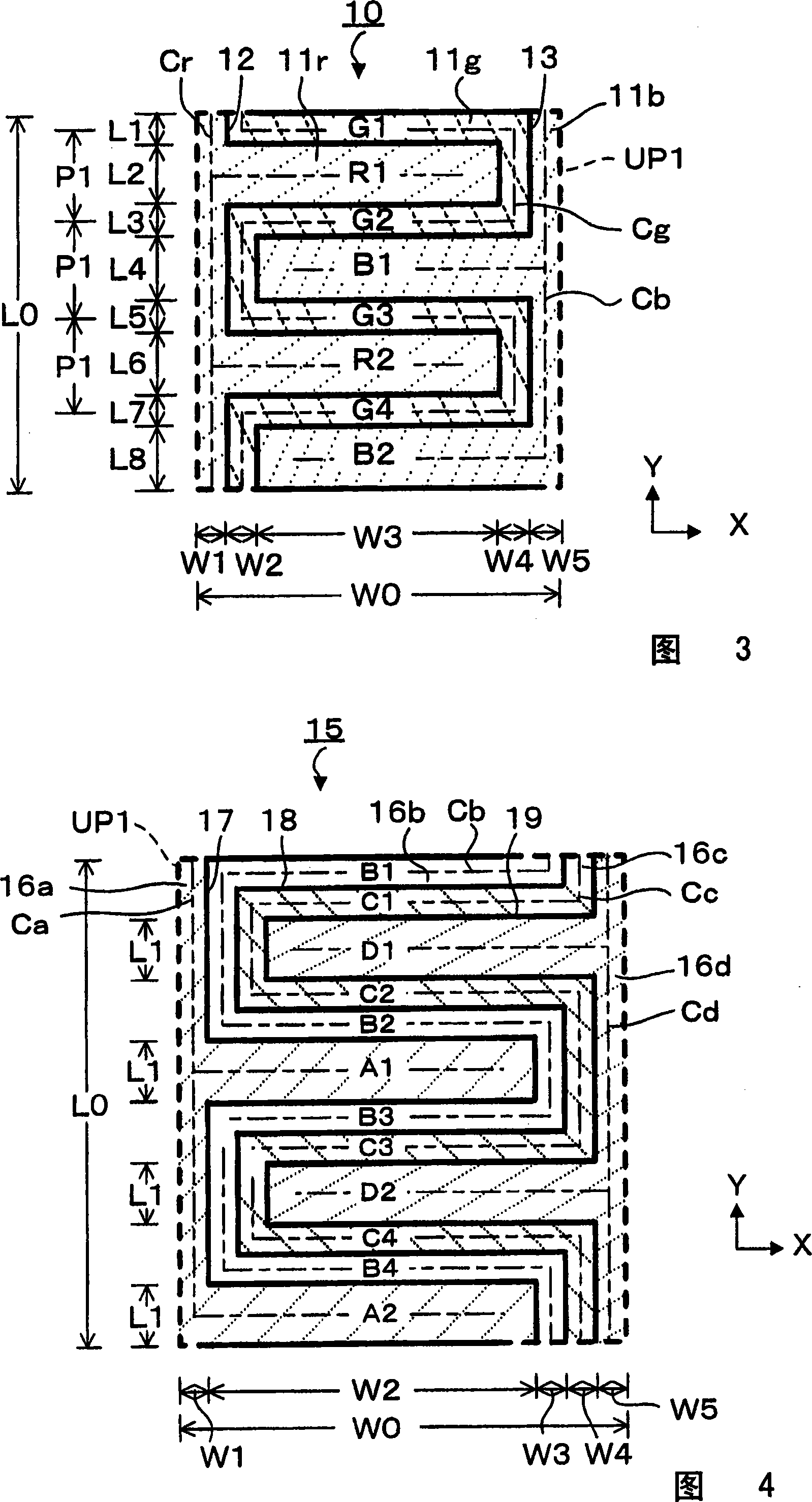

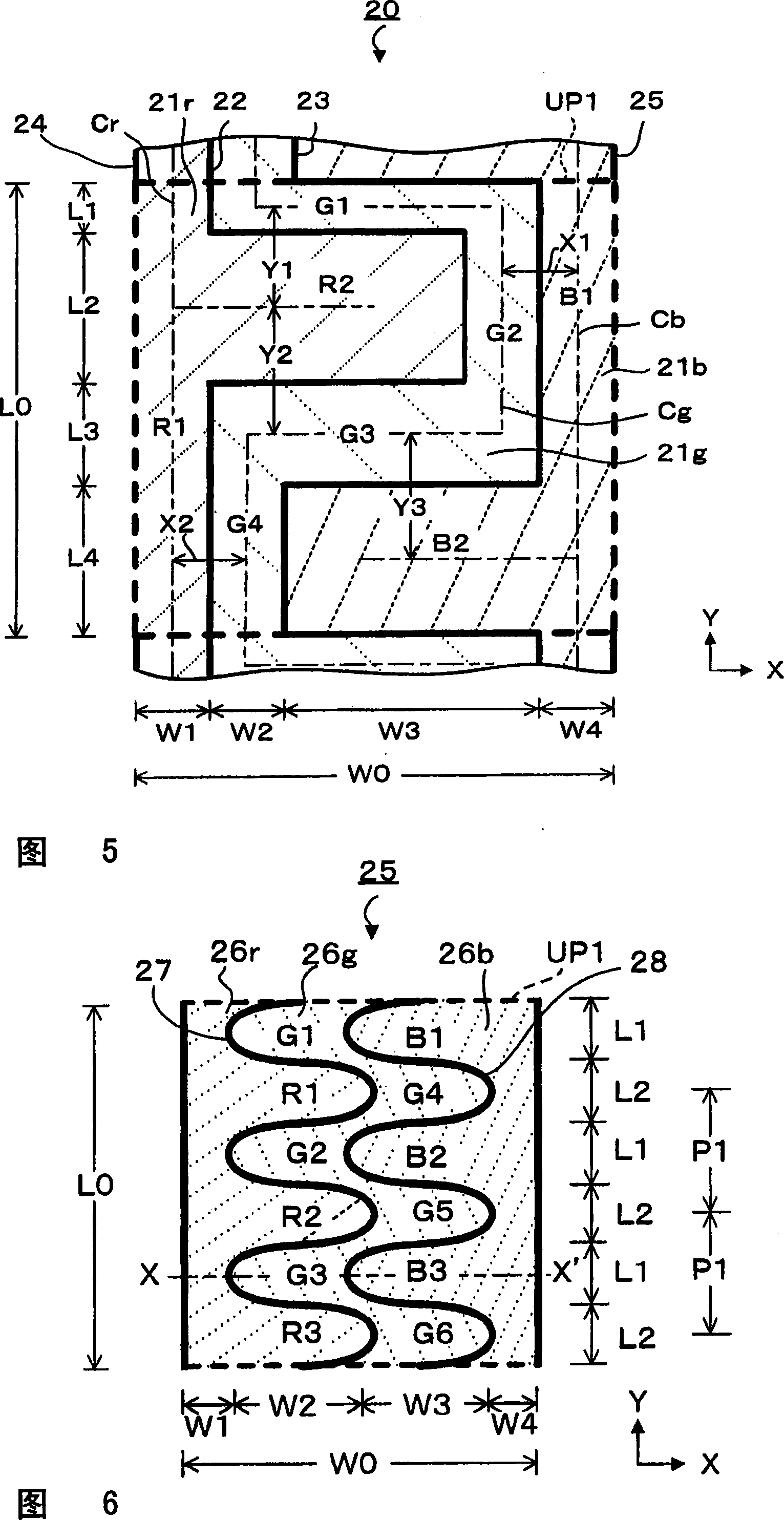

Color filter substrate, LCD device and color display device using the same

In a color filter substrate in which a unit pixel is composed of a plurality of sub-pixels of different colors and arranged two-dimensionally in a matrix, if the area of the unit pixel exceeds 40,000 square microns, the sub-pixels constituting the color can be seen, The display quality is degraded. A plurality of sub-pixels with different colors constitute a unit pixel, the area of a unit pixel is more than 40,000 square microns, and the sub-pixels have a periodic shape with a line width of no more than 100 microns. Periodically shaped regions of one sub-pixel are arranged so as to engage with each other, so that an observer can recognize a display after additive color mixing.

Owner:DAWNCREST IP LLC

Method for producing synthetic gas through continuous catalysis of methane by oxygen-carrying membrane

InactiveCN102424360AEasy to synthesizeActs as an oxygen permeable membraneHydrogenBulk chemical productionPartial oxidationLiquid hydrocarbons

The invention provides a method for producing synthetic gas through continuous catalysis of methane by oxygen-carrying membrane. The method comprises: introducing methane that is adopted as the reaction raw material gas from one side of an oxygen-carrying catalyzing membrane with thickness of 1-3mm, and simultaneously introducing a regeneration gas from the other side of the oxygen-carrying catalyzing membrane, in per square micrometer of which methane passes at flow of 0.008-0.076Ncm<3>.min<-1> and the regeneration gas passes at flow of 0.012-0.082Ncm<3>.min<-1>, conducting reaction under a reaction pressure of 1-2atm and a temperature of 800-1000DEG C for 0.5-50h, and carrying out collecting at the oxygen-carrying catalyzing membrane side where the raw material gas is introduced, thus obtaining the synthetic gas. The method of the invention has a totally short process, high efficiency, higher yield than traditional methane partial oxidation methods, and lower cost than other methane membrane reactions. The method provided in the invention can make mixing of different proportions according to the preparation technological demands of downstream chemicals or liquid hydrocarbon, thus broadening the application scope.

