Electrode with pit patterns for secondary battery, and preparation method and application of electrode

A secondary battery and electrode technology, which is applied in the field of secondary battery electrodes and its preparation, can solve the problems of battery internal resistance increase, electrode pulverization failure, large volume change, etc., to improve safety performance and cycle life, and maintain stability The effect of safety and integrity, simplicity of preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This example is used to illustrate the electrode of the present invention and its preparation method and application.

[0069] 1. Preparation of copper electrodes with pit pattern (recessive pit pattern)

[0070] A pit array structure is processed on the flat surface of the copper foil by laser etching, wherein the laser wavelength used in the laser etching method is 355nm, the laser power is 3W, and the single hole drilling time is 0.5ms.

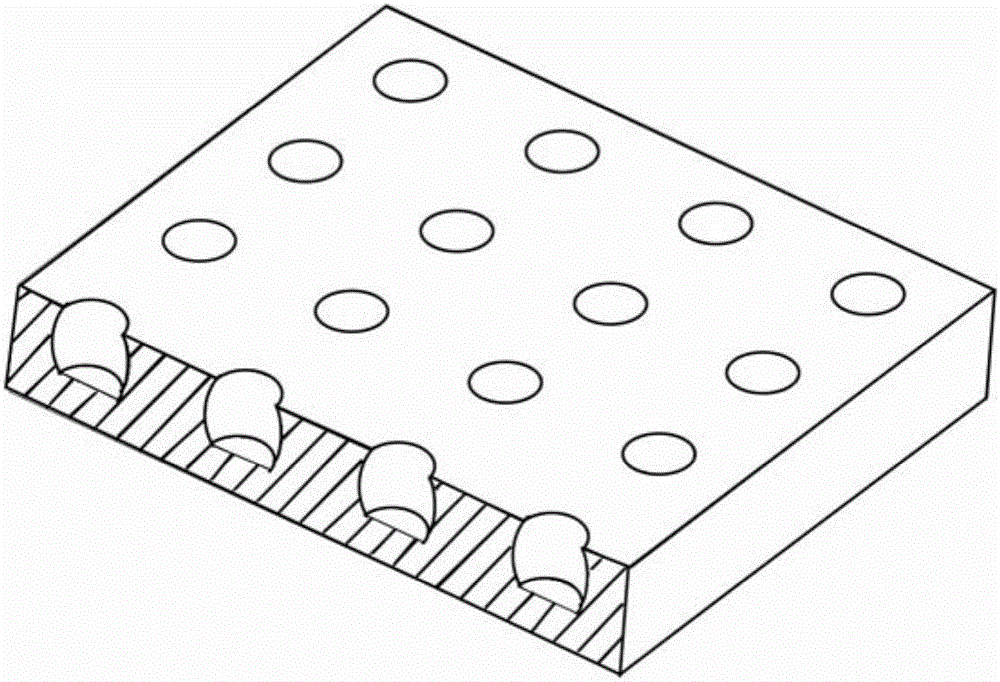

[0071] Such as Figure 6 As shown, the prepared pits are cylindrical, with a pore diameter (projected diameter of the top surface) of 6 μm, a depth of 5 μm, and a center-to-center distance of adjacent pits of 20 μm.

[0072] The above copper electrodes were ultrasonically cleaned with citric acid, deionized water and alcohol respectively, and then the cleaned copper electrodes were dried in a vacuum oven at 110°C for 6 hours.

[0073] 2. Lithium metal secondary battery

[0074] With the copper electrode prepared in this embodimen...

Embodiment 2

[0082] This example is used to illustrate the electrode of the present invention and its preparation method and application.

[0083] 1. Preparation of copper electrodes with pit pattern (recessive pit pattern)

[0084] A pit array structure is processed on the flat surface of the copper foil by laser etching, wherein the laser wavelength used in the laser etching method is 355nm, the laser power is 3W, and the perforation time of a single hole is 3.2ms.

