Iron carbide-based composite material and preparation method thereof

A technology of iron carbide-based and composite materials, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of poor conductivity of iron-based nanomaterials, complex preparation methods, and easy agglomeration of nanocrystals, and achieves a favorable industrial scale. Production, increasing utility and versatility, promoting penetration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

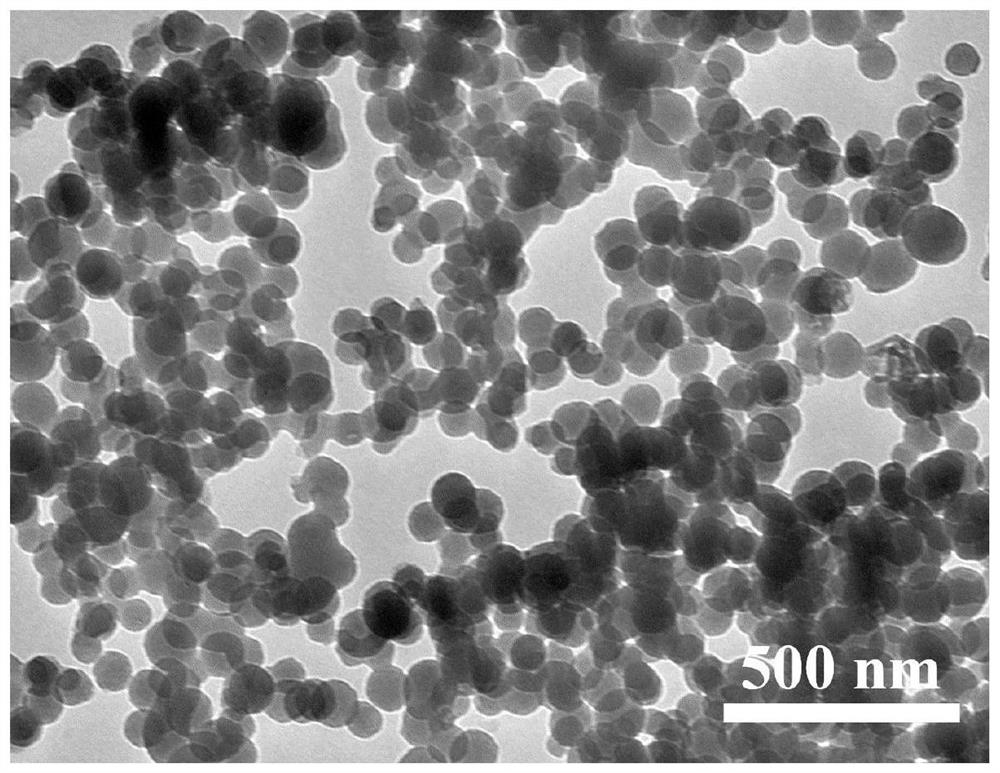

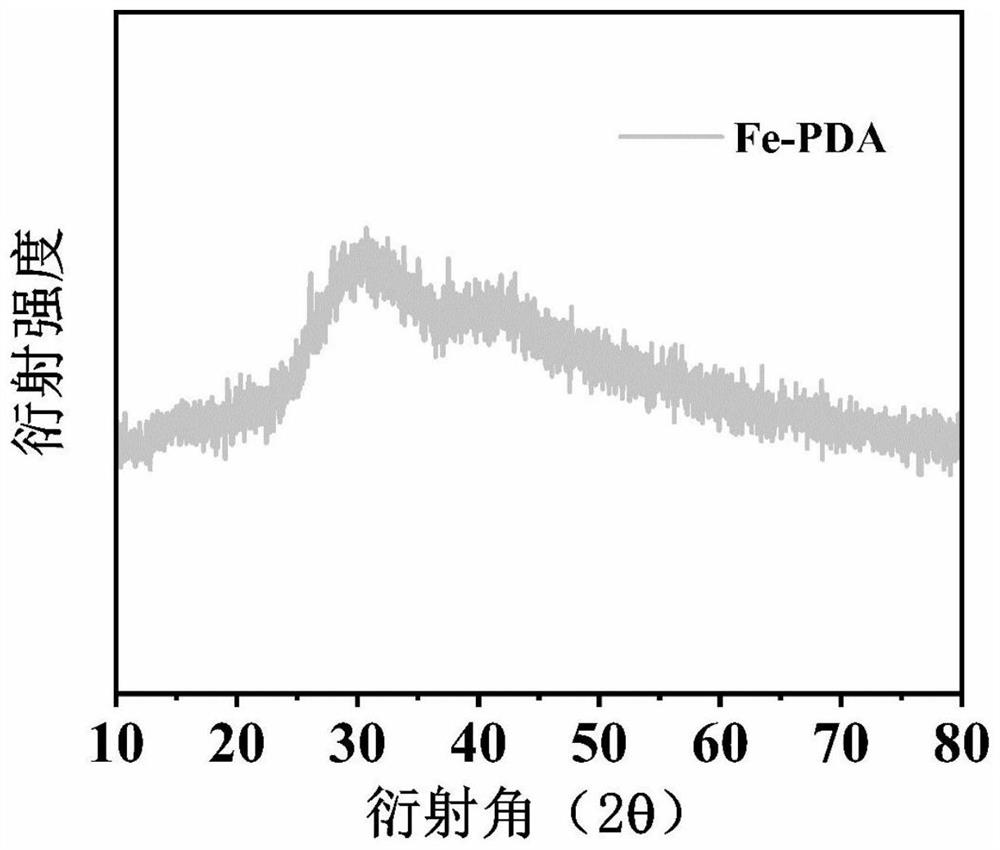

[0035] A preparation method of iron-dopamine composite material, comprising the following steps:

[0036] Weigh 20 mg of dopamine and dissolve in 5 mL of deionized water to obtain solution A; 20 mg of ferric acetylacetonate is dissolved in 8 mL of acetone to obtain solution B; after solution A and solution B are mixed uniformly, 40 mg of tris is added and stirred continuously. 12h, a black-purple turbid liquid was obtained; then centrifuged at a speed of 8000-10000r.p.m for 5-7min; then washed with ethanol 1-3 times (acetone can be dissolved in organic solvents such as ethanol, so it will not introduce Various solvents), and dried in an oven at 60 °C for 4 h to obtain a black-purple iron-dopamine hybrid composite.

