Color filter substrate, LCD device and color display device using the same

A color filter and substrate technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as display quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

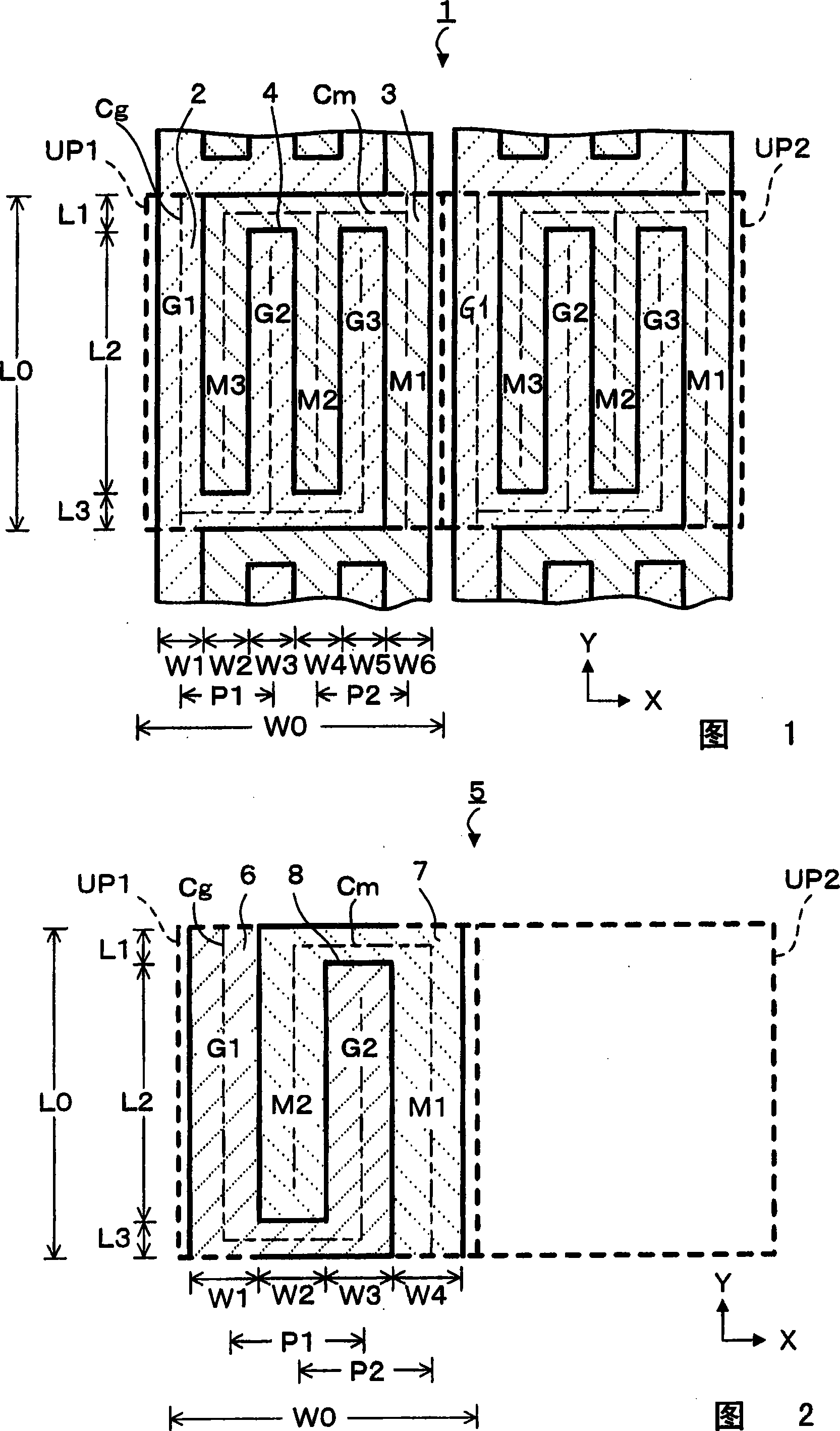

[0043]The shape and arrangement of the color filter substrate and the colored layer of the display device according to this embodiment will be described using the plan view of FIG. 1 . As shown in the figure, the unit pixel UP1 and the same unit pixel UP2 as the unit pixel UP1 are arranged side by side. The unit pixel UP1 has a rectangular shape with a length of 200 μm (L0) and a width of 222 μm (W0). A plurality of unit pixels UP1 are arranged in the X direction and the Y direction to form a matrix. The unit pixel UP1 has a first color sub-pixel 2 and a second color sub-pixel 3 with different colors. For example, the first-color sub-pixel 2 is a green colored layer or light-emitting portion, and the second-color sub-pixel 3 is a magenta colored layer or light-emitting portion. In addition, each sub-pixel has a continuous single plane area, and the first-color sub-pixel 2 and the second-color sub-pixel 3 are separated by a boundary 4 . The border area 4 is a black color fil...

Embodiment 2

[0053] FIG. 2 schematically shows the state of the two-color color filter substrate (color layout 5 of the colored layer) of the present embodiment when viewed in plan. As shown in the figure, the first color sub-pixel 6 and the second color sub-pixel 7 having different colors are formed in the unit pixel UP1. The sub-pixel 6 of the first color and the sub-pixel 7 of the second color are divided by the boundary area 8 . The unit pixel UP1 has a rectangular shape with a length L0 and a width W0, and has a 40000 μm 2 above the area. The sub-pixels 6 of the first color and the sub-pixels 7 of the second color respectively have a single continuous plane area. The first color sub-pixel has a region G1 with a length of L0 and a width of W1 and a region G2 with a length of L2 and a width of W3. Similarly, the second color sub-pixel 7 has a region M1 with a length L0 and a width W4 and a region M2 with a length L2 and a width W2. Here, W1 to W4 each have the same length and are no...

