Graphene-containing conductive printing ink and preparation method thereof and flexible paper-based conductive circuit

A technology of conductive ink and graphene, which is applied in ink, household utensils, applications, etc., can solve problems such as insufficient performance, instability of graphene nano-silver conductive ink, impurities, etc., achieve good results, reduce complexity, and strengthen dispersion effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

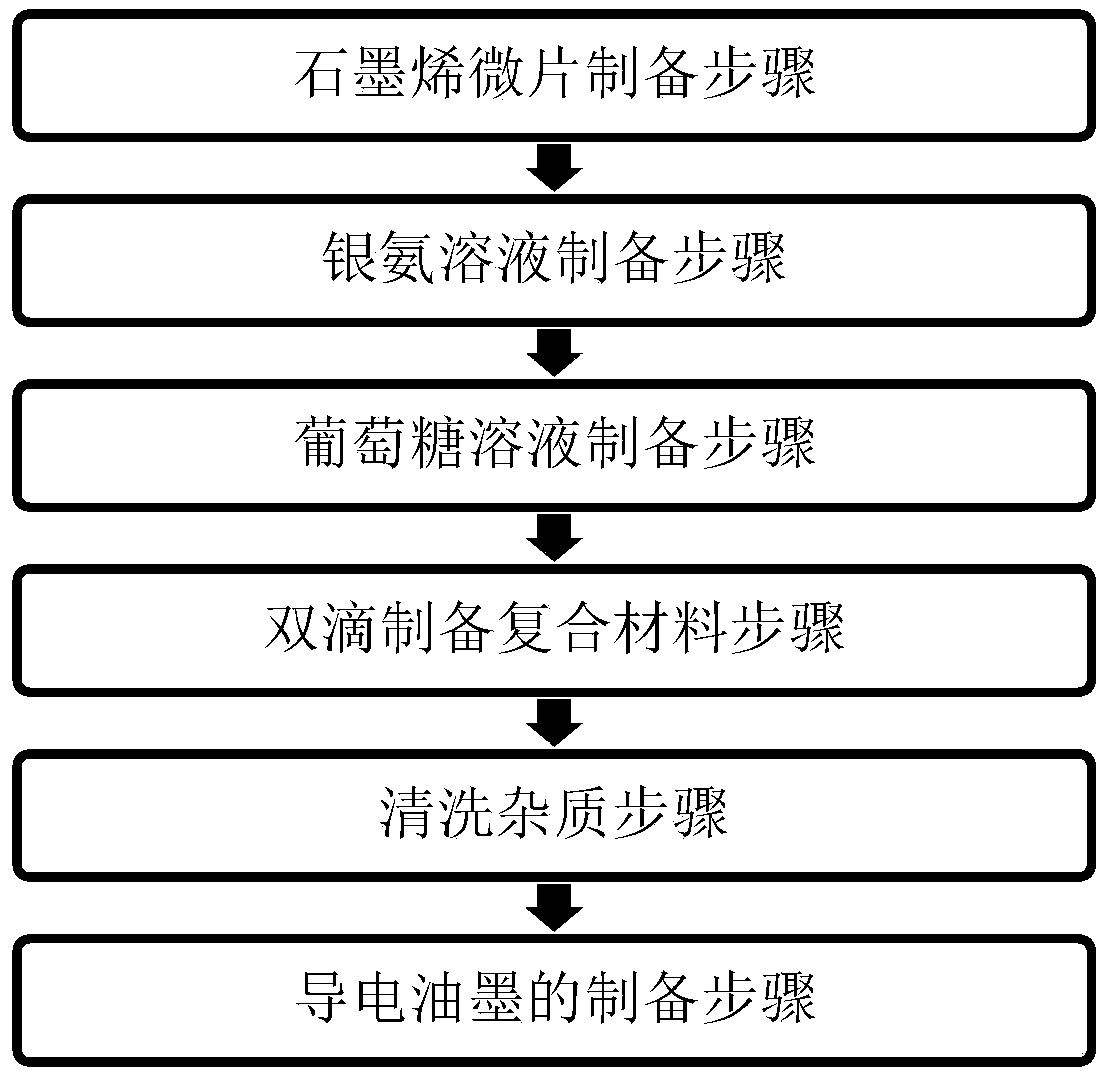

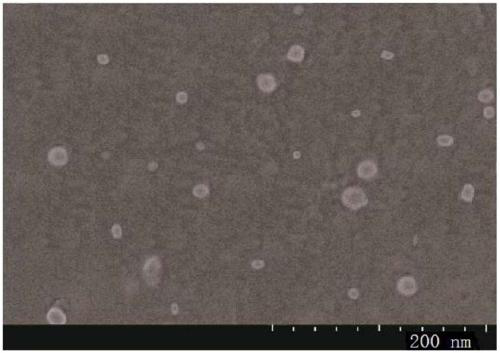

[0014] A kind of preparation method of conductive ink containing graphene, it is characterized in that, comprises the following steps: 1) graphene microchip preparation step: take prefabricated a large amount of expanded graphite flakes as raw material, in dehydrated alcohol through more than 1-2h Ultrasonic stripping produces graphene microsheet dispersion; after low-frequency ultrasound, the upper dispersion is taken out, and the unstripped graphite is left in the container; the solvent of the upper dispersion is added to more than 200-300ml of absolute ethanol, and high-intensity ultrasonic vibration is performed for 3- 5min, let it stand for 5-10s, immediately discard half of the dispersion liquid in the upper layer, and then add absolute ethanol to a volume above 200-300ml, repeat the above process at least 10-20 times, until the graphene microchips are confirmed by AFM or SEM. The average radial size is higher than 5-10um; all solvents are evaporated by rotary evaporation...

Embodiment 2

[0022] A kind of preparation method of conductive ink containing graphene, it is characterized in that, comprises the following steps: 1) graphene microchip preparation step: take prefabricated a large amount of expanded graphite flakes as raw material, in dehydrated alcohol through the ultrasonic wave of more than 1.5h Exfoliate to form a dispersion of graphene microflakes; after low-frequency ultrasound, take out the upper dispersion, and leave the unexfoliated graphite in the container; add the solvent of the upper dispersion to more than 220ml of ethanol, oscillate with high-intensity ultrasound for 4 minutes, and let it stand for 8 seconds , Immediately discard half of the dispersion in the upper layer, and then add absolute ethanol to a volume of more than 220ml, repeat the above process at least 15 times, until the average radial size of the graphene microplatelets is confirmed by AFM to be higher than 5um; spin evaporate all solvents , dry at room temperature to obtain ...

Embodiment 3

[0024]A method for preparing a graphene-containing conductive ink, characterized in that it comprises the following steps: 1) Graphene microsheet preparation step: using a large amount of prefabricated expanded graphite sheets as raw material, in dehydrated alcohol through ultrasonic peeling for more than 2h Generate a dispersion of graphene microflakes; after low-frequency ultrasound, take out the upper dispersion, and leave the unstripped graphite in the container; add the solvent absolute ethanol of the upper dispersion to more than 270ml, high-intensity ultrasonic vibration for 5 minutes, and let it stand for 10s. Immediately discard half of the dispersion in the upper layer, and then add absolute ethanol to a volume of more than 270ml, repeat the above process at least 20 times, until the average radial size of the graphene microflakes is confirmed by SEM to be higher than 6um; spin evaporate all solvents, Dry at room temperature to obtain graphene microflakes with a large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com