Owner:KUNMING UNIV OF SCI & TECH

High-strength aluminum alloy product and method of producing the same

A high-strength Al—Cu—Mg—Si aluminum alloy product obtained by extrusion is characterized in that the microstructure of the entire surface of the cross-section of the aluminum alloy product is formed of recrystallized grains, the grains have an average aspect ratio (L / t) of 5.0 or less and the orientation density of the grains in the microstructure, for which the normal direction to the {001} plane is parallel to the extrusion direction in comparison with the grains orientated to random orientations, is 50 or less. The high-strength Al—Cu—Mg—Si aluminum alloy product is characterized in that rod-shaped precipitates are arranged in the grains of the matrix in the <100> direction, the precipitates have an average length of 10 to 70 nm and a maximum length of 120 nm or less, and the number density of the precipitates in the [001] direction measured from the (001) plane is 500 or more per square micrometer.

Owner:SUMITOMO LIGHT METAL INDS LTD

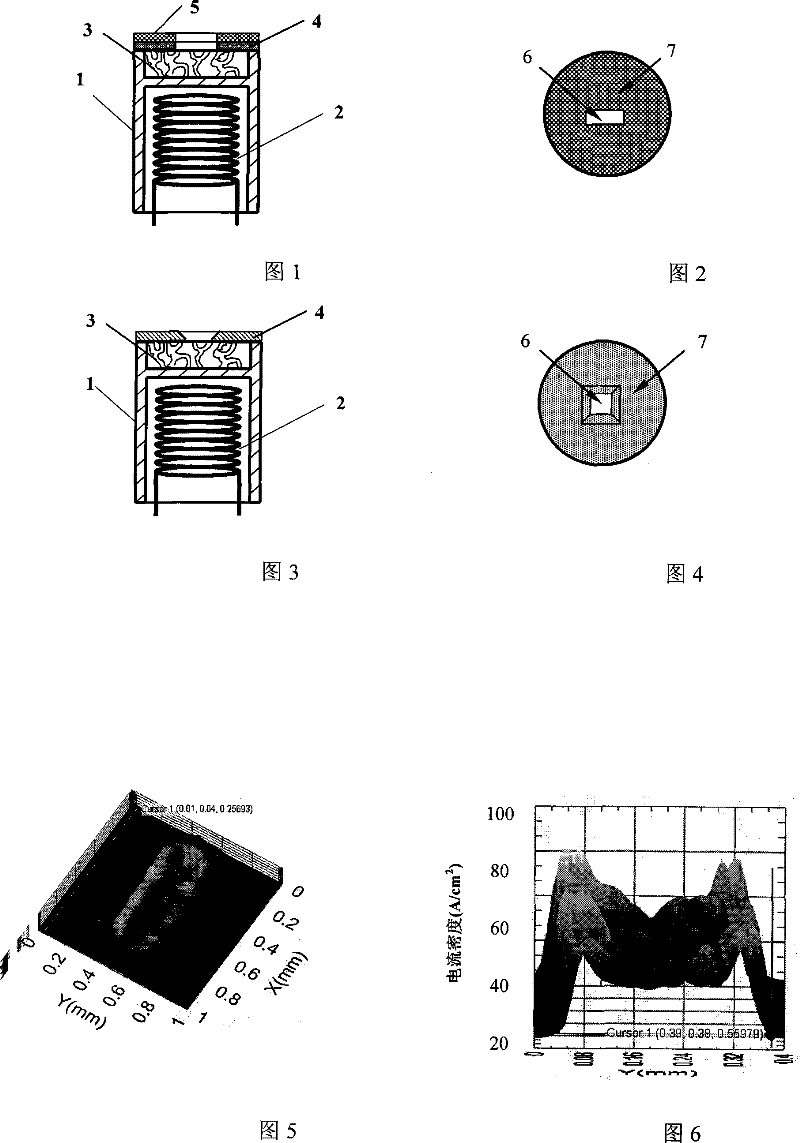

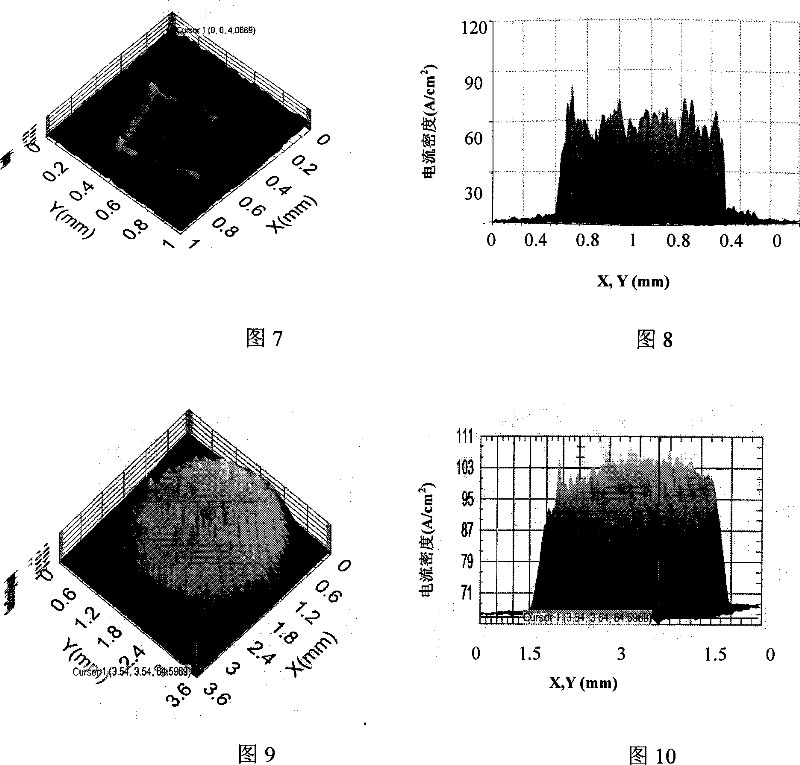

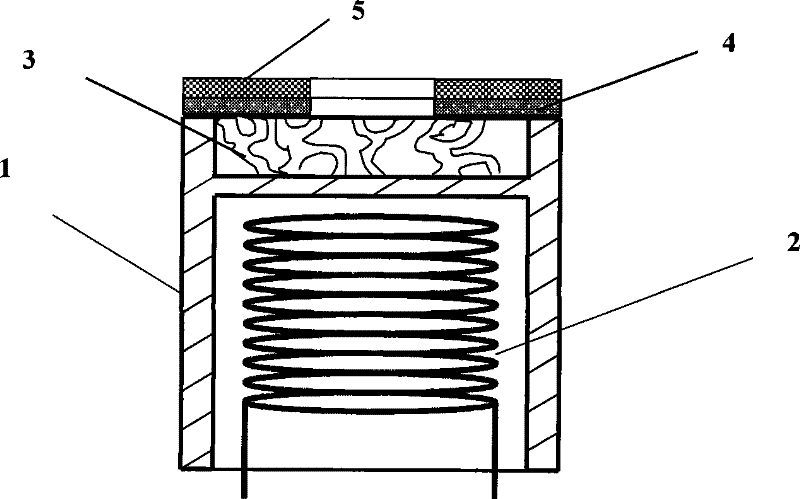

High-curren density heterogeneous beam electron source

InactiveCN101075515BThermionic cathodesDischarge tube solid thermionic cathodesHigh current densityBeam electron

This is an electron source of high current density and hetero-stream. The traditional method for hetero-stream is by using of magnetic focusing on round stream, which needs strong permanent magnetic field, so leads to bigger size and weight of the instrument. This invention makes it available to get hetero-stream directly from cathode without or only little compressing. The source is composed by a diffuse cathode of high current density with metal Sc and a shaping device for hetero-stream. The two parts are fabricated in a molybdenum sleeve and proper heater. The size of the source is within dozens of square micrometers to several square centimeters. The current density is over 50A / cm<2>.

