Preparation method of a three-dimensional hierarchical porous copper-zinc composite current collector

A technology of hierarchical porous and current collectors, applied in the direction of electrode carrier/current collector, lithium battery, non-aqueous electrolyte battery, etc., can solve the problems of high preparation cost, unbalanced performance and cost, poor effect, etc., and achieve the utilization rate of raw materials. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

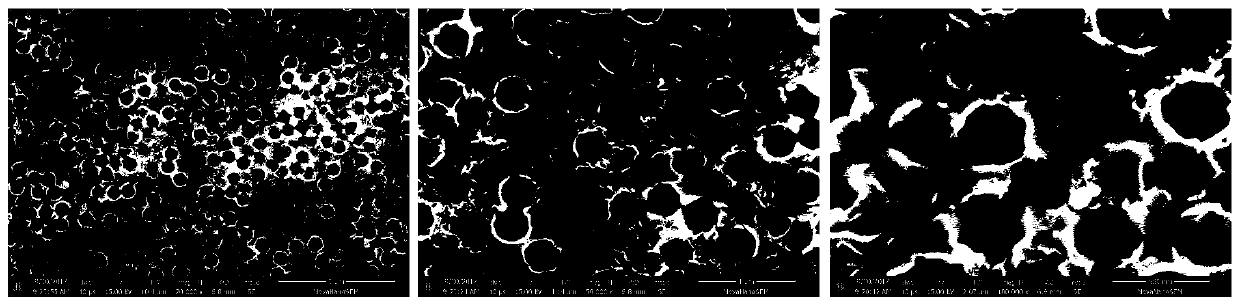

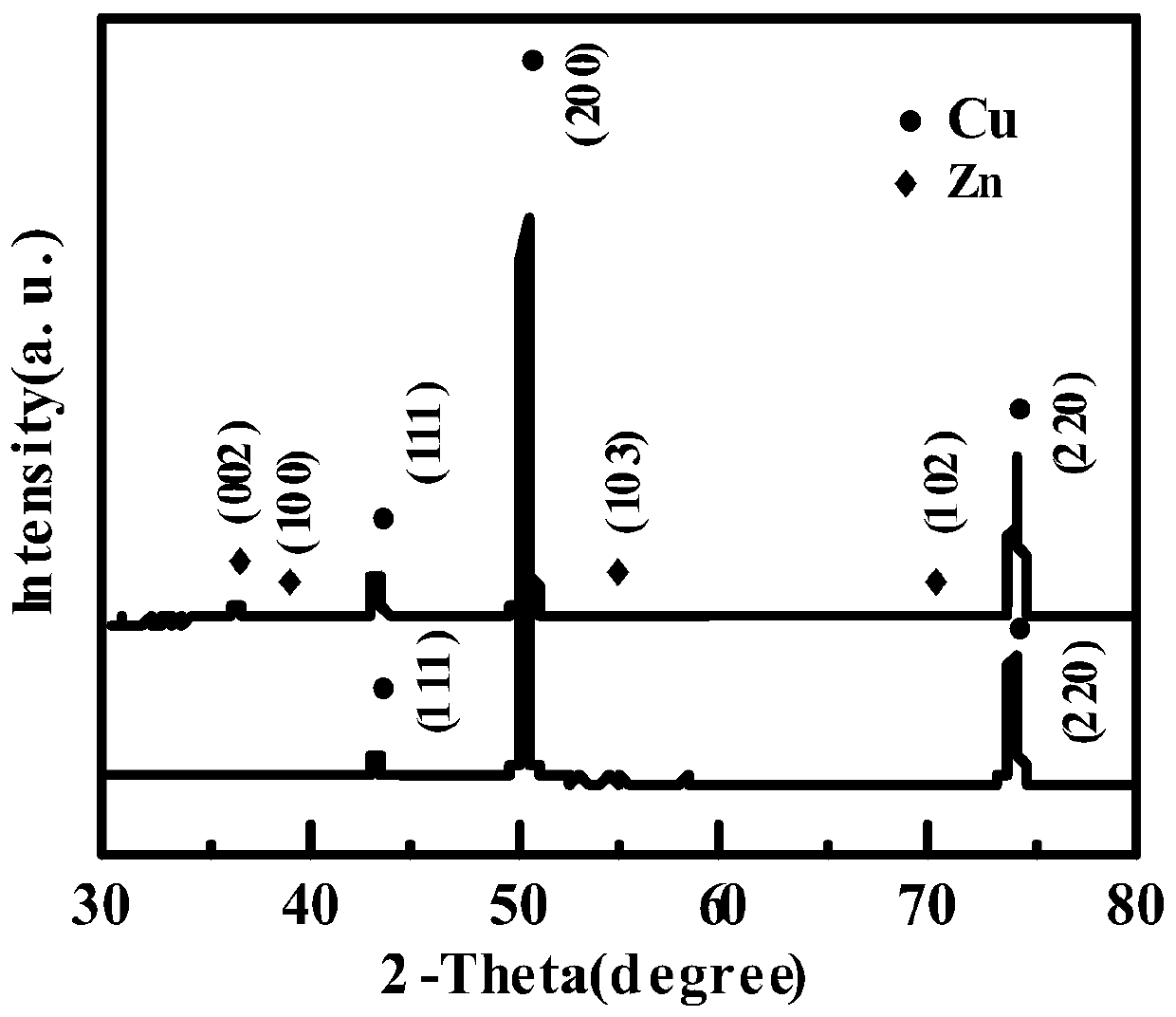

[0043] A preparation method of a three-dimensional hierarchical porous copper-zinc composite current collector, the preparation method comprising the following preparation steps:

[0044] 1) placing the wood flour in the pretreated copper-containing waste liquid, ultrasonically vibrating or stirring under constant temperature heating conditions, and filtering and separating to obtain filter residue and filtrate;

[0045] 2) Grinding the pretreated kenaf stalk into kenaf stalk powder, adding the filter residue and kenaf stalk powder to PMMA dilute solution, mixing and stirring evenly, electrophoresis deposition at constant voltage, and heat preservation and drying to obtain a template;

[0046] 3) The template is placed in the copper plating solution, washed and dried after constant current electrochemical deposition, then placed in a special atmosphere for calcination for a period of time, after calcination is completed, placed in an organic liquid for a period of time, cleaned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com