Optical fiber with large effective area

An effective area, optical fiber technology, applied in the direction of cladding optical fiber, multi-layer core/cladding optical fiber, light guide, etc., can solve the problems of silicon-oxygen tetrahedral structure damage, expanding the scope of micro-cracks, affecting the strength of the optical fiber, etc. Ensure the effect of strength, good roundness and large effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

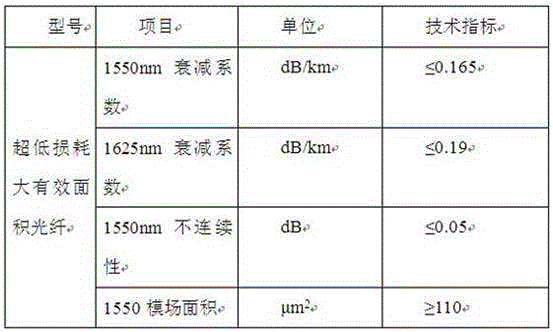

[0017] In high-speed and large-capacity DWDM (Dense Wavelength Division Multiplexing) systems, the transmission distance of traditional G.652D optical fibers and ultra-low loss optical fibers is limited due to nonlinear effects. With the emergence of various new coding methods (such as RZ (Return to Zero Code), etc.), error correction technologies (such as FEC (Forward Error Correction), SFEC (Super Forward Error Correction), etc.) and various low noise amplifiers (such as the development of DRA (Distributed Raman Fiber Amplifier), etc.), the OSNR (Optical Signal-to-Noise Ratio) tolerance requirements and OSNR degradation of DWDM systems have been significantly improved, and fiber loss is no longer the decisive factor limiting system transmission. . In the current DWDM system, the nonlinear effect has become the main limiting factor of the current high-speed optical fiber communication system. Under optical power transmission, nonlinear effects such as Raman scattering and Ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com