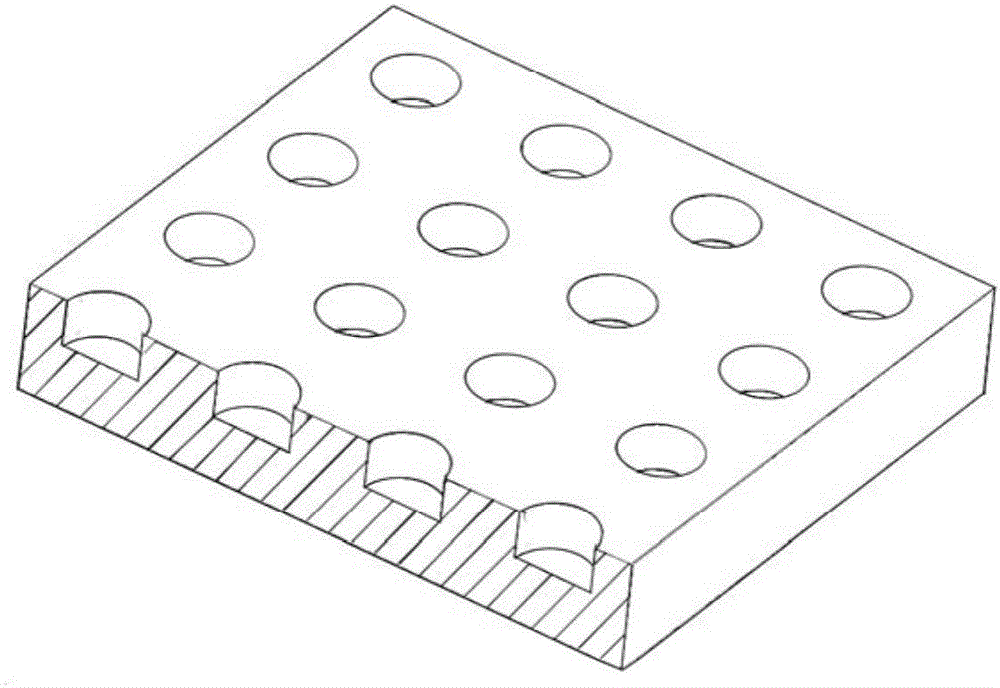

[0085] Such as Figure 10 As shown, the prepared pits are cylindrical, with a pore diameter (projected diameter of the top surface) of 15 μm, a depth of 5 μm, and a center-to-center distance of 30 μm.

[0086] The above copper electrodes were ultrasonically cleaned with citric acid, deionized water and alcohol respectively, and then the cleaned copper electrodes were dried in a vacuum oven at 110°C for 6 hours.

[0087] 2. Lithium metal secondary battery

[0088] With the copper electrode prepared in this embodiment as ne...

Embodiment 3

[0096] This example is used to illustrate the electrode of the present invention and its preparation method and application.

[0097] 1. Preparation of titanium electrodes with pit patterns (recessive pit patterns)

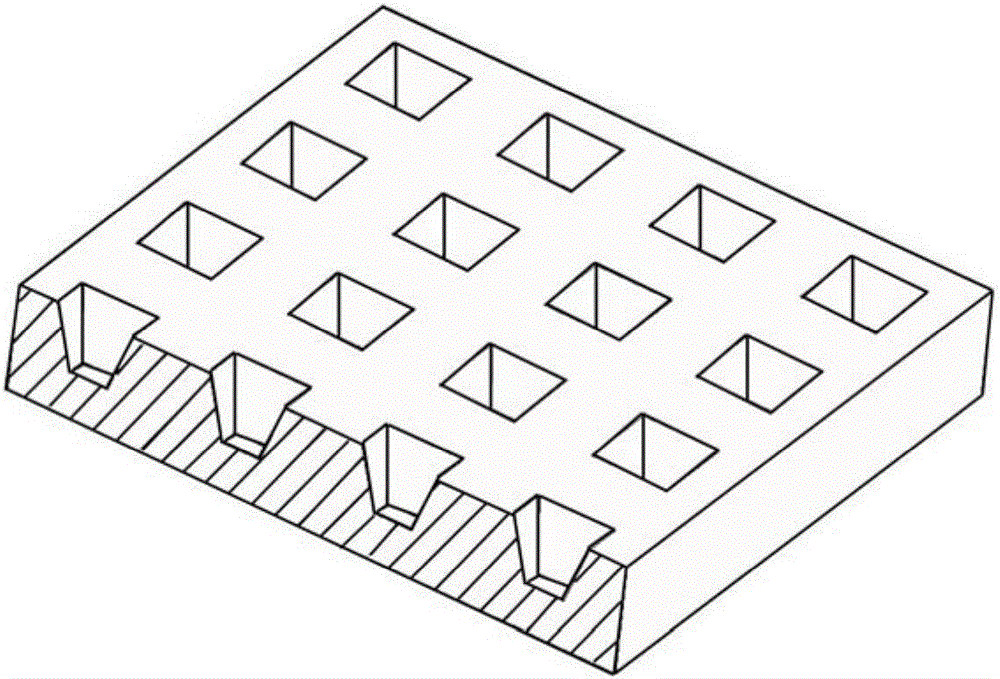

[0098] A cuboid pit array structure is processed on the flat surface of the titanium foil by using the focused ion beam etching method. Such as Figure 12 As shown, the dimensions of the cuboid pits are: the projected side length of the top surface is 5 nm, the pit depth is 10 nm, and the pit center distance is 10 nm.

[0099] The above titanium electrodes were ultrasonically cleaned with citric acid, deionized water and alcohol respectively, and then the cleaned metal titanium substrate was dried in a vacuum oven at 110° C. for 6 h.

[0100] 2. Lithium metal secondary battery

[0101] With the titanium electrode prepared in this embodiment as the negative electrode, with LiCoO 2 As the positive electrode material, the concentration is 1mol L -1 LiPF 6 A sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com