Embodiment 3

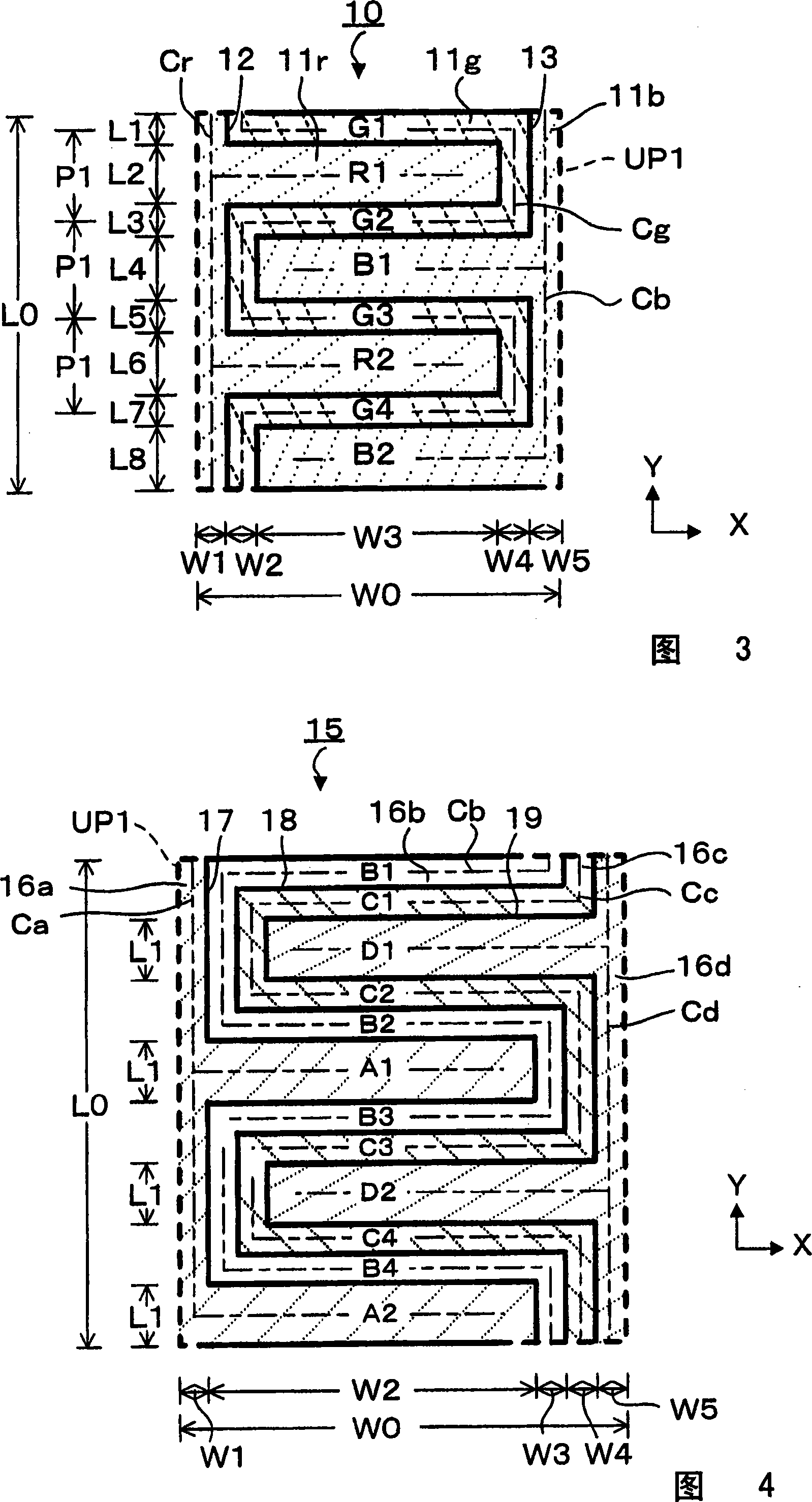

[0059] FIG. 3 is a plan view schematically showing the color filter substrate (color layout 10 of colored layers) of this embodiment. As shown in the figure, the unit pixel UP1 has three sub-pixels: a red first sub-pixel 11r, a green second sub-pixel 11g, and a blue third sub-pixel 11b. The unit pixel UP1 is a square whose length L0 and width W0 are respectively 300 μm, and its area (L0×W0) is 90000 μm 2, arranged in the X direction and the Y direction to form a matrix. In addition, the second sub-pixel 11g is arranged between the first sub-pixel 11r and the third sub-pixel 11b. The first sub-pixel 11r and the second sub-pixel 11g are divided by the boundary area 12 , and the second sub-pixel 11g and the third sub-pixel 11b are divided by the boundary area 13 .

[0060] The first sub-pixel 11r has a region R1 with a width of 50 μm (L2) and a length of 225 μm (W2+W3) and a region R2 with a width of 50 μm (L6) and a length of 225 μm (W2+W3). Therefore, the width of each regio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com