Three-dimensional orderly porous copper current collector preparation method

A three-dimensional ordered, porous copper technology, applied in the direction of electrode carrier/collector, non-aqueous electrolyte battery, lithium battery, etc., can solve the problems of unbalanced performance and cost, high preparation cost, poor effect, etc., to reduce local The effect of current density, large specific surface area, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

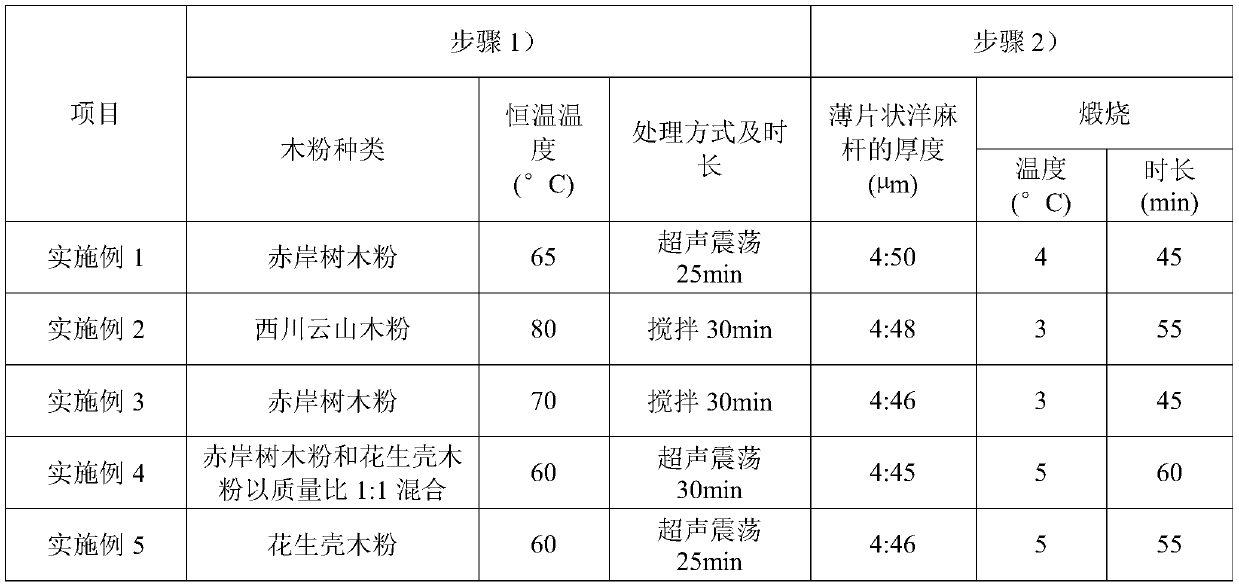

[0040] A method for preparing a three-dimensional ordered porous copper current collector, the method comprising:

[0041] 1) placing the wood powder in the pretreated copper-containing waste liquid, ultrasonically vibrating or stirring under constant temperature heating conditions, and filtering and separating to obtain filter residue and filtrate;

[0042] 2) acid-treating the pretreated flaky kenaf stalks, dispersing the separated filter residue in absolute ethanol to make a suspension, placing the acid-treated flaky kenaf stalks horizontally and dipping them in the suspension The filter residue is adsorbed in the middle, the suspension is impregnated with one-third of the thickness of the paper kenaf stalk, and a layered sheet-shaped template is obtained after the impregnation;

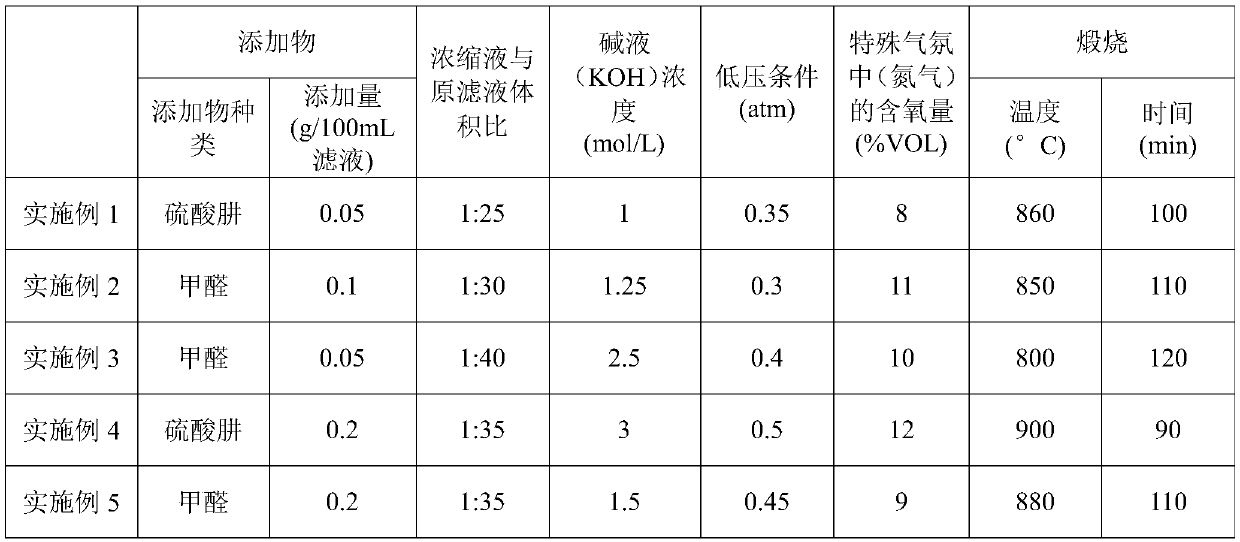

[0043] 3) adding hydrazine sulfate or formaldehyde to the separated filtrate, and rotary evaporation to obtain a concentrated solution;

[0044] 4) Lay the side of the sheet-shaped template on wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com