Owner:BEIJING UNIV OF TECH

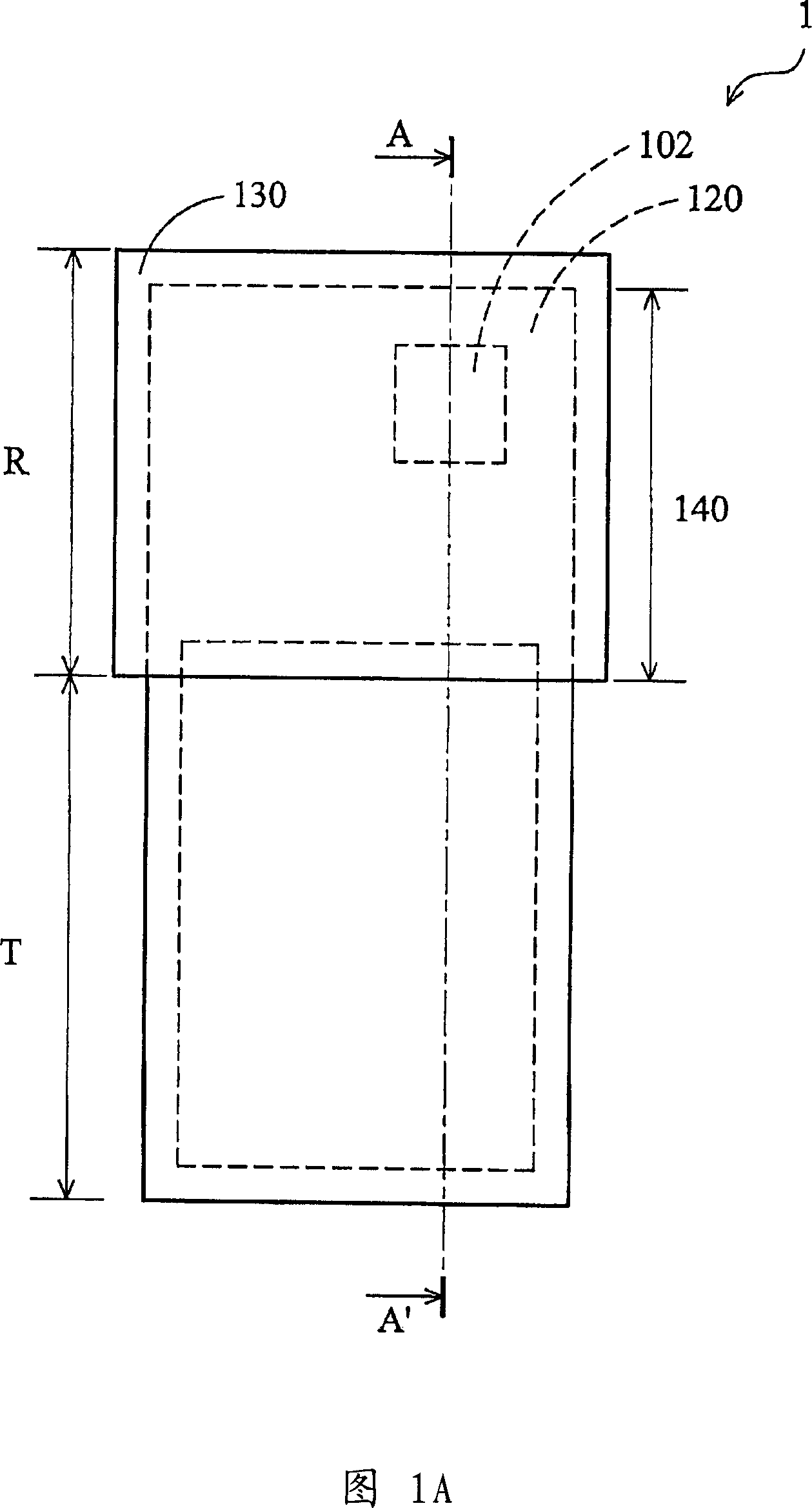

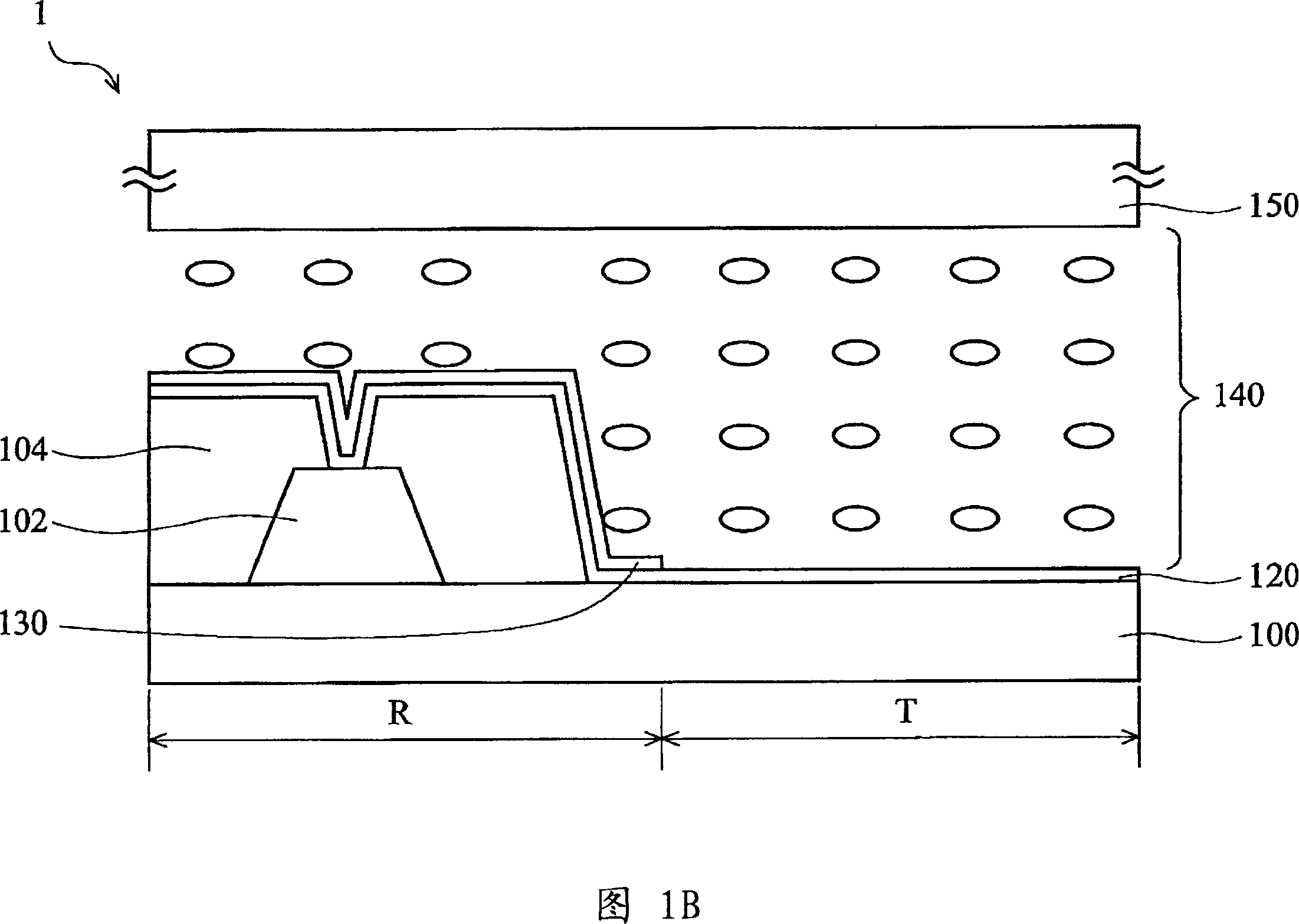

Systems for displaying images

InactiveCN1979315ATransistorStatic indicating devicesThin-film-transistor liquid-crystal displaySquare Micrometer

Systems for displaying images and methods of fabricating are provided. A representative system incorporates a transflective thin film transistor liquid crystal display (TFT-LCD) panel having a plurality of subpixels. The display panel comprises a first substrate with a transparent electrodeformed thereon, a reflective electrode on the transparent electrode, a second substrate opposite the first substrate, a liquid crystal layer between the first substrate and the second substrate. The panel also exhibits at least one of: the reflective electrode and the transparent electrode overlap by substantially between 100 and 1000 square micrometers; the reflective electrode and the transparent electrode overlap such that a ratio of an area of overlap of the reflective electrode and the transparent electrode to an area of a corresponding subpixel is substantially between 0.05 and 0.12; and a ratio of an area of the transparent electrode to an area of a corresponding subpixel is substantially between 0.5 and 0.6.

