Energy storage device with steam as energy storage medium

A technology of energy storage and steam, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of lower system efficiency, complex heat exchanger structure, and low energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

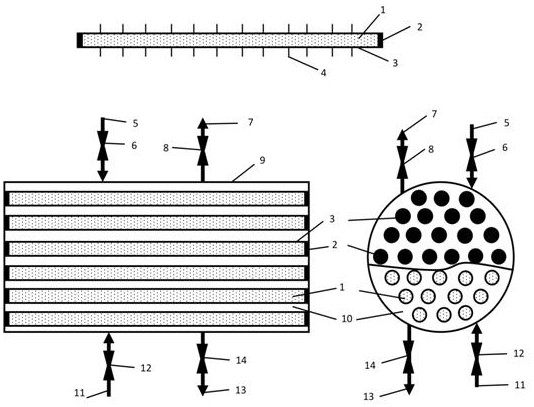

[0011] figure 1 is the best embodiment of the present invention, the following is combined with the appendix figure 1 The present invention will be further described.

[0012] An energy storage device that uses steam as an energy storage medium, and the components used include a gas-liquid mixed working medium 1, a steam energy storage rod head 2, a steam energy storage rod shell 3, a heat exchange fin 4, and a heat release medium inlet 5. , exothermic medium inlet valve 6, endothermic medium outlet 7, endothermic medium outlet valve 8, accumulator shell 9, exothermic or endothermic heat exchange medium 10, endothermic medium inlet 11, endothermic medium inlet valve 12 , the exothermic medium outlet 13, and the exothermic medium outlet valve 14. Both ends of the casing 3 of the steam energy storage rod are connected with heads 2 to prevent the leakage of the gas-liquid mixed working medium 1 inside. The steam energy storage rod 3 is installed on the casing of the accumulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com