Embodiment 2

[0038] A preparation method of iron-dopamine composite material, comprising the following steps:

[0039] Weigh 20 mg of dopamine and dissolve it in 5 mL of deionized water to obtain solution A; 20 mg of ferric acetylacetonate is dissolved in 8 mL of acetone to obtain solution B; after solution A and solution B are mixed uniformly, 40 mg of tris is added and stirred continuously. 12h, a black-purple turbid liquid was obtained; then centrifuged at a speed of 8000-10000r.p.m for 5-7min; then washed with ethanol 1-3 times (acetone can be dissolved in organic solvents such as ethanol, so it will not introduce Various solvents), dried in an oven at 80°C for 2 hours to obtain black-purple iron-dopamine hybrid composite microspheres; heat treatment of the dried iron-dopamine hybrid nanocomposite microspheres to obtain in-situ transformed iron-dopamine composite nanospheres Microspheres; wherein, the heat treatment is carbonization heat treatment, and the conditions are as follows: th...

Embodiment 3

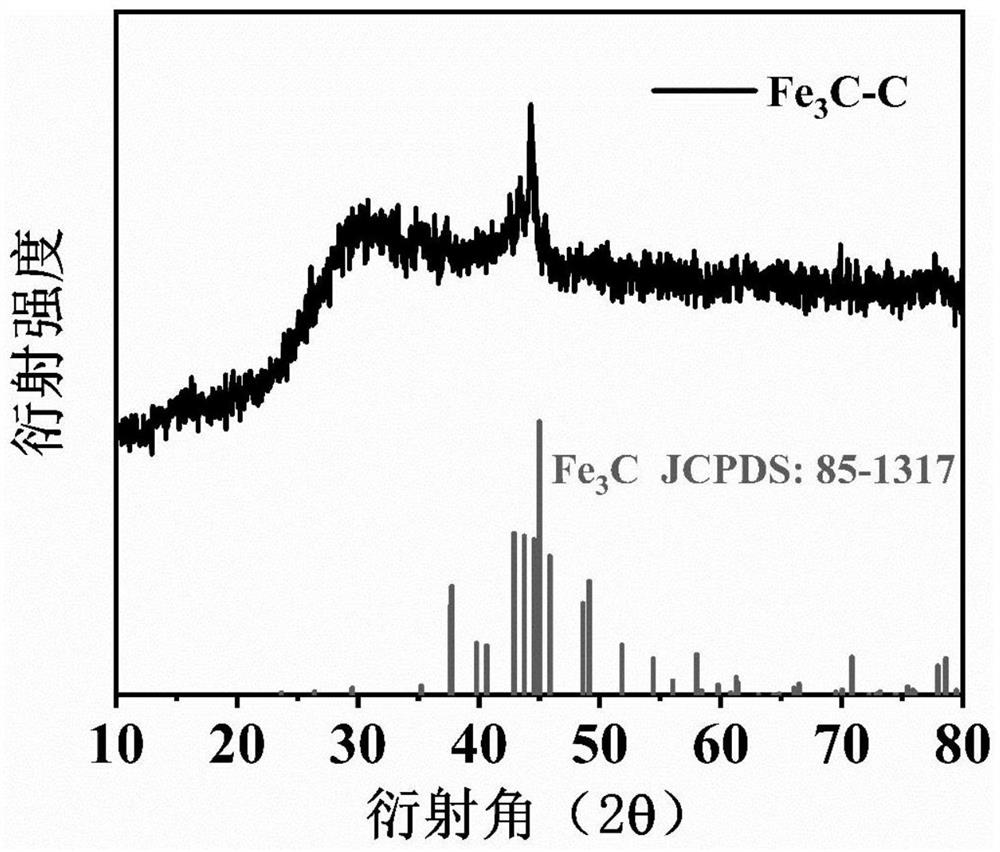

[0041] A preparation method of an iron carbide-based composite material, comprising the following steps:

[0042] Weigh 10 mg of dopamine and dissolve it in 5 mL of deionized water to obtain solution A; 10 mg of ferric acetylacetonate is dissolved in 8 mL of acetone to obtain solution B; after solution A and solution B are mixed uniformly, 20 mg of tris is added and stirred continuously. 12h, a black-purple turbid liquid was obtained; then centrifuged at a speed of 8000-10000r.p.m for 5-7min; then washed with ethanol 1-3 times (acetone can be dissolved in organic solvents such as ethanol, so it will not introduce Various solvents), and then dried in an oven at 40 °C for 12 h to obtain iron-dopamine hybrid microspheres; heat treatment of the dried iron-dopamine hybrid nano-microspheres to obtain in-situ transformed iron carbide-based composite nano-microspheres; wherein , the heat treatment is carbonization heat treatment, and the conditions are as follows: the carbonization tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com