Owner:TPO DISPLAY

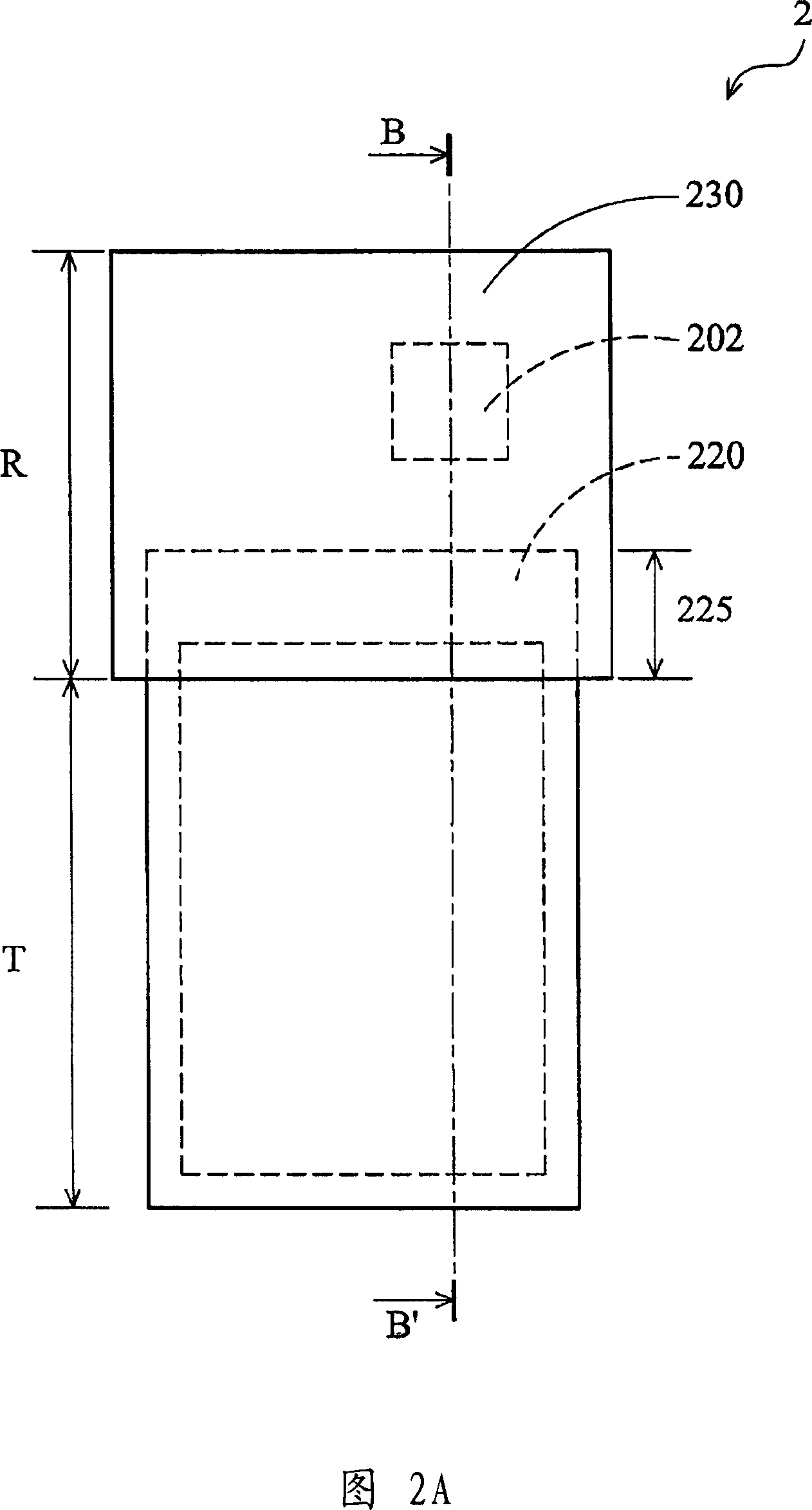

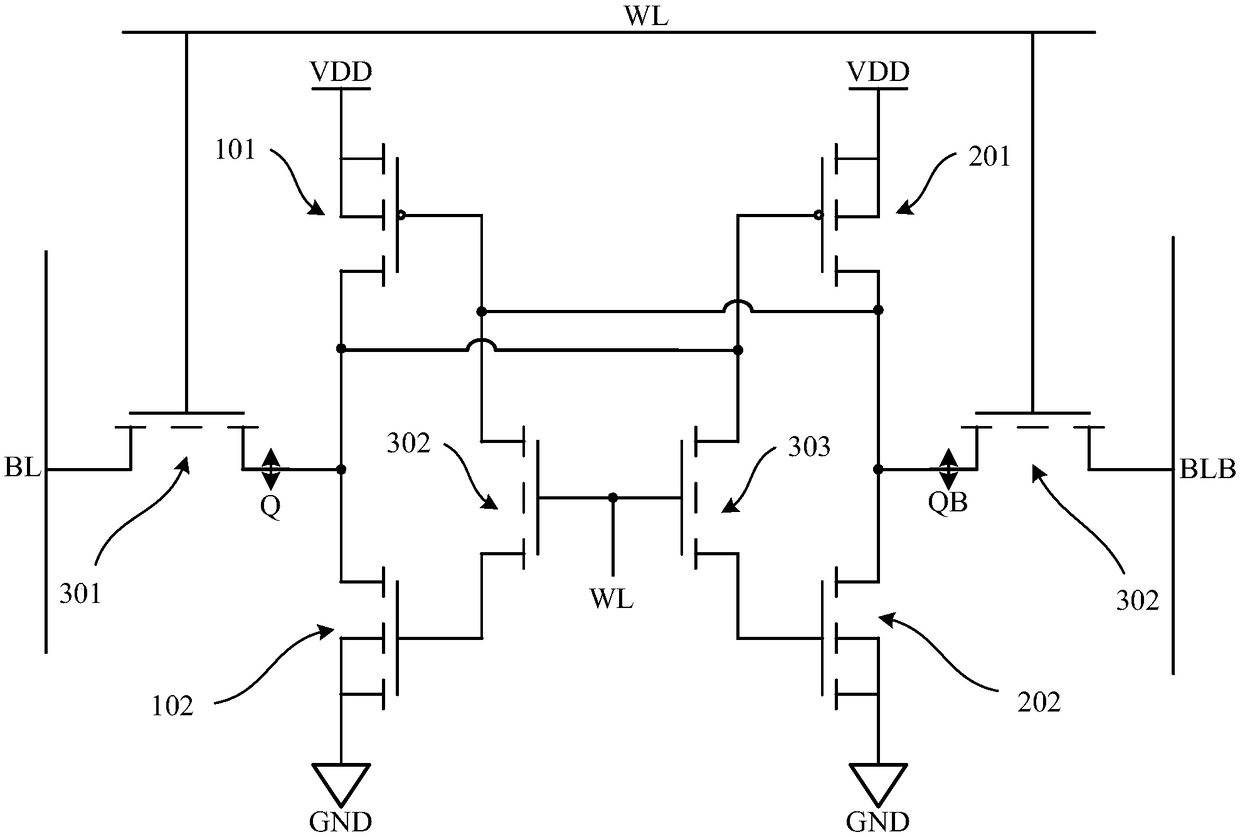

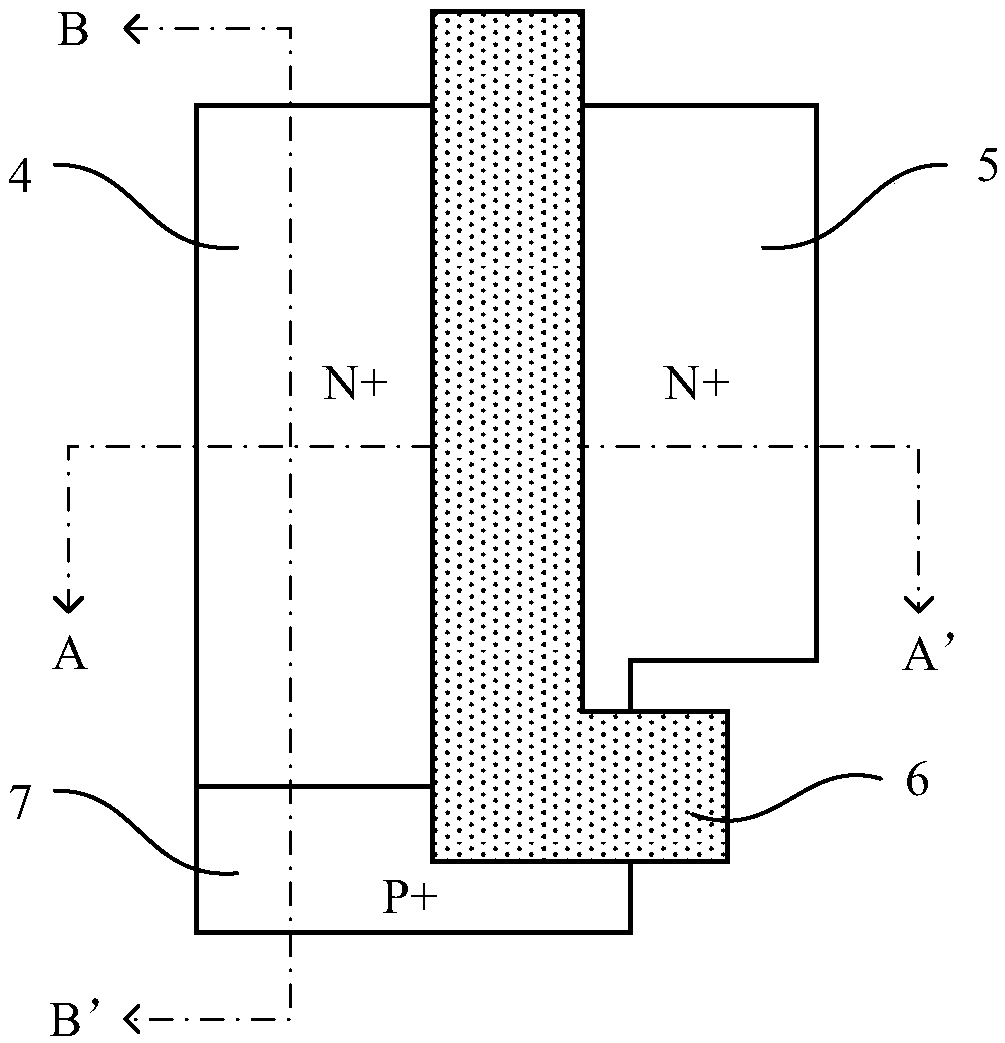

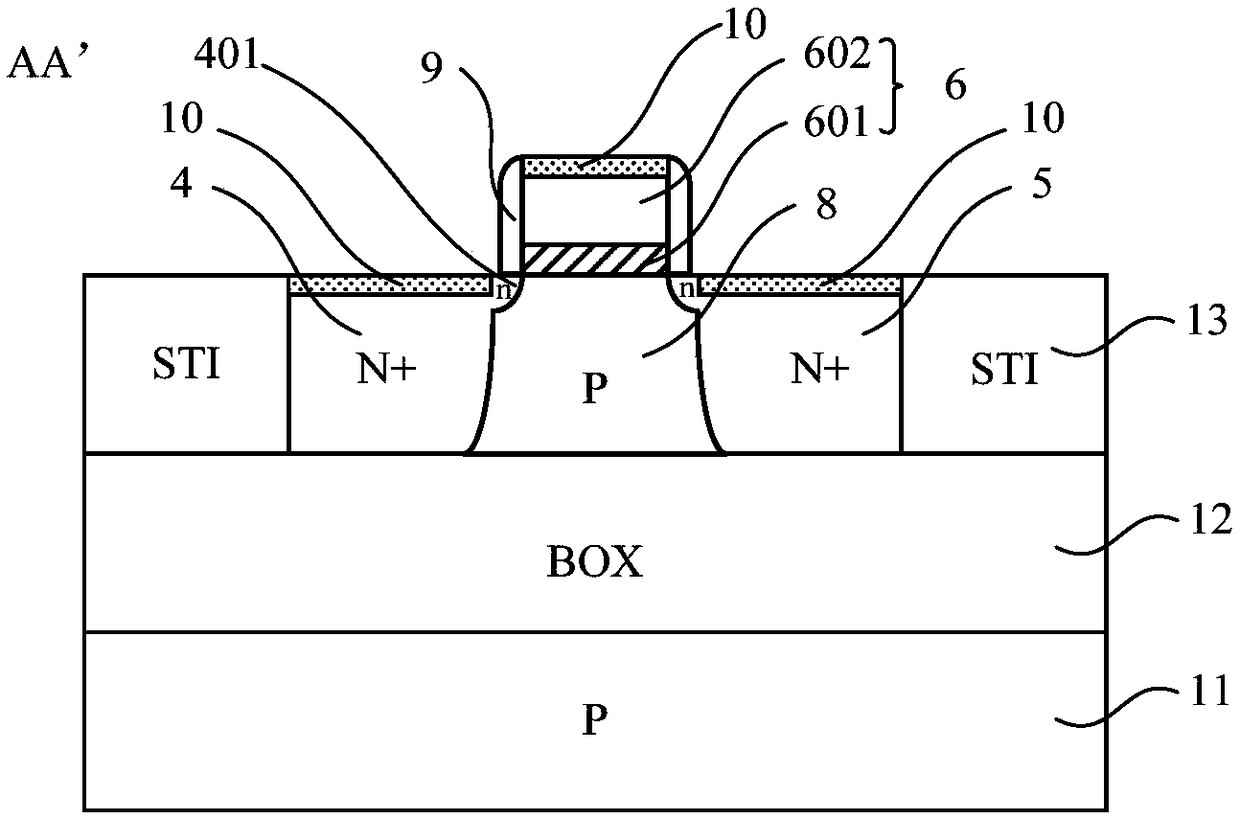

Static random access memory and fabrication method thereof

ActiveCN108878426AImprove noise immunitySize matchTransistorSolid-state devicesFloating body effectStatic random-access memory

The invention provides a static random access memory and a fabrication method thereof. A pull-up transistor and a pull-down transistor both employ L-shaped gates, a floating body effect in a partially-depleted (PD) SOI device, leakage power consumption caused by a parasitic triode effect and transistor threshold voltage drift can be effectively prevented under the condition that relatively small unit area can be sacrificed (the final effective unit area can be smaller than 8 square micrometers), and the noise-resistant capability of the unit is improved; and moreover, no extra mask is introduced to the fabrication method of the static random access memory, the fabrication method is completely compatible with a traditional logic process, a central symmetric structure is employed in the unit, the matching of the size and the threshold value of a MOS tube is facilitated, array formation is also facilitated, and a static random access memory (SRAM) chip is convenient to completely customize.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

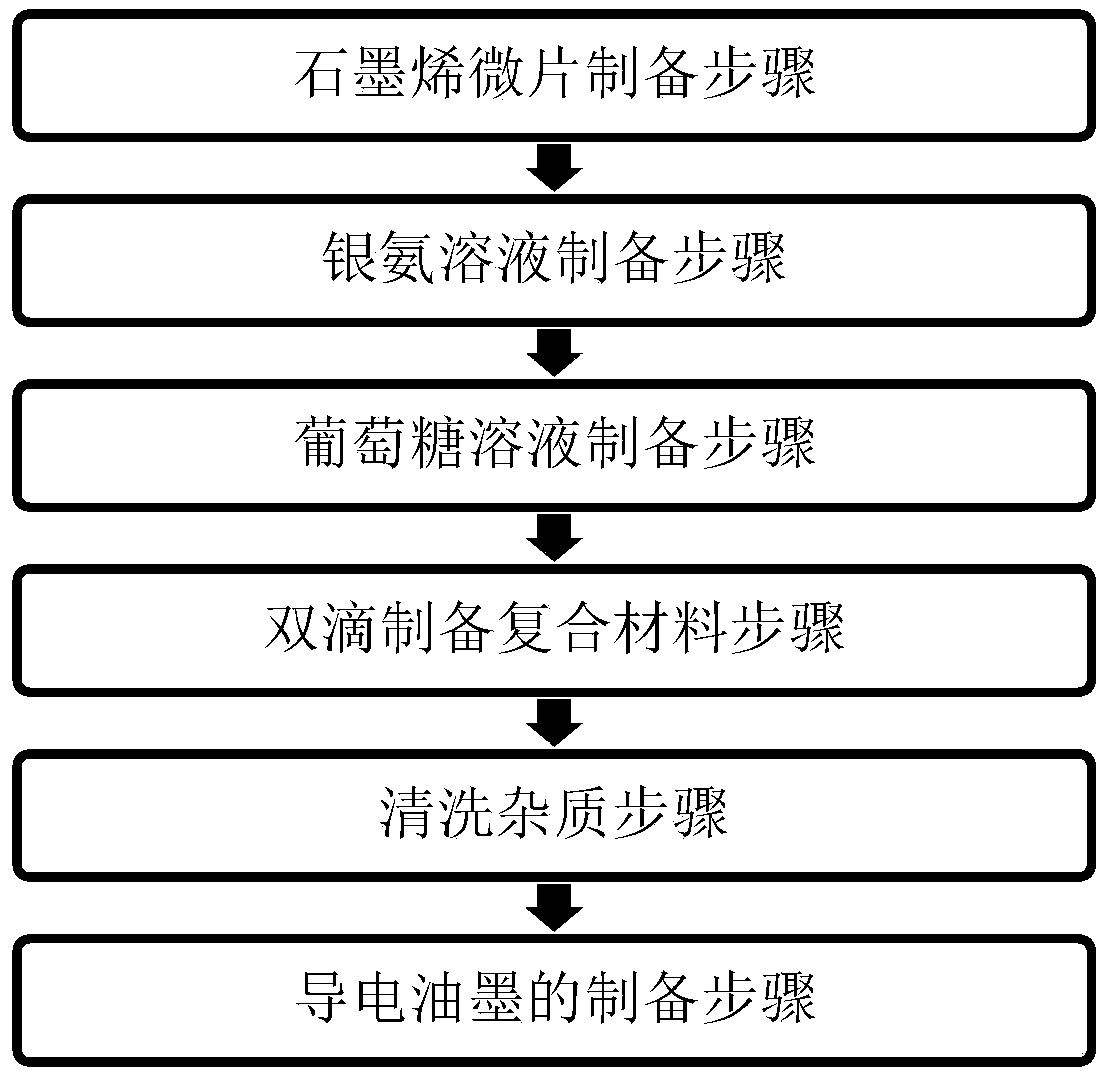

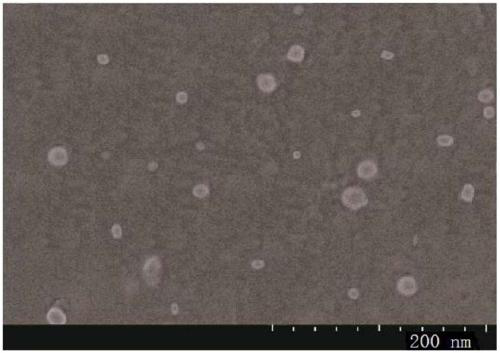

Graphene-containing conductive printing ink and preparation method thereof and flexible paper-based conductive circuit

The invention relates to a graphene-containing conductive printing ink and a preparation method thereof and a flexible paper-based conductive circuit. The method comprises the following steps: a graphene microchip preparation step, a silver-ammonia solution preparation step, a glucose solution preparation step, a double-droplet composite preparation step, an impurity cleaning step, and a conductive printing ink preparation step. The28-29 parts by weight of the printing ink contains 10 parts by weight of a graphene / nano-silver particle filler, more than 80% of the nano-silver particles in the filler have a radial size of less than 70-80 nm, and the particle agglomeration number of the nano-silver attached to micro-sheets per square micrometer is higher than 75 to 80. The actual measured resistivity of the conductive ink circuit is between 0.87-0.75 x 10<-7> ohm.meter.

