Fe-p based copper alloy sheet excellent in strength, heat resistance and bending processibility

A technology of bending workability and copper alloy plate, applied in the direction of metal rolling, etc., can solve the problem of unresearched punchability, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

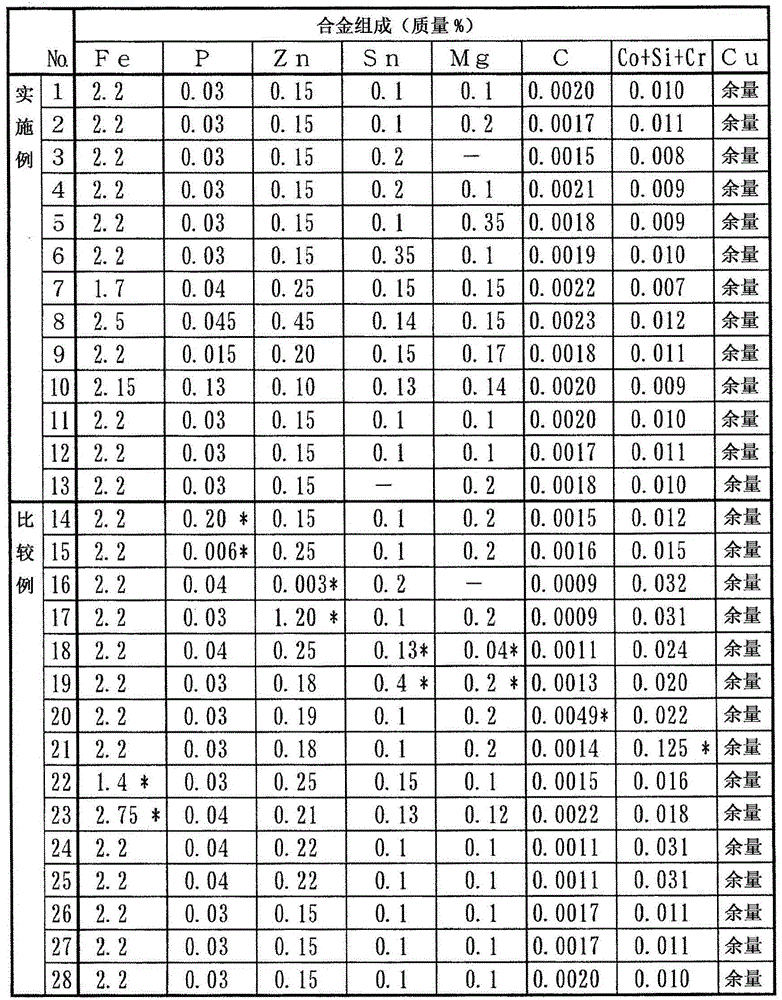

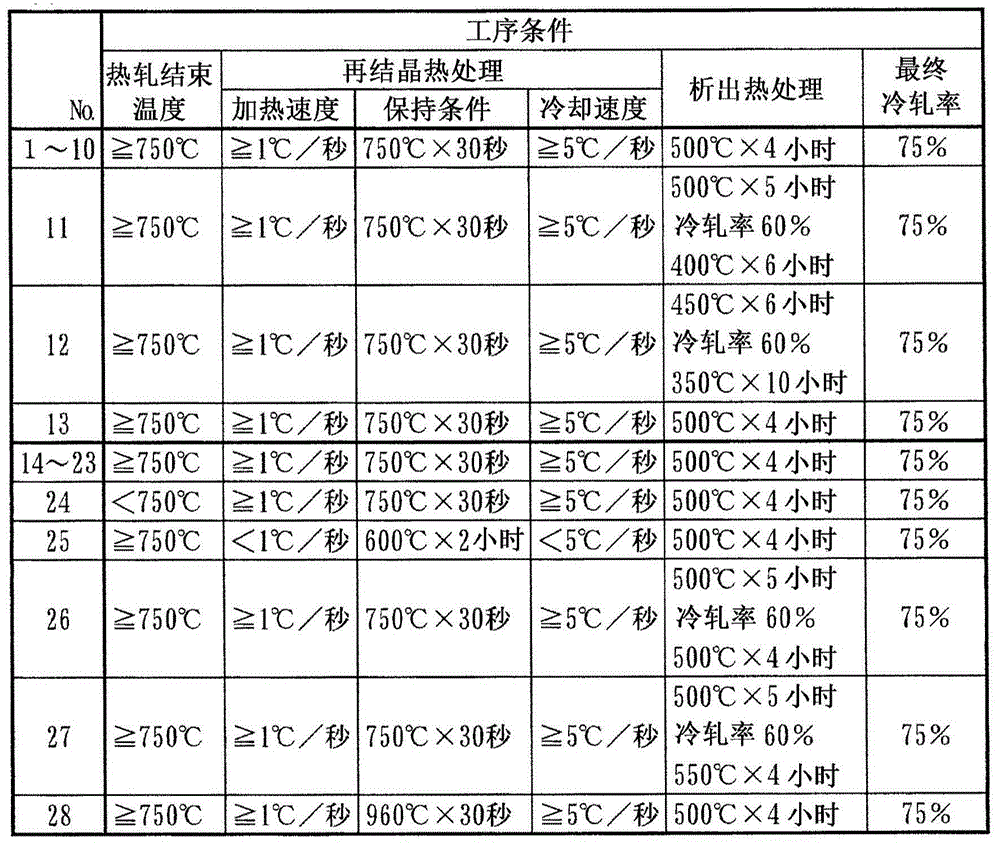

[0024] Hereinafter, the Fe—P-based copper alloy sheet of the present invention will be described more specifically.

[0025] (Chemical Composition of Fe-P Copper Alloy)

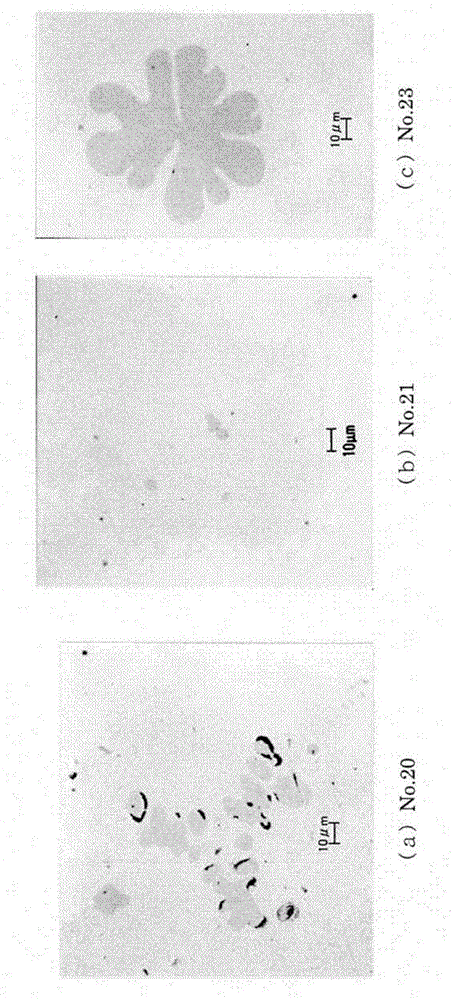

[0026] Fe contributes to the improvement of the strength and heat resistance of the Fe—P-based copper alloy sheet, and also has the effect of suppressing grain growth during hot rolling or recrystallization heat treatment. When the content of Fe is less than 1.6% by mass, the above effects are insufficient. On the other hand, if the Fe content is higher than 2.6% by mass, coarse Fe particles (a few μm or more in diameter) will be generated due to phase separation and crystallization during melting and casting, and the plating and etching properties will be reduced. Therefore, the content of Fe is 1.6 to 2.6% by mass, the lower limit is preferably 1.7% by mass, more preferably 1.8% by mass, and the upper limit is preferably 2.5% by mass, more preferably 2.4% by mass.

[0027] In addition to being helpful as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com