Reflecting film

A reflective film, hollow technology, applied in the field of film manufacturing, can solve the problems of poor stiffness and toughness, reduced tensile strength and elongation at break, brittle film, etc., to achieve good stiffness and toughness, improve reflectivity, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

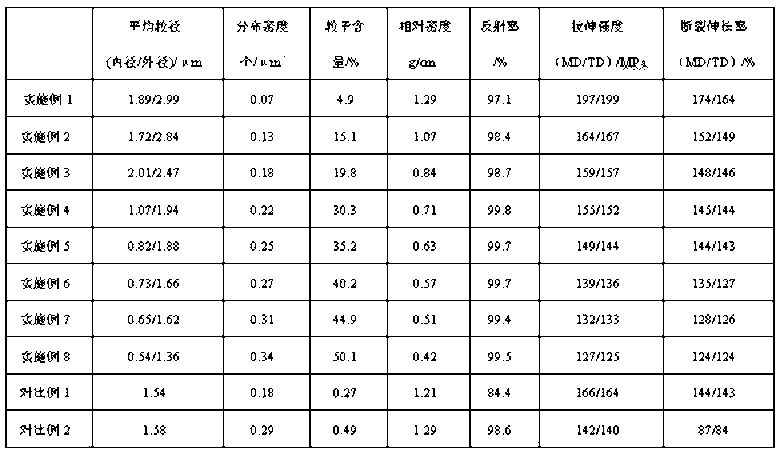

Embodiment 1

[0034] The masterbatch containing 35% hollow resin particles cross-linked styrene-propylene and virgin polyester chips were mixed at a ratio of 14:86. Melt in a twin-screw extruder and cast on a rotating cooling roll to obtain an amorphous cast slab with a thickness of about 2000 μm. Carry out longitudinal stretching, send the longitudinally stretched sheet film to a transverse tenter, and carry out transverse stretching at a ratio of 3.2:1 under the condition of about 110°C, and the polyester film oriented by biaxial stretching is Heat setting at about 180°C, and finally after cooling, winding and other processes to obtain a reflective film, measure its reflectivity, tensile strength and elongation at break.

Embodiment 2

[0036] A masterbatch containing 35% hollow resin particles cross-linked styrene-propylene and virgin polyester chips were mixed in a ratio of 43:57. Melt in a twin-screw extruder and cast on a rotating cooling roll to obtain an amorphous cast slab with a thickness of about 2000 μm. Carry out longitudinal stretching, send the longitudinally stretched sheet film to a transverse tenter, and carry out transverse stretching at a ratio of 3.2:1 under the condition of about 110°C, and the polyester film oriented by biaxial stretching is Heat setting at about 180°C, and finally after cooling, winding and other processes to obtain a reflective film, measure its reflectivity, tensile strength and elongation at break.

Embodiment 3

[0038] A masterbatch containing 45% hollow resin particles cross-linked styrene-propylene and virgin polyester chips were mixed in a ratio of 44:56. Melt in a twin-screw extruder and cast on a rotating cooling roll to obtain an amorphous cast slab with a thickness of about 2000 μm. Carry out longitudinal stretching, send the longitudinally stretched sheet film to a transverse tenter, and carry out transverse stretching at a ratio of 3.2:1 under the condition of about 110°C, and the polyester film oriented by biaxial stretching is Heat setting at about 180°C, and finally after cooling, winding and other processes to obtain a reflective film, measure its reflectivity, tensile strength and elongation at break.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com