Owner:国宏中晶集团有限公司

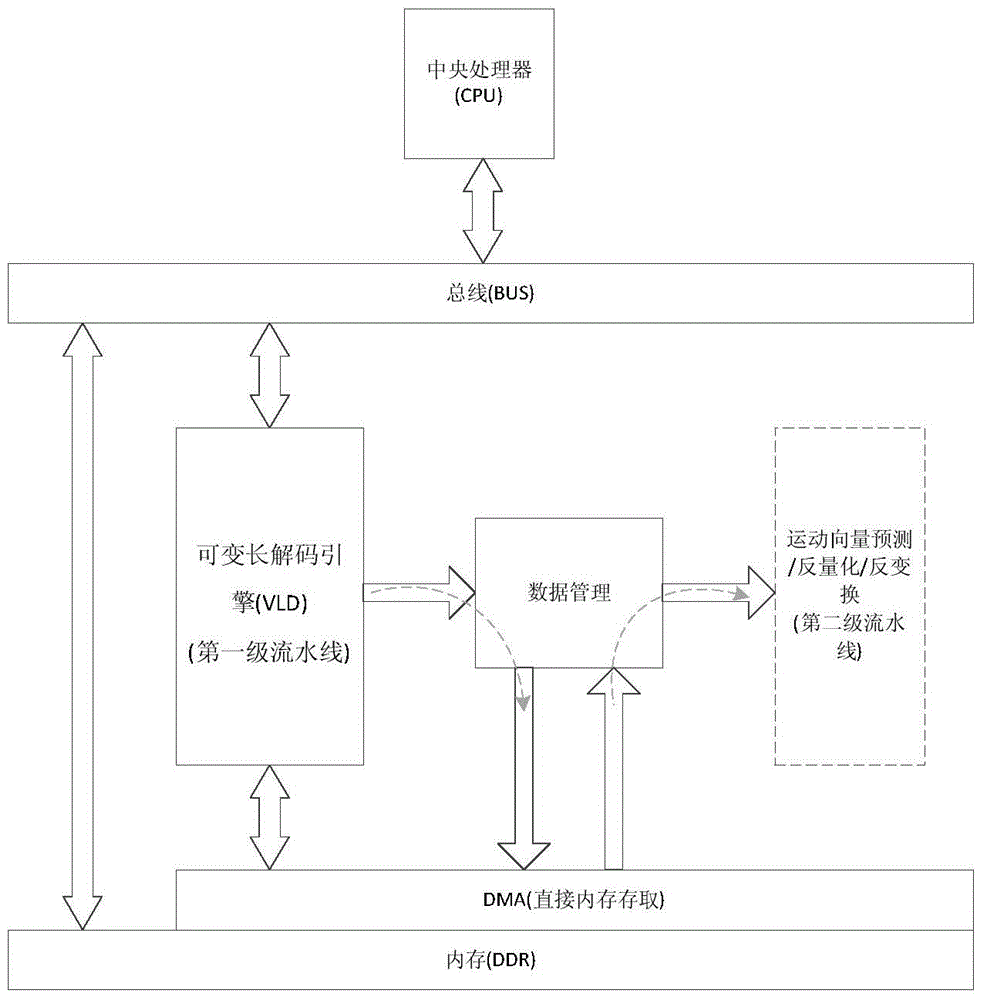

Novel Decoder and Decoding Method

ActiveCN103596013BLow costSave extra spaceDigital video signal modificationDecoding methodsVideo bitstream

The invention provides a novel decoder and a decoding method. The novel decoder at least comprises a DDR, a variable-length decoding engine, a data management module and a direct memory access module, wherein the DDR is used for caching a video bitstream before decoding and output data of the variable-length decoding engine; the variable-length decoding engine is used for decoding the video bitstream obtained from the DDR and outputting the decoded data into the data management module; the data management module is used for outputting the decoded data of the variable-length decoding engine to the direct memory access module and outputting the data obtained from the direct memory access module; the direct memory access module is used for outputting the decoded data, output by the data management module, of the variable-length decoding engine into the DDR and outputting the decoded data, obtained from the DDR, of the variable-length decoding engine to the data management module. According to the novel decoder, a reading channel and a writing channel are added to the direct memory access module, namely a small logic is increased, and two 416X22 single-port SRAMs and two sets of registers for caching parameters are omitted. Thus, compared with design in the prior art, the novel decoder has the advantages that the comprehensive area of a chip is saved by about 80000 square micrometers, the integral area of the chip is reduced by about 6%, and therefore cost of the corresponding chip is greatly reduced.

Owner:SHANGHAI HIGH DEFINITION DIGITAL TECH IND

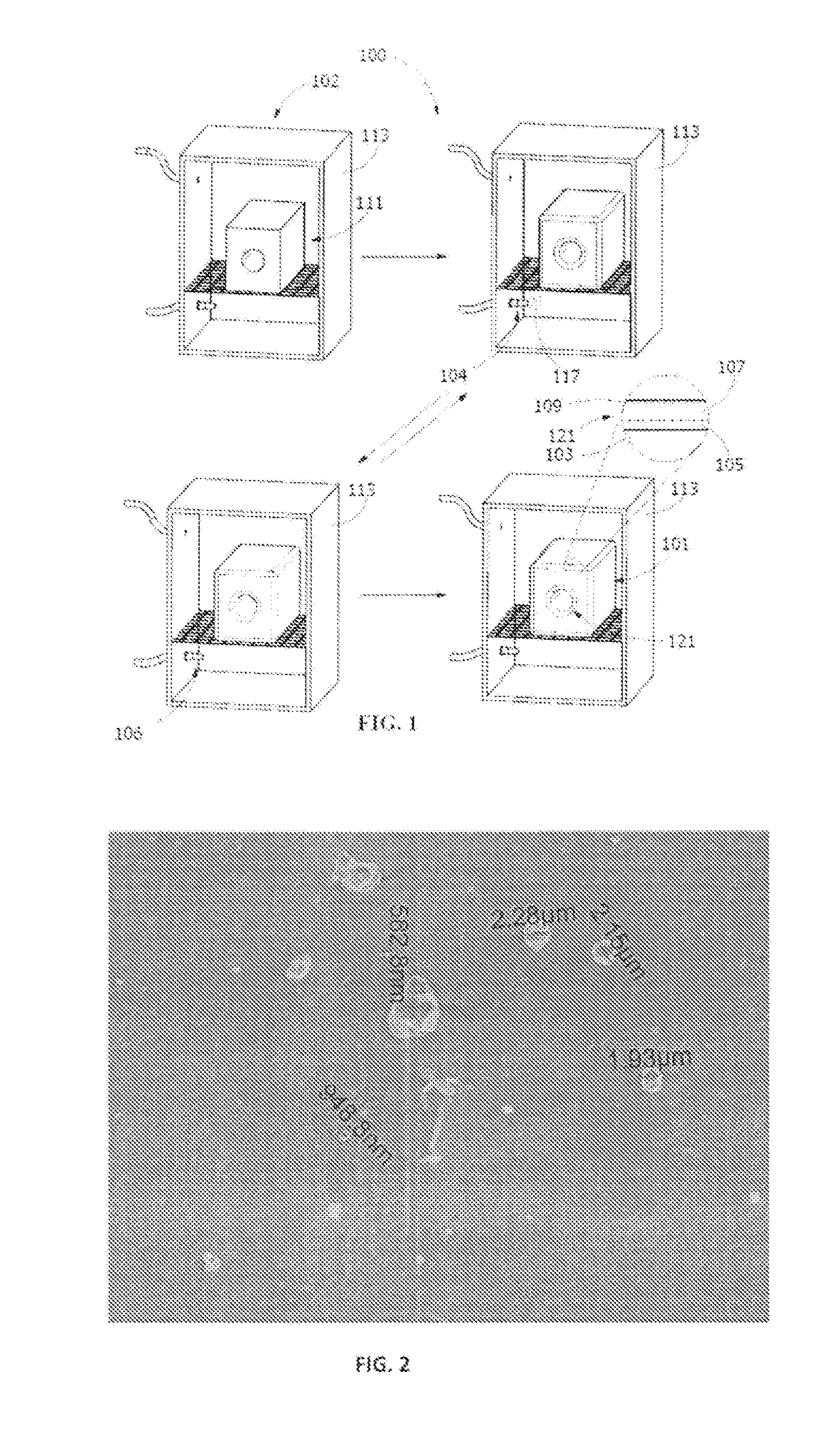

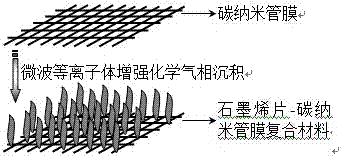

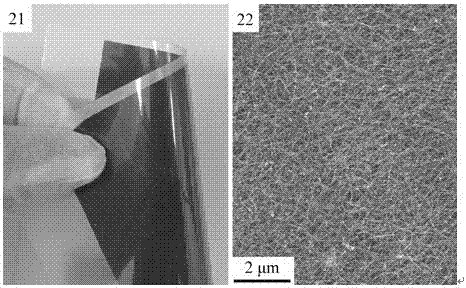

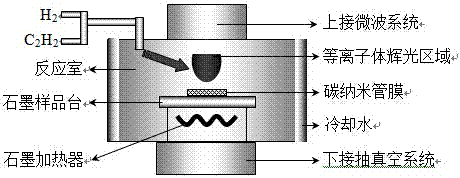

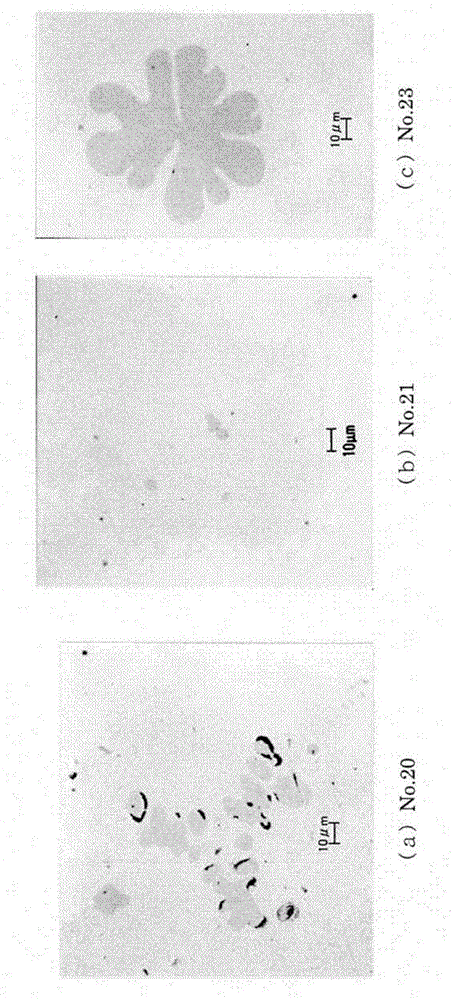

A flexible composite material of graphene sheet-carbon nanotube film and its preparation method and application

InactiveCN105244249BGood field emission stabilityField emission current density does not drop significantlyElectric discharge tubesCold cathode manufactureField emission currentMicrowave

The invention discloses a graphene sheet-carbon nanotube film flexible composite material, a preparation method and an application thereof. It uses microwave plasma enhanced chemical vapor deposition method to prepare graphene sheet on carbon nanotube film, and uses the obtained graphene sheet-carbon nanotube film flexible composite material as a cathode to assemble a field emitter. The graphene sheet-carbon nanotube film flexible composite material prepared by this method has the characteristics of flexibility, and the graphene sheet is distributed on the carbon nanotube in an array state, and the number of graphene sheet layers is 1-10 layers, on the carbon nanotube film The distribution density on the surface is 8-12 pieces / square micron, and the width is 0.5-1.2 micron. Compared with the graphene sheet grown on the planar silicon substrate, the graphene sheet-carbon nanotube film flexible composite material prepared by this method has lower turn-on electric field and larger field emission current density, and can It works stably under the field emission current density and has high application value.

Owner:TIANJIN NORMAL UNIVERSITY

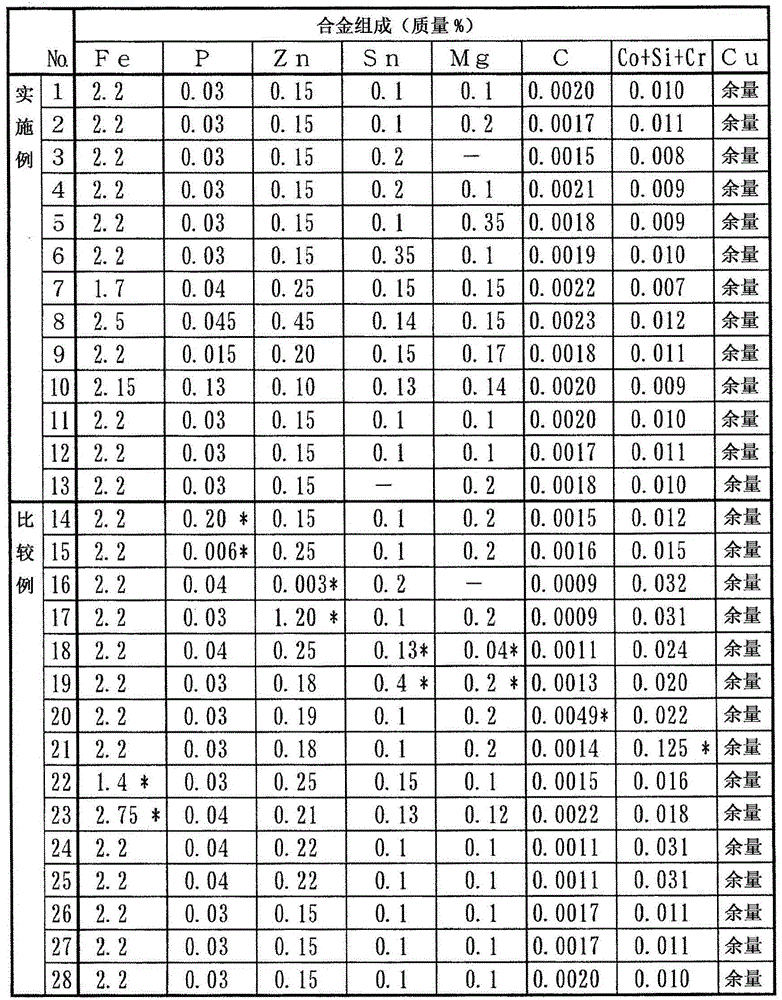

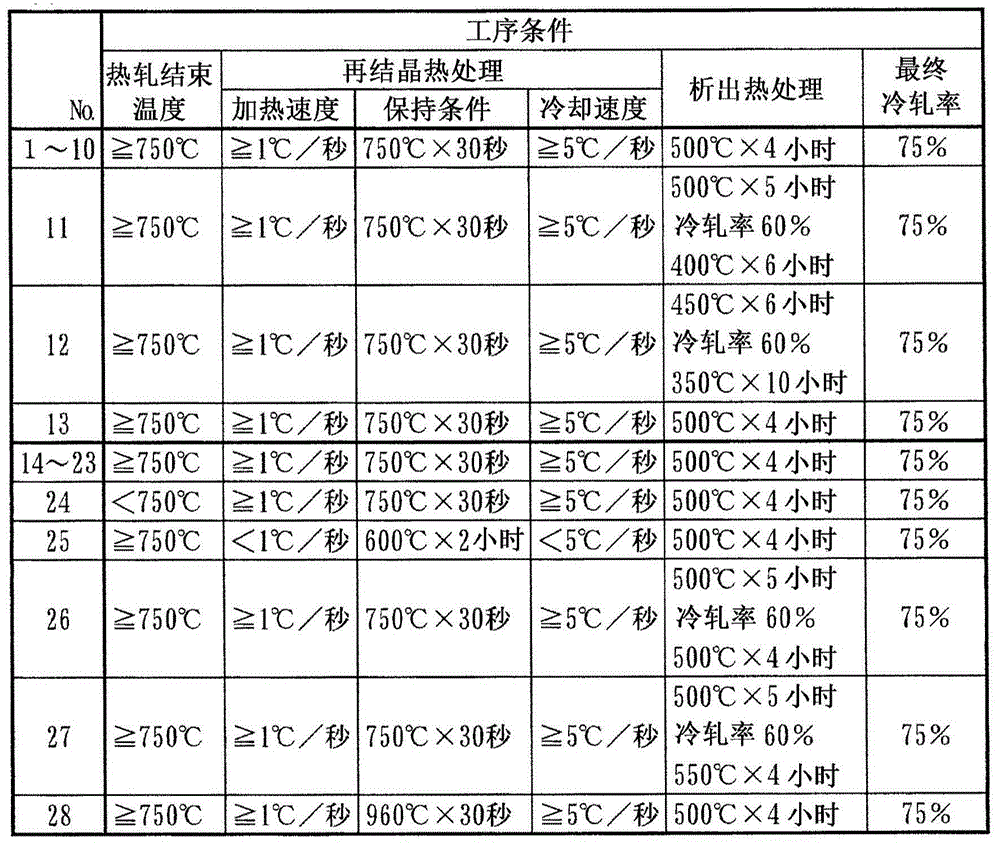

Fe-p based copper alloy sheet excellent in strength, heat resistance and bending processibility

ActiveCN104928521AExcellent adhesionHigh strengthMetal rolling arrangementsCrystal structureUltimate tensile strength

The invention provides a Fe-P based copper alloy sheet excellent in strength, heat resistance and bending processibility. The Fe-P based copper alloy sheet is composed of, by mass, 1.6 to 2.6% Fe, 0.01 to 0.15% P, 0.01 to 1.0% Zn, 0.1 to 0.5% Sn and / or Mg, 0.003% C, 0.05% Co, Si and Cr, and the balance being Cu and inevitable impurities. When observing crystal structures on a section in parallel with a rolling direction and perpendicular to the board plane with EBSD, the weighted average obtained by weighting equivalent circular diameter of grains with area is less than 10 micrometers. The conductivity is more than 50%IACS. The Vickers hardness is higher than 180Hv. When the equivalent circular diameter is 10 to 40 nm, the existence density of precipitated particles of Fe or Fe-P compound is more than 20 per square micrometers.

Owner:KOBE STEEL LTD

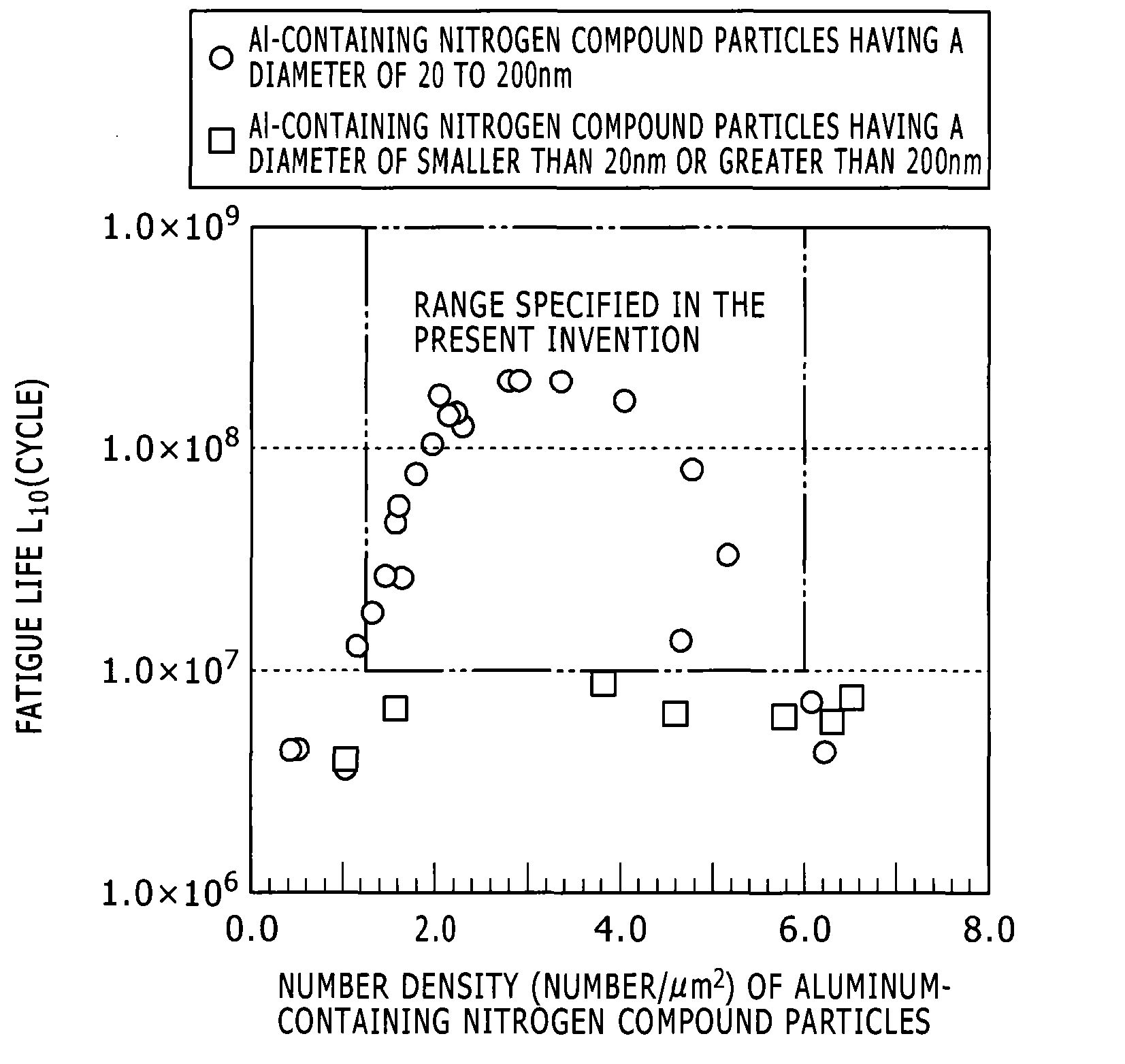

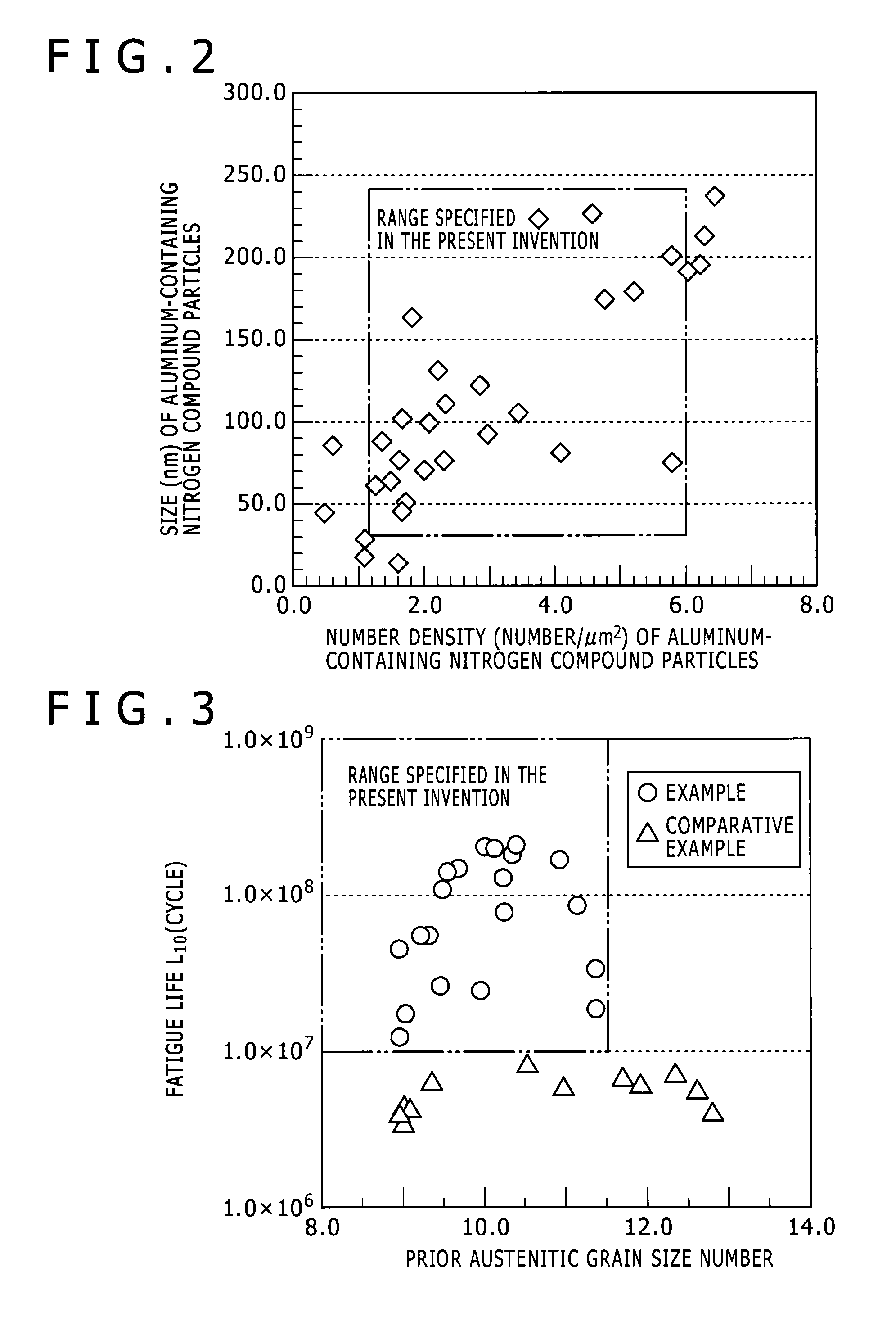

Steel with excellent rolling-contact fatigue properties

ActiveUS9303302B2Fatigue propertyGood workmanshipFurnace typesHeat treatment furnacesRolling contact fatigueMetallurgy

Disclosed is a steel having high manufacturability and better rolling-contact fatigue properties. The steel contains C of 0.65% to 1.30%, Si of 0.05% to 1.00%, Mn of 0.1% to 2.00%, P of greater than 0% to 0.050%, S of greater than 0% to 0.050%, Cr of 0.15% to 2.00%, Al of 0.010% to 0.100%, N of greater than 0% to 0.025%, Ti of greater than 0% to 0.015%, and O of greater than 0% to 0.0025% and further contains iron and unavoidable impurities. Al-containing nitrogen compound particles dispersed in the steel have an average equivalent circle diameter of 25 to 200 nm, and Al-containing nitrogen compound particles each having an equivalent circle diameter of 25 to 200 nm are present in a number density of 1.1 to 6.0 per square